Rotary wheel body big and small axle holes coaxially processing method

A processing method and technology of a runner body, which are applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as sagging, and achieve the effect of simple processing method and saving processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

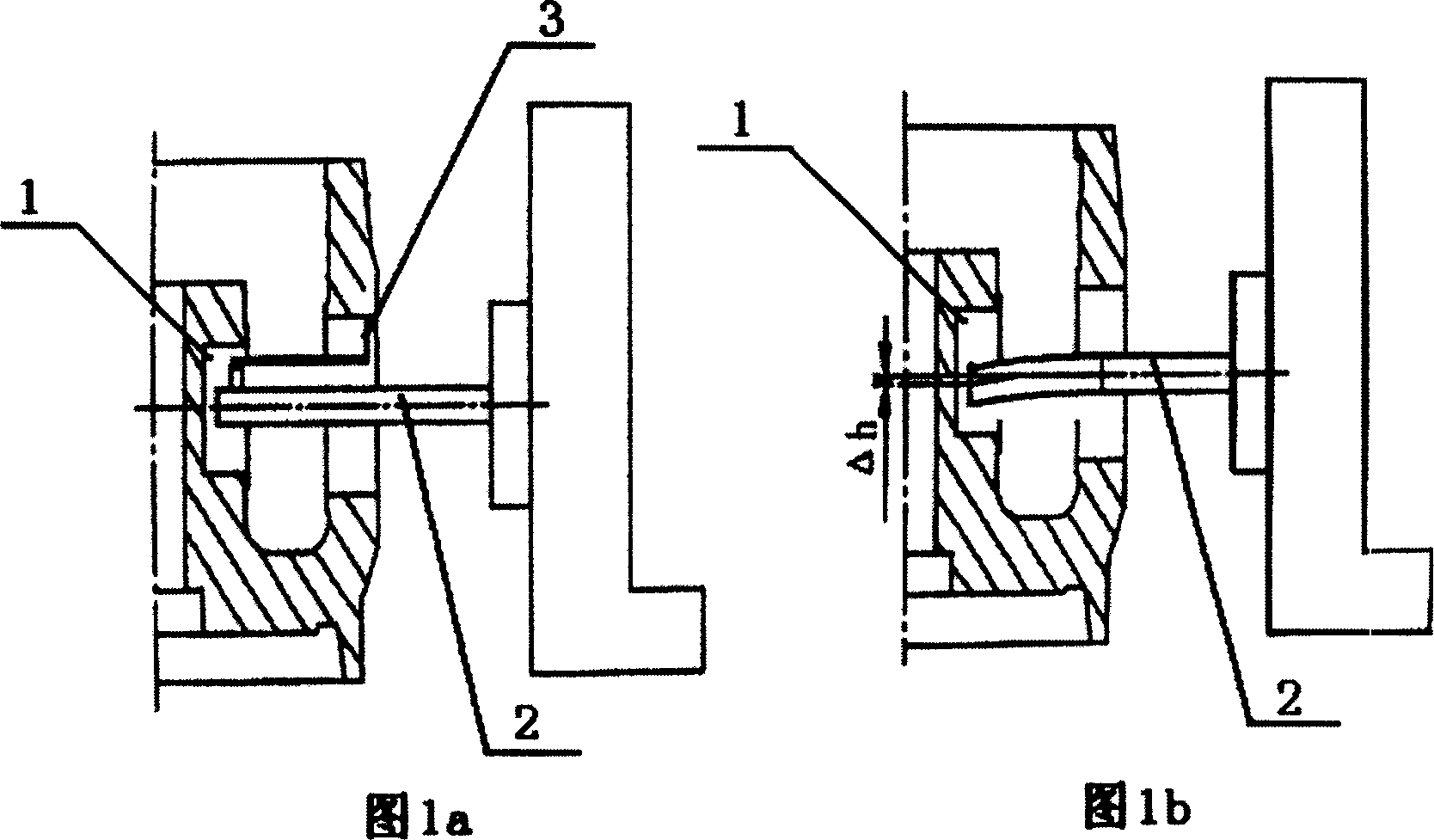

[0009] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing: As Fig. 1 a, comprise runner body 1, boring machine main shaft 2, the coaxial processing method of runner body big and small axis hole is: process big shaft hole first, then the boring machine main shaft stretches into For the small shaft hole, set a dial indicator 3 near the end of the boring shaft, and find out the runout Δh of the large shaft hole from the dial indicator 3.

[0010] As shown in Figure 1b, after finding the runout Δh of the large shaft hole, artificially raise the spindle of the boring machine by half of the runout according to the runout Δh, that is, Δh / 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com