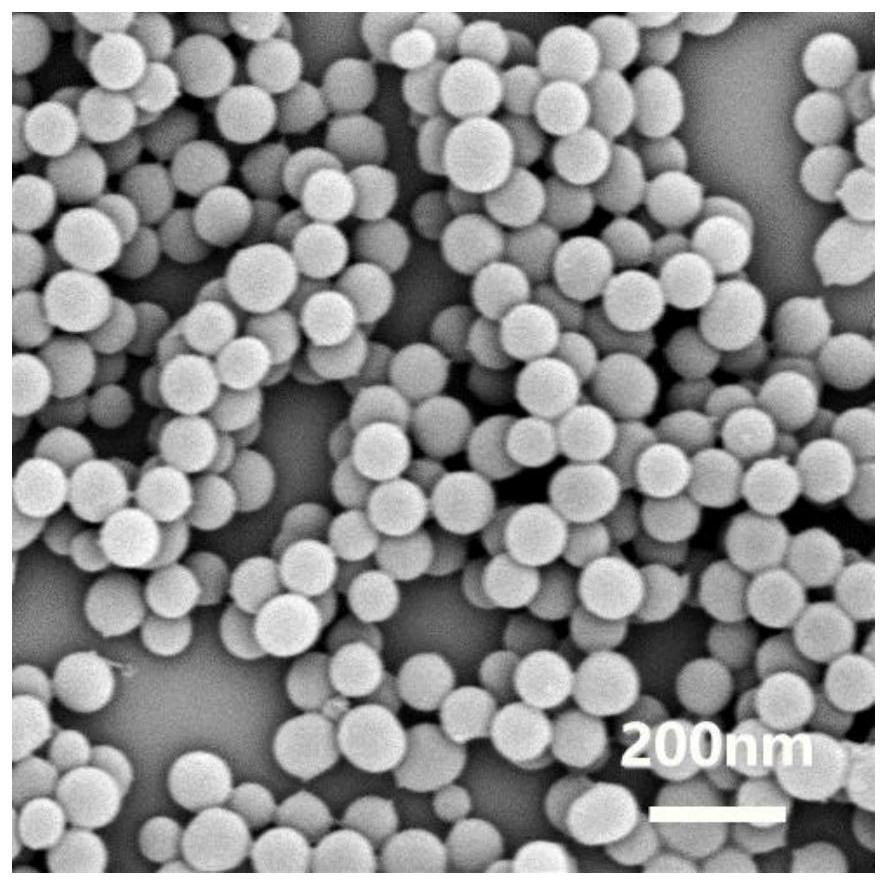

Manganous oxide doped isomelanin nano material with electromagnetic shielding function, preparation method of thin film and product

A manganese oxide, nanomaterial technology, applied in the field of melanin application, can solve the problems of difficult to achieve polymerization, difficult to achieve effective standardized production, slow process, etc., to achieve simple process synergy, good industrialization prospects, and simple thickness and size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a preparation method of a manganese oxide-doped isomelanin nanomaterial, comprising the following steps:

[0046] S1 prepare 1,8-dihydroxynaphthalene solution

[0047] Specifically, prepare a 1,8-dihydroxynaphthalene solution, wherein the solvent is a mixed solvent of acetonitrile and water, carry out ultrasonic dispersion treatment for 3-10 minutes, preferably 5 minutes, and then fully stir it at room temperature for 3-10 minutes, It is preferably 5 minutes to obtain a uniform, transparent and colorless 1,8-dihydroxynaphthalene solution;

[0048] Wherein, the volume fraction of acetonitrile in the mixed solvent is 10-20%, preferably 10%, and the volume fraction of water is 80-90%, preferably 90%;

[0049] Wherein, the content of 1,8-dihydroxynaphthalene in the 1,8-dihydroxynaphthalene solution is 1-3 mg / mL, preferably 2 mg / mL;

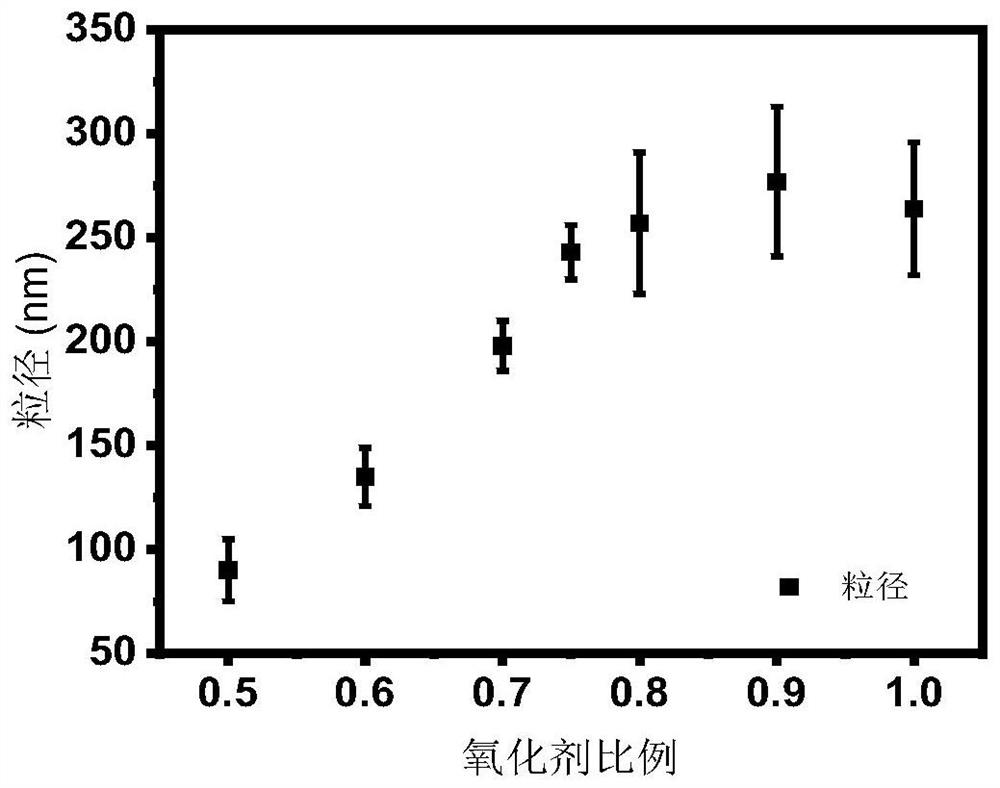

[0050] S2 slowly adds potassium permanganate aqueous solution to the 1,8-dihydroxynaphthalene solution of S1, and sti...

Embodiment 1

[0068] A preparation method of a manganese oxide-doped isomelanin nanomaterial, comprising the following steps:

[0069] S1 firstly prepare a 1,8-dihydroxynaphthalene solution, wherein the solvent is a mixed solvent of acetonitrile and water, carry out ultrasonic dispersion treatment for 8 minutes, and then fully stir it at room temperature for 5 minutes to obtain a uniform and transparent colorless solution;

[0070] Specifically, the volume fraction of acetonitrile in the solvent is 10%, and the volume fraction of water is 90%;

[0071] The content of 1,8-dihydroxynaphthalene in the solution is 2 mg / mL;

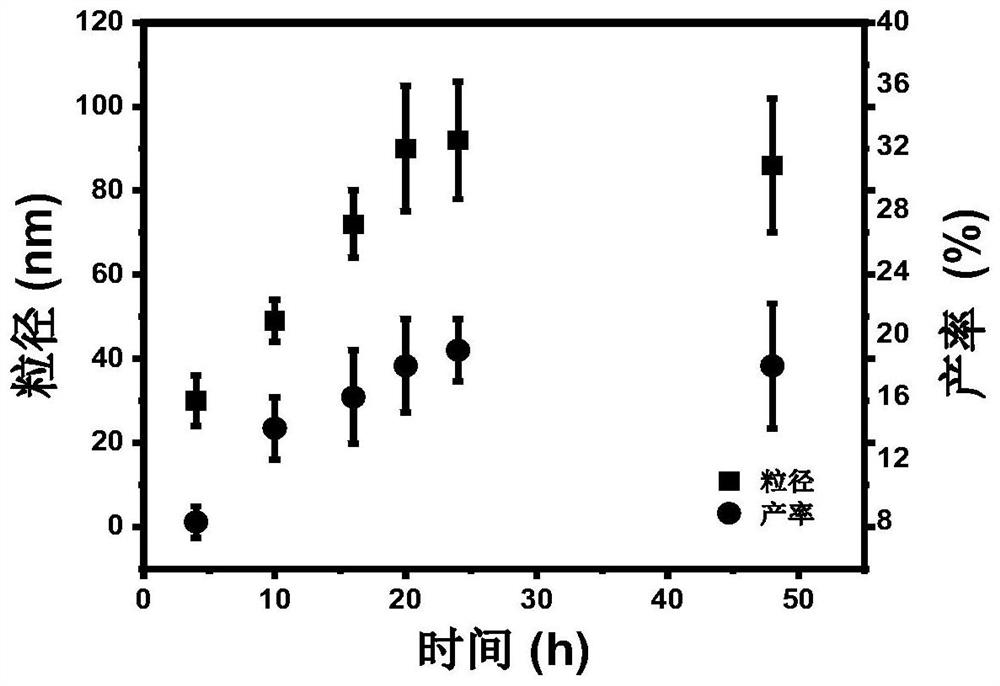

[0072] The potassium permanganate aqueous solution slowly added by S2 to the 1,8-dihydroxynaphthalene solution of S1 maintained a uniform stirring speed at room temperature, and a uniform and stable black turbid solution was obtained after 20h of continuous stirring;

[0073] Wherein, the concentration of potassium permanganate in the potassium permanganate aqueous solutio...

Embodiment 2

[0082] The steps of the preparation method of the manganese oxide-doped isomelanin nano-film are as follows.

[0083] The manganese oxide-doped isomelanin nanomaterial prepared in the previous example 1 was mixed with a polytetrafluoroethylene dispersion in a certain mass ratio, and then 1 mass part of water was added, and ultrasonic treatment was carried out for 10 minutes to mix and disperse, and then sent into Dry in an oven at about 80°C for 20 minutes to obtain a black gelatinous substance, and roll to obtain a manganese oxide-doped isomelanin nanofilm with a customizable thickness. In this embodiment, the thickness is 3 mm.

[0084] Among them, the mass ratio of polytetrafluoroethylene and manganese oxide-doped isomelanin nanomaterials is 1:8.

[0085] Examples 2-1 to 2-3 are similar to Example 2, with thicknesses of 1 mm, 2 mm and 4 mm, respectively;

[0086] Examples 2-4 to 2-6 are similar to Example 2, except that the manganese oxide-doped isomelanin nanomaterials pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com