Patents

Literature

42results about How to "High degree of anti-counterfeiting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

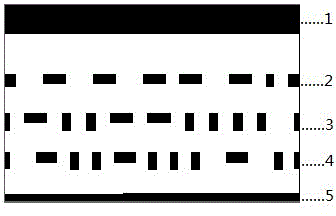

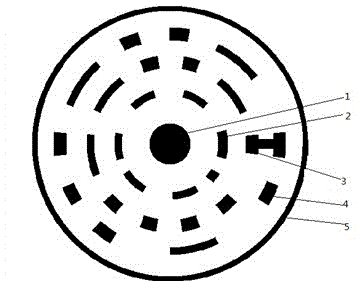

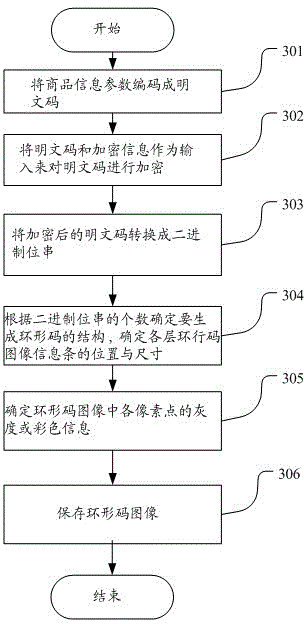

Anti-counterfeiting annular code and encoding method thereof

InactiveCN102800243AImprove reliabilityLow costCoding/ciphering apparatusTheoretical computer scienceEncryption

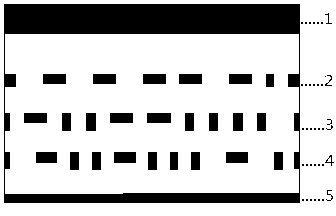

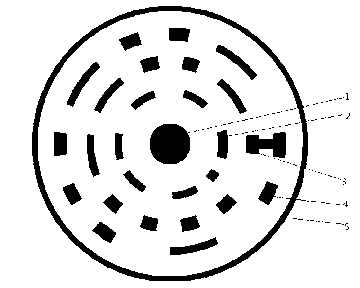

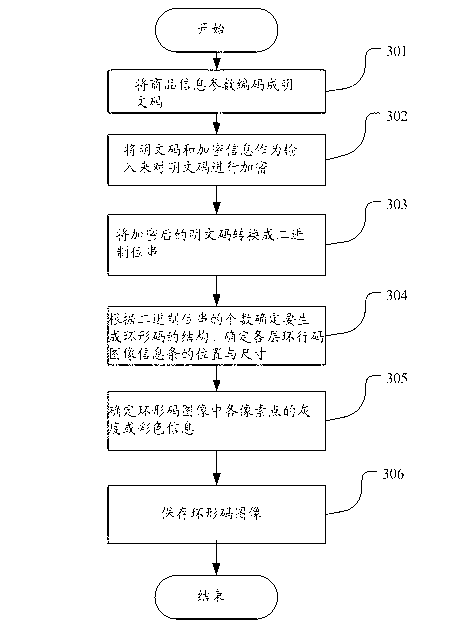

The invention provides an anti-counterfeiting annular code and an encoding method thereof. The annular code expresses a number and letter string by a plurality of concentric rings; each concentric ring consists of full lines with unequal lengths and gaps; the number and letter string of the annular code is converted into a binary bit string through encryption; and a layer quantity of the annular code and a quantity of binary numbers in each layer can be determined according to the quantity of the binary bit strings. With the adoption of the anti-counterfeiting annular code provided by the invention, the anti-countering degree is greatly improved, so that not only can an anti-counterfeiting sequence code be difficult to obtain, but also the technical difficulty that a label in an annular code structure is formed is overcome. Therefore, the reliability of the annular code is greatly improved. The annular code has the advantages of low cost, and convenience and rapidness of searching.

Owner:长沙高新技术产业开发区诺美网络技术有限公司

Variable color thermoprinting membrane and making method thereof

ActiveCN103921582AIncrease contrastImprove visual recognitionDuplicating/marking methodsMetal layered productsMicro nanoHot stamping

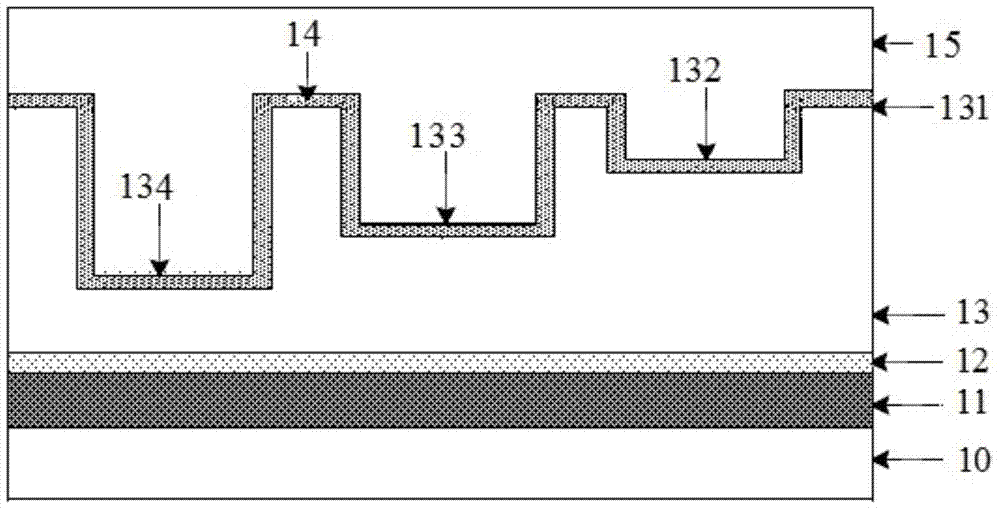

The invention relates to a variable color thermoprinting membrane and a making method thereof. The variable color thermoprinting membrane includes a base membrane, a release layer, a transflective metal layer, an information medium layer, a total reflecting metal layer and a hot melt adhesive layer, the information medium layer is a yieldable organic medium coating, steps with different heights are arranged on the at least one surface of the information medium layer or in the information medium layer, and the height of each of the steps corresponds to the Fabri-Perot cavity of a color. The above Fabri-Perot cavities enable a plurality of variable color zones, variable color figures and characters to be formed on a same hot stamping membrane, can realize the change of the color effect with the viewing angle under different polarization, and the color of the novel thermoprinting membrane changes. The thermoprinting membrane is made in a roll-to-roll manner, a heat evaporation coating partially substitutes a vacuum sputter coating, the organic medium coating is made in an efficient nano-coating manner, and steps and a micro-nano structure are obtained through an impression means, and the method is simple and efficient, and is suitable for wide format production.

Owner:SUZHOU UNIV +1

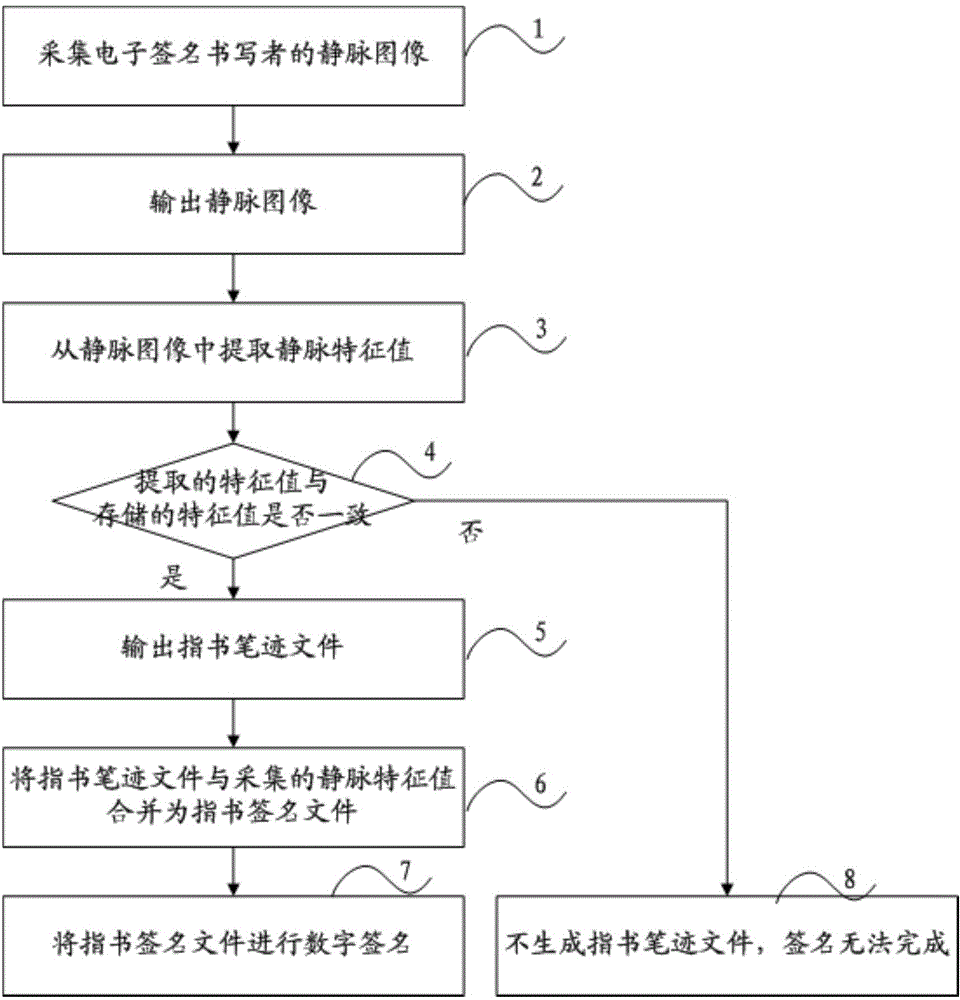

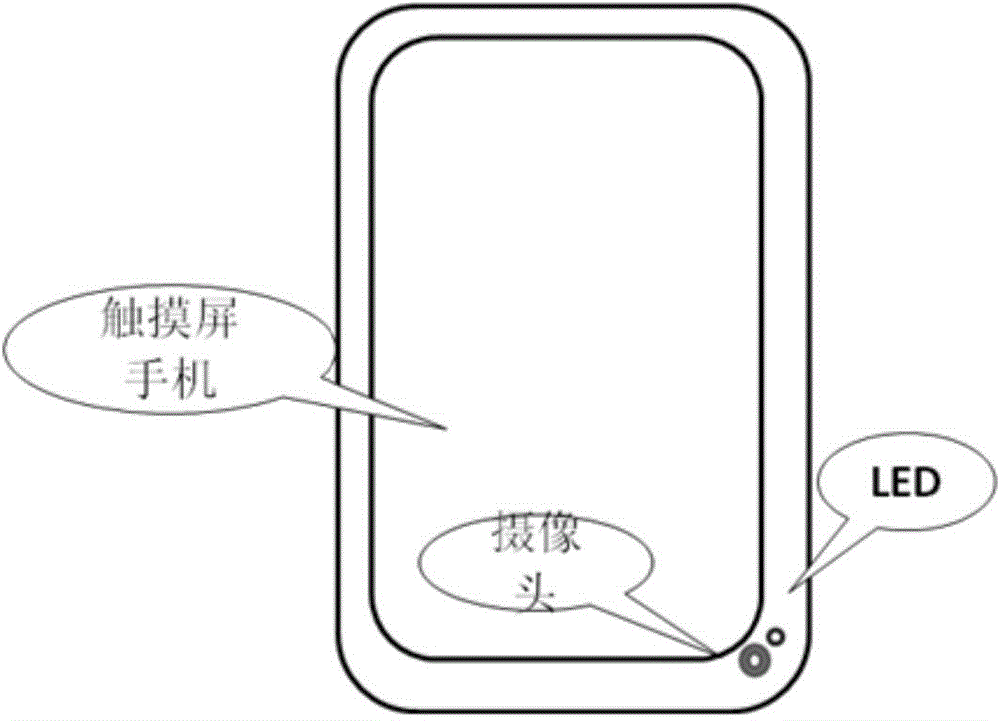

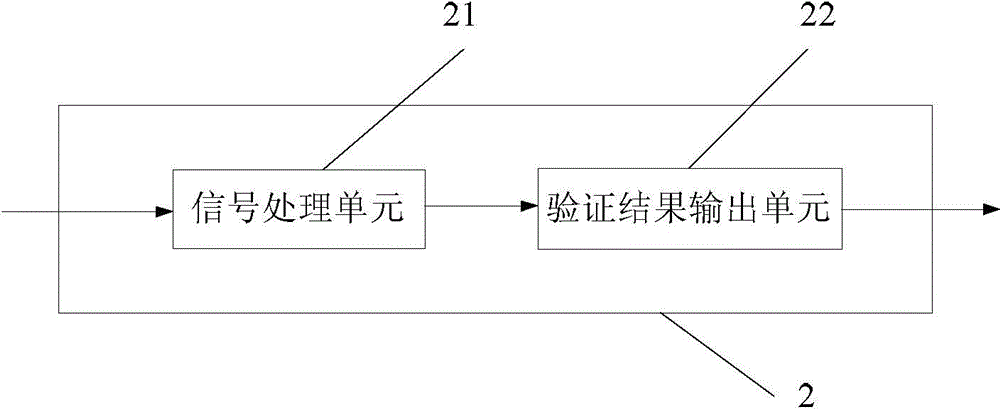

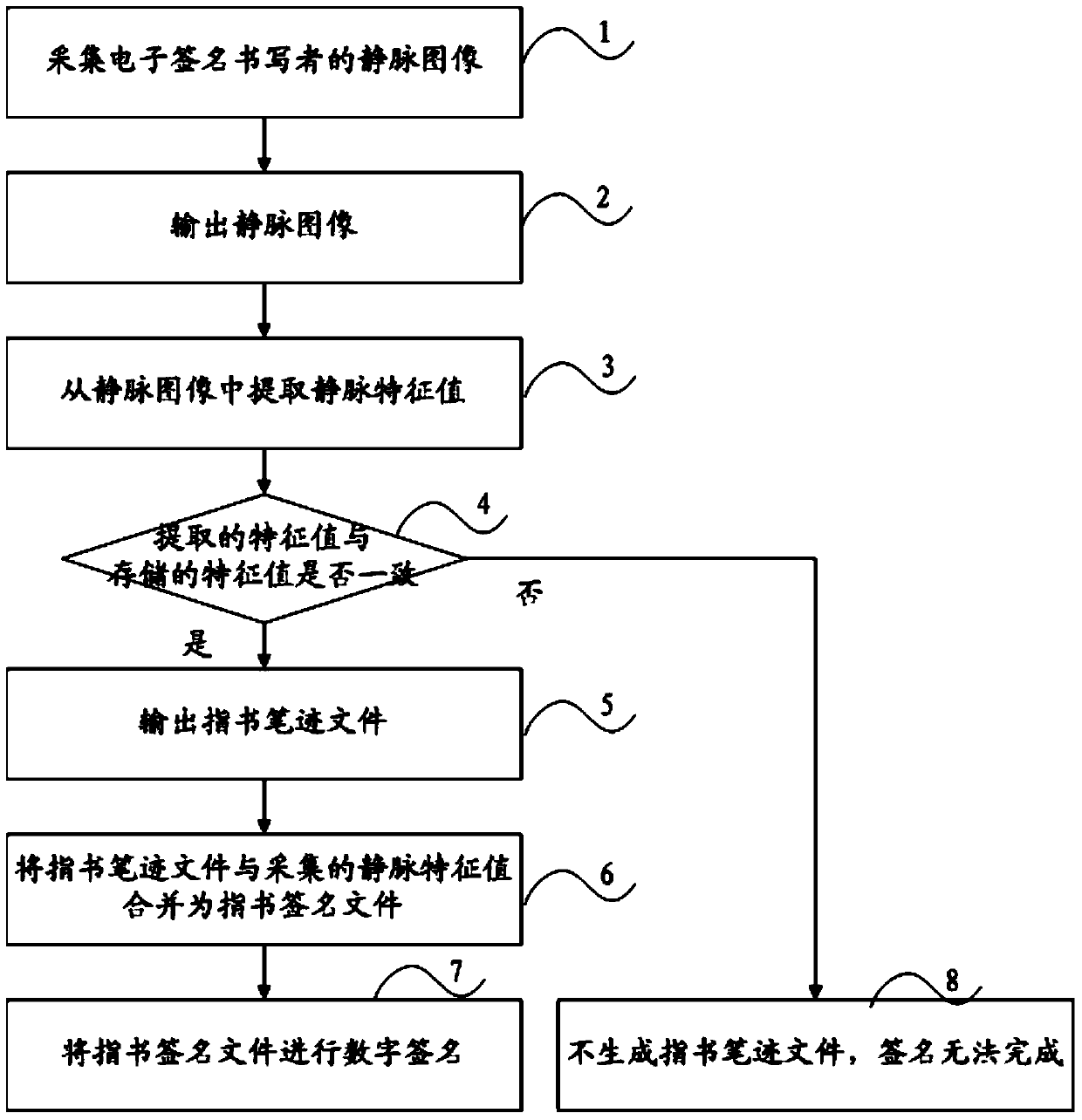

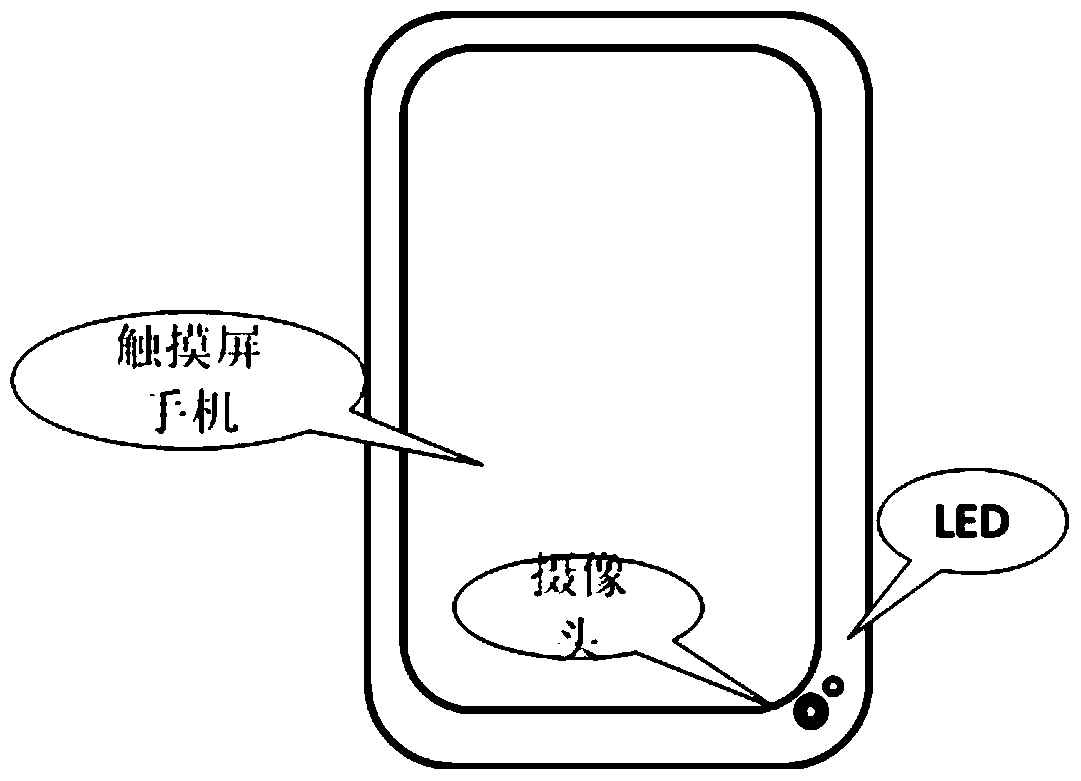

Method and system for finger-writing signatures on touch screen

ActiveCN104462908AImprove accuracyAnti-counterfeitingDigital data authenticationHandwritingPattern recognition

The invention discloses a method and a system for finger-writing signatures on a touch screen. The method includes: a vein image of a writer of an electronic signature; outputting the vein image; extracting vein feature values from the vein image; comparing the extracted vein feature values to stored vein feature values; if consistence is confirmed, outputting finger writing files, and combing the finger writing files and the extracted vein feature values into a finger-written signature file. The method and the system have the advantages that authentication is more accurate and faking and tampering is prevented.

Owner:CHINA TELECOM CORP LTD

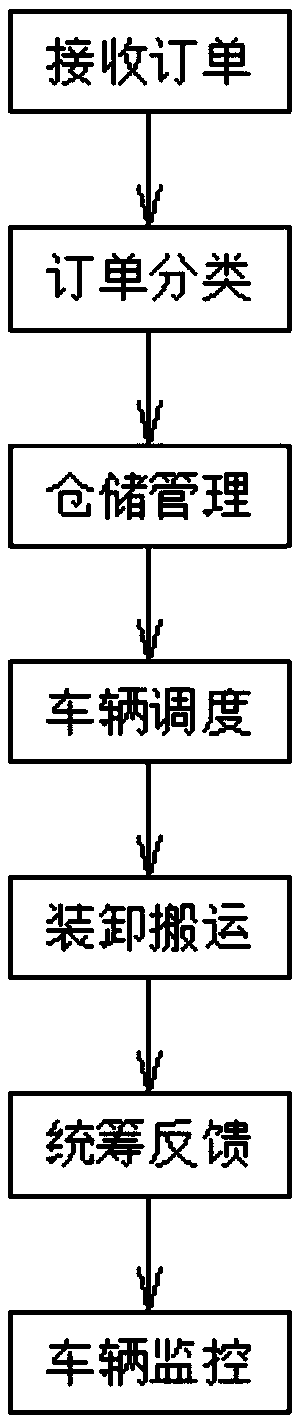

An intelligent logistics transportation vehicle passage control management system and method

InactiveCN109447540AReal-time understanding of driving conditionsImprove satisfactionCo-operative working arrangementsResourcesLogistics managementManagement unit

The invention discloses an intelligent logistics transportation vehicle passage control management system and method, belonging to the technical field of logistics transportation management. The system comprises an order receiving unit, an order classification unit, a warehousing management unit, a vehicle scheduling unit, a loading and unloading handling unit, an overall feedback unit and a vehicle monitoring unit. The method comprises the following steps of receiving an order, classifying the order, classifying the order according to the order priority and the delivery address; carrying outthe warehouse management, assigning warehouse for order; dispatching vehicles for transporting goods; loading and unloading; feeding back overall to control the receipt of orders based on current order volume, warehouse usage and vehicle usage; monitoring vehicles. The technical proposal of the example of the invention intelligently realizes the docking of the vehicle and the warehousing and the monitoring of the vehicle, and improves the management efficiency of the logistics industry.

Owner:李哲

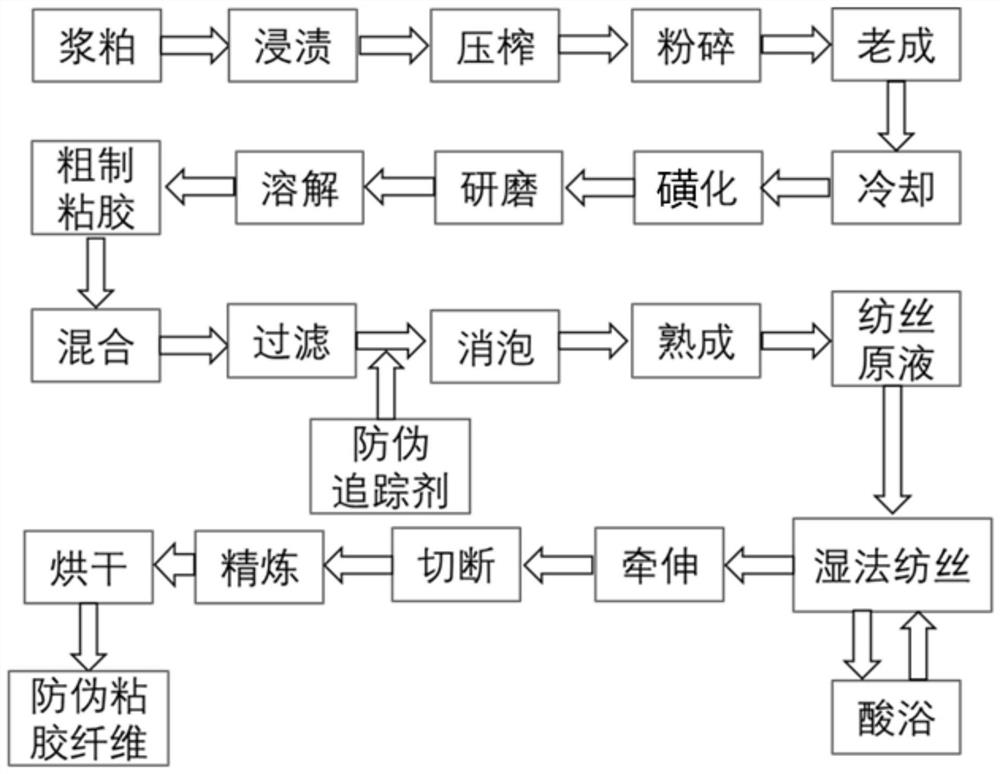

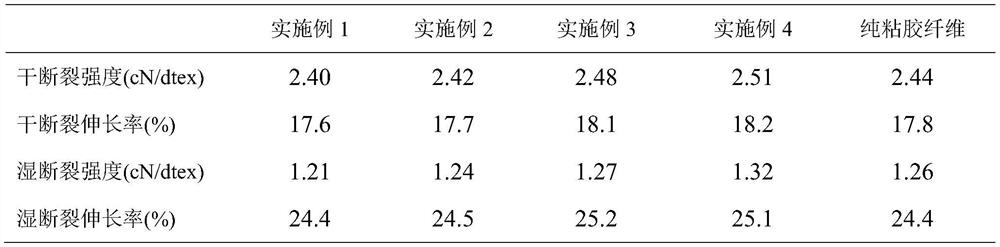

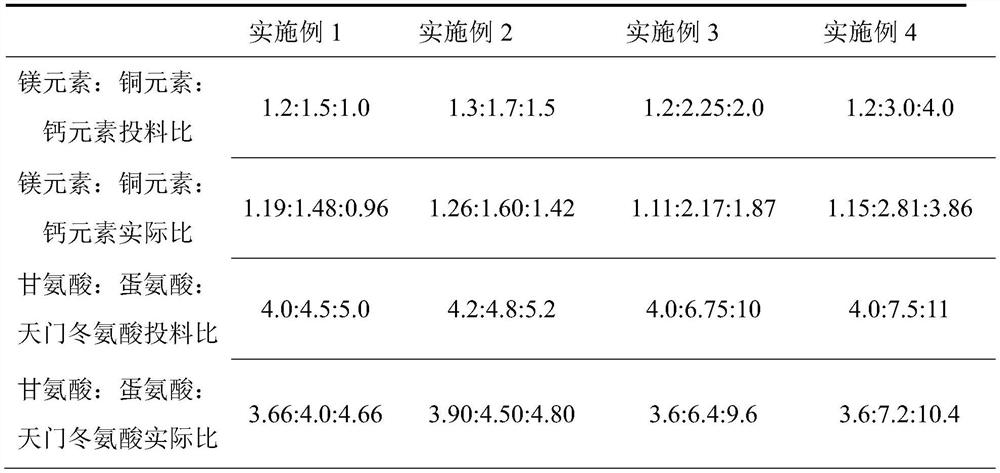

Anti-counterfeiting viscose fiber, preparation method and anti-counterfeiting method

ActiveCN112501705AEasy to detect and identifyImprove timelinessMaterial analysis by electric/magnetic meansAnalysis by thermal excitationSpinningMetal chelate

The invention relates to a preparation method of an anti-counterfeiting viscose fiber. The preparation method comprises the following steps of dipping pulp in an aqueous solution of alkali, squeezing,crushing, aging, cooling, sulfonating, and dissolving in a dilute alkali solution to obtain a crude viscose; uniformly mixing the crude viscose with various amino acid metal chelates, and carrying out defoaming and ripening to obtain a spinning stock solution; carrying out wet spinning and acid bath on the spinning stock solution, and then carrying out drafting, cutting, refining, oiling and drying treatment to obtain the anti-counterfeiting viscose fiber, wherein the sum of the mass of metal elements contained in the amino acid metal chelates accounts for 0.03-0.11% of the mass fraction of the anti-counterfeiting viscose fiber. The anti-counterfeiting viscose fiber disclosed by the invention is subjected to anti-counterfeiting encryption treatment by utilizing various amino acid metal chelates, and anti-counterfeiting identification is carried out by detecting and encoding metal elements and amino acid types, so that the anti-counterfeiting degree is high, and the anti-counterfeitingconcealment is good.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

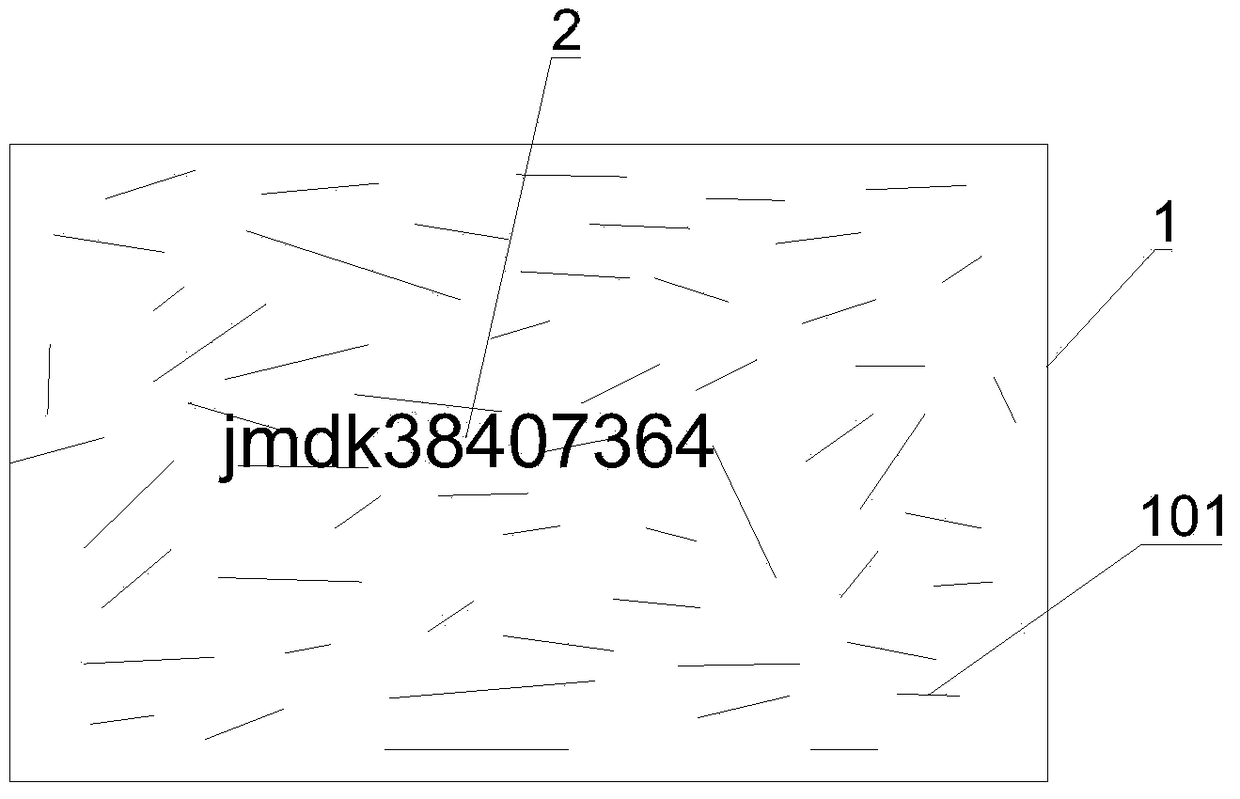

Fragile anti-fake label with fibers arrayed randomly and directionally and preparation method of fragile anti-fake label

The invention provides a fragile anti-fake label with fibers arrayed randomly and directionally and a preparation method of the fragile anti-fake label, and belongs to the field of anti-fake labels. The anti-fake label comprises three layers which sequentially include release paper, a self-adhesive layer and an anti-fake coating, wherein the surface of the self-adhesive layer is coated with water-based ink, and then drying is conducted to obtain the anti-fake coating; the water-base ink is prepared from water-base resin, a dispersing agent, a defoaming agent, a leveling agent, a thickening agent, titanium dioxide and calcium carbonate, and fiber-shaped objects can be further included in the water-based ink. By adding the water-base resin with a large molecular weight and a chain structure,the resin is arrayed into a membrane through a fiber mode during membrane forming, the added fiber-shaped objects are arrayed in a selected direction, during random coating, the fiber-shaped objectsare arrayed more uniformly, and the prepared anti-fake label has generality and is convenient to apply and popularize. Meanwhile, the fragile anti-fake label has the advantages of having strong threedimension and a touch feeling, being provided with the fibers capable of being touched, and being capable of being used for writing and fragile; recognizing is easy, and the anti-fake degree is high.

Owner:广州山木新材料科技有限公司

Traceability voucher code anti-counterfeiting system and method

PendingCN111598592AEasy to understandAvoid lostCo-operative working arrangementsCommerceVoucherOperating system

The invention discloses a traceability voucher code anti-counterfeiting system and method. The system comprises a cloud server, an anti-counterfeiting platform registration module, an institution management module, a traceability voucher code generation unit, a scanning module, a display module, a reporting module, a merchant appeal module, and a release module. The anti-counterfeiting method is convenient for consumers to visually understand the positions of fake merchants, avoids purchasing fake products, is beneficial to protecting the interests of the consumers and production enterprises,also can avoid economic and reputation loss caused by malicious report of the merchants, and maintains the legal rights and interests of the merchants, Meanwhile, the whole anti-counterfeiting methodhas the characteristics of simple process, strong operability and easiness in implementation.

Owner:刘晏周

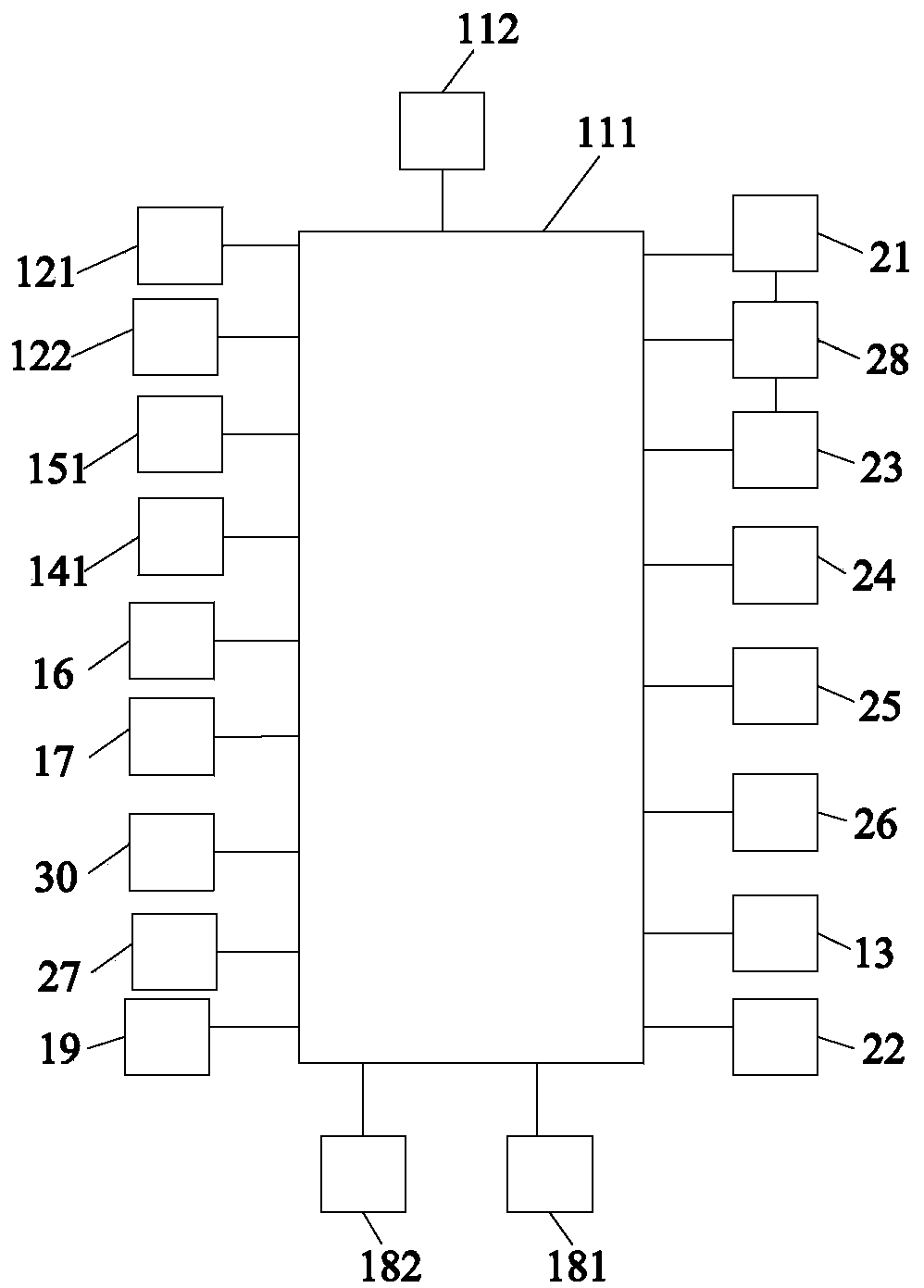

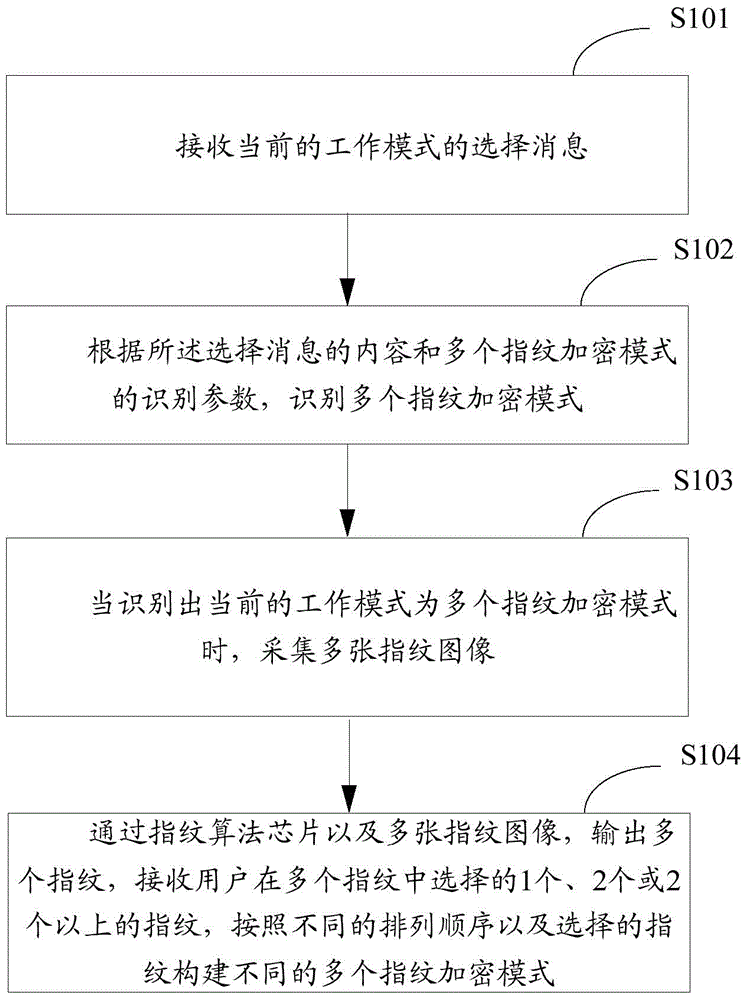

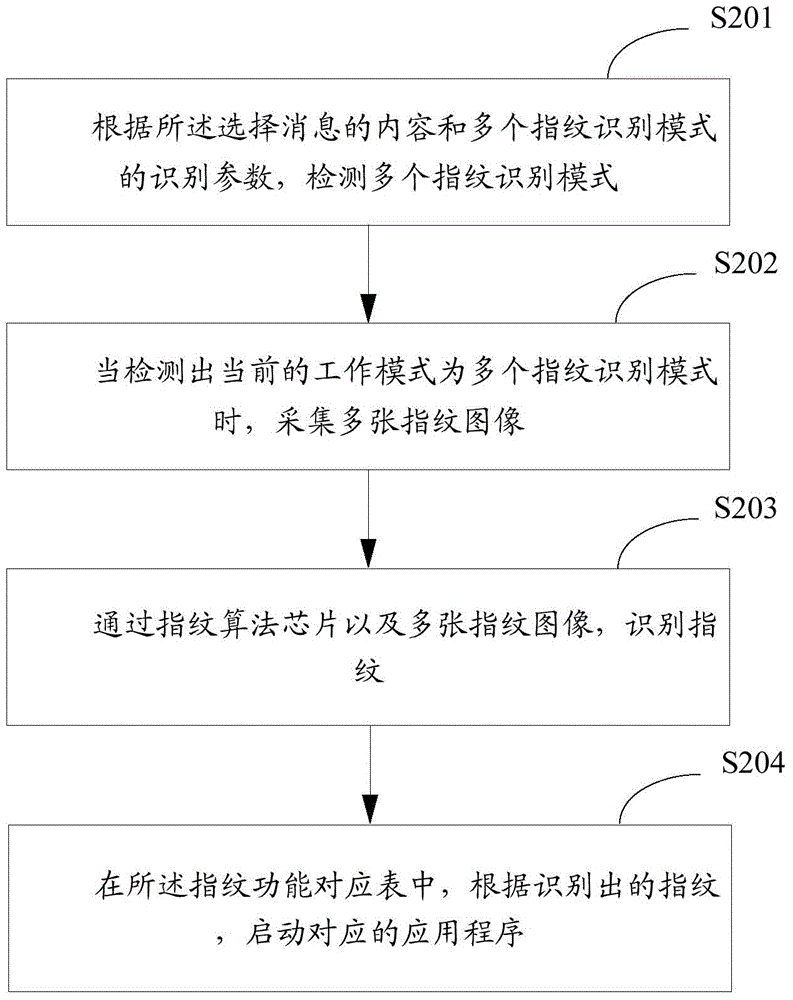

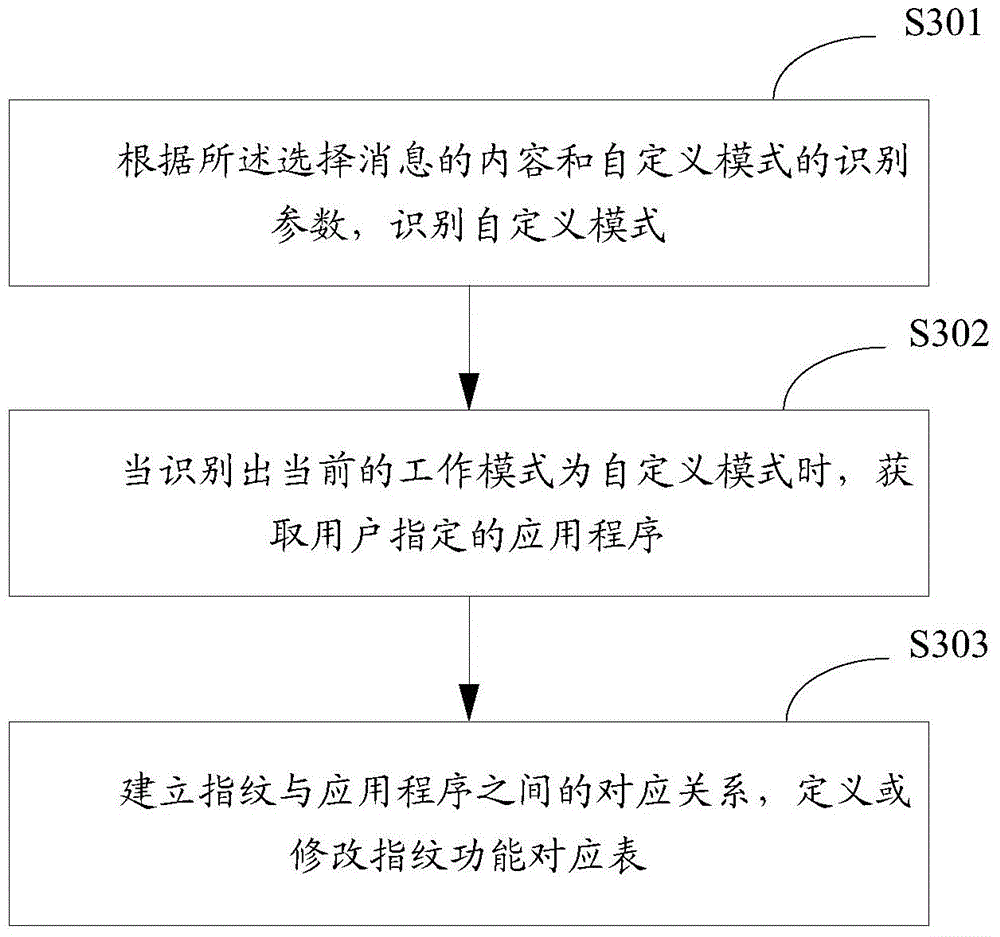

Fingerprint mode application method and device

InactiveCN106295472AImprove encryptionImprove reliabilityCharacter and pattern recognitionComputer hardwareApplication areas

The invention is applicable to the field of fingerprint mode applications, and provides a fingerprint mode application method and device. The fingerprint mode application method comprises the steps of receiving a selection message for the current operating mode; recognizing a multi-fingerprint encryption mode according to the content of the selection message and recognition parameters of the multi-fingerprint encryption mode; acquiring multiple fingerprint images when the current operating mode is recognized to be a multi-fingerprint encryption mode; outputting multiple fingerprints through a fingerprint algorithm chip and the multiple fingerprint images, receiving one, two or more than two fingerprints selected by a user from the multiple fingerprints, and constructing different multi-fingerprint encryption modes according to different arrangement sequences and the selected fingerprints. According to the invention, a multi-fingerprint encryption mode, a multi-fingerprint recognition mode and a user-defined mode are adopted, and the device has the characteristics of high encryption performance, high safety performance, high reliability, high anti-counterfeiting degree, low sampling cost, high recognition success rate, convenient modification, great market application and wide applicable group of people.

Owner:SHENZHEN FINGERCHIP INTELLIGENT TECH

Anti-counterfeiting annular code and encoding method thereof

InactiveCN102800243BImprove reliabilityLow costCoding/ciphering apparatusGraphicsTheoretical computer science

The invention provides an anti-counterfeiting annular code and an encoding method thereof. The annular code expresses a number and letter string by a plurality of concentric rings; each concentric ring consists of full lines with unequal lengths and gaps; the number and letter string of the annular code is converted into a binary bit string through encryption; and a layer quantity of the annular code and a quantity of binary numbers in each layer can be determined according to the quantity of the binary bit strings. With the adoption of the anti-counterfeiting annular code provided by the invention, the anti-countering degree is greatly improved, so that not only can an anti-counterfeiting sequence code be difficult to obtain, but also the technical difficulty that a label in an annular code structure is formed is overcome. Therefore, the reliability of the annular code is greatly improved. The annular code has the advantages of low cost, and convenience and rapidness of searching.

Owner:长沙高新技术产业开发区诺美网络技术有限公司

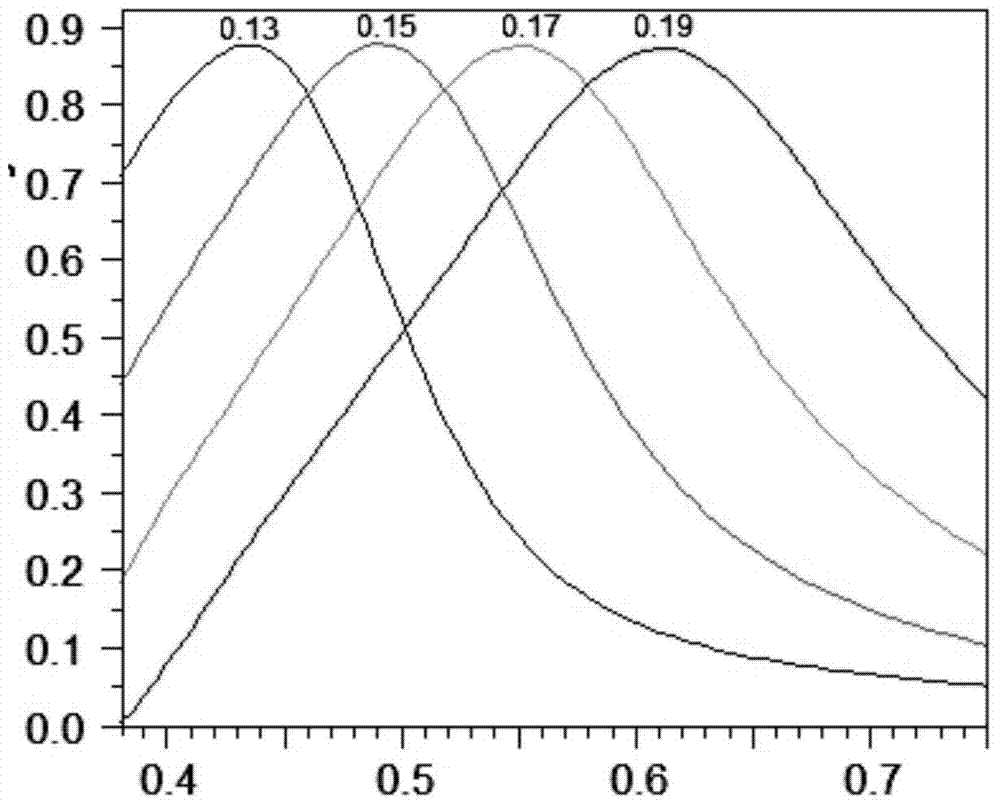

Infrared absorption anti-fake ink

InactiveCN110218485AStrong concealmentHigh degree of anti-counterfeitingInksNear infrared absorptionSolvent

The invention discloses an infrared absorption anti-fake ink which comprises the following raw materials in parts by weight: 10-20 parts of an infrared absorption material A, 10-20 parts of an infrared absorption material B, 12-24 parts of a connecting material, 15-20 parts of a pigment, 30-40 parts of a synthetic resin, 6-8 parts of plant oil, 2-4 parts of mineral oil, 16-20 parts of a filler, 2-4 parts of a composite drying agent, 30-40 parts of a solvent and 0.3-0.5 part of an anti-caking agent, wherein the maximum absorption peak of the infrared absorption material A is within 700-900nm; the maximum absorption peak of the infrared absorption material B is within 950-1250nm; the infrared absorption material A or the infrared absorption material B comprises copper ions, phosphate radicals and carbonate; and the position of the maximum absorption peak is determined by contents of the copper ions, the phosphate radicals and the carbonate in the infrared absorption materials. The infrared absorption anti-fake ink is not easy to imitate and convenient in anti-fake characteristic detection, is approximately colorless, is applicable to various tickets, notes, trademarks and similar articles, can be adopted to print various hidden bar codes which are invisible by naked eyes, is good in concealing, and is capable of effectively preventing copy and imitation.

Owner:李兴宇 +1

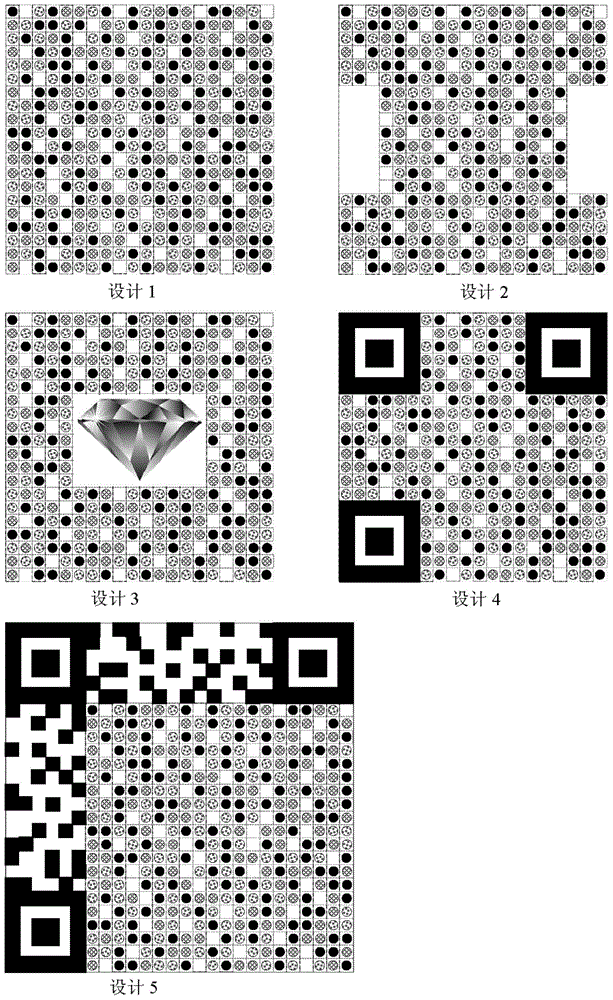

Two-dimensional code anti-counterfeit label and printing method thereof

ActiveCN104680216AHigh degree of anti-counterfeitingLow costPattern printingRecord carriers used with machinesAdditive ingredientPrinting ink

The invention belongs to the technical field of anti-counterfeit and particularly relates to a two-dimensional code anti-counterfeit label and a printing method thereof. The two-dimensional code anti-counterfeit label is obtained by the following method comprising the following steps: (1) preparing pearlescent microbeads of different colors, wherein the particle size of each pearlescent microbead is 0.1-3mm; (2) adding the pearlescent microbeads obtained in the step (1) to printing ink taking resin as a main ingredient, and mixing to obtain special printing ink for printing the two-dimensional anti-counterfeit label, wherein the use amount of the pearlescent microbeads is 5-80 percent of the weight of the resin and more than three colors of pearlescent microbeads are selected; (3) printing a two-dimensional code pattern by adopting the special printing ink on a product or label paper to be subjected to two-dimensional code printing, so that each cell of the two-dimensional code is internally printed with no more than one pearlescent microbead, and the pearlescent microbeads of more than three colors randomly form a special two-dimensional code pattern. The two-dimensional code anti-counterfeit label disclosed by the invention is hardly repeated, the repetition probability is less than 10 parts per billion, and even so, the repetition can be eliminated through a detection system.

Owner:广东航迈新材料科技有限公司

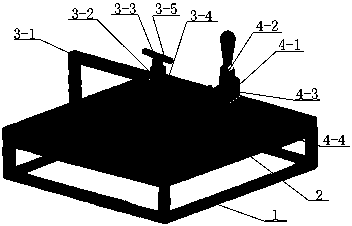

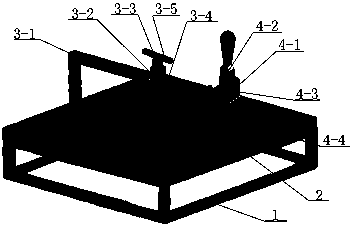

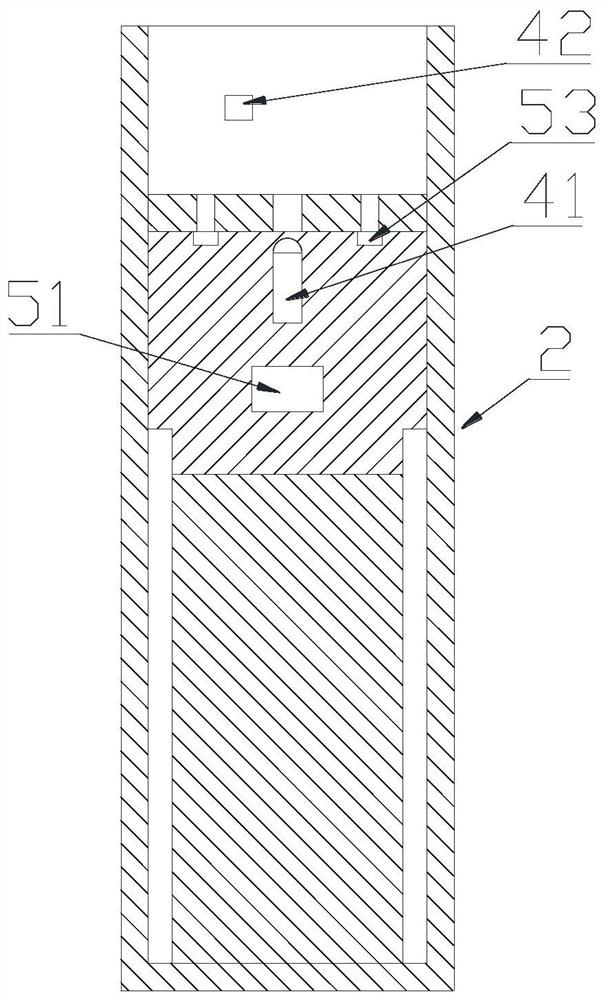

Circuit board perforating mechanism capable of carrying out marking

PendingCN107803879ASolve the hole punching problemSolve the problem of how to markMetal working apparatusStampingMarking outProcess engineering

The invention discloses a circuit board perforating mechanism capable of carrying out marking. The problem of perforating a circuit board is solved, the problem how to mark the circuit board in the circuit board production process is also solved, by arranging a marking device, different types of label seals can be printed on the circuit board, the anti-fake degree of the circuit board is improved,the risk that the circuit board is counterfeited by other factories is reduced, moreover, the whole operation is easy, precision is high, the manufacturing cost is low, the effect is enhanced remarkably, and the overall high efficiency and operation reliability are also improved.

Owner:SHANGHAI NCATEST TECH CO LTD

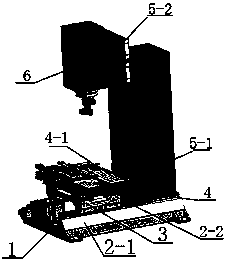

Multifunctional marking machine for circuit boards

InactiveCN107891674ASolve the problem of how to markHigh degree of anti-counterfeitingStampingMarking outElectrical and Electronics engineering

The invention discloses a multifunctional marking machine for circuit boards. The multifunctional marking machine solves the problem of how to mark the circuit boards in the production process of thecircuit boards. According to the multifunctional marking machine, a marking device is arranged so that marks of different types can be printed on the circuit boards, and therefore the anti-counterfeitdegree of the circuit boards can be improved, the risk that the circuit boards are counterfeited and produced by other manufacturers can be reduced, in addition, the operation in the whole process issimple, the accuracy is extremely high, the manufacturing cost is low, the effect can be remarkably enhanced, and the overall efficiency and the operation reliability can be greatly improved.

Owner:SHANGHAI NCATEST TECH CO LTD

Black-to-green color changing thermal transfer ribbon

InactiveCN107160887AWith color changing anti-counterfeiting functionEasy to identifyFireproof paintsInksBoPETEngineering

The invention discloses a black-to-green color-changing thermal transfer carbon belt, which comprises: a BOPET film, a heat-resistant coating, a release layer, an ink layer, a heat-resistant coating on the outside of the BOPET film, and a coating on the inside of the BOPET film. A release layer is covered, and an ink layer is coated on the outside of the release layer. The invention has the anti-counterfeiting function of turning black into green, which is convenient for distinguishing the authenticity of tickets, official documents and products, and improves the anti-counterfeiting degree.

Owner:鹏码新材料(安徽)有限公司

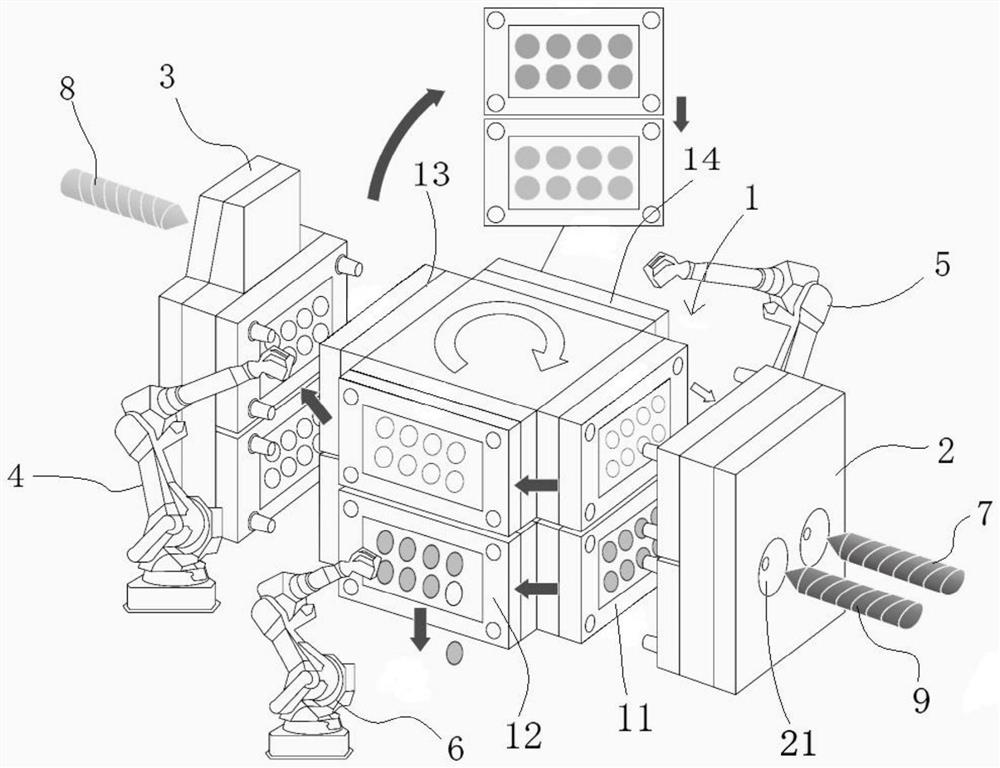

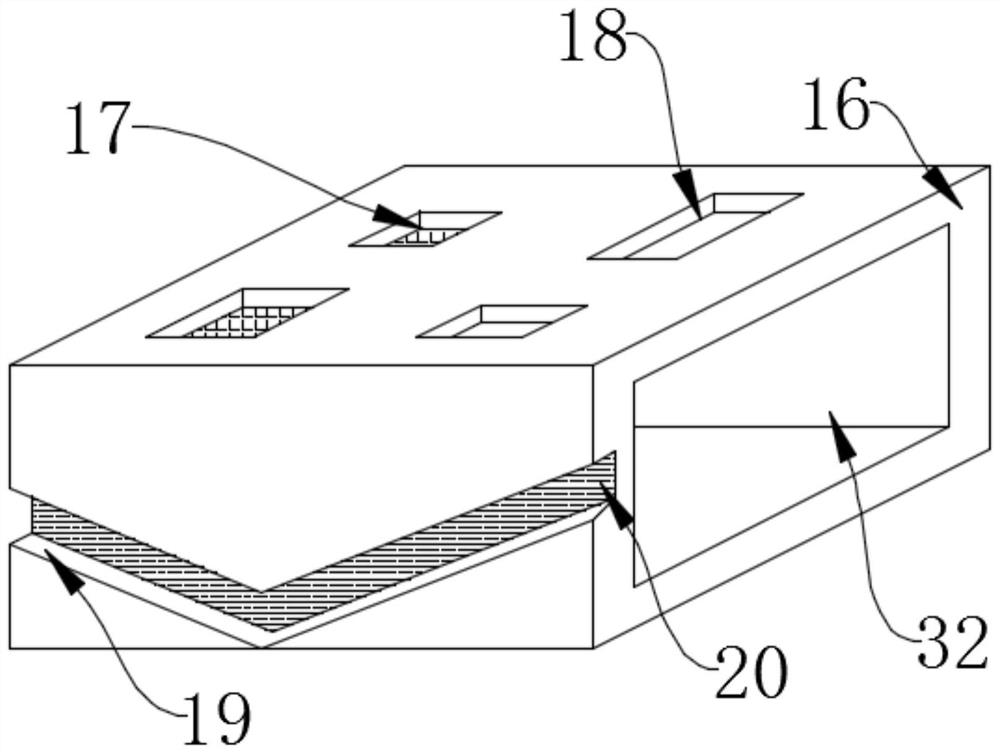

A kind of manufacturing method of anti-counterfeiting sealed bottle cap

ActiveCN108943563BImprove processing technologyIncrease production difficultyDomestic articlesInjection molding machineBottle cap

The invention relates to a manufacturing method of an anti-counterfeiting sealing bottle cap. The method adopts a special injection molding device for operation, wherein the injection molding device comprises an injection molding machine body, a first movable mold, a second movable mold, a first mechanical arm, a second mechanical arm, a third mechanical arm, a first screw rod, a second screw rod,a third screw rod and a PLC controller, and a first station, a second station, a third station and a fourth station are arranged on the outer side of the injection molding machine body; the manufacturing method of the anti-counterfeiting sealing bottle cap comprises the following steps that injection molding of a sealing ring is carried out; the sealing ring is cooled and shaped; a membrane innerlabel is placed; injection molding of a lower cover is carried out; an upper cover is assemble on the lower cover; injection molding of an anti-theft ring is carried out; and a finished product is taken out. According to the manufacturing method of the anti-counterfeiting sealing bottle cap, the process is complex, the manufacturing threshold is relatively high, effective sealing and anti-counterfeiting can be realized, moreover, the four stations of the special injection molding machine can work synchronously, and the working efficiency is improved.

Owner:GUANGZHOU CHENGTIAN PACKAGING DESIGN CO LTD

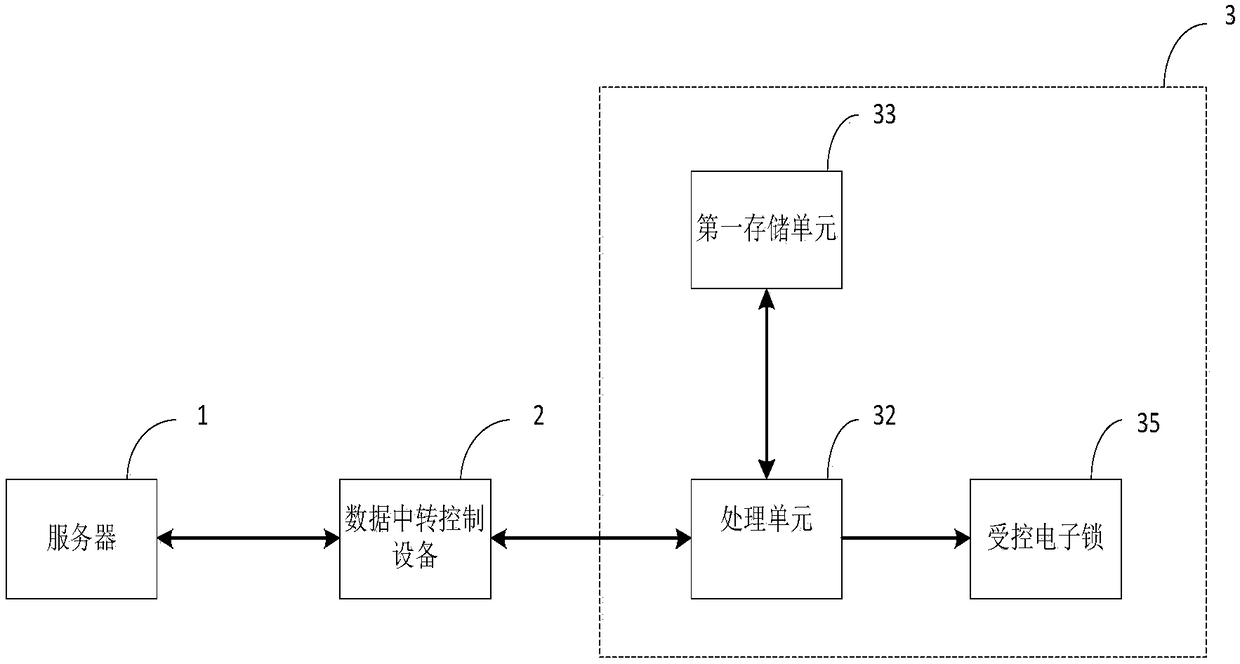

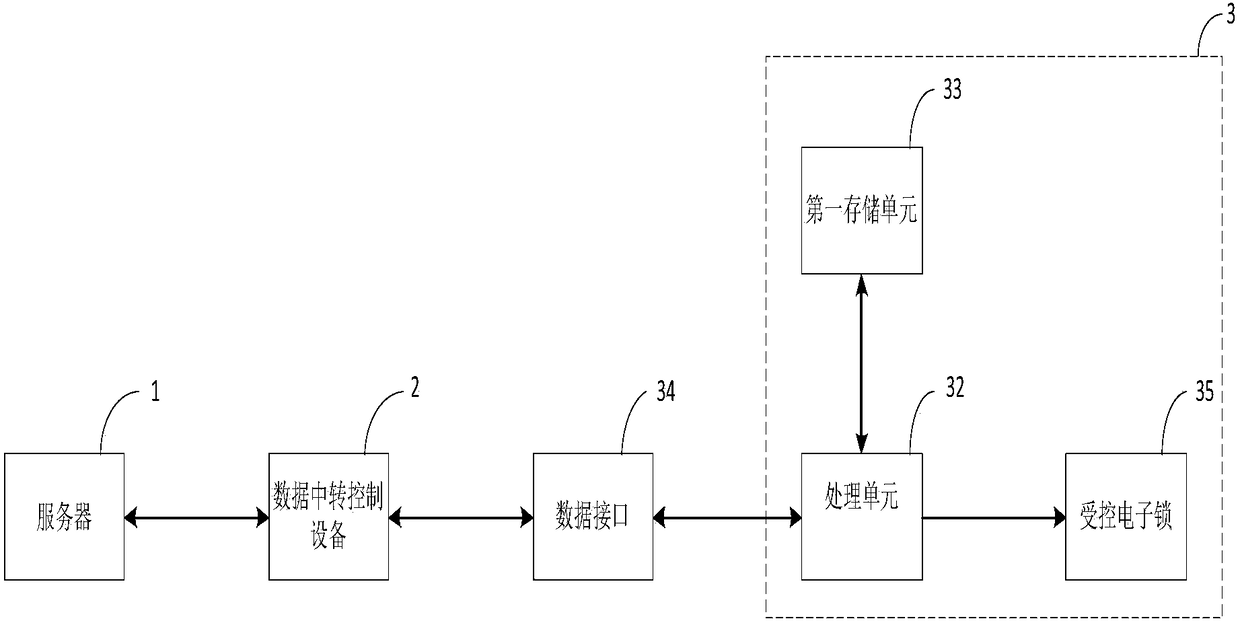

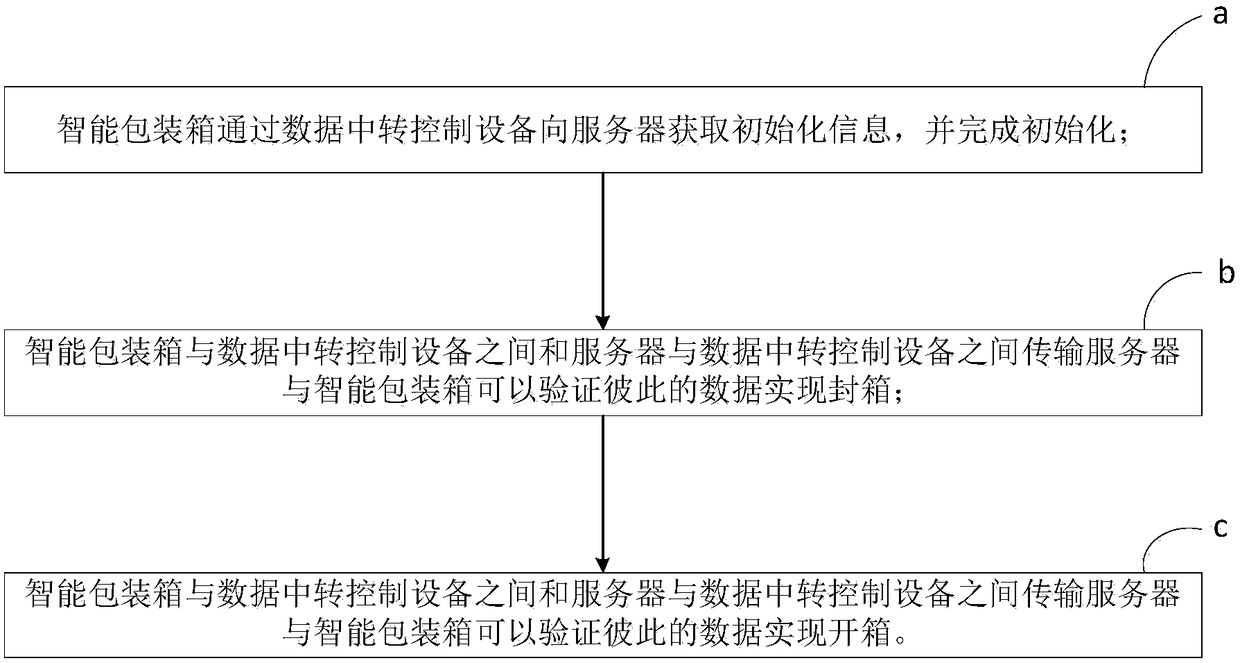

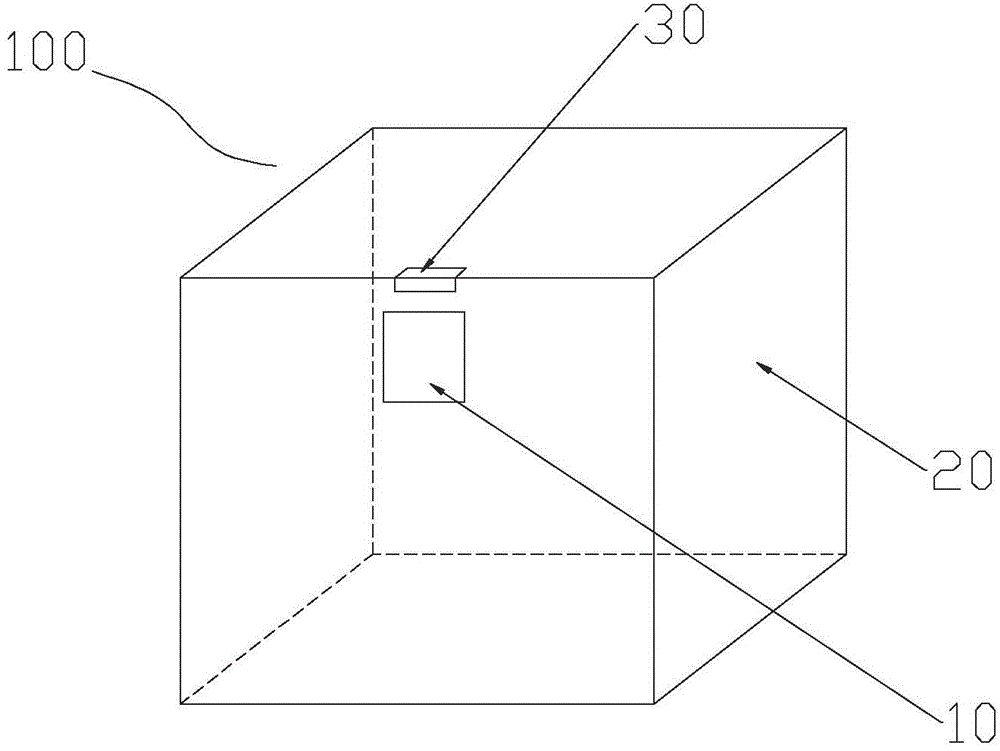

Intelligent packaging system and packaging method

The invention relates to an intelligent packaging system which comprises a server, data relay control equipment and an intelligent packaging box. The server is connected with the data relay control equipment through network data, the intelligent packaging box comprises a box body, a processing unit, a first storage unit and a controlled electronic lock, the processing unit is electrically connected with the first storage unit and the controlled electronic lock, and the data relay control equipment is electrically connected with the processing unit; and the server is used for generating and / orstoring identity data of the intelligent packaging box, used for generating and / or storing authentication data, used for verifying and / or storing information verified by the authentication data and coming from the intelligent packaging box and used for verifying whether data come from the intelligent packaging box or not through the authentication data when packaging box operation commands are generated or request commands are received. By means of the intelligent packaging system, the problem that an existing packaging technology has resource waste is solved, the using cost is reduced, and the anti-fake degree is improved.

Owner:广州子灵信息科技有限公司

Bar code thermal transfer ribbon special for printing and preparation method thereof

InactiveCN111907235AEasy to produceIncrease productivityInk ribbonsPolyureas/polyurethane adhesivesMechanical engineeringPhysics

The invention discloses a bar code thermal transfer ribbon special for printing. The bar code thermal transfer ribbon comprises a ribbon base, a back coating and a thermal transfer printing layer, andis characterized in that an anti-counterfeiting layer is also arranged between the thermal transfer printing layer and the ribbon base; the anti-counterfeiting layer comprises a surface adhesive baselayer; a magnetic particle layer is laid on the lower surface of the surface adhesive base layer; a color layer is arranged on the side surfaces or the lower surfaces of magnetic particles in the magnetic particle layer; and a primer base layer is arranged on the lower surface of the magnetic particle layer. The bar code thermal transfer ribbon special for printing is provided with the anti-counterfeiting layer, a magnetic heater moves on the surface of the anti-counterfeiting layer, the magnetic particles are turned over, the color layer below the magnetic particles can be displayed, a userrecognizes the authenticity of a product according to the color layer, a bar code and counterfeiting prevention are combined, production is more convenient, and the production efficiency can be betterimproved. Meanwhile, a manufacturer can carry out specific design on anti-counterfeiting colors and patterns according to own requirements, so that the anti-counterfeiting degree is further improved.

Owner:广州中码科技股份有限公司

A kind of production method of holographic hot stamping film

ActiveCN105172408BExquisite patternNot easy to forgeDuplicating/marking methodsLaminationHot stampingCompanion animal

The invention provides a production method for a holographic hot stamping film. An anti-counterfeiting work plate is formed for silver spraying and electroforming operations of a photoetching offset plate etched with a holographic pattern; a positron emission tomography (PET) thin film is coated with a mold releasing agent to form a mold releasing layer; the mold releasing layer is coated with a resin solution mixed with toner to form a toner layer; the holographic pattern on the anti-counterfeiting work plate is die stamped on the toner layer of the PET thin film; metal aluminum is plated on the toner layer, and a aluminum-plated layer is coated with glue to form a glue layer; and finally, the PET thin film is divided, cut and packed. According to the hot stamping film produced through the production method not only exquisite in pattern, but also high in anti-counterfeiting degree and difficult to counterfeit; a used hot stamping film can not be reused. The photoetching offset plate sprayed with silver is even in thickness and high in strength, so that the rate of finished products of photoetching offset plates is increased by a large margin, and accordingly the quality of the anti-counterfeiting work plate and the hot stamping film is improved; meanwhile, the raw material consumption can be reduced, and the production cycle for making the anti-counterfeiting work plate is shortened. The electroformed anti-counterfeiting work plate has good strength, hardness and malleability resistance; the working life is pronged by near one time.

Owner:JIANGSU XINGGUANG PACKAGING SCI & TECH CO LTD

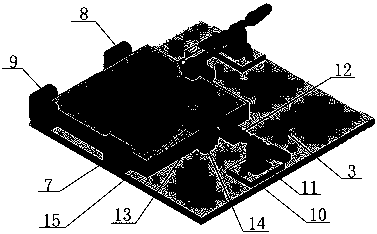

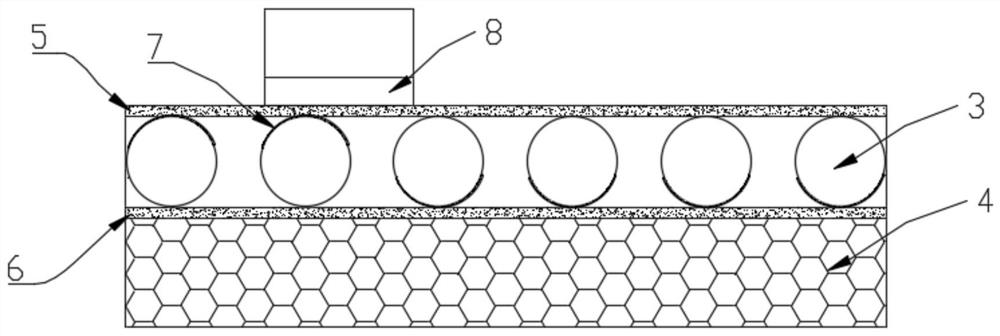

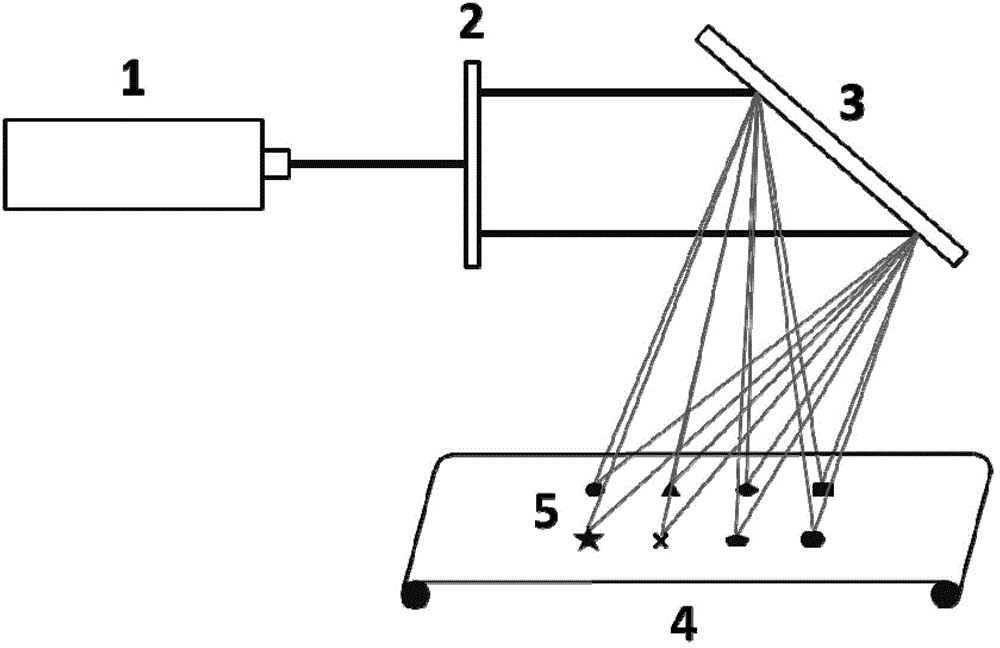

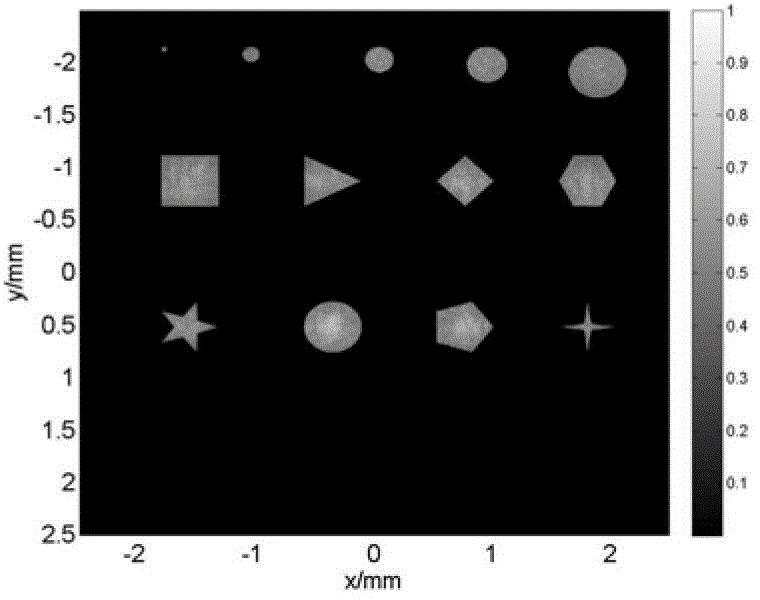

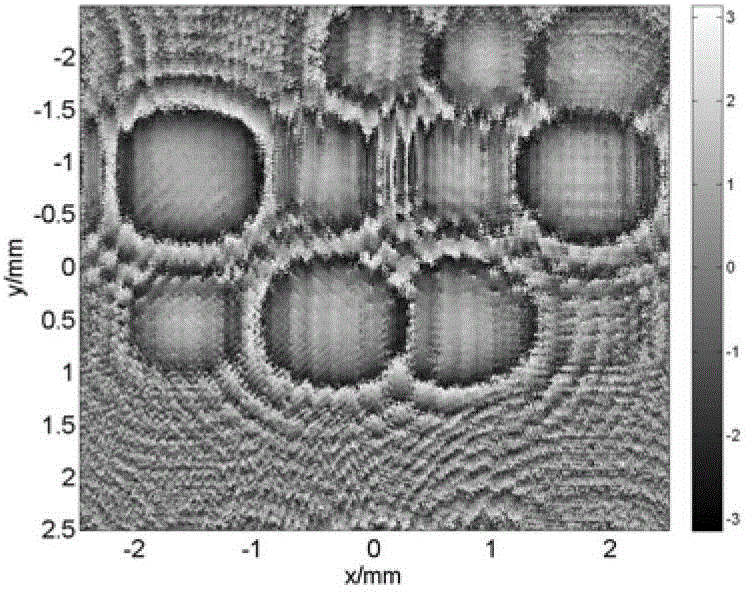

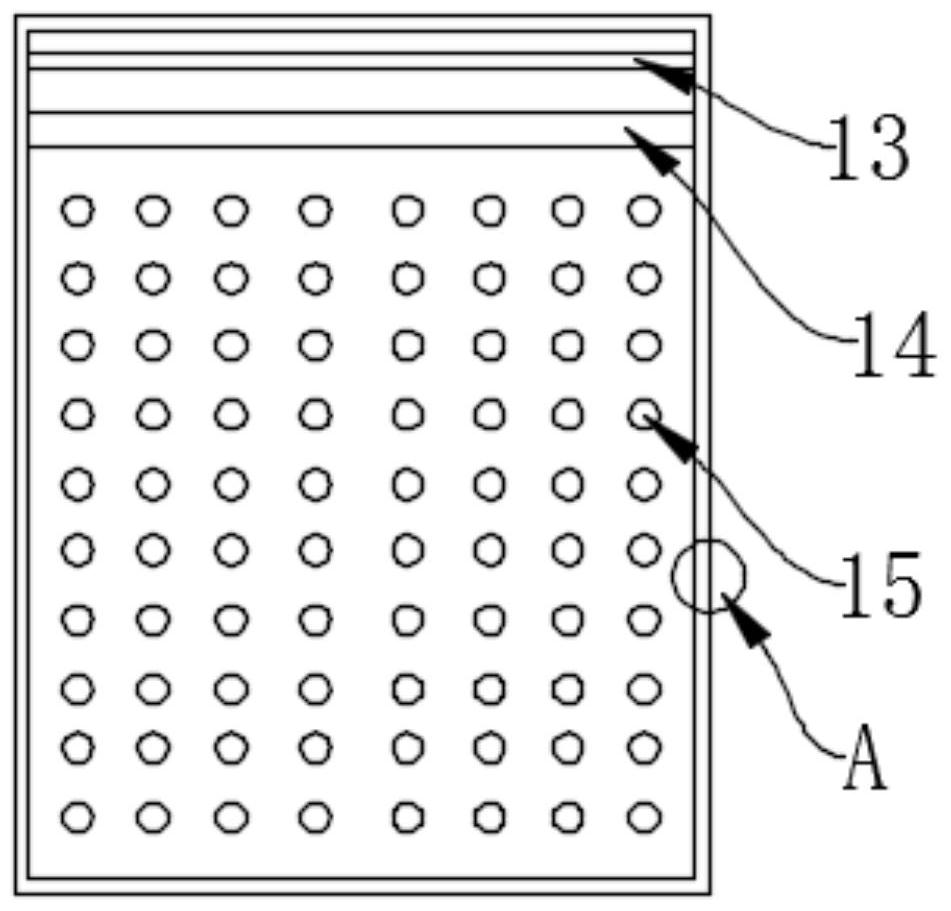

Graphical hole tipping paper punching equipment

ActiveCN103252586BHigh peak powerImprove breathabilityLaser beam welding apparatusOptical elementsBeam expanderVery large scale integrated circuits

The invention discloses graphical hole tipping paper punching equipment. The graphical hole tipping paper punching equipment comprises a paper feeding system, a pulse laser device, a beam expander and a reflection type diffractometer. According to the graphical hole tipping paper punching equipment, the reflection type diffractometer is used for enabling a pulse laser with the beam expanded to be used as incident light, and the incident light is focused on the surface of the tipping paper in a reflecting mode so that a plurality of holes in independent shapes can be punched; the reflection surface of the reflection type diffractometer has a coaxial reappearance function and has predetermined diffraction efficiency and is formed due to the fact that a step or continuous embossment structure is generated on a substrate through etching based on the diffraction optical theory, by means of the computer aided design and through the super-large-scale integrated circuit manufacturing technology. The pulse laser with high peak energy is output by the pulse laser device and enters the surface of the reflection type diffractometer through the beam expander, the incident light can be focused on the surface of the tipping paper by the reflection type diffractometer in the reflecting mode, and then the holes with diameters of 20-500 microns are punched. The graphical hole tipping paper punching equipment is good in stability and strong in generality. The holes punched with the equipment are good in air permeability. Security degree is high.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

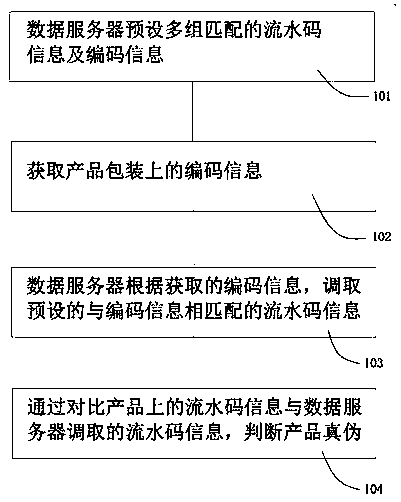

Novel anti-counterfeiting method and anti-counterfeiting goods fleeing preventing product

InactiveCN108876413AHigh degree of anti-counterfeitingNot easy to imitateCo-operative working arrangementsCommerceChannel conflictComputer science

The invention relates to a novel anti-counterfeiting method and an anti-counterfeiting goods fleeing preventing product, wherein the product anti-counterfeiting method comprises a data server, the data server presets multi-group matching water code information and code information, a product package has the code information , and the product has the water code information. The product anti-counterfeiting method comprises the following steps of: acquiring code information on the product package; the data server retrieving, according to the acquired code information, the preset water code information matching with the code information; and judging the authenticity of the product by comparing the water code information on the product with the water code information retrieved by the data server. According to the novel anti-counterfeiting method and the anti-counterfeiting goods fleeing preventing anti-channel conflict product, the product is certified using double authentications of the water code and code, so that the anti-counterfeiting degree is higher and the product is not liable to be counterfeited, thereby making purchasers feel more reassured.

Owner:HEFEI LANGJIN ANTI COUNTERFEITING TECH CO LTD

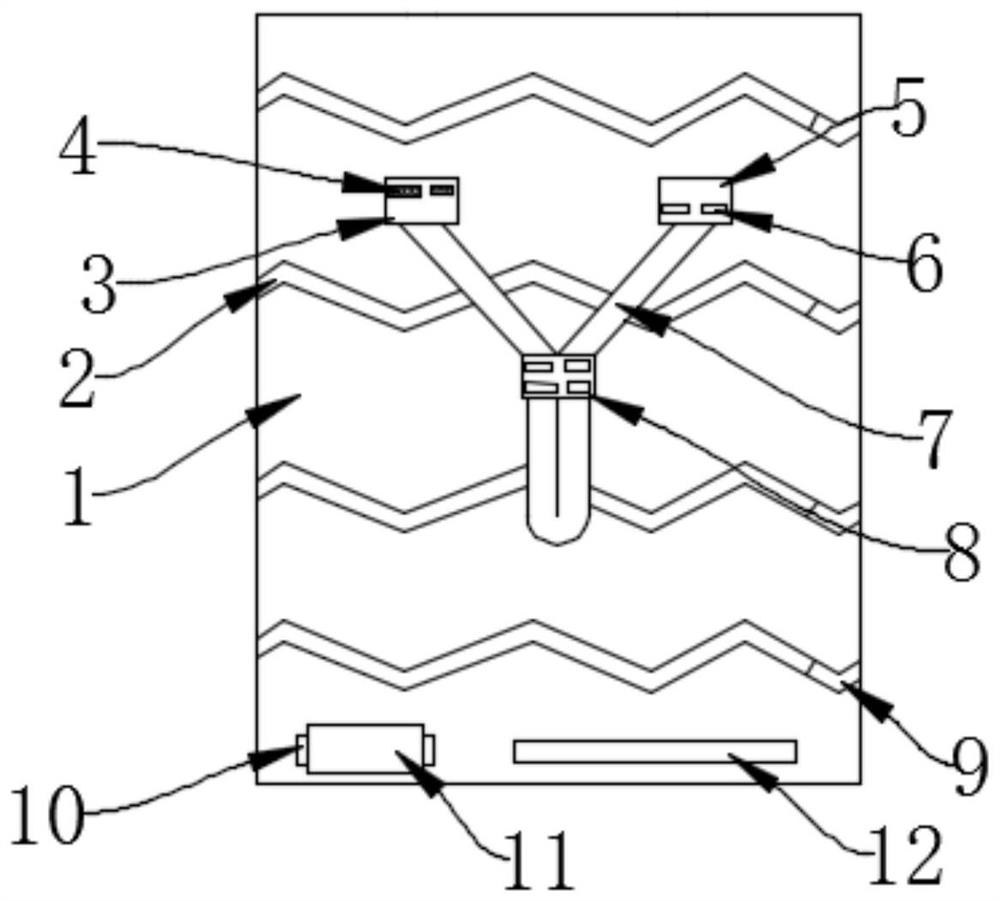

A flexible packaging bag with integrated anti-counterfeiting function

ActiveCN110203532BIncrease manufacturing difficultySolve the problem that is easy to be imitatedBagsSacksEngineeringStructural engineering

The invention discloses a soft packaging bag with an integrated anti-counterfeiting function, which comprises a main body of the soft packaging bag. Anti-slip fixing parts are installed on both sides of the main body of the soft packaging bag, and a V-shaped anti-counterfeiting fixing part is installed on one end of the anti-slip fixing part. An anti-counterfeit lifting rope is installed on one side of the main body of the soft packaging bag, a first fixing member is installed on one end of the anti-counterfeiting lifting rope, a first anti-counterfeiting bump is installed on the top of the first fixing piece, and the other end of the anti-counterfeiting lifting rope A second fixing part is installed, a second anti-counterfeiting projection is installed above the second fixing part, a fixed anti-counterfeiting block is arranged on one side of the anti-counterfeiting lifting rope, and an anti-counterfeiting strip is arranged under the anti-counterfeiting lifting rope, An anti-counterfeiting barcode is arranged on one side of the anti-counterfeiting strip. The present invention effectively improves the anti-counterfeiting and identification degree of the anti-counterfeiting mark by setting the first anti-counterfeiting bump, the second anti-counterfeiting bump and the anti-counterfeiting strip.

Owner:江苏伟光铝塑包装有限公司

Using method for circuit board punching mechanism capable of conducting marking

InactiveCN107839007ASolve the hole punching problemSolve the problem of how to markMetal working apparatusStampingPunchingEngineering

The invention discloses a using method for a circuit board punching mechanism capable of conducting marking. The punching problem of a circuit board is solved, and the difficulty of marking of the circuit board in the production process of the circuit board is also solved. By arranging a marking device, different types of markers can be printed to the circuit board, the anti-counterfeiting degreeis improved, the risk that the circuit board is produced by other manufacturers in a counterfeiting manner is reduced, moreover, the operation in the whole process is extremely easy, the precision degree is extremely high, the manufacturing cost is low, the function is remarkably enhanced, and the high efficiency of the whole circuit board punching mechanism and the operation reliability are greatly improved.

Owner:SHANGHAI NCATEST TECH CO LTD

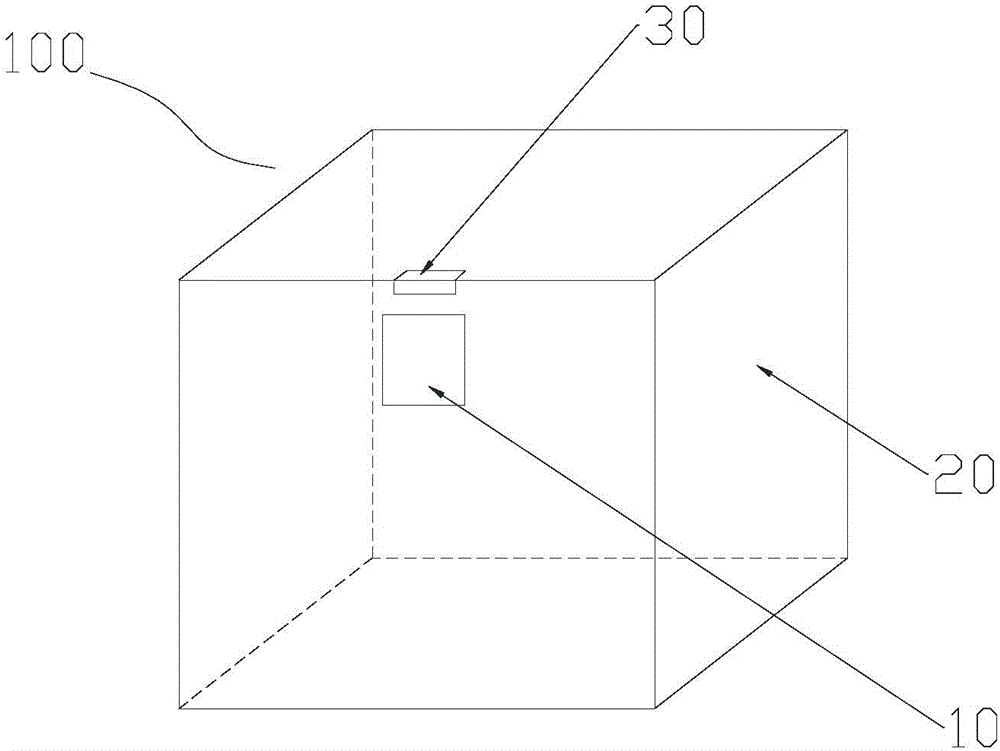

Packaging component, packaging component control system and method

ActiveCN103818636BIncreased protectionHigh degree of anti-counterfeitingLocking devicesControl systemIndustrial engineering

Owner:KUANG CHI INTELLIGENT PHOTONIC TECH

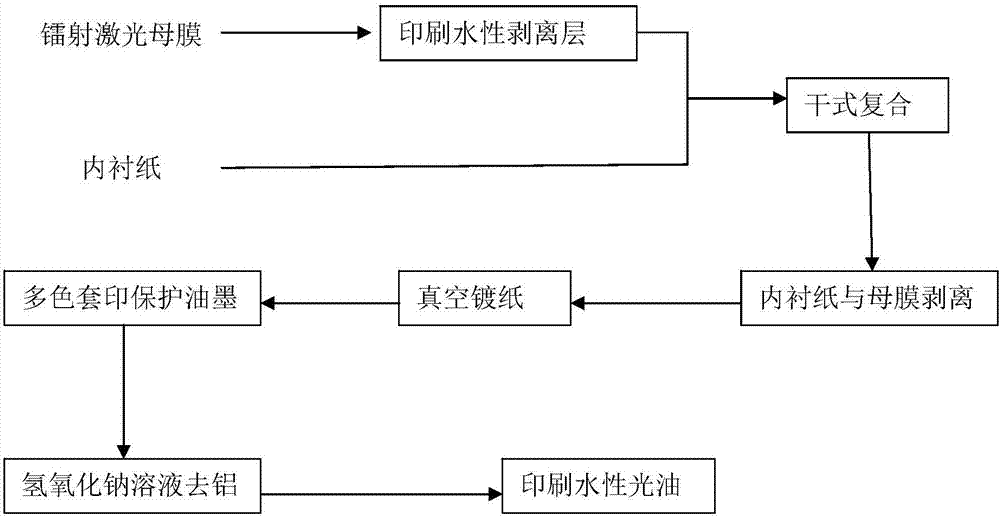

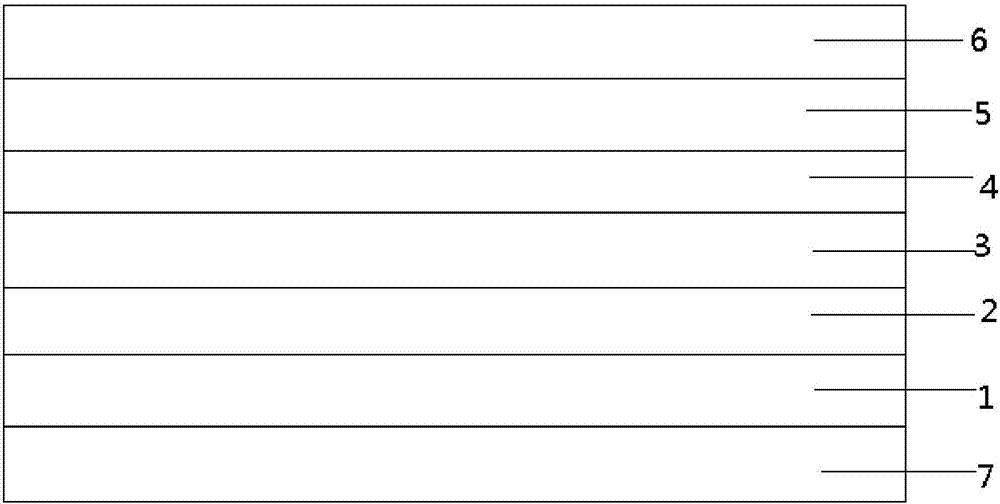

Laser lined paper for cigarettes and preparation method thereof

InactiveCN106939532AHigh reuse rateHigh degree of anti-counterfeitingSpecial visual effect coatingsNon-fibrous pulp additionColor printingAluminium

The invention discloses a preparation method of a laser lined paper for cigarettes. The preparation method comprises 1) printing a water-based peeling layer material on the surface of a laser main film to fill a laser grating on the laser main film, 2) carrying out dry compounding on a colored lined paper and the laser main film coated with the water-based peeling layer material, 3) stripping the compounded lined paper and the main film, 4) carrying out vacuum evaporation on the stripped lined paper, 5) carrying out multi-color printing ink protection on the lined paper subjected to vacuum evaporation, and cleaning to remove the aluminum layer of the unprinted part through a sodium hydroxide solution, and 6) printing a water-based polishing oil layer on the surface of the lined paper of which the aluminum is removed by the sodium hydroxide solution. The invention also discloses a laser lined paper for cigarettes. The laser lined paper is prepared by the preparation method. The laser lined paper and the preparation method have the characteristics of low production cost and high anti-counterfeiting degree.

Owner:GUANGZHOU HUADU LIANHUA PACKING MATERIAL CO LTD

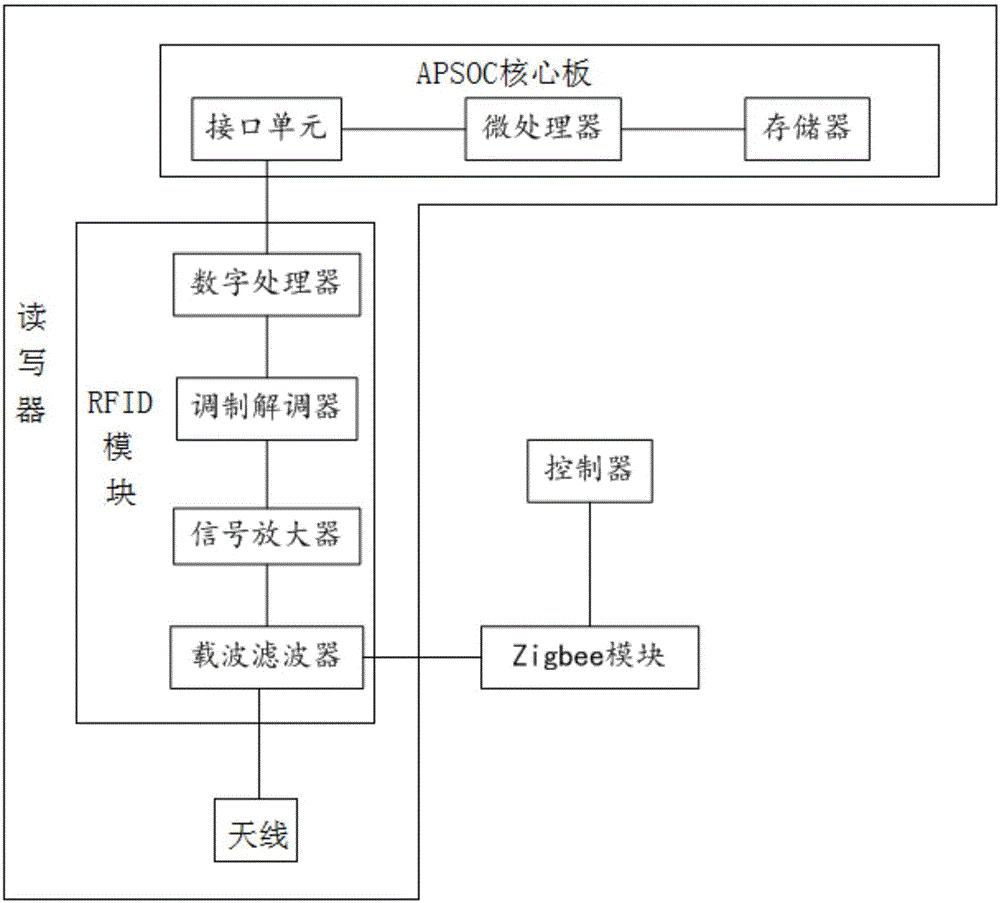

RFID IOT chip

InactiveCN105095954AQuality improvementHigh degree of anti-counterfeitingRecord carriers used with machinesEmbedded systemReader writer

The invention relates to an RFID (Radio Frequency Identification) IOT (Internet of Things) chip. The RFID IOT chip comprises a reader-writer, a controller and a Zigbee module which are sequentially connected, wherein the reader-writer comprises an APSOC core plate, an RFID module and an antenna; the RFID module is connected with the APSOC core plate and the antenna; and the controller is connected with the RFID module. The RFID IOT chip has the advantages that the reader-writer, the controller and the Zigbee module are used, so that the anti-counterfeiting degree can be effectively improved; meanwhile, a memory is also arranged in the RFID IOT chip, so that the requirements of data storage volume and data modification volume relevant to a product can met; and the quality of the chip is improved.

Owner:WUHAN WEDO INFORMATION & TECH

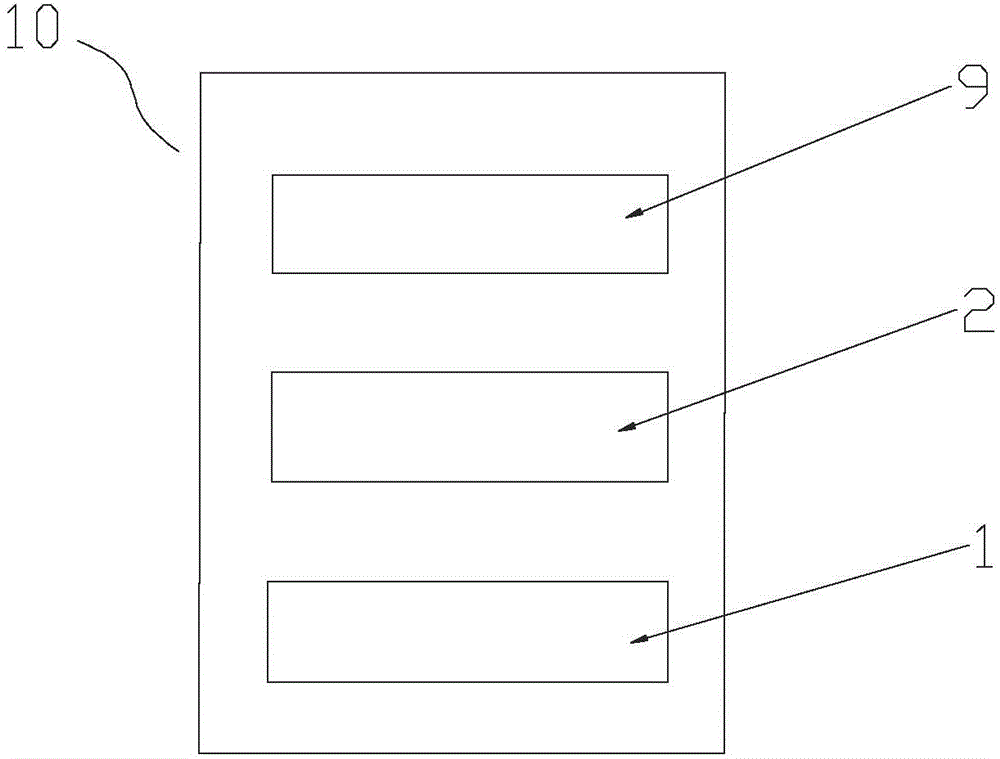

Label

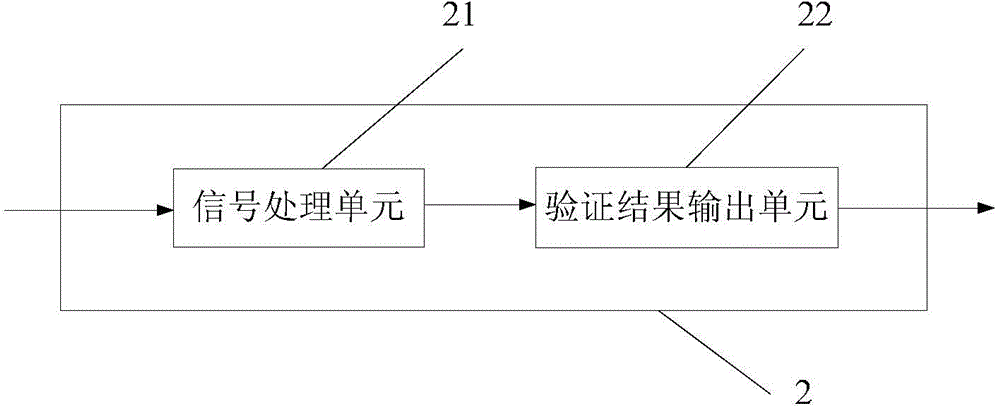

ActiveCN103824103AHigh degree of anti-counterfeitingImprove securityRecord carriers used with machinesLocking devicesSpeaker verificationThe Internet

The invention provides a label. The label comprises a self-examining device which receives external control information, examines the control information and outputs examination information. With the label, the anti-counterfeiting degree of a product packaged by a package assembly can be effectively improved. Furthermore, through the self-examining device, secondary verification can be carried out on primary verification information which is transmitted via the Internet and is primarily verified according to first source information carried by the package assembly itself, so that a verification result of double verification is obtained, and the verification security of the product packaged by the package assembly can be further improved.

Owner:KUANG CHI INTELLIGENT PHOTONIC TECH

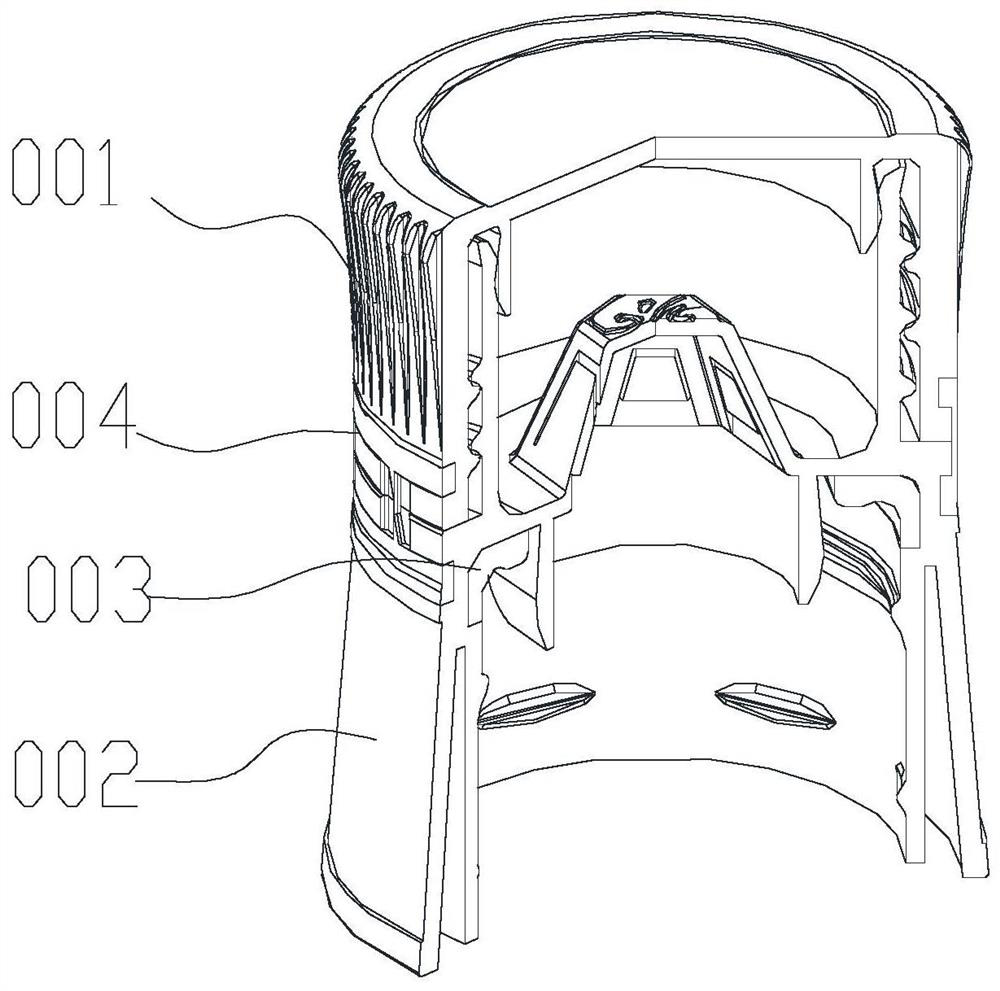

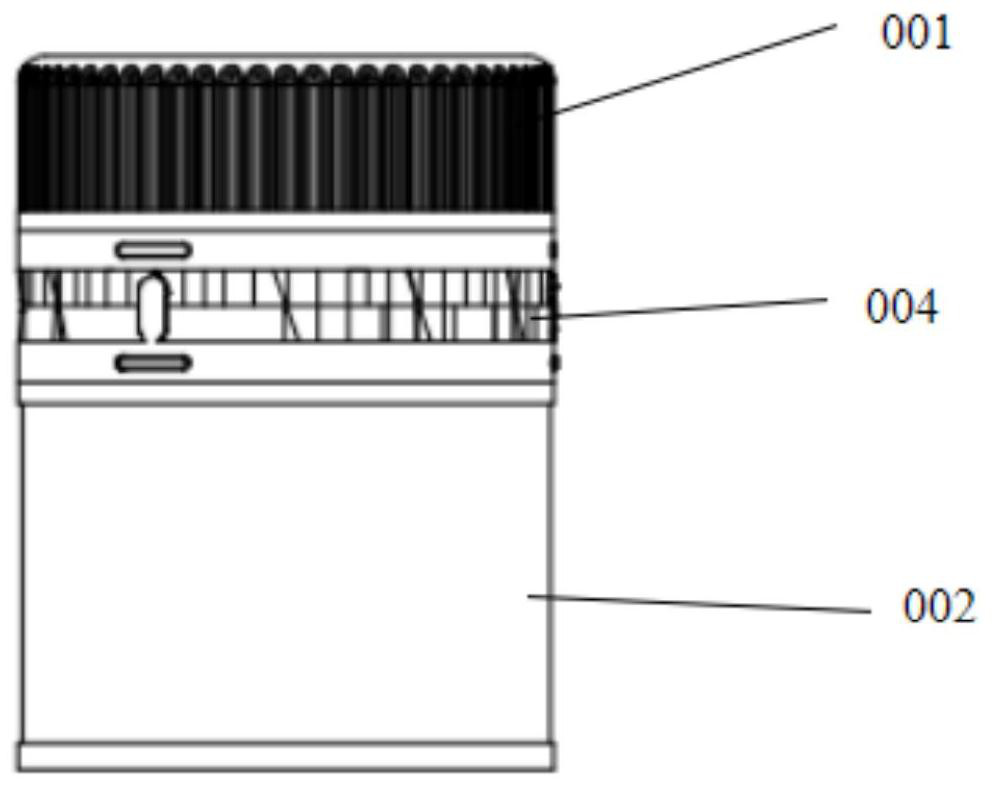

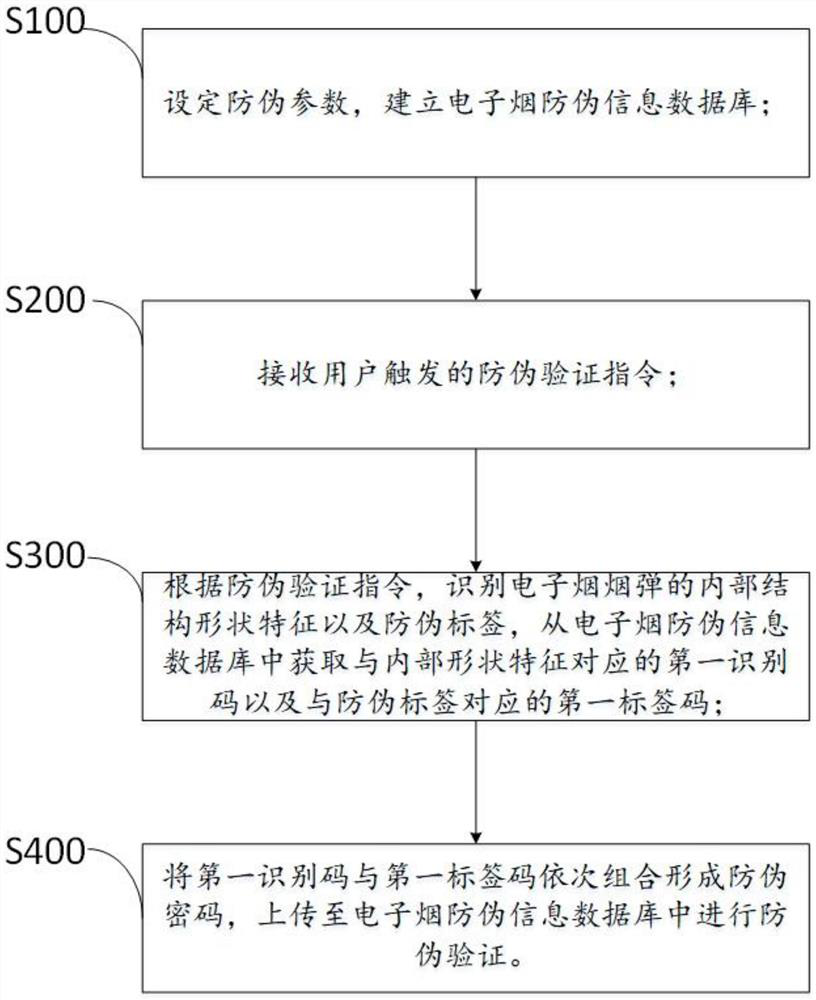

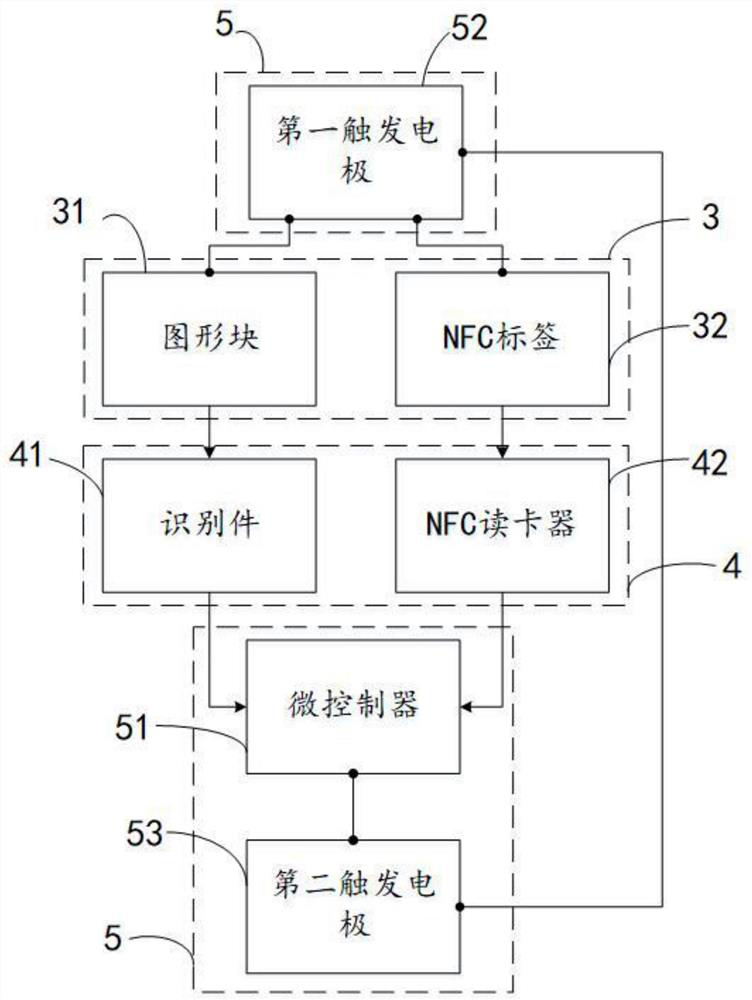

Electronic cigarette anti-counterfeiting method, device and system

The invention relates to an electronic cigarette anti-counterfeiting method, device and system, and the method comprises the following steps: setting anti-counterfeiting parameters, and building an electronic cigarette anti-counterfeiting information database; receiving an anti-counterfeiting verification instruction triggered by a user; according to the anti-counterfeiting verification instruction, identifying an internal structure shape feature and an anti-counterfeiting label of the electronic cigarette cartridge, and obtaining a first identification code corresponding to the internal shape feature and a first label code corresponding to the anti-counterfeiting label from an electronic cigarette anti-counterfeiting information database; combining the first identification code and the first label code sequentially to form an anti-counterfeiting password, and uploading the anti-counterfeiting password to an electronic cigarette anti-counterfeiting information database for anti-counterfeiting verification; according to the scheme, the identification code and the label code need to be obtained at the same time to form the anti-counterfeiting password to perform anti-counterfeiting authentication, the anti-counterfeiting degree is high, cracking is difficult, protection of the electronic cigarette is facilitated, and use of bad substitutes is prevented.

Owner:惠州市大亚湾区新鹏城科技发展有限公司

A method and system for writing a signature with a finger on a touch screen

ActiveCN104462908BImprove accuracyAnti-counterfeitingDigital data authenticationPattern recognitionHandwriting

The invention discloses a method and a system for finger-writing signatures on a touch screen. The method includes: a vein image of a writer of an electronic signature; outputting the vein image; extracting vein feature values from the vein image; comparing the extracted vein feature values to stored vein feature values; if consistence is confirmed, outputting finger writing files, and combing the finger writing files and the extracted vein feature values into a finger-written signature file. The method and the system have the advantages that authentication is more accurate and faking and tampering is prevented.

Owner:CHINA TELECOM CORP LTD

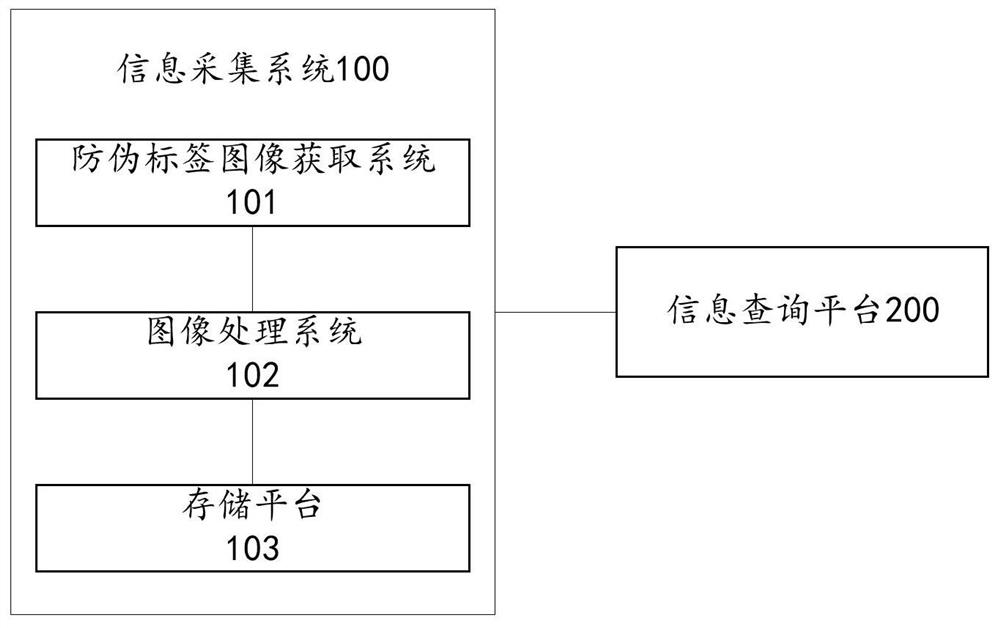

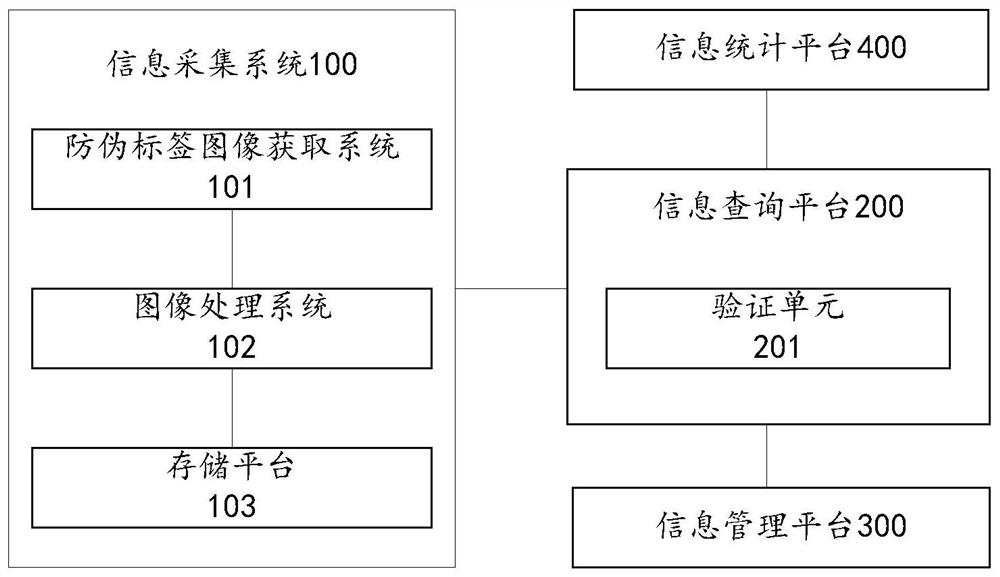

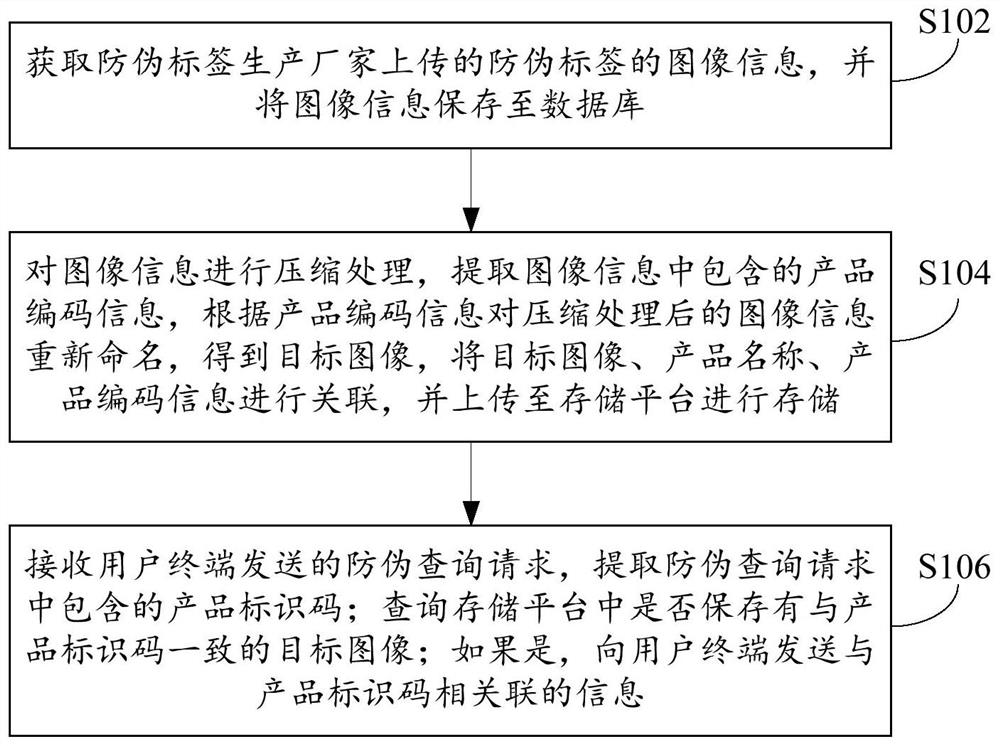

Anti-counterfeiting verification sharing system and verification method

ActiveCN107609883BPrevent imitationIncrease credibilityCommerceImaging processingSoftware engineering

The invention provides an anti-counterfeiting verification sharing system and verification method, which relate to the technical field of product label identification. The system includes an information collection system and an information query platform; the information collection system includes an anti-counterfeiting label image acquisition system, an image processing system and a storage platform; anti-counterfeiting The label image acquisition system is used to obtain the image information of the anti-counterfeit label; the image processing system is used to compress the image information, rename the compressed image information according to the product code information, obtain the target image, and perform information association; information query The platform is used to receive an anti-counterfeiting query request, and query whether the target image is stored in the storage platform; if yes, send the information associated with the product identification code to the user terminal. The anti-counterfeit verification sharing system and verification method provided by the present invention can effectively avoid imitation by other merchants, have high credibility, and further facilitate product promotion while improving the anti-counterfeiting degree.

Owner:戴安乾

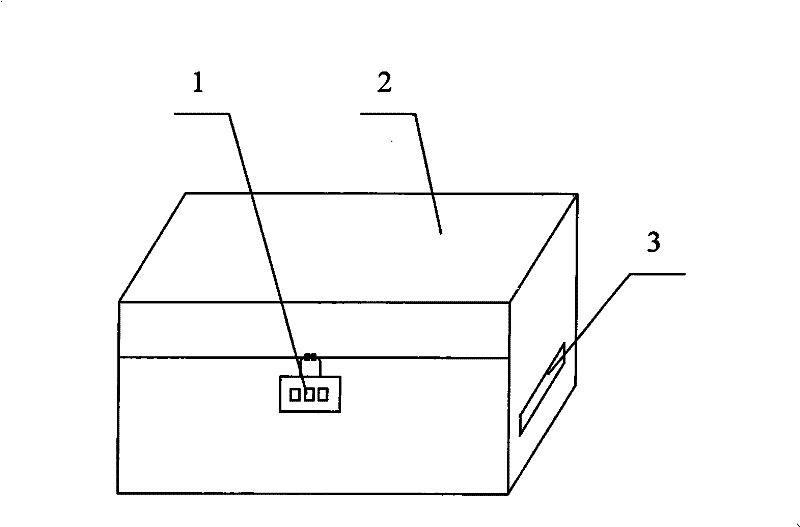

A kind of commodity anti-counterfeiting method

InactiveCN101870391BPrevent counterfeitingHigh degree of anti-counterfeitingLocking devicesService personnelPassword

The invention discloses an anti-counterfeiting method for commodities, aiming at providing an anti-counterfeiting method which combines the password lock technology and the password set inside the manufacturer to prevent counterfeiting. A combination lock with a preset unlock password is installed on the product packaging box, and the unlock password of the combination lock is stored in the manufacturer's password database; There is a commodity code, and the commodity code is stored in the manufacturer's password database at the same time. In the manufacturer's password database, the commodity code corresponds to the unlock password one by one; when the customer dials the manufacturer's service number, the service personnel will enter the password according to the password in the manufacturer's password database. The product code provided by the customer searches for the unlocking code corresponding to the product code, and provides it to the customer, and the customer unlocks the combination lock on the product packaging box according to the unlocking code provided by the manufacturer. The anti-counterfeit method of the present invention has high anti-counterfeit degree and good anti-counterfeit effect.

Owner:黎明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com