Two-dimensional code anti-counterfeit label and printing method thereof

A technology of anti-counterfeiting labels and printing methods, applied in the field of anti-counterfeiting, can solve the problems of lack of uniqueness, inability to achieve the circulation of counterfeit and inferior products, and complicated circulation pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

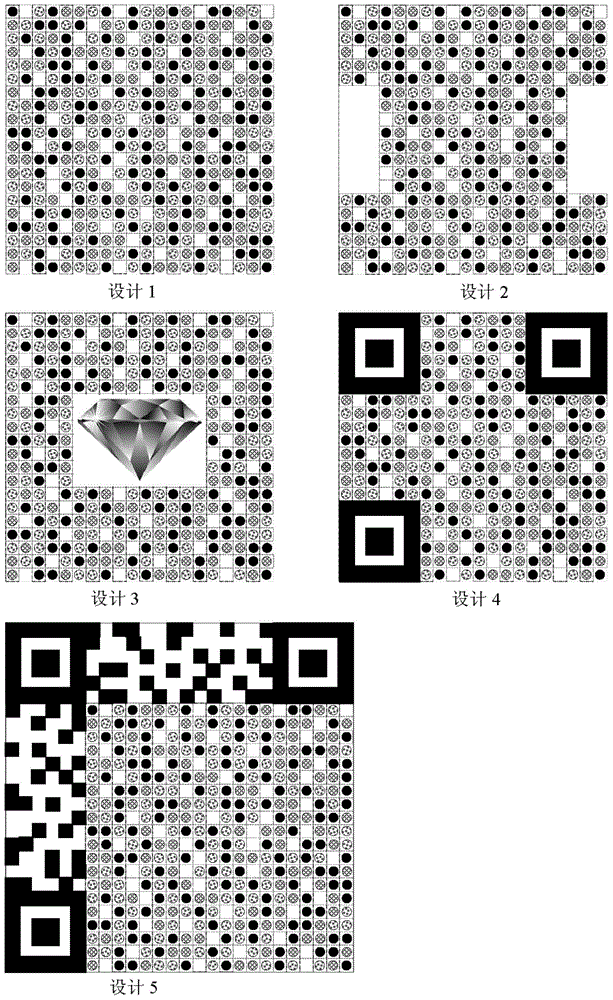

Image

Examples

Embodiment 1

[0075] Embodiment 1: the production of pearlescent microspheres——liquid epoxy resin granulation method

[0076] 1. Disperse and mix 10% 325-mesh golden yellow pearlescent toner with liquid bisphenol F epoxy resin with a molecular weight of about 500 at a speed of 8000rpm to obtain a uniform slurry. The dispersion time is 1 hour, and the particle size is less than 30 microns;

[0077] 2. Water-soluble 10% weight diethylenetriamine is mixed with deionized water to obtain mixed solution and add the sodium dodecylbenzenesulfonate surfactant of mixed solution weight 0.2%, the consumption of deionized water is (epoxy resin+ Pearlescent toner) 3 times, the dispersion speed is medium and low speed, with no large amount of foam as the index;

[0078] 3. Add the material obtained in step 2 into the water in which the curing agent is dissolved and stir to cure the epoxy resin into small particles, and the dispersion speed is about 1200rpm;

[0079] 4. Continue to stir and heat to 60...

Embodiment 2

[0087] Embodiment 2: the production of pearlescent microbeads---microbead method

[0088] 1. Wash the glass beads between 32-35 mesh with an equal volume of 1N sulfuric acid, then treat with an equal volume of 1N sodium hydroxide lye, and finally wash with deionized water, and filter the water through a sieve.

[0089] 2. Add 2N ferric sulfate aqueous solution to the treated microbeads in step 1, the weight of the ferric sulfate aqueous solution is twice the weight of the microbeads, and the stirring speed ensures that the microbeads do not sink to the bottom, so that the reaction is uniform.

[0090] 3. Use a metering pump to add 2N sodium hydroxide lye at a constant speed to make the pH of the microbead solution reach 9. The pump speed is 4 hours to add the required lye, and continue to react for 5 hours, and then wash with deionized water to near neutrality.

[0091] 4. The microbeads obtained in step 3 were filtered and dehydrated through a sieve, dried under ventilati...

Embodiment 3

[0092] Embodiment 3 ink production process

[0093] Dissolve 20% by weight of polymethacrylate in a solvent mixed with 80% by weight of dimethylbenzene and methyl isobutyl ketone at a weight ratio of 1:1, stir at high speed to dissolve, and let stand overnight to debubble to obtain a transparent resin solution ;

[0094] Add the required three colors of pearlescent beads, the size of which is 32-35 mesh, the total amount of pearlescent beads is 30% of the total weight of the resin solution, and the volume ratio of various colored pearlescent beads is 1:1:1. Mix evenly at low speed to get ink. If the viscosity is too high, you can use solvent to lower it. The viscosity range is 1000-2000cP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com