Laser lined paper for cigarettes and preparation method thereof

A manufacturing process and lining paper technology, which is applied to the manufacturing process of cigarette laser lining paper and the field of cigarette laser lining paper, can solve the problem of single product surface color, low reuse rate of laser laser aluminized master film, and limited Product technology development and other issues, to achieve the effect of increasing diversity, improving reuse rate, and improving anti-counterfeiting degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

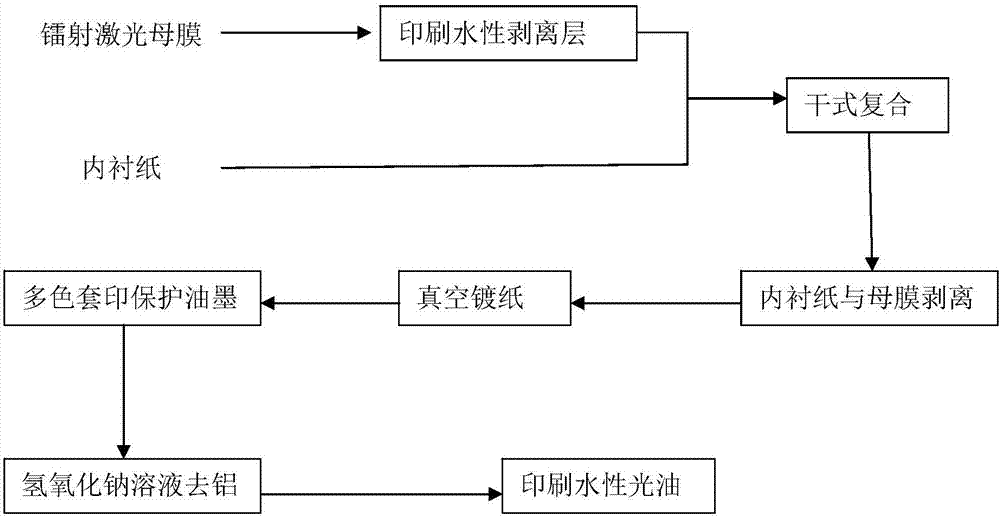

[0019] figure 1 The manufacturing process of the laser lining paper for cigarettes according to the present invention is shown, which includes the following steps:

[0020] 1) Print a water-based peeling layer material on the surface of the unplated laser laser mother film or beam laser mother film by gravure printing, so as to fill up the laser grating on the laser laser mother film; wherein, the unplated The aluminum plain laser laser mother film or light column laser laser mother film is a BOPP film with a thickness of 22 μm-35 μm; the water-based peeling layer material is:

[0021] 2) Carry out dry compounding of the colored inner lining paper base paper and the laser master film coated with the water-based release layer material in step 1);

[0022] 3) stripping / unwinding the inner liner paper and the mother film after compounding in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com