Anti-counterfeiting viscose fiber, preparation method and anti-counterfeiting method

A viscose fiber and viscose technology, applied in the field of anti-counterfeiting fibers, can solve the problems of easy destruction of anti-counterfeiting features, poor anti-counterfeiting concealment, single anti-counterfeiting features, etc., achieve effective encryption and traceability, and have a good market application prospect , Easy to detect and identify the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

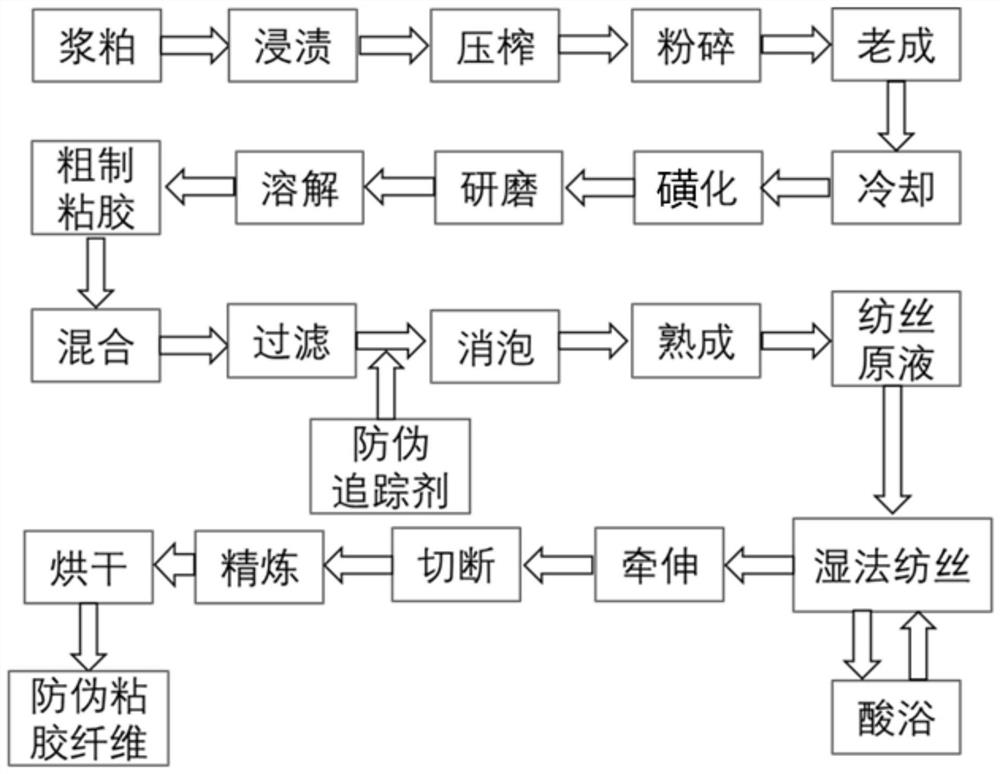

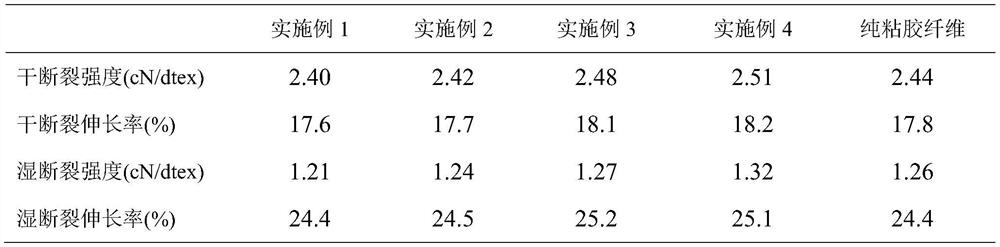

[0046] The present embodiment provides a kind of anti-counterfeit viscose fiber and preparation method thereof, and its technological process is as follows figure 1 As shown, its raw materials include wood pulp (the degree of polymerization is 200) and anti-counterfeit tracking agent.

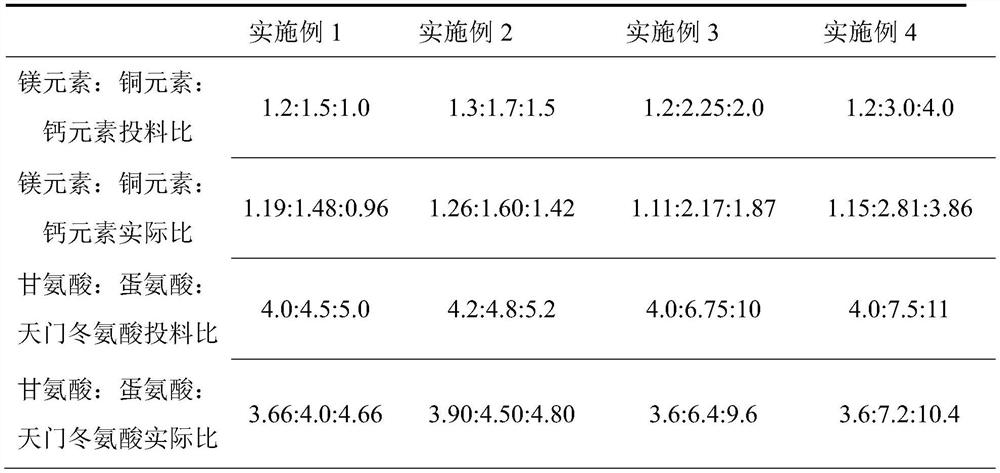

[0047] The anti-counterfeit tracking agent is composed of the following raw materials in parts by weight: 10 parts of glycine chelated magnesium (1.2 parts of magnesium element content, 4 parts of glycine content), 10 parts of methionine chelated copper (1.5 parts of copper element content, 4.5 parts of methionine content), Tianmen 10 parts of particic acid chelated calcium (1 part of calcium element content, 5 parts of aspartic acid content), 70 parts of deionized water; wherein magnesium element: copper element: calcium element mass ratio = 1.2:1.5:1; wherein glycine :Methionine:Aspartic acid mass ratio=4:4.5:5. The preparation method of anti-counterfeit tracer is:

[0048] (1) Glycine chel...

Embodiment 2

[0058] This example provides an anti-counterfeit viscose fiber and a preparation method thereof, the raw materials include wood pulp (polymerization degree: 210) and an anti-counterfeit tracer.

[0059] The anti-counterfeit tracking agent is composed of the following raw materials in parts by weight: 10 parts of glycine chelated magnesium (1.3 parts of magnesium element content, 4.2 parts of glycine content), 10 parts of methionine chelated copper (1.7 parts of copper element content, 4.8 parts of methionine content), Tianmen 10 parts of particic acid chelated calcium (1.5 parts of calcium element content, 5.2 parts of aspartic acid content), 70 parts of deionized water; wherein magnesium element: copper element: calcium element mass ratio=1.3:1.7:1.5; wherein glycine : Methionine: Aspartic acid mass ratio=4.2:4.8:5.2. The preparation method of the anti-counterfeit tracer is the same as in Example 1.

[0060] The concrete preparation steps of anti-counterfeit viscose fiber ar...

Embodiment 3

[0068] This example provides an anti-counterfeit viscose fiber and a preparation method thereof. The raw materials include wood pulp (with a degree of polymerization of 221) and an anti-counterfeit tracer.

[0069] The anti-counterfeit tracking agent is composed of the following raw materials in parts by weight: 10 parts of glycine chelated magnesium (1.2 parts of magnesium element content, 4 parts of glycine content), 15 parts of methionine chelated copper (2.25 parts of copper element content, 6.75 parts of methionine content), Tianmen 20 parts of particic acid chelated calcium (2 parts of calcium element content, 10 parts of aspartic acid content), 80 parts of deionized water; wherein magnesium element: copper element: calcium element mass ratio = 1.2:2.25:2; wherein glycine : Methionine: Aspartic acid mass ratio=4:6.75:10. The preparation method of the anti-counterfeit tracer is the same as in Example 1.

[0070] The concrete preparation steps of anti-counterfeit viscose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com