Anti-counterfeiting bamboo pulp fiber, preparation method and anti-counterfeiting method

A technology of bamboo pulp fiber and bamboo pulp, which is applied in the field of anti-counterfeiting bamboo pulp fiber and preparation, can solve the problems such as the use of amino acid metal chelate anti-counterfeiting materials that have not been disclosed in the technology, achieve effective encryption and traceability, and increase complexity. Safety and processing cost, good effect of anti-counterfeiting and concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

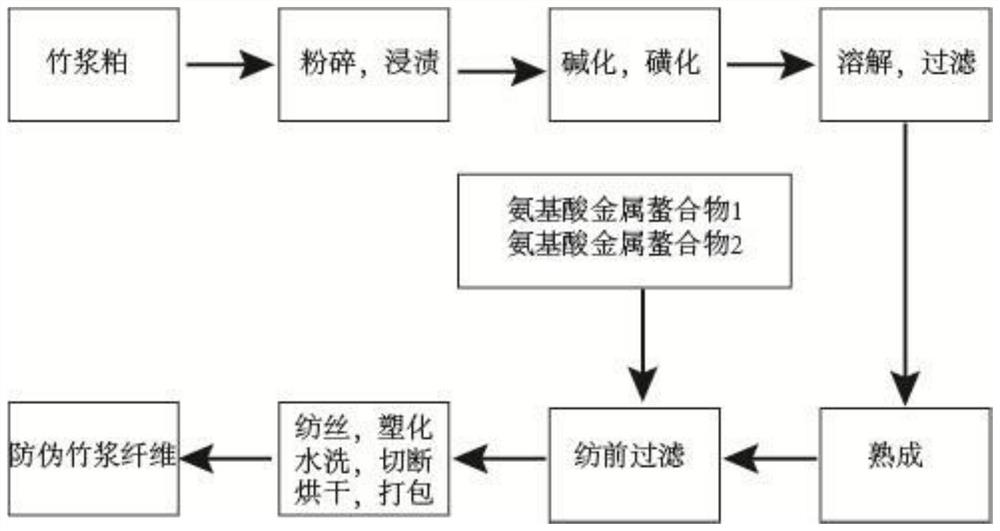

Method used

Image

Examples

Embodiment 1

[0051] The present embodiment provides a kind of preparation method of anti-counterfeit bamboo pulp fiber, and concrete steps are as follows:

[0052] (1) Grind the raw bamboo pulp through a pulverizer, add NaOH solution for two impregnations, the impregnation bath ratio is 1:20, wherein, the first impregnation uses NaOH aqueous solution, its concentration is 230g / L, and the alkali temperature is 45°C, and the second impregnation The impregnation uses NaOH aqueous solution, its concentration is 195 / L, and the alkali temperature is 55°C. When soaking in the alkali solution, Berol Visco388 produced by Akzo Nobel Company is also added in the alkali solution, and the addition amount is 0.1% of the weight of methylcellulose in the bamboo pulp. Then prepare cellulose xanthate through alkalization and sulfonation, then add ionic liquid 1-ethyl-3-methylimidazolium acetate ([EMIM]Ac), go through two dissolving and two filtering processes, and then ripen Preparation of spun viscose. S...

Embodiment 2

[0057] This example provides a kind of preparation method of anti-counterfeit bamboo pulp fiber, and concrete steps are as follows:

[0058] (1) Same as step (1) of Example 1.

[0059] (2) After filtering before spinning, add anti-counterfeiting tracer metal amino acid chelate manganese egg amino acid and copper glycyl amino acid and stearyl alcohol polyoxyethylene ether dispersant, the mass fraction of the dispersant is 5% of bamboo pulp, egg amino acid The mass ratio of manganese and glycine amino acid copper is 1:3, and the total mass of the two metal amino acid chelates is 1‰ of the mass fraction of bamboo pulp. Ultrasonic vibration, stirring evenly to obtain spinning solution.

[0060] (3) is the same as step (3) of embodiment 1.

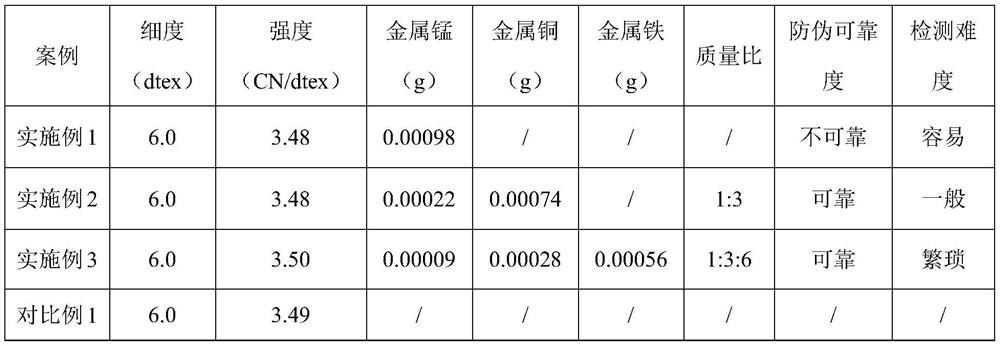

[0061] The bamboo pulp fiber fineness that makes is 6.0dtex, intensity: 3.48CN / dtex; Detect metal manganese content and be 0.00022g, metal copper content is 0.00074g, metal manganese and metal copper mass ratio are about 1:3, detect Methioni...

Embodiment 3

[0063] This example provides a kind of preparation method of anti-counterfeit bamboo pulp fiber, and concrete steps are as follows;

[0064] (1) Same as step (1) of Example 1.

[0065] (2) After filtering before spinning, add anti-counterfeiting tracer metal amino acid chelate egg amino acid manganese, glycyl amino acid copper, aspartic amino acid iron and stearyl alcohol polyoxyethylene ether dispersant, the mass fraction of the dispersant is 1% of bamboo pulp 5%, the mass ratio of manganese methanoate, copper glycine and iron aspartate is 1:3:6, and the total mass of the three metal amino acid chelates is 1‰ of the mass fraction of bamboo pulp. Ultrasonic vibration, stirring evenly to obtain spinning solution.

[0066] (3) is the same as step (3) of embodiment 1.

[0067] The bamboo pulp fiber fineness that makes is 6.0dtex, intensity: 3.50CN / dtex; Detect metal manganese content and be 0.00009g, metal copper content be 0.00028g, metal iron content be 0.00056g, metal calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com