Using method for circuit board punching mechanism capable of conducting marking

A circuit board, punching pin technology, applied in printing, stamping, metal processing and other directions, can solve the problems of circuit board production process and marking process can not be carried out at the same time, waste of manpower and economic costs, to reduce counterfeit production. risk, improve the reliability of operation, and improve the effect of anti-counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

[0013] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

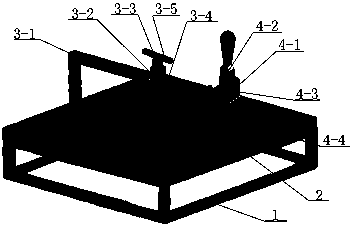

[0014] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. as attached figure 1 As shown, the circuit board punching mechanism capable of marking includes a base 1, the base 1 is provided with a base plate 2, and the base plate 2 is fixedly provided with a punching device 3 and a marking device 4. The hole device 3 and the marking device 4 are distributed at 90 degrees. The punch device 3 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com