A kind of manufacturing method of anti-counterfeiting sealed bottle cap

A production method and bottle cap technology, which are applied to household appliances, other household appliances, household components, etc., can solve the problems of lack of sealing performance, low counterfeiting cost, low alcohol content, etc., and achieve increased anti-counterfeiting performance and advanced processing technology. , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

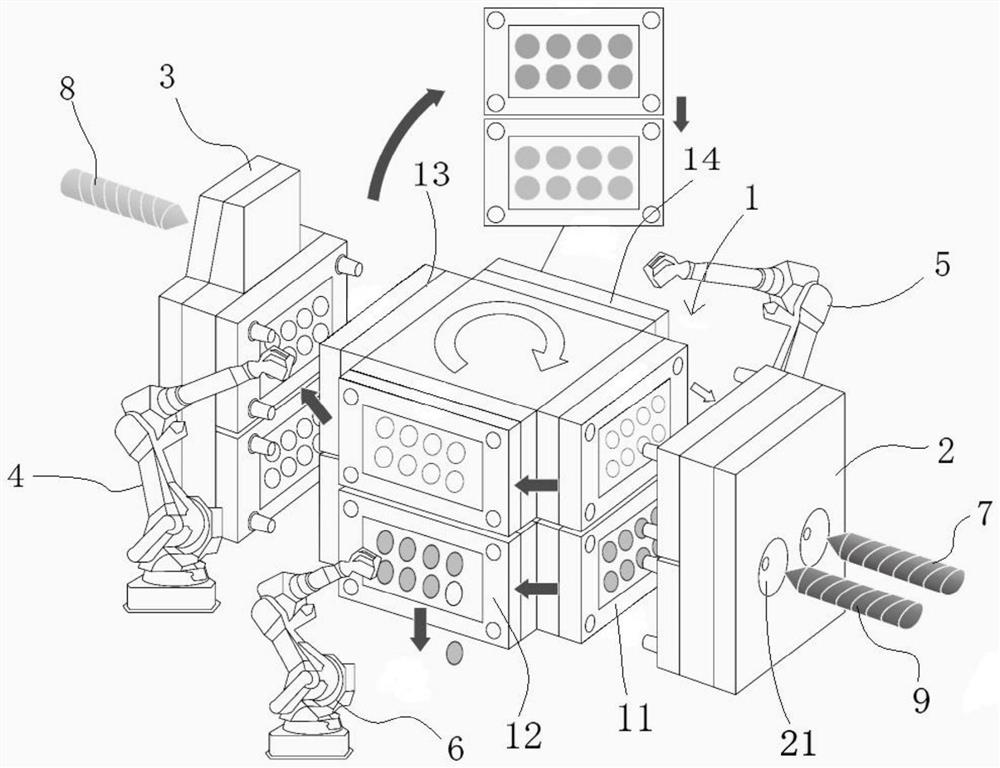

[0030] Below in conjunction with accompanying drawing, the specific mode of the present invention is explained, and the implementation direction of the present invention is with figure 1 The direction of is standard.

[0031] Such as figure 1 As shown, the manufacturing method of the anti-counterfeiting sealed bottle cap of the present invention adopts special injection molding equipment to operate, and the injection molding equipment includes an injection molding machine body 1, a first movable mold 2, a second movable mold 3, and a first mechanical arm 4 , the second mechanical arm 5, the third mechanical arm 6, the first screw 7, the second screw 8, the third screw 9, PLC controller, wherein the injection molding machine body 1 is in the shape of a cuboid, the injection molding machine body 1 is vertically arranged, and the injection molding machine The main body 1 is provided with a rotating shaft, a driving motor and a positioning device, so that the main body 1 of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com