Discharge ablation machining method for difficult-to-machine metal materials based on quantitative high-pressure composite low-pressure intake system

A metal material and air intake system technology, which is applied in the field of discharge induced ablation processing and discharge ablation processing of difficult-to-machine metal materials, can solve the problems of large electrode loss, flammability, low efficiency, etc., and achieves improved processing efficiency and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by taking turning as an example.

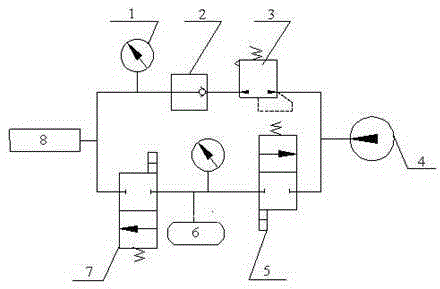

[0033] The present invention is used in the quantitative high-pressure composite low-pressure air intake system in the discharge ablation machining in the specific implementation mode of the turning (taking oxygen as an example) The schematic diagram of the air intake system is as follows figure 2 shown.

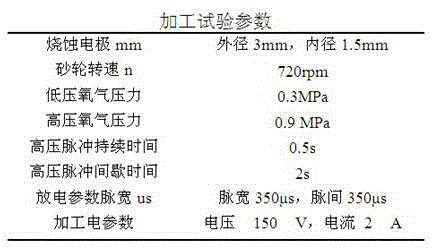

[0034] Among them, taking titanium alloy TC4 as an example, the method of controlling a single variable is used to compare the processing speed and surface quality of the material when the oxygen pressure is 0.3Mpa and 0.9Mpa. The specific test parameters are as follows: figure 1 shown.

[0035] The present invention is based on the discharge ablation processing method of difficult-to-machine metal materials based on quantitative high-pressure composite low-pressure air intake system, which includes the following steps:

[0036] The first step: make the hollow inductive ablatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com