Guide hole machining method

A processing method and technology of guide holes, applied in the field of inner hole processing, can solve the problems of high cost, difficulty in meeting the delivery date and cost requirements of users' batch products, low production efficiency, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment takes the production of the tapered hole of the bushing as an example, and gives a detailed explanation of the method for producing the tapered hole of the bushing provided by the present invention.

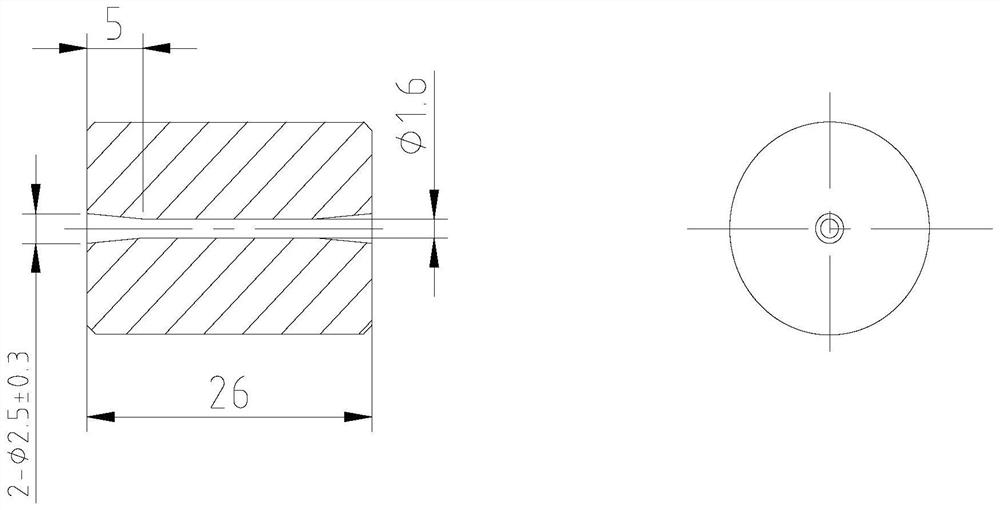

[0050] In this embodiment, the shaft sleeve with tapered hole to be processed is as follows: figure 1 As shown, the inner straight hole of the shaft sleeve is required to have an inner diameter of Φ1.6+(0~0.025)mm, and the size of the guide hole of the shaft sleeve is required to be a diameter of Φ2.5±0.3mmx5±1mm.

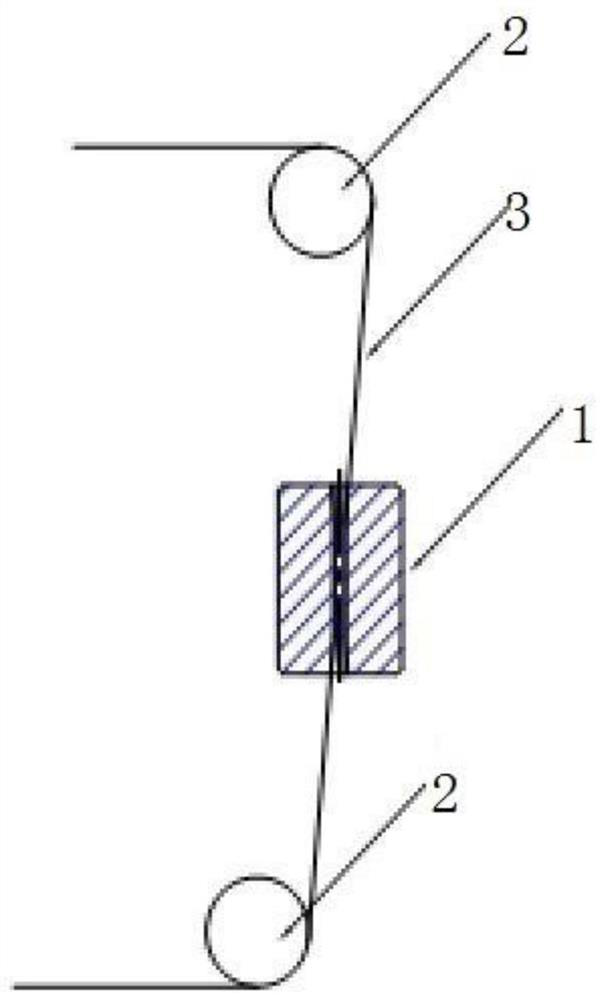

[0051] The processing method adopted in this embodiment is wire electric discharge cutting to ensure the shape of the taper hole. The method for processing the above-mentioned bushing taper hole provided in this embodiment includes the following steps:

[0052] (1) After the commissioning is completed, the wire cutting inner hole taper tooling is completed, the program origin is set, the program is positioned at the program origin, the wire drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com