A simple forging die for fan rotor blades and innovative processing method for rotor blades

A processing method and moving blade technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of wasting raw materials, consuming alloy cutter heads, occupying machine hours, etc. less material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

[0019] An innovative processing method for fan blades, the specific steps are as follows:

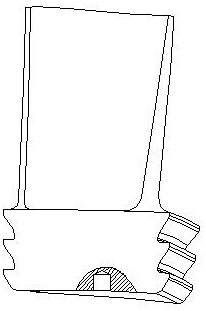

[0020] S1: Processing of pre-forgings: High-chromium alloy steel is used to process the pre-forgings of the integral fan moving blades, including the pre-forgings of the blade body and the pre-forging of the blade root.

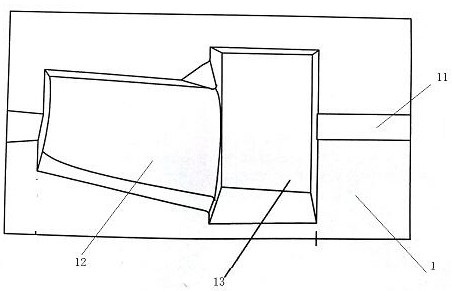

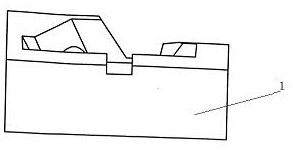

[0021] S2: Forming of the blade blank: put the pre-forging into a special forging die to forge the blade blank; the blade body part of the blade blank forms an arc profile, and the blade root part of the blade blank forms a prismatic structure;

[0022] S3: Drilling of the blade blank: Drill a center hole at the blade body end of the blank and the blade root end of the blank, and measure and check the position of the center of the drilling through the three-thimble p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com