Production line for hydraulically assembling valve guide rod of cylinder cover

A technology for production lines and valve guide rods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to guarantee assembly quality, time-consuming and laborious, low work efficiency, etc., and achieve stable assembly quality, low labor intensity, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

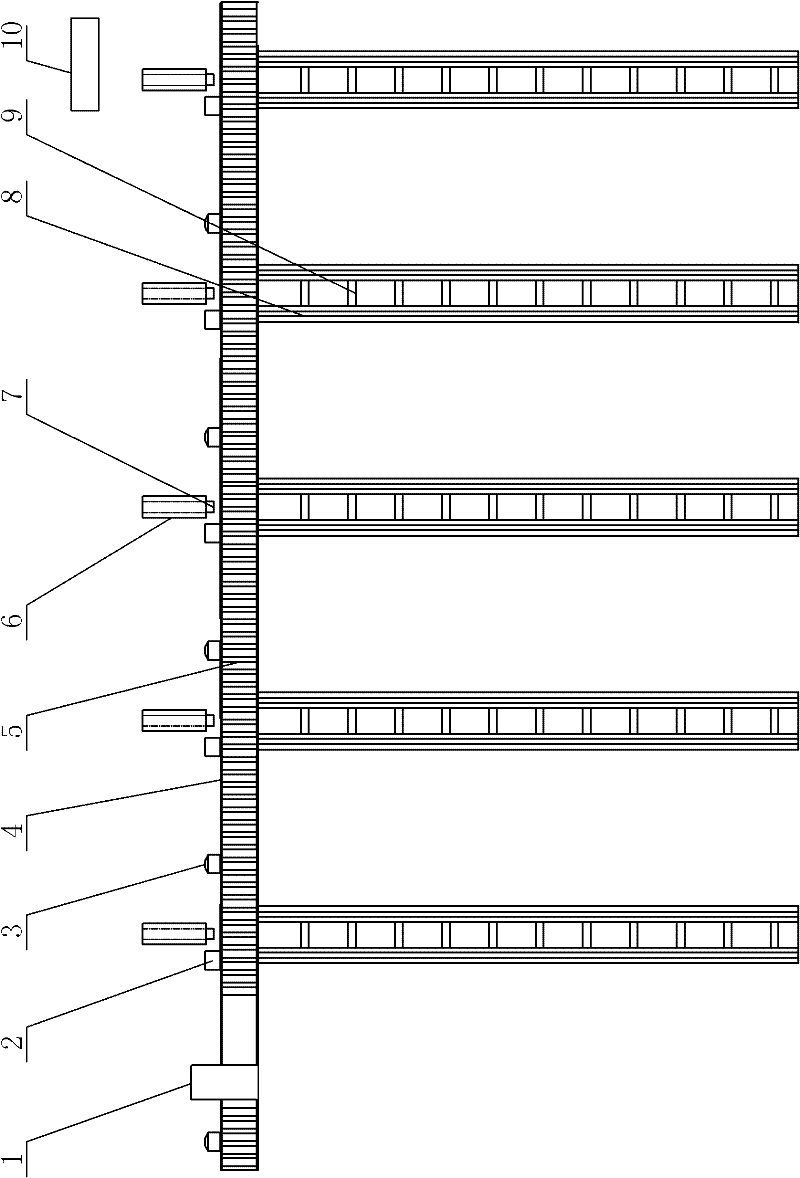

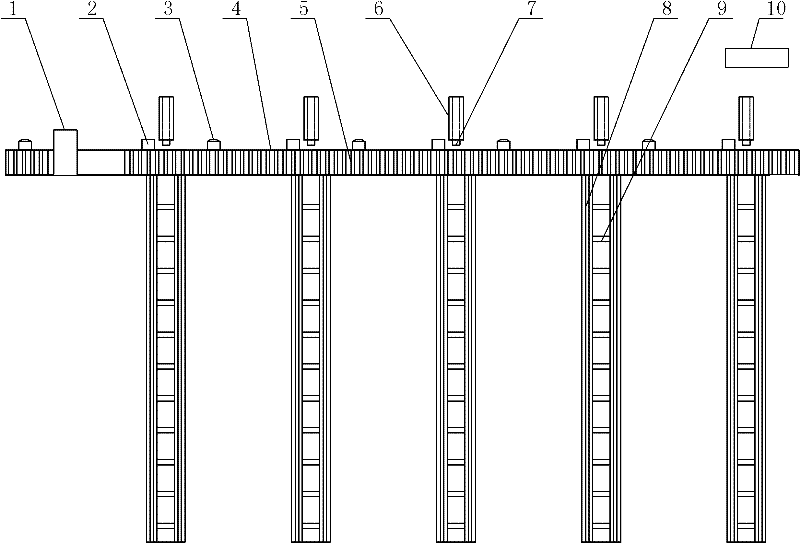

[0017] As shown in the accompanying drawings: the present invention includes 1 horizontally arranged chain conveying line and 5 vertically arranged assembly lines, the chain conveying line includes a conveying line frame body 4, a motor 3 and a rotating roller 5, and the chain conveying The front end of the line is provided with a hydraulic press 1, and the model of the hydraulic press is TY41-16. There are five motors 3, one of which is installed at the bottom of the wire frame body 4 before the hydraulic press 1, and the remaining four are respectively installed at the bottom of the wire frame body 4 between two assembly lines, the assembly line including the wire frame Body 8 and idler 9, five corresponding push devices are provided on the outside of the joint between the chain conveyor line and the assembly line. There are also five proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com