Closed large-tonnage four-point servo toggle rod stamping device

A stamping device and large-tonnage technology, applied in the field of stamping and forming, can solve the problems of large stamping pressure reduction, fast stamping pressure reduction, small stamping stroke, etc., to achieve small pressure attenuation, prevent interference, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

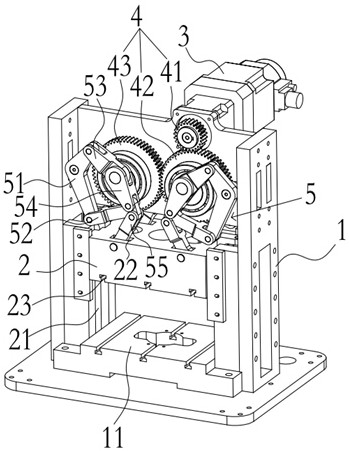

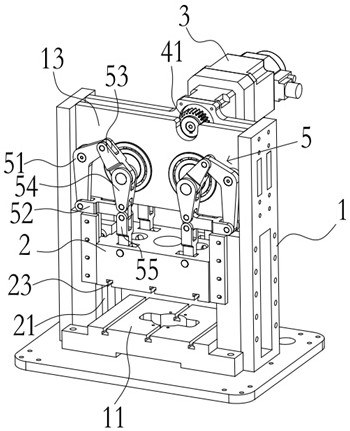

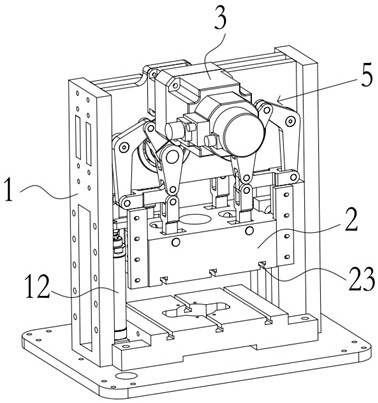

[0027] Such as Figures 1 to 4 As shown, the closed large-tonnage four-point servo toggle punching device includes a frame 1, a punching station 11 is arranged on the frame 1, and a punching table 2 driven up and down by a punching transmission structure is arranged above the punching station 11. The stamping transmission structure includes: a servo motor 3 fixedly installed on the frame 1, a transmission gear set 4 that is in transmission with the servo motor 3, four sets of toggle structures 5 that are in transmission with the transmission gear set 4, four sets of toggle structures 5 and Stamping table 2 transmission connection;

[0028] The toggle structure 5 includes a first transmission rod 51 riveted with the frame 1, the two ends of the first transmission rod 51 are respectively riveted with a second transmission rod 52 and a third transmission rod 53, and the third transmission rod 53 is far away from the first transmission rod 51 One end is riveted with a fourth tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com