Financial binding machine

A binding machine and financial technology, applied in binding, metal processing, etc., can solve the problem of a large handle, and achieve the effect of uniform punching force, convenient operation, and reduced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

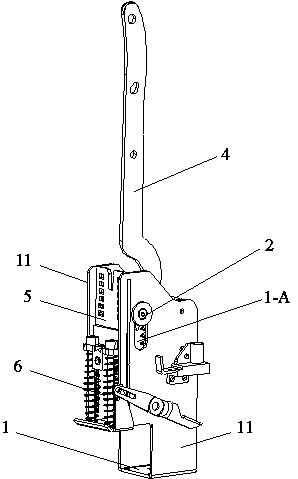

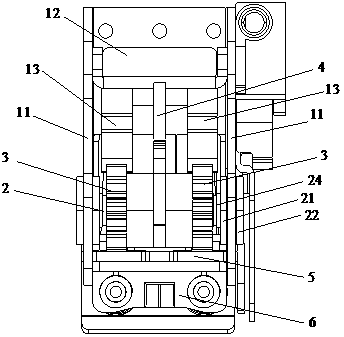

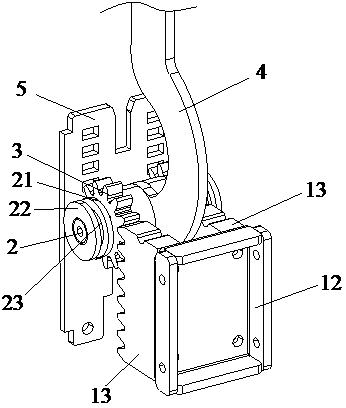

[0026] refer to Figure 1-Figure 3 , financial bookbinding machine, it comprises frame 1, and two side parts 11 of described frame 1 are respectively provided with a linear installation groove 1-A, and both are left and right symmetrical about described frame 1, and described installation groove 1-A is arranged vertically, and its upper and lower ends are in the shape of semi-circular arcs. The frame 1 is provided with a horizontal rotating shaft 2, and the two ends of the rotating shaft 2 respectively pass through the two installation slots 1-A.

[0027] The two ends of the rotating shaft 2 are sleeved and fixed with guides respectively, and the guides include a first part 21, a second part 22, and a third part 23. The third part 23 is an annular structure, and its position is set The part of the rotating shaft 2 located in the installation groove 1-A, and the second part 22 is slidingly fitted with the two vertical side walls of the installation groove 1-A, the first part 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com