Splicing device

A technology of splicing device and mounting seat, which is used in metal processing, metal processing equipment, forming tools, etc., can solve the problems of wrong splicing position, weak splicing, and defective products, so as to avoid module falling off, ensure assembly quality, and improve production. The effect of manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

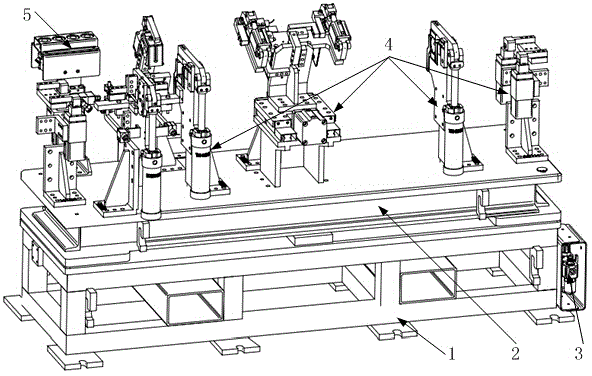

[0011] figure 1 The splicing device provided by the present invention is shown, and the splicing device includes a base 1, a mounting base 2, a cylinder control box 3, a second console, several brackets 4 and a first console 5, and the mounting base 2 is located on the On the base 1, several supports 4 are respectively arranged on the mounting base 2, the cylinder control box 3 is arranged on the side of the base 1, and the first console 5 is arranged on the side of the base, The output ends of the second console and the first console 5 are respectively connected to the input ends of the cylinder control box 3 . It can provide sufficient and stable stamping force during the assembly process of different modules, which can fully guarantee the assembly quality of the mold, effectively avoid the module falling off caused by weak splicing, realize the rapid assembly of the mold, and improve the manufacturing efficiency .

[0012] The base 1 is connected to the mounting base 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com