12 kV solid insulation single-phase and single-cavity sealed type shell

A solid insulation and shell technology, which is used in the installation of substation/distribution device shells, switchgear with resin shells, etc. Poor ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention and specific implementation thereof are described in further detail below in conjunction with accompanying drawing:

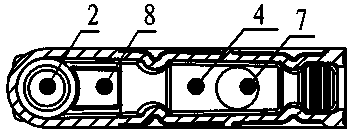

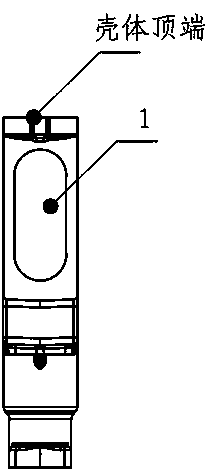

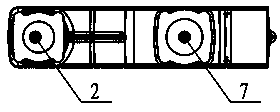

[0025] see Figure 1 to Figure 5 , the present invention comprises a shell made of solid epoxy resin, a cavity 5 is provided in the shell, an opening communicating with the cavity 5 is provided on the top of the shell 5, and an oval opening 1 is provided on the front outer wall of the shell 5 , the rear lower part of the housing 5 is provided with a cylindrical cavity 2, which is characterized in that: between the cylindrical cavity 2 and the housing is a silica gel layer 3, the bottom of the cavity 5 is inlaid with a conductor 8, and the conductor 8 and the cylinder The body cavities 2 are isolated by the silica gel layer 3 , and the bottom of the cavity 5 is provided with a hole 7 , and the conductor 8 is between the cylinder cavity 2 and the hole 7 .

[0026] The center of the plane of the elliptical opening 1 is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com