A device and method for controlling heat treatment deformation of non-machined surface of welding part installation side

A heat treatment deformation and control method technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as unqualified, collapsed, etc., and achieve the effects of stable product quality, good consistency, and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

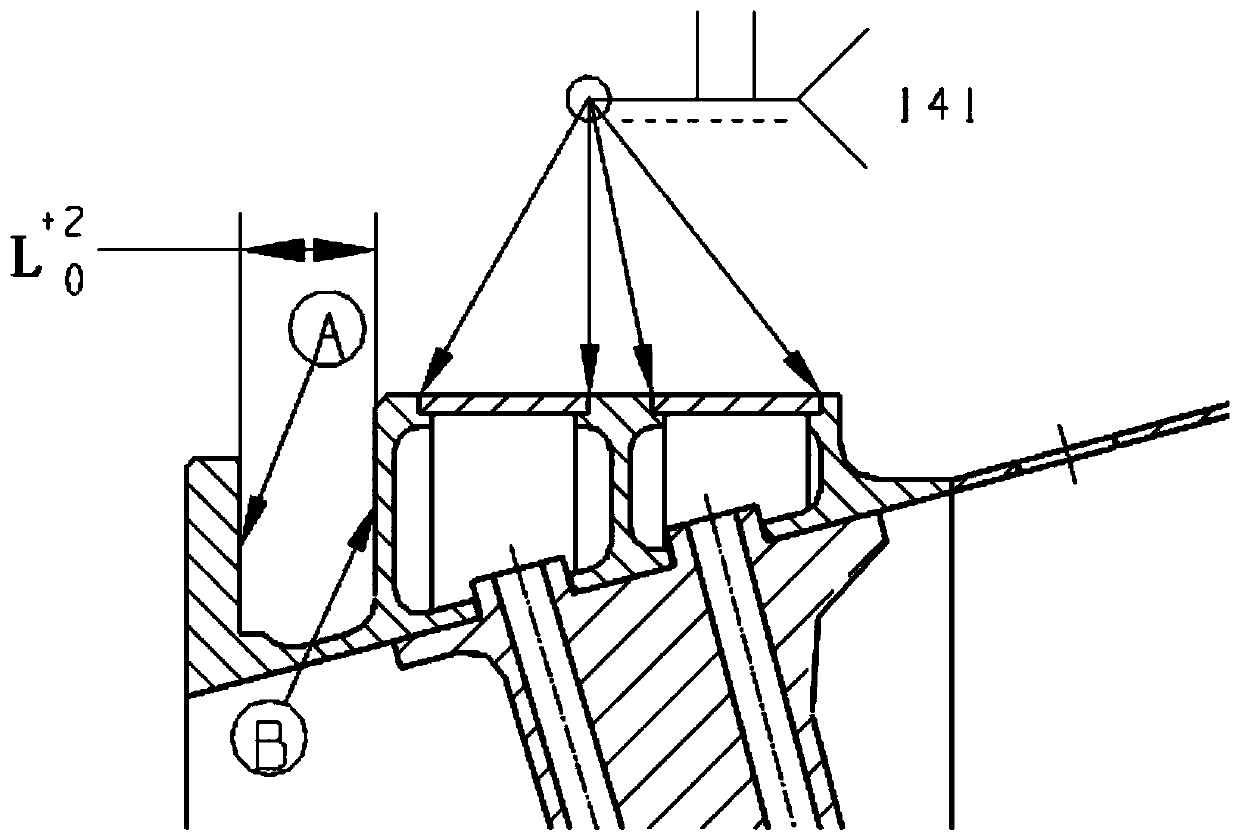

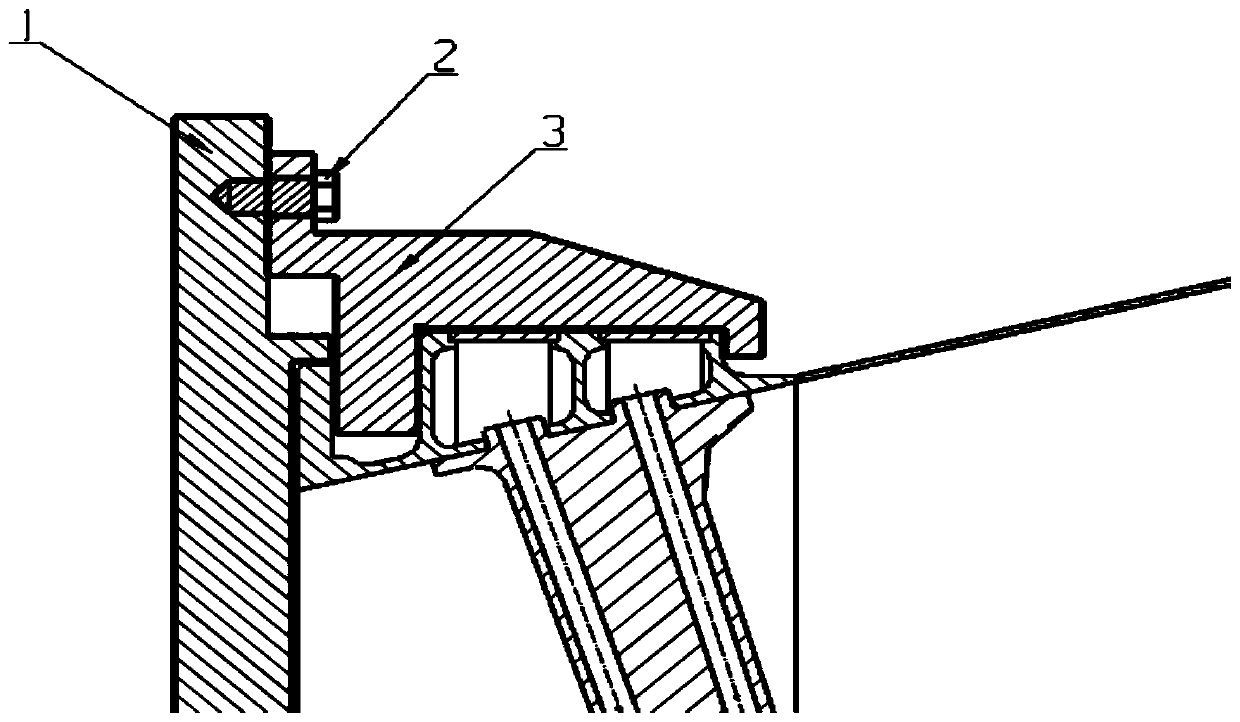

[0022] Such as figure 2 As shown, since the non-processed surface collapses toward the large end as a whole during the heat treatment process, the inner ring surface of the positioning ring 3 matching the non-processed surface and the upper and lower protrusions are used to clamp and fix the deformed part to limit the heat treatment process. At the same time, the lower protrusion inserted into the groove of the outer surface of the weldment and the end surface of the bottom plate 1 together play a role in supporting the installation edge and preventing the installation edge from warping. Through the above method, the flatness of the non-processed surface can be effectively controlled during the heat treatment, so that the groove width can be guaranteed in the subsequent machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com