Permanent magnet assembly fixture for large permanent magnet direct-driven wind generator and assembly method of permanent magnet assembly fixture

A wind turbine, permanent magnet direct drive technology, used in metal processing, manufacturing tools, workpiece clamping devices, etc., can solve the problems of surface damage of permanent magnet pole pieces, risk of fan operation, difficult to assemble in place, etc., and achieve convenient movement. , high safety, simple use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

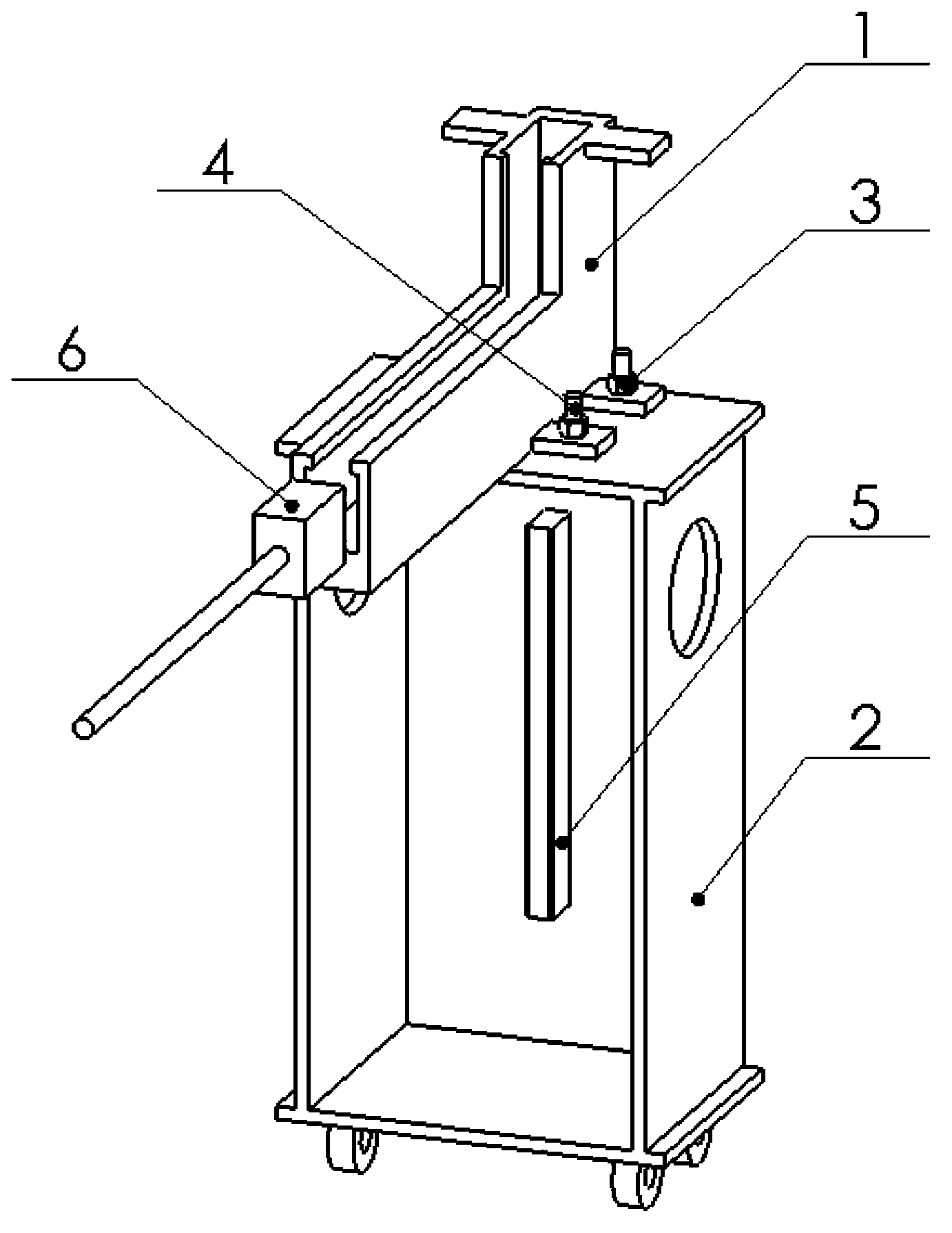

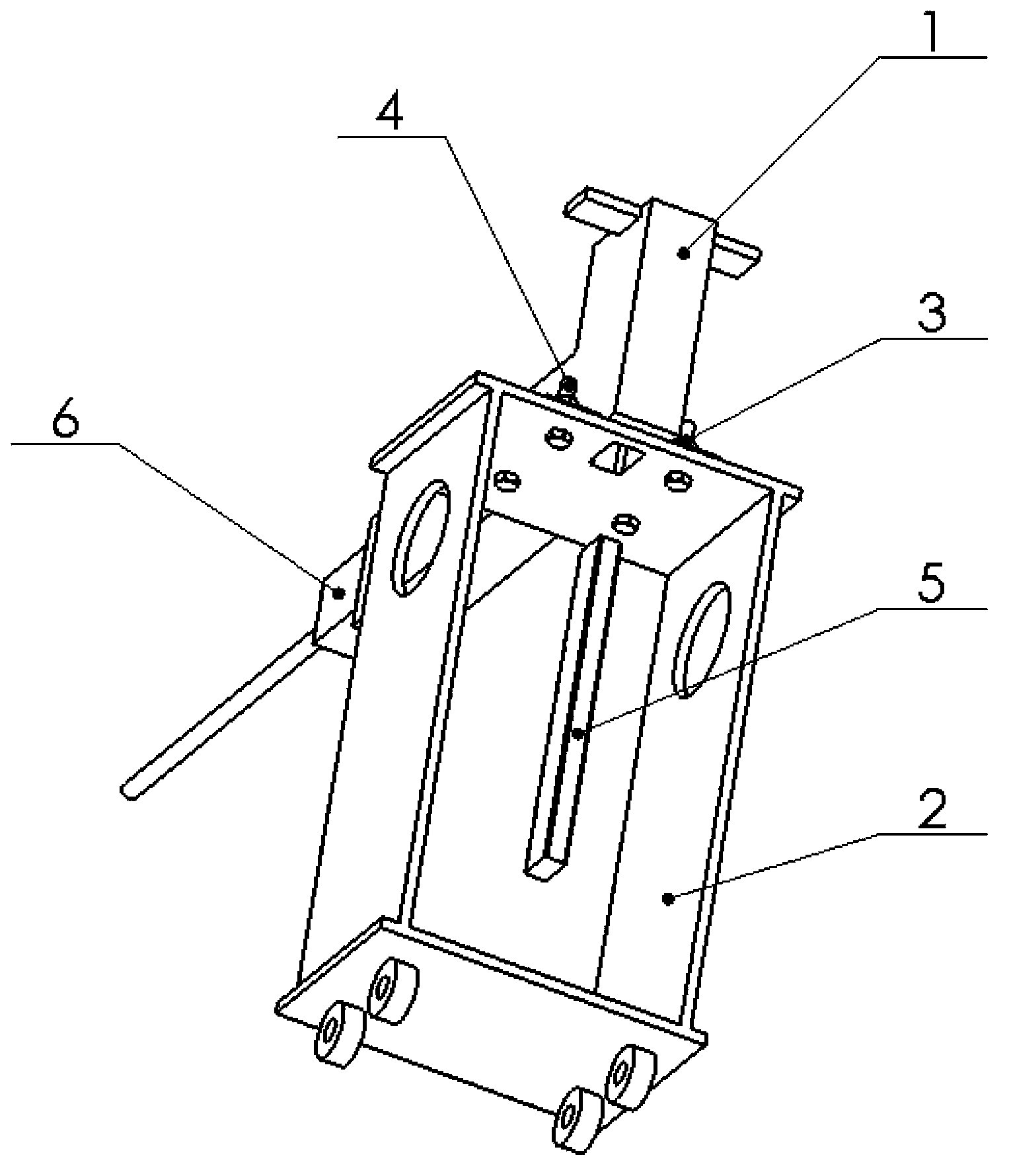

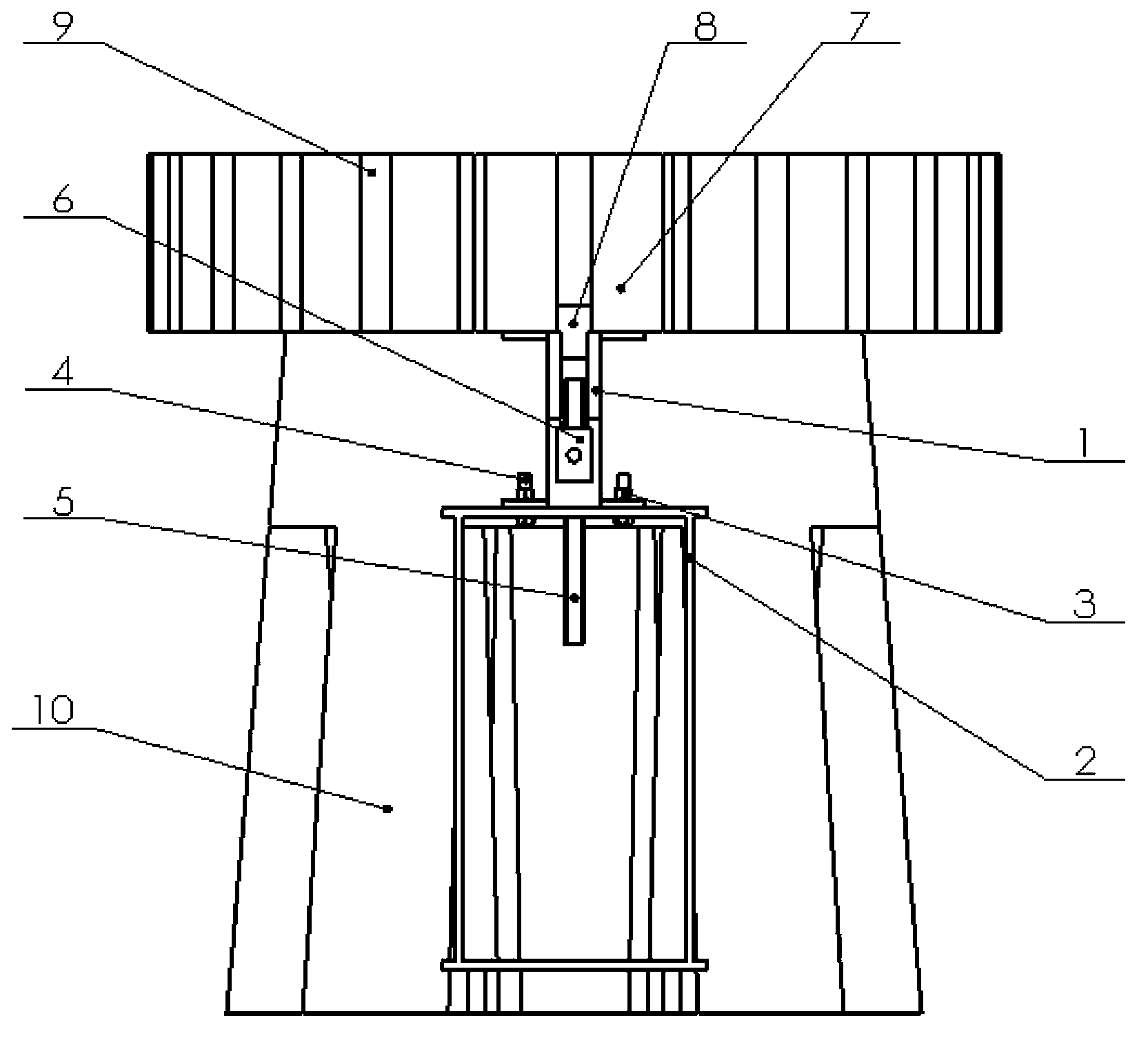

[0023] see figure 1 , figure 2 As shown, a permanent magnet assembly tool for a large permanent magnet direct drive wind power generator according to the present invention mainly includes a bracket 2 , a permanent magnet guide groove 1 and a conductive rod 5 . The permanent magnet guide groove 1 is L-shaped, includes a horizontal section and a vertical section, and is fixedly installed above the bracket 2 . The conducting rod 5 can be slidably installed in the bracket 2 up and down, and a conducting hole corresponding to the top of the conducting rod 5 is provided on the bracket 2 and the permanent magnet guide groove 1 . After assembly, the conduction rod 5 can smoothly pass through the conduction hole of the permanent magnet guide groove 1 and the roller bracket 2 .

[0024] Wherein, the shape of the permanent magnet guide groove 1 should match the shape of the permanent magnet, and an appropriate tolerance is selected to ensure that the permanent magnet can pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com