Flexible support device suitable for multiple model powertrain assemblies

A flexible support and powertrain technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing labor intensity of workers, increasing production costs, and reducing assembly efficiency, so as to save storage space and reduce operating intensity , the effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

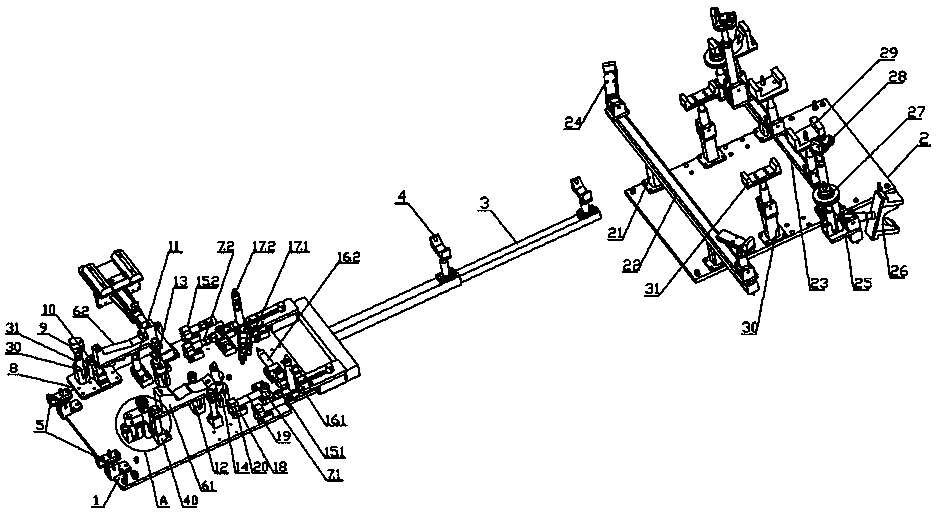

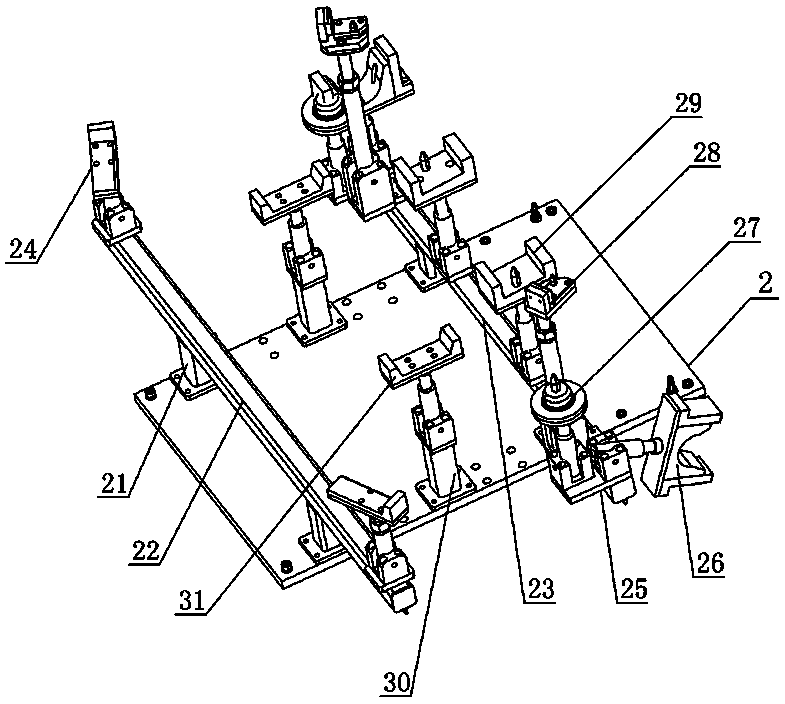

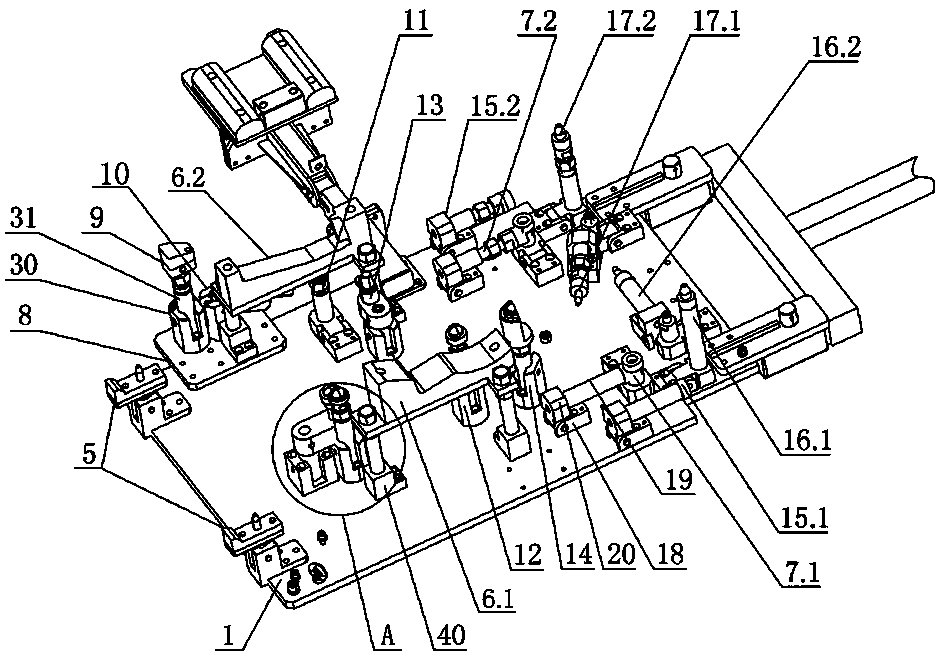

[0020] like figure 1 As shown, the flexible support device of the present invention suitable for powertrain assembly of various vehicle types includes left mounting base 1 and right mounting base 2 arranged at intervals, and the right end of left mounting base 1 is horizontally provided with a support beam extending to the right 3. The support beam 3 is a telescopic structure to meet the assembly requirements of different models; support blocks 4 are arranged at intervals on the support beam 3 to support the drive shaft of the four-drive model;

[0021] like figure 1 , image 3 , Image 6 As shown, the left mounting seat 1 is provided with a first positioning support mechanism for supporting and positioning the engine. The first positioning support mechanism includes the first positioning seat 5, the first support seat and the S12 which are sequentially arranged at intervals from left to right. The second support seat that matches the model, the first positioning seat 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com