Piezoelectric plane horn

A piezoelectric and planar technology, applied to electrical components, sensors, etc., can solve problems such as low sound pressure, high complexity of multi-layer structure, and limited vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

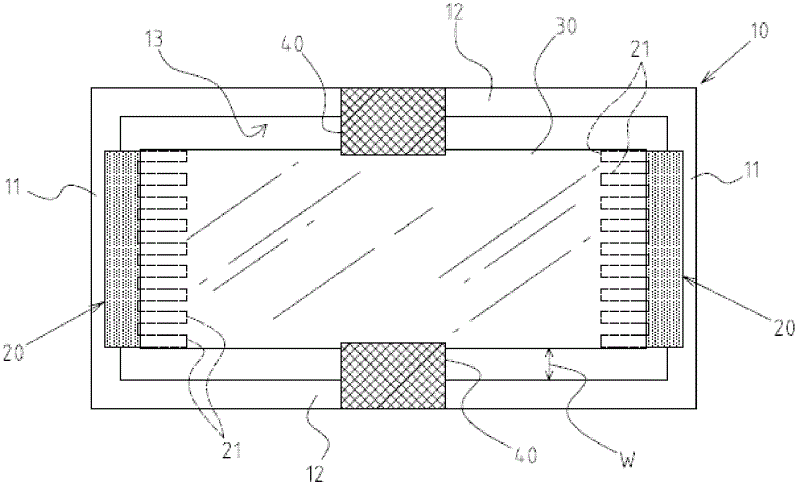

[0021] Such as figure 1 , 2 , Shown in 3, the preferred embodiment of piezoelectric planar horn of the present invention, this embodiment is only for illustration, is not limited by this structure on patent application; Described piezoelectric planar horn comprises:

[0022] A frame 10 is made of a hard substrate (which can be plastic, metal, wood, ceramics, etc.), and is in the form of a frame; the frame 10 includes side frame parts 11, 12, and the side frame parts 11, 12 form a closed structure ; and a hollow-shaped assembly space 13 formed in the center of the side frame portions 11 and 12 . The frame 10 of this embodiment is a rectangular frame, but it is not limited thereto, and it can also be made into a polygonal frame, a circular frame, etc.;

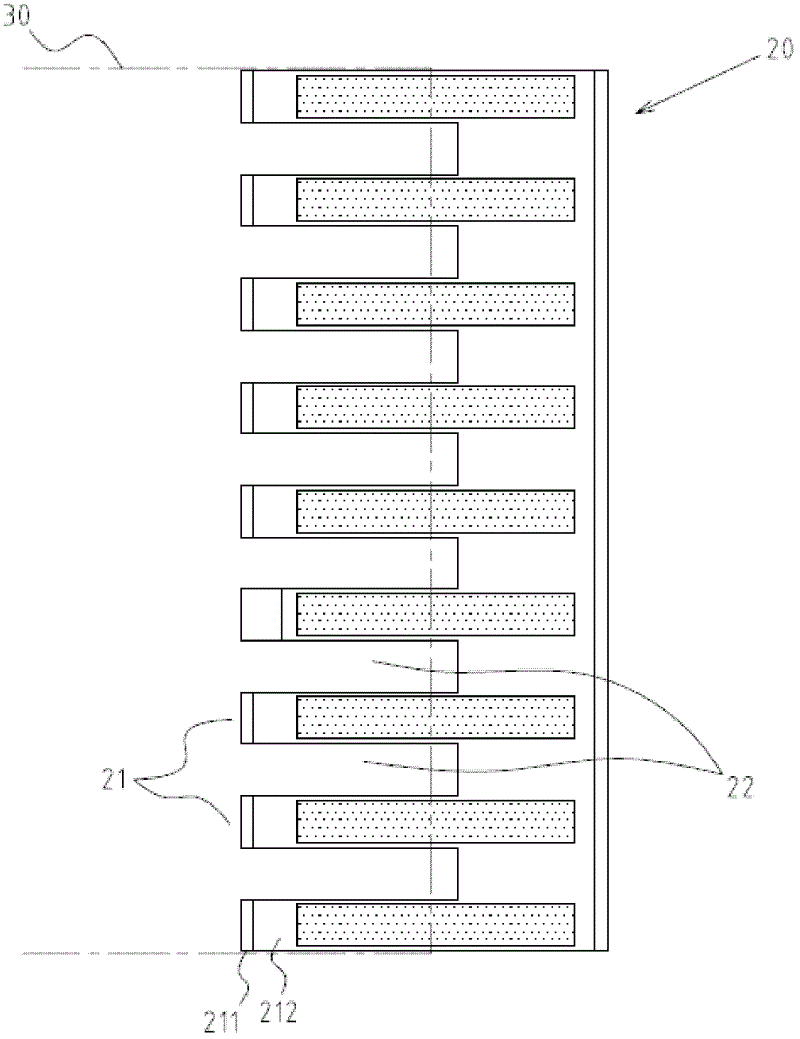

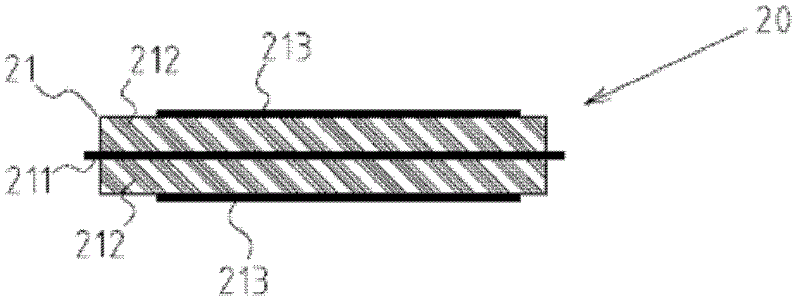

[0023] The piezoelectric actuators 20 are set in groups on the two side frame parts 11, and the two side frame parts 11 are arranged oppositely in the frame 10; each of the piezoelectric actuators 20 includes at least two dual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com