Hard rock stone head deep hole slotting and blasting method

A rock roadway and hard rock technology, which is applied in blasting and other directions, can solve the problems of low blasting efficiency, large clamping effect, and large number of blast holes, so as to improve the utilization rate of blast holes, reduce the clamping effect, and improve blasting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

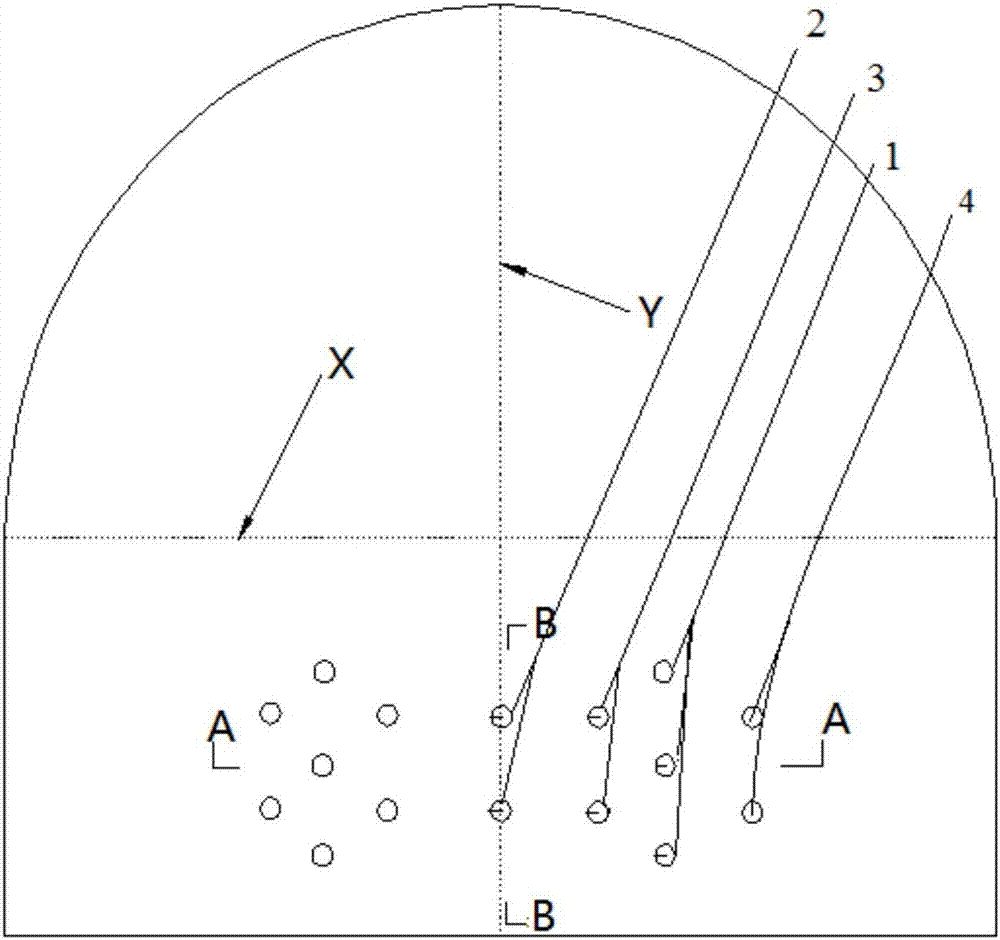

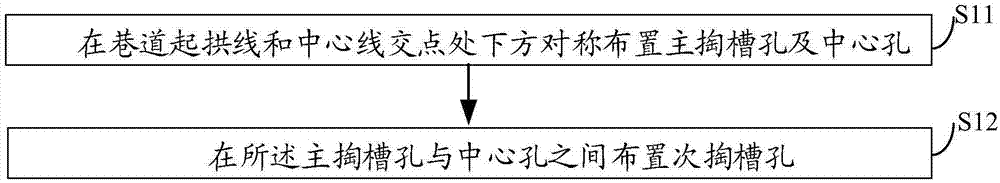

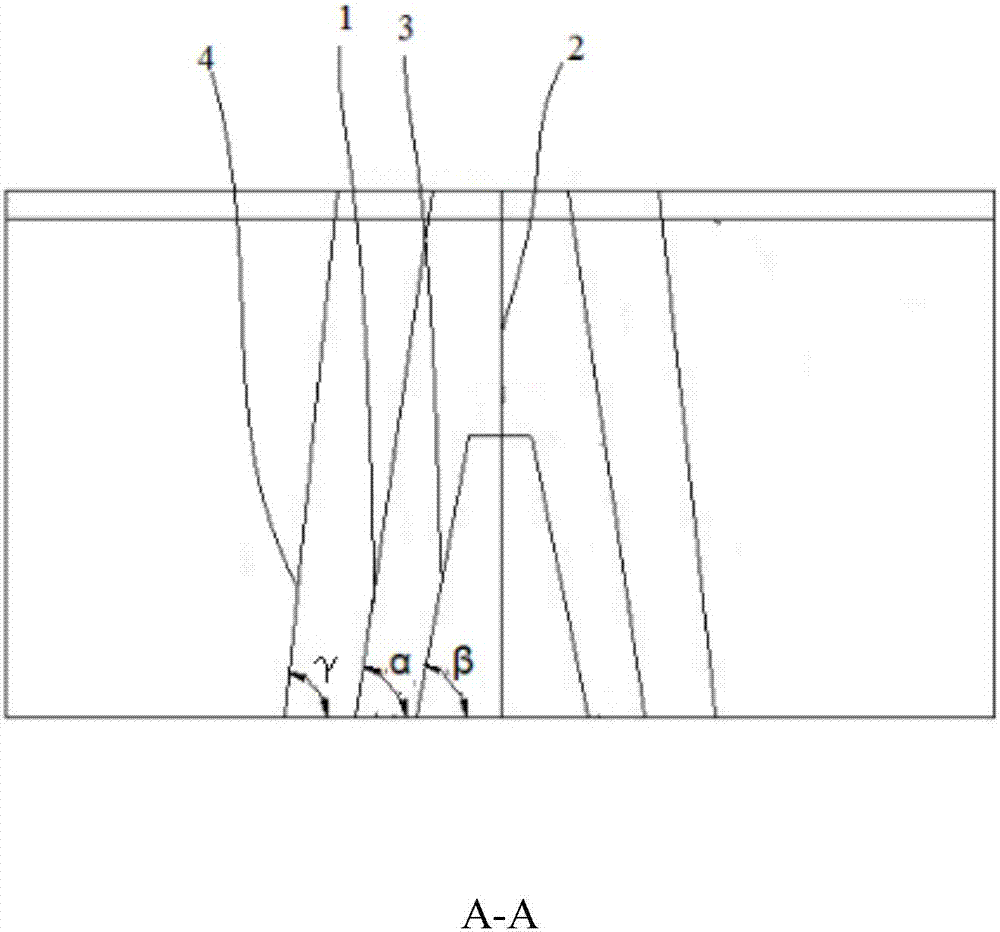

[0079] see Figure 1 to Figure 4 As shown in the figure, the embodiment of the present invention is a deep hole cutting method for hard rock roadways, which is mainly suitable for rock drilling operations, tunnels, roadway operations, and blasting engineering operations such as mines. Roadways with a property coefficient (Platinum coefficient) f greater than or equal to 7 also include hard rock roadways determined by other arbitrary surrounding rock classification methods. The deep hole in the embodiment of the present invention specifically refers to a blast hole with a blast hole depth greater than or equal to any depth of 2.5m or more, especially refers to a blast hole with a depth of 2.5-3.5m. Including steps: S11, symmetrically arrange the main undercut hole 1 and the center hole 2 below the intersection of the roadway arching line X and the center line Y; S12, arrange the secondary undercut hole 3 between the main undercut hole and the center hole . The number of the m...

Embodiment 2

[0091] see Figure 5 As shown in the figure, an embodiment of the present invention is a deep hole undercut blasting method for hard rock roadway, which is characterized in that it includes the steps of: S21, symmetrically arranging main undercut holes and secondary undercuts at the intersection of the roadway arching line and the center line hole and center hole; S22, charging rolls into the main undercutting hole, secondary undercutting hole and center hole; S23, blocking the main undercutting hole, secondary undercutting hole and center hole; S24, first align all the Detonating the central hole and the secondary undercutting hole; S25, detonating the primary undercutting hole again.

[0092] The embodiment of the present invention is a deep hole undercut blasting method for hard rock roadway. By arranging primary and secondary undercut holes, the secondary undercut hole and the central hole are blasted first, and then the main undercut hole is blasted. The deep hole blasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com