Up and down hole combined cutting-well-free slot broaching method

A technology of cutting wells and pulling grooves, which is applied in earthwork drilling, underground mining, surface mining, etc., and can solve the problem of high accuracy requirements for forced pulling groove blast hole construction, difficult cutting groove single-stage blasting process, and medium-deep veins outside the veins. The problem of heavy hole construction workload and other problems, to achieve the effect of small blasting clamping effect, improve the working environment, and reduce the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

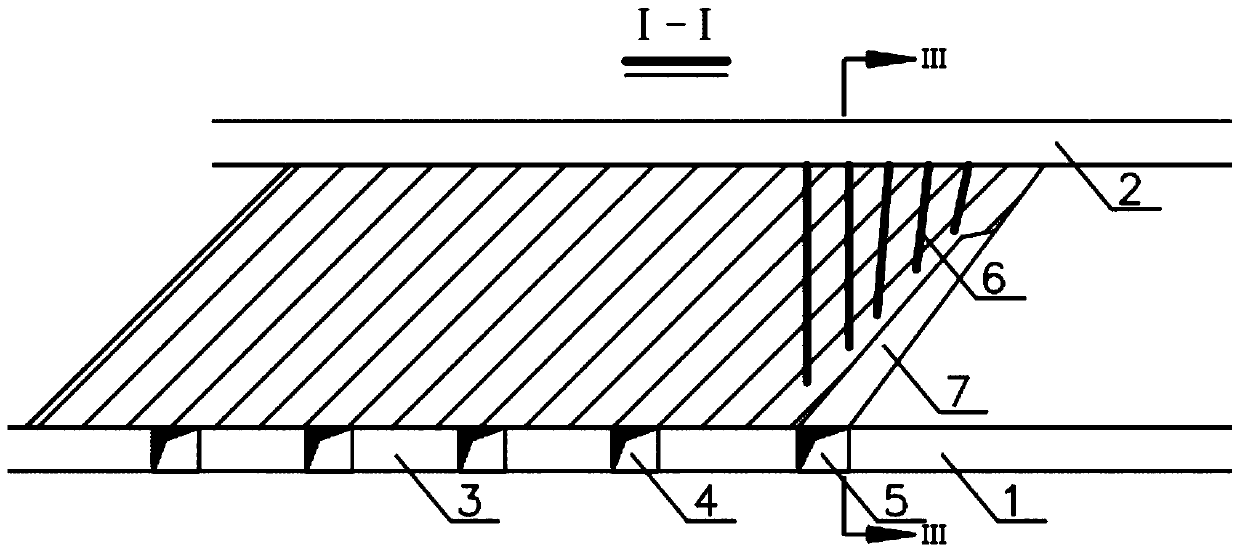

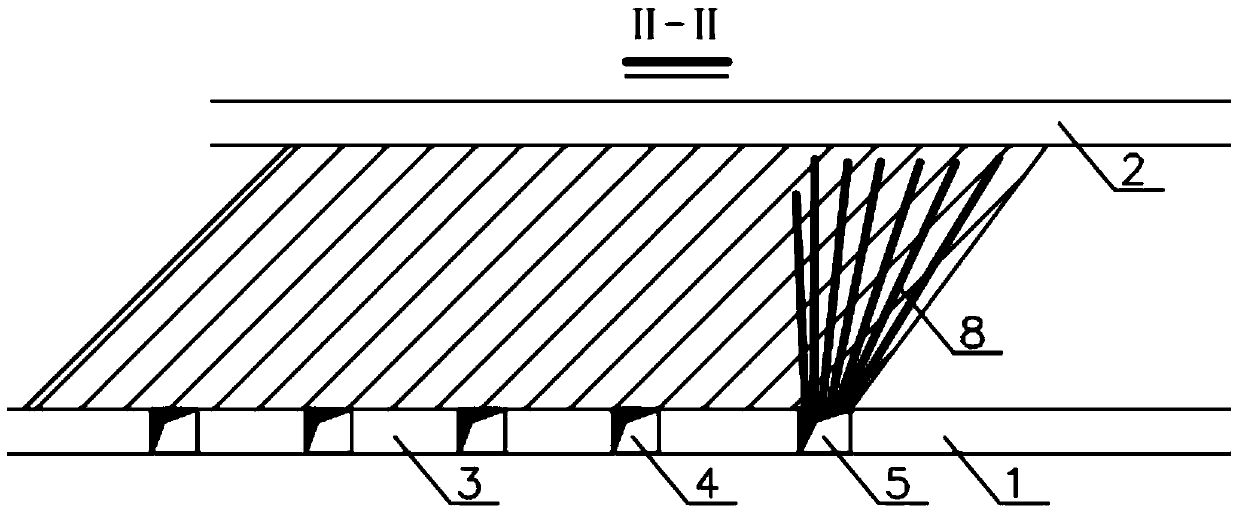

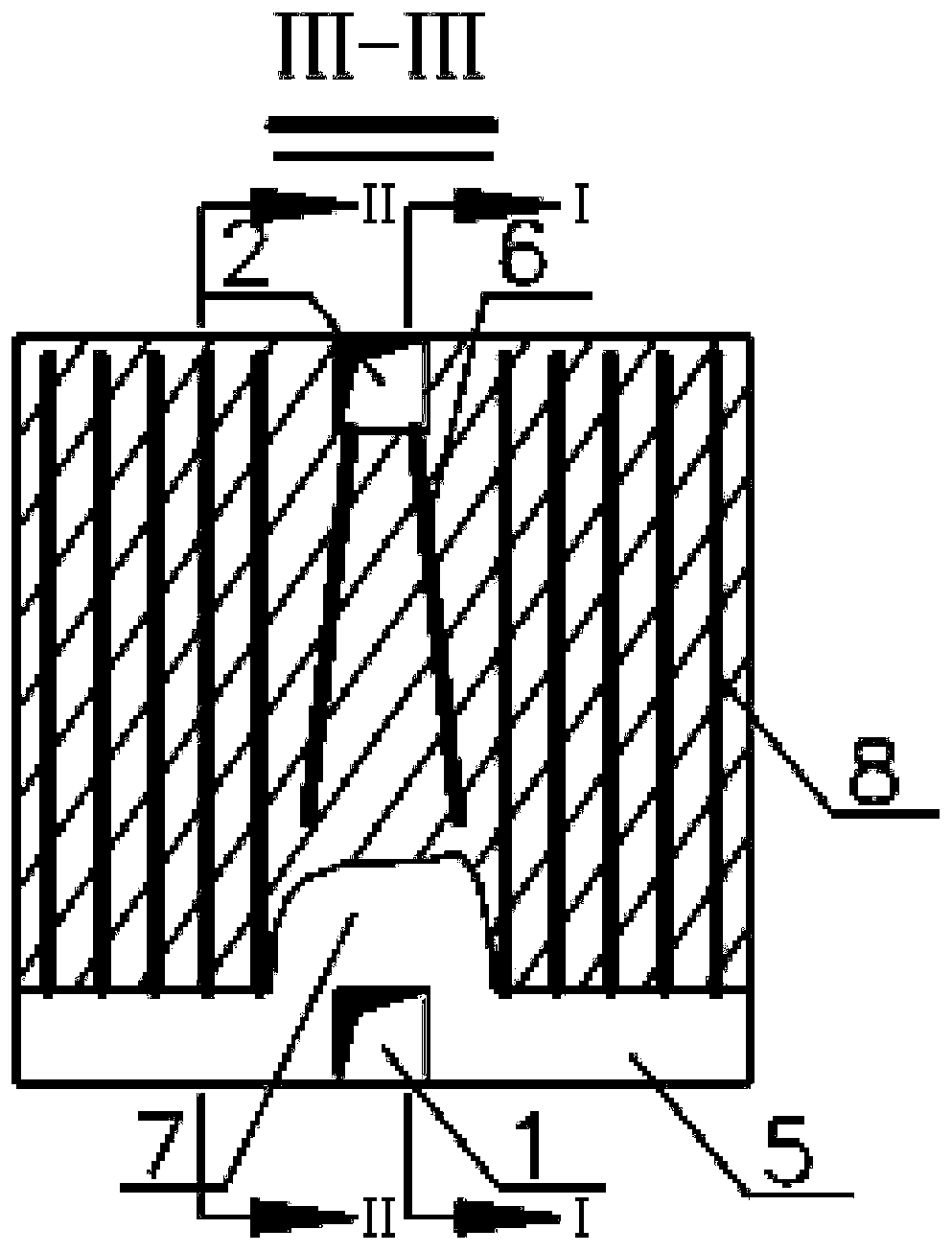

[0048] see Figure 1 to Figure 3 As shown, this embodiment provides a method of pulling grooves in combination with up and down holes without cutting wells:

[0049] Implementation background: In a gold mine, the average dip angle of the ore body is 38°, and the average thickness is 10m. The ore body occurs in the structural alteration zone and is strictly controlled by the structural fracture zone. Cut wells towards construction.

[0050] The specific construction steps of the slotting method are as follows:

[0051] S1, before pulling the cutting groove, first complete the layout and construction of the lower layer drilling roadway 1, the upper layer rock drilling roadway 2, the mine exit roadway 3, and the ore loading approach roadway 4, relying on the footwall of the ore body and vertically Under the construction of layer rock drilling roadway 1, layer cutting horizontal roadway 5, such as figure 1 and figure 2 shown; wherein, the section specification of the lower la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com