Guidance method and device for steel caisson positioning

A technology of guiding devices and caissons, which is applied in caissons, buildings, infrastructure engineering, etc., can solve the problems of large influence on river navigation, many process conversions, and many equipment layouts, so as to reduce the impact of river navigation and reduce the water area , Reduce the effect of process conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] An embodiment of the present invention provides a guiding method for steel caisson positioning, including the following steps:

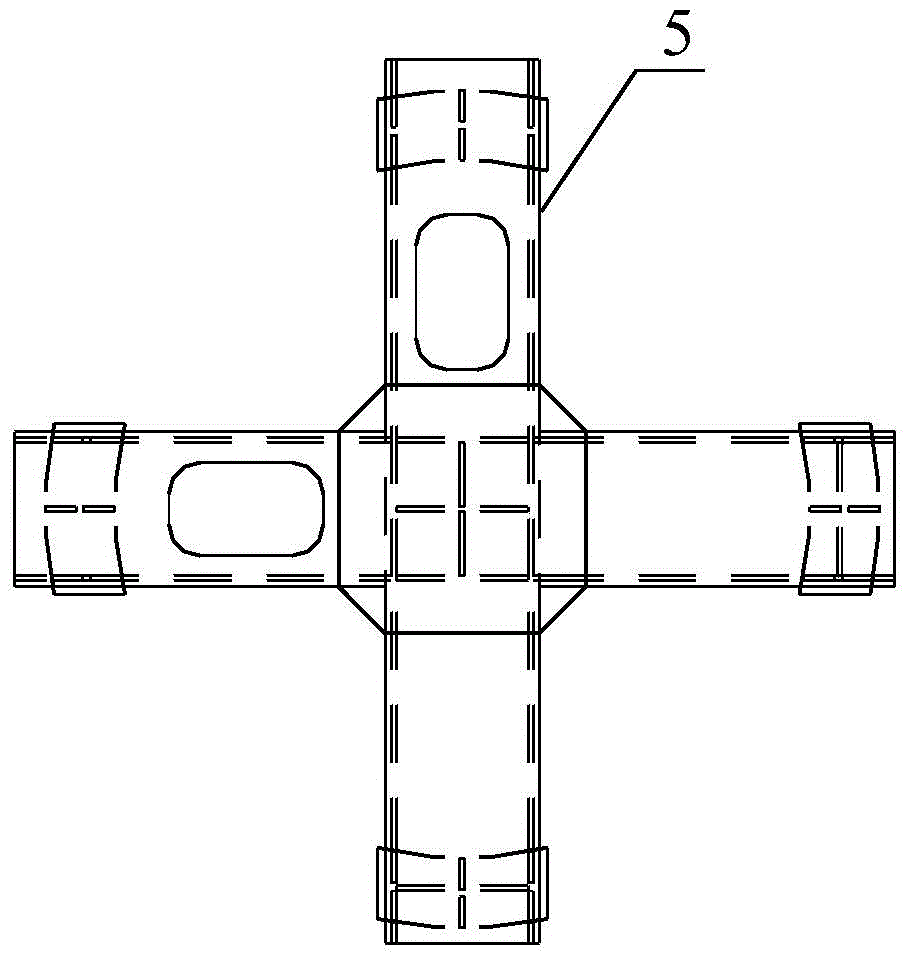

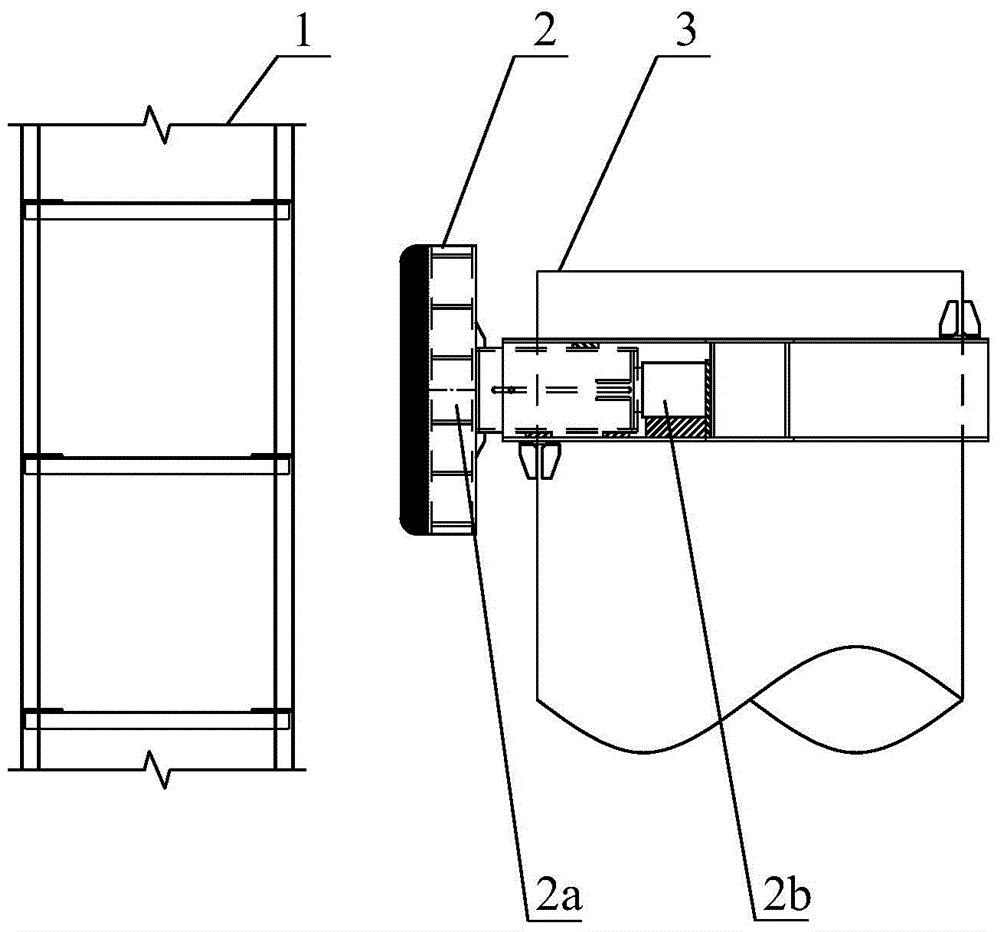

[0029] S1: Make at least 4 supporting anchor piles 3 and at least 4 cross beams 5, each cross beam 5 includes 4 arms, and the ends of two adjacent arms have receiving cavities, go to step S2.

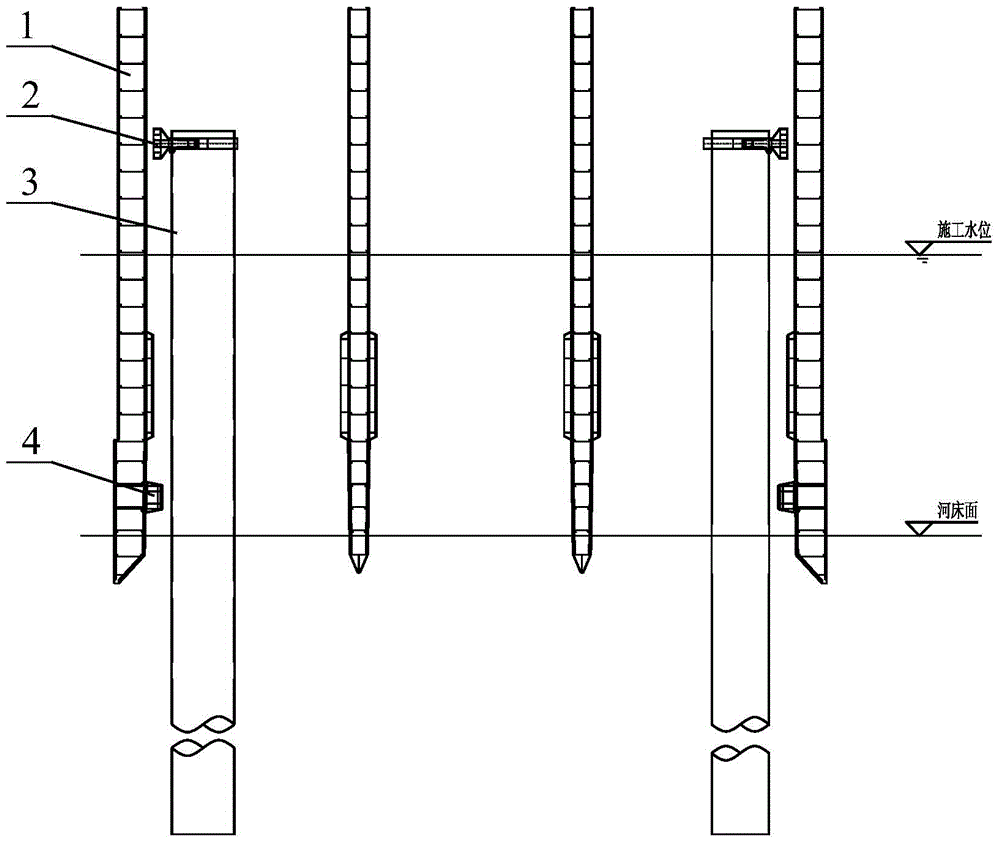

[0030] S2: see figure 1 with figure 2 As shown, in the pier well hole of the steel caisson 1, all support anchor piles 3 are vertically inserted and positioned, and all support anchor piles 3 are distributed symmetrically along the center of the pier well hole; A cross beam 5 is horizontally fixed on the top, and each cross beam 5 has a support arm with an accommodation cavity close to the inner wall of the pier well hole, and a supporting device 2 is installed in each accommodation cavity, and then go to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com