Splicing type fixing device for automatic instrument

A fixed device and splicing technology, which is applied in the direction of non-rotational vibration suppression, supporting machines, mechanical equipment, etc., can solve the problems of inconvenient dismantling of instruments, lack of instruments, time-consuming and labor-intensive efficiency, etc., to achieve easy dismantling, time-saving and labor-saving efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

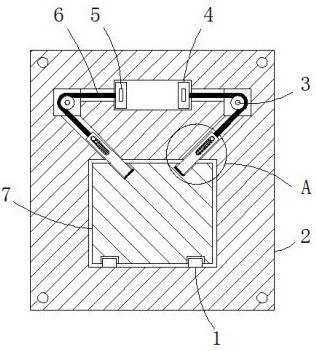

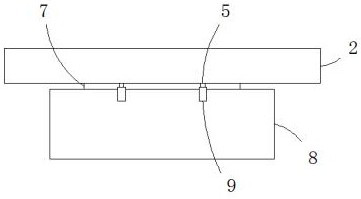

[0025] Example 1 as Figure 1-3 As shown, this spliced fixing device for automatic instruments includes a mounting plate 2 and an instrument body 8 arranged on the front side of the mounting plate. A rectangular hole is opened in the middle of the front side wall of the mounting plate 2, and a fixing block is slidably connected inside the rectangular hole. 7. The front side wall of the fixed block 7 extends to the outside of the rectangular hole and is fixedly connected with the rear side wall of the instrument body 8. The left and right ends of the lower side hole wall of the rectangular hole are symmetrically fixedly connected with the block 1, and the lower end of the fixed block 7 The left and right sides are provided with the first card slots matching with the two clamping blocks 1, the inside of the mounting plate 2 is located on the upper side of the rectangular hole and a first cavity is opened, and the inside of the mounting plate 2 is located in the first cavity Th...

Embodiment 2

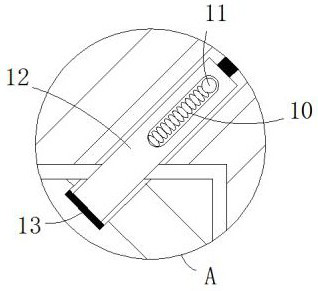

[0026] Embodiment 2 is on the basis of embodiment 1 such as image 3 As shown, its clamping mechanism includes a clamping rod 12, a fixed rod 11 and a spring 10. The rod wall of the clamping rod 12 is slidably connected with the hole wall of the second through hole, and one end of the clamping rod 12 close to the rectangular hole extends to a rectangular In the inside of the hole, the side wall of the fixed block 7 is provided with a second draw-in groove matched with the clamp rod 12, and the front side wall of the clamp rod 12 is provided with a first strip-shaped hole, and the fixed rod 11 is longitudinally arranged in the first strip-shaped hole. and the front and rear ends of the fixed rod 11 are fixedly connected with the hole wall of the second through hole, and the two ends of the two springs 10 are respectively connected with the side rod wall of the fixed rod 11 near the rectangular hole and the first bar-shaped hole. The hole wall is fixedly connected.

Embodiment 3

[0027] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, its pulling mechanism includes a roller 3, a pull cord 6, a slider 4 and a connecting block 5, the roller 3 is rotationally connected with the wall of the second cavity through a rotating shaft, and the slider 4 is connected with the wall of the first cavity. Slidingly connected, one end of the stay cord 6 is fixedly connected to one end of the clamp rod 12 located in the second through hole, and the other end of the stay cord 6 goes around the roller 3 and passes through the first through hole to be fixedly connected to the slider 4. The block 5 is fixedly connected to the front side wall of the slider 4, and the front side wall of the first cavity is vertically provided with a second strip-shaped hole matched with the connecting block 5, and the front side wall of the connecting block 5 passes through the second The strip-shaped hole extends to the outside of the first cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com