Numerical control double-headed sawing center for aluminum profiles

A double-headed saw and aluminum profile technology, which is applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc., can solve the problems of low efficiency and cumbersomeness, achieve low material loss, improve work efficiency, and save workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings:

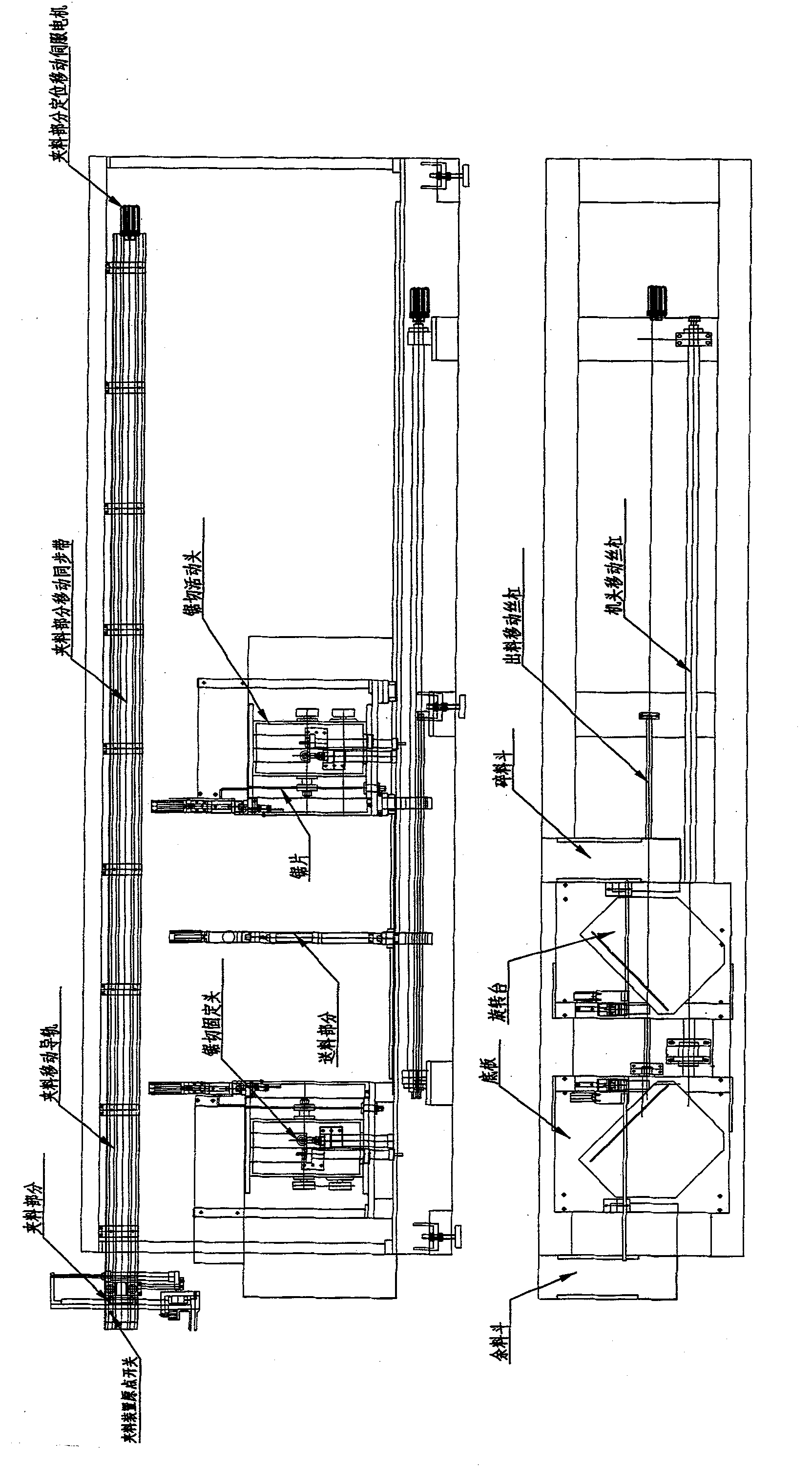

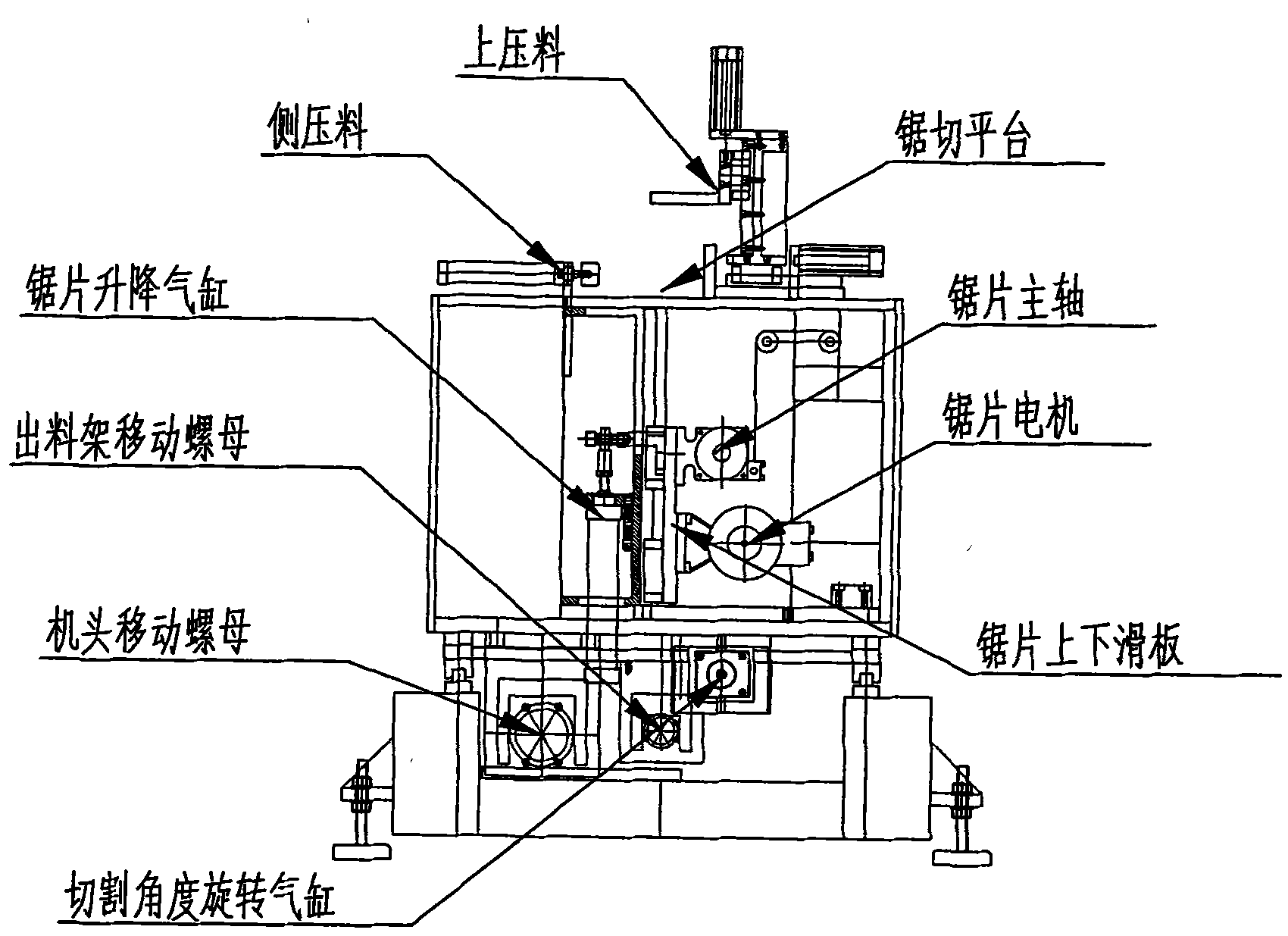

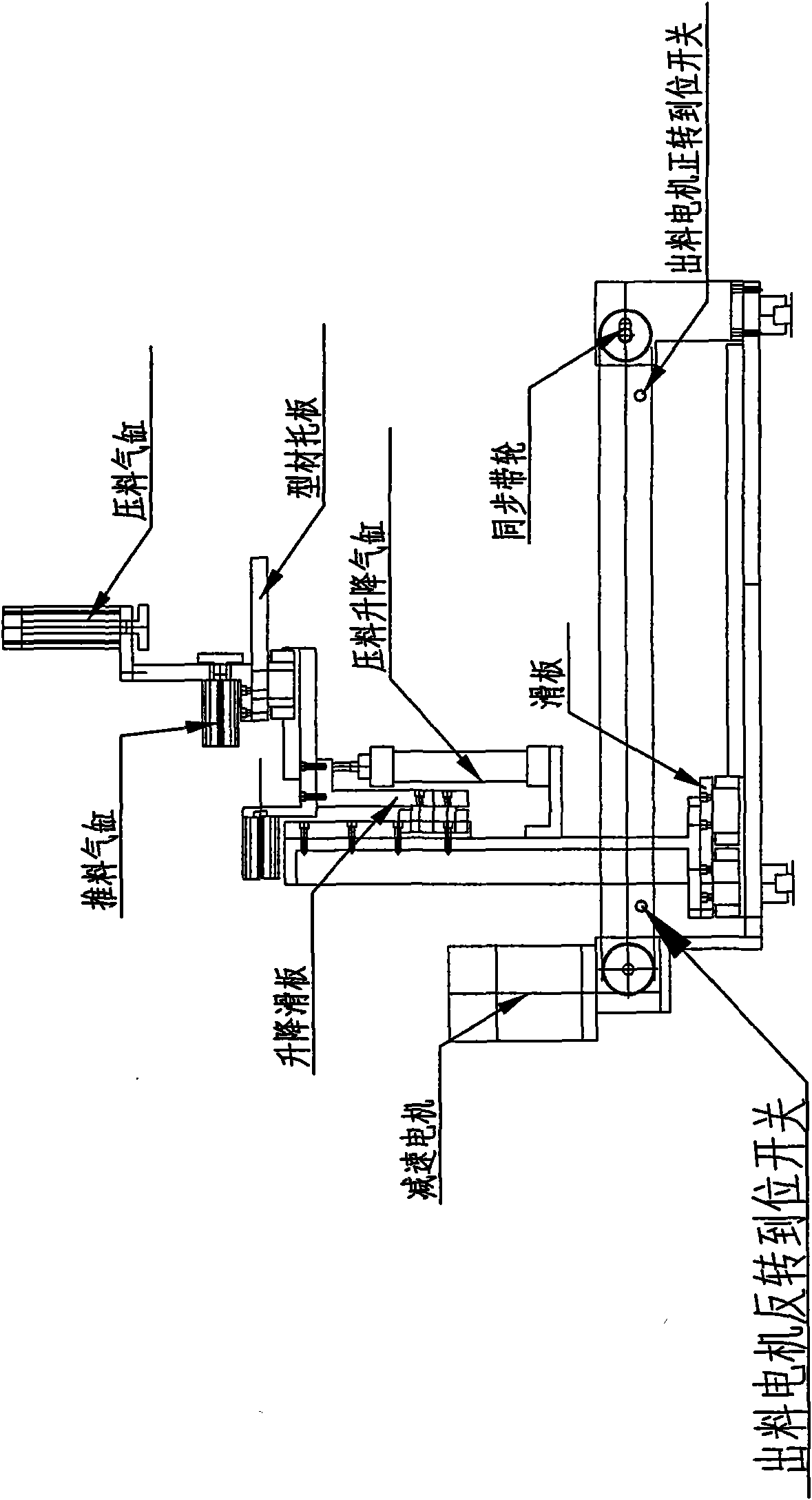

[0020] Such as figure 1 , 2 , 3, 4, 5, and 6, the upper and lower sawing parts of the aluminum profile CNC double-head sawing center are mainly composed of two sawing heads, one moving and one static, arranged on the frame, and each sawing machine The sawing platform is set on the top plate of the head. The moving sawing head moves horizontally under the action of the head screw through the head slide rail; Rotate around the centering shaft connected on the rotating bottom plate; the saw blade pillar is connected with a slide plate through the saw blade slide rail, and the saw blade motor and the saw blade main shaft connected by a belt are fixedly arranged on the slide plate, and the saw blade is provided on the saw blade motor; the slide plate It is connected with the telescopic rod of the saw blade lifting cylinder. This setting enables the saw blade to cut the large basic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com