Steel ball self-locking mechanical connecting device and connecting method

A technology of mechanical connection and steel balls, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of operation convenience, cumbersome troubles, etc., achieve stable and effective resistance to pulling force, and low probability of false contact , good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

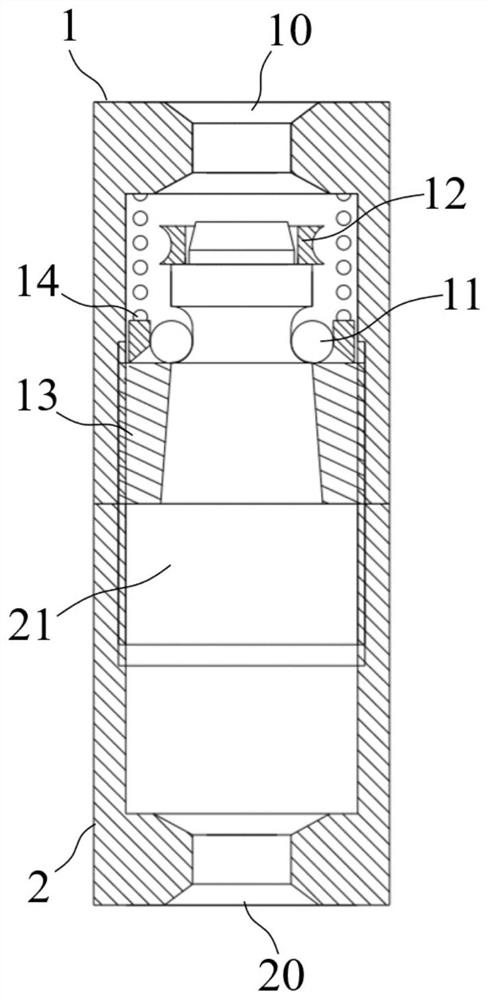

[0062] The steel ball self-locking mechanical connection device of this embodiment includes:

[0063] The upper joint 1 is hollow columnar;

[0064] The lower joint 2 is hollow cylindrical, and its upper end surface abuts against the lower end surface of the upper joint 1;

[0065] Also includes:

[0066] Steel balls 11, several of which are placed in the upper joint 1;

[0067] Support ring 12, which is a ring, has a depression on its outer surface, the shape of the depression matches the spherical shape of the steel ball 11, and the spherical surface of the steel ball 11 is in contact with the depression and arranged circumferentially along the outer surface of the support ring 12;

[0068] The limiting member 13 is connected to the inner lower end of the upper joint 1, the middle part of the limiting member 13 runs through a through hole up and down, and the limiting member 13 restricts the tendency of the supporting ring 12 to fall downward;

[0069] The support 14, whi...

Embodiment 2

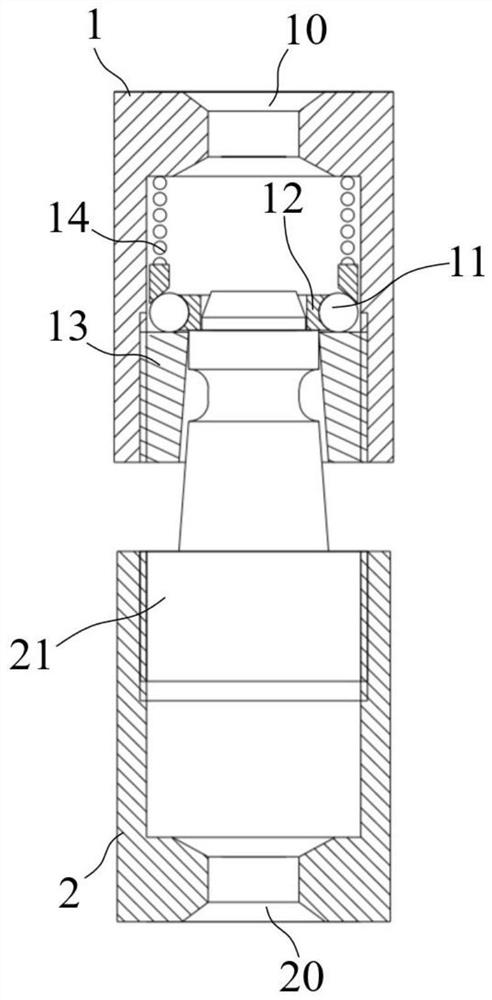

[0079] The steel ball self-locking mechanical connection device of this embodiment is further improved on the basis of Embodiment 1. The stopper 13 is a hollow ring, and its outer wall is provided with threads, and the lower end of the inner wall of the upper joint 1 is provided with corresponding threaded structure; the lower end of the plug 21 is threaded inside the lower joint 2 .

[0080] Such as image 3 and Figure 4 As shown, the stopper 13 is screwed to the inner lower end of the upper joint 1, and the plug 21 is screwed to the inner upper end of the lower joint 2. Through the structural design of this embodiment, the assembly of the device before use is convenient and quick.

Embodiment 3

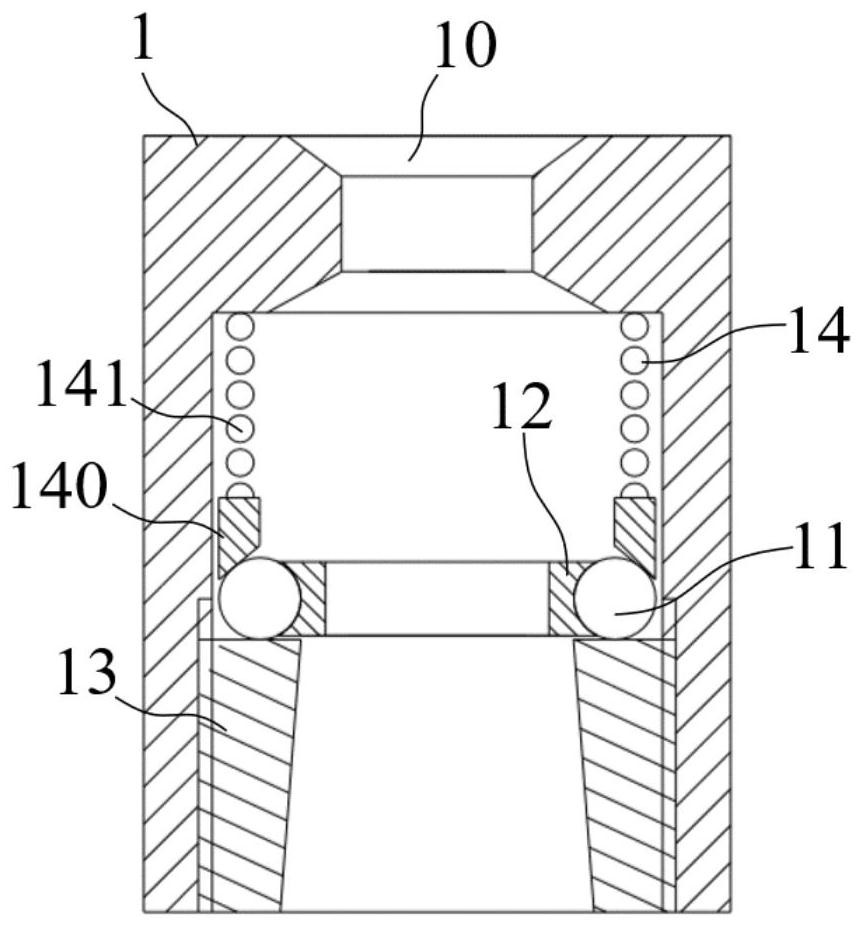

[0082] The steel ball self-locking mechanical connection device of this embodiment is further improved on the basis of Embodiment 2, and the support member 14 includes:

[0083] Wedge ring 140, which is a ring, the lower end is wedge-shaped, the inner wall diameter of the lower end gradually decreases from bottom to top, and the inner wall diameter of the upper end is the same;

[0084] A spring 141, one end of which is connected to the upper end of the wedge ring 140, and the other end is connected to the inner upper end of the upper joint 1;

[0085] The spring 141 is in a compressed state;

[0086] When the upper joint 1 and the lower joint 2 are not in contact, the wedge-shaped inclined surface at the lower end of the wedge-shaped ring 140 is in contact with the spherical surface above the side of the steel ball 11; touch.

[0087] There are many structures of the support member 14 that can provide downward and centripetal force for the steel ball 11, such as using wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com