Complete equipment for garbage transfer

A complete set of equipment and garbage transfer technology, applied in the direction of garbage cans, garbage delivery, garbage collection, etc., can solve the problems of sewage dripping, falling out, poor working environment, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

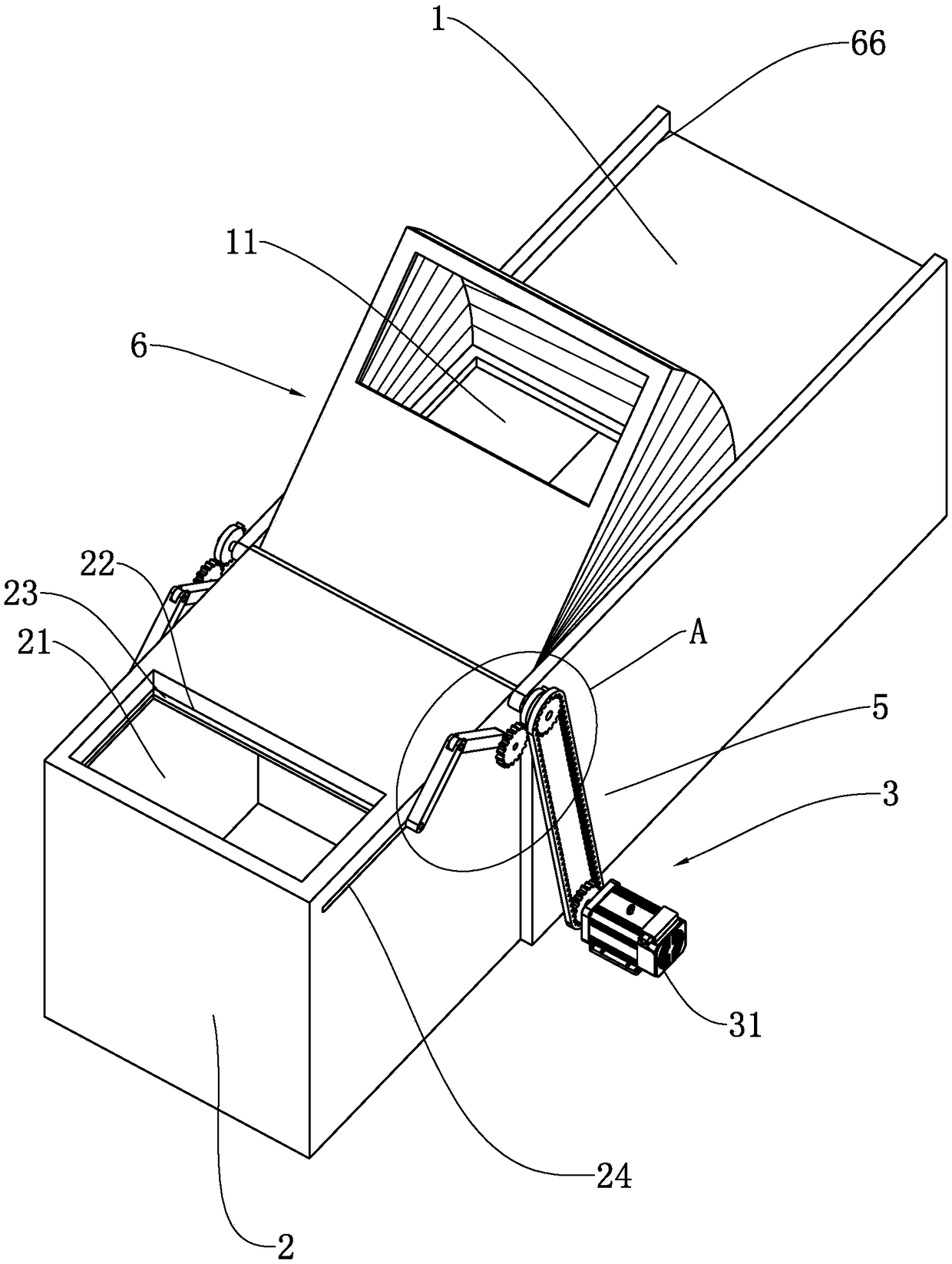

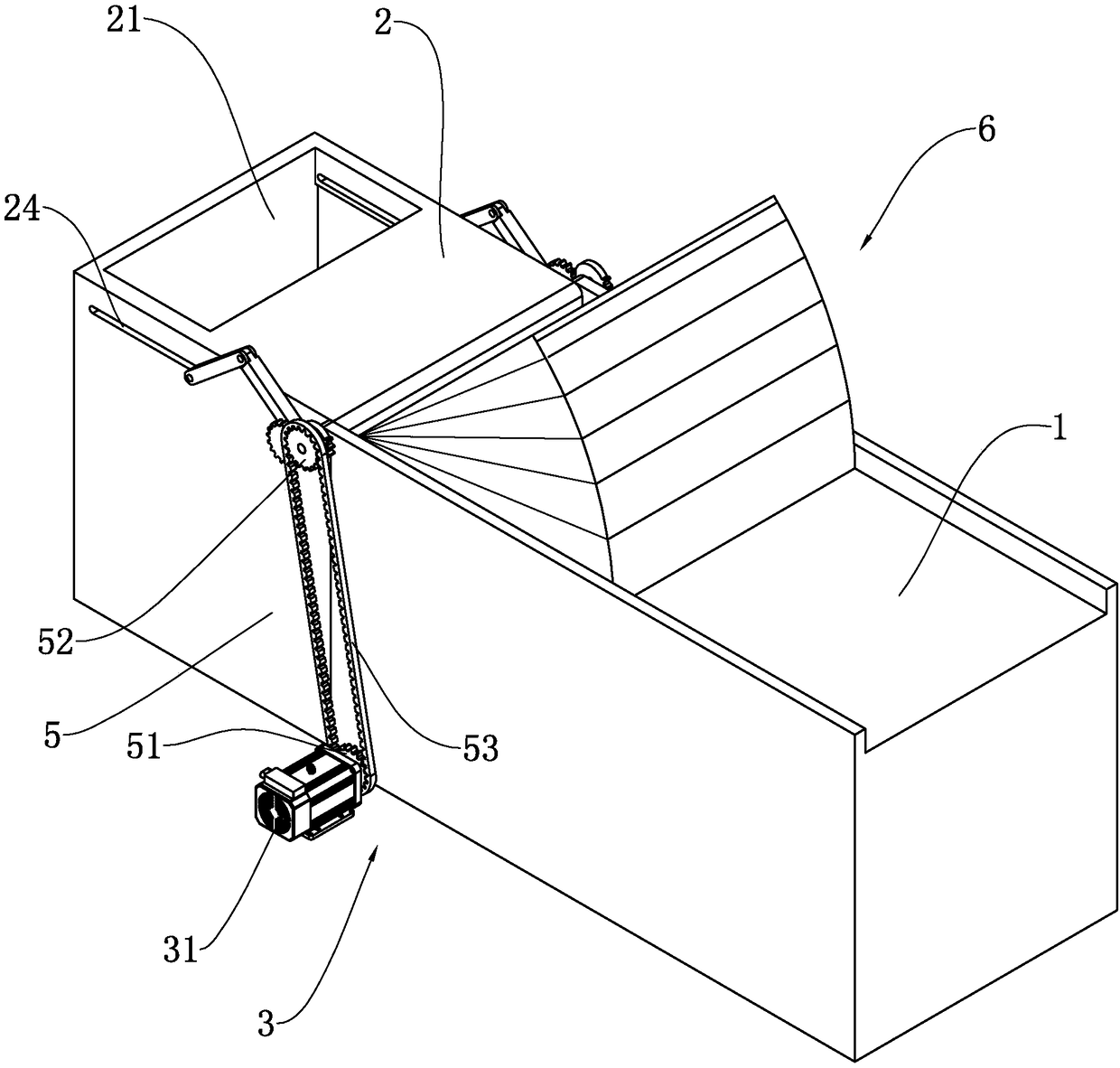

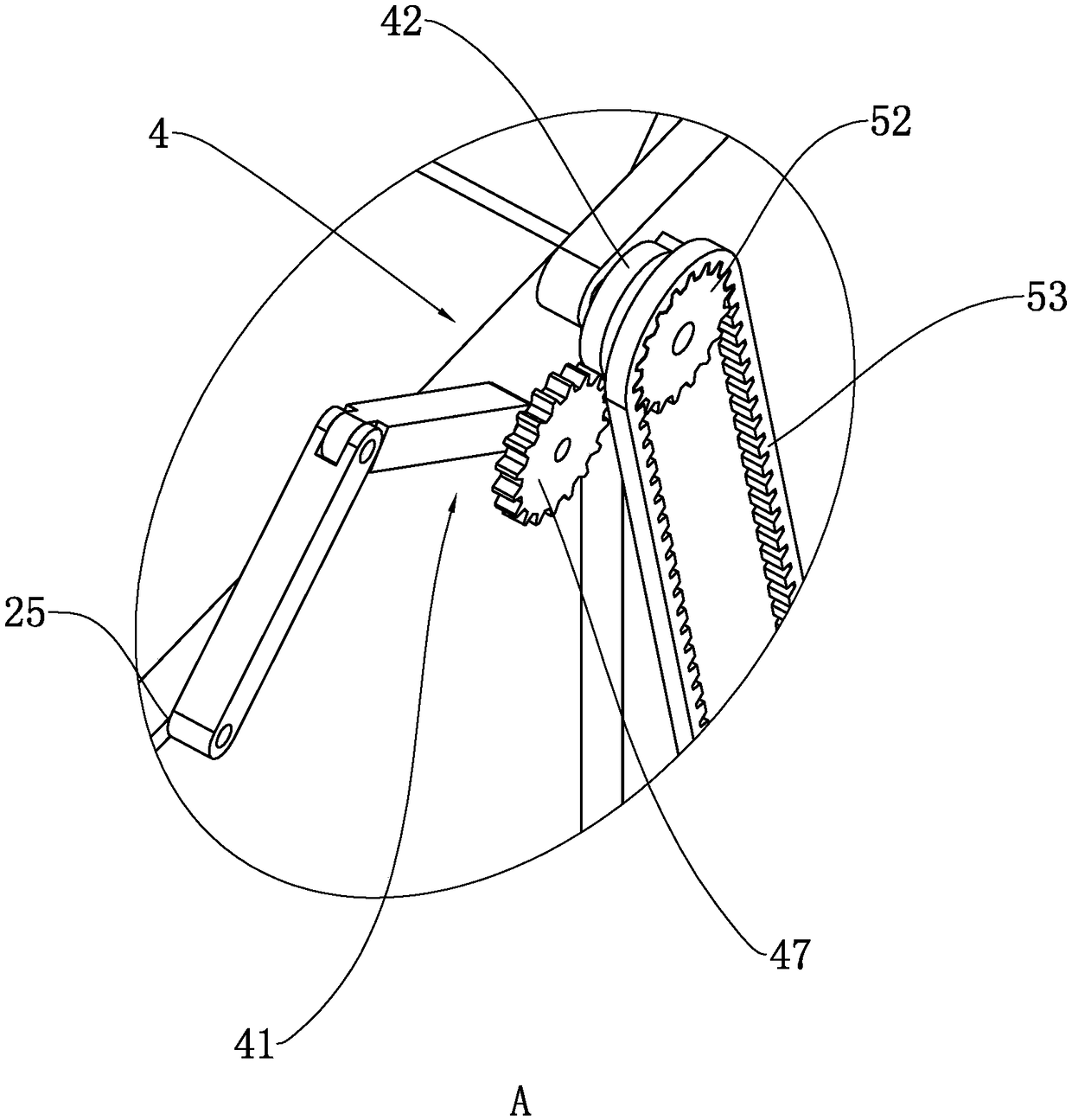

[0036] Embodiment 1: A complete set of garbage transfer equipment, such as figure 1 , figure 2 As shown, it includes a garbage compression device 1 provided with a first feeding port 11, a storage box 2 rotatably connected to the opening end of the garbage compression device 1, a drive device 3 located between the storage box 2 and the garbage compression device 1, Wherein, the top of the storage box 2 is provided with a second feed port 21 coordinating with the first feed port 11, and the side wall of the second feed port 21 is provided with a storage tank 22, which is slidably connected with a closed second feed port 22 in the storage tank 22. Closing plate 23 for port 21. When the garbage compression device 1 handles the garbage, the garbage to be processed is put into the storage box 2, so that after the garbage compression device 1 compresses the garbage, new garbage can be quickly filled into the garbage compression device 1; During the process of filling the bin 2 in...

Embodiment 2

[0044] Embodiment 2: A complete set of garbage transfer equipment such as Figure 7 As shown, the difference from Embodiment 1 is that when the storage box 2 is close to the garbage compression device 1, the closing plate 23 will be opened, and the garbage may still fall out of the storage box 2 to the ground during this process, so in this The first feed port 11 is provided with a shielding mechanism 6 that cooperates with the material storage box 2 and wraps the second feed port 21 .

[0045] like Figure 7 As shown, the blocking mechanism 6 includes a blocking plate 61 that is rotatably connected to the garbage compacting device 1, and a folding frame 62 that is connected between the garbage compacting device 1 and the blocking plate 61, wherein the blocking plate 61 is provided to cooperate with the second feeding port 21. The pouring opening 63, the folding frame 62 includes folding straight plates 64 connected to both sides of the shielding plate 61, and folding arc pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com