Short-sleeper long-lump integrated ballast bed seamless track construction method

A technology of integral ballast bed and seamless track, which is applied in the direction of roads, tracks, laying tracks, etc., can solve the problems of small traction force, small track radius, and increased upsetting resistance during welding, so as to reduce frictional resistance and make curve lines round The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

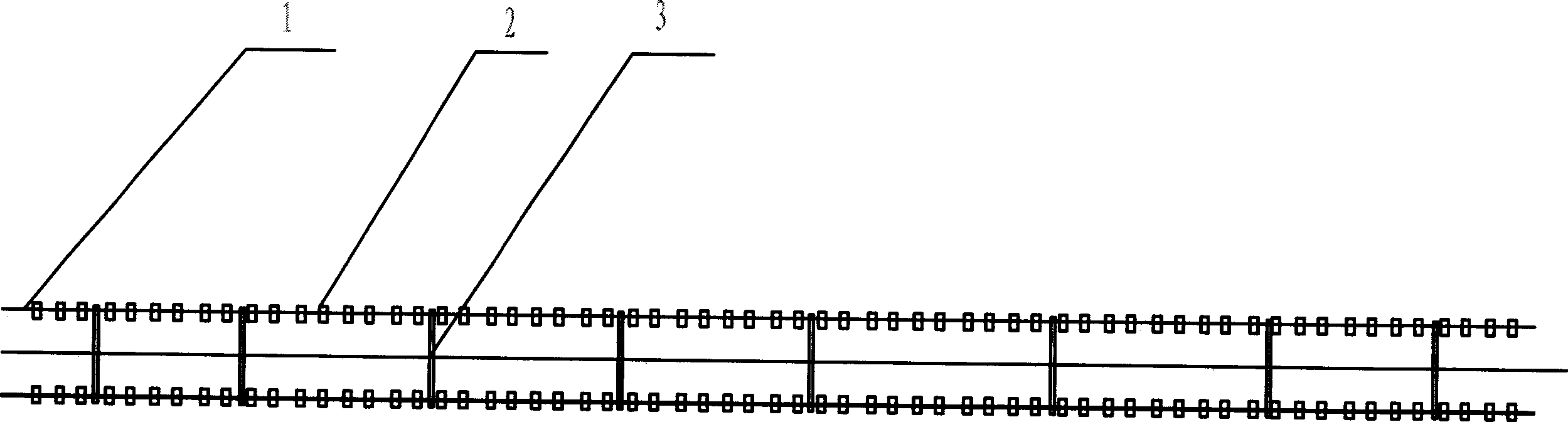

[0033] The construction method of the monolithic track bed seamless track with short sleepers and long rail rows of the present invention will be described in detail below with reference to the drawings (taking 5 25-meter standard rails assembling 125-meter long rail rows as an example).

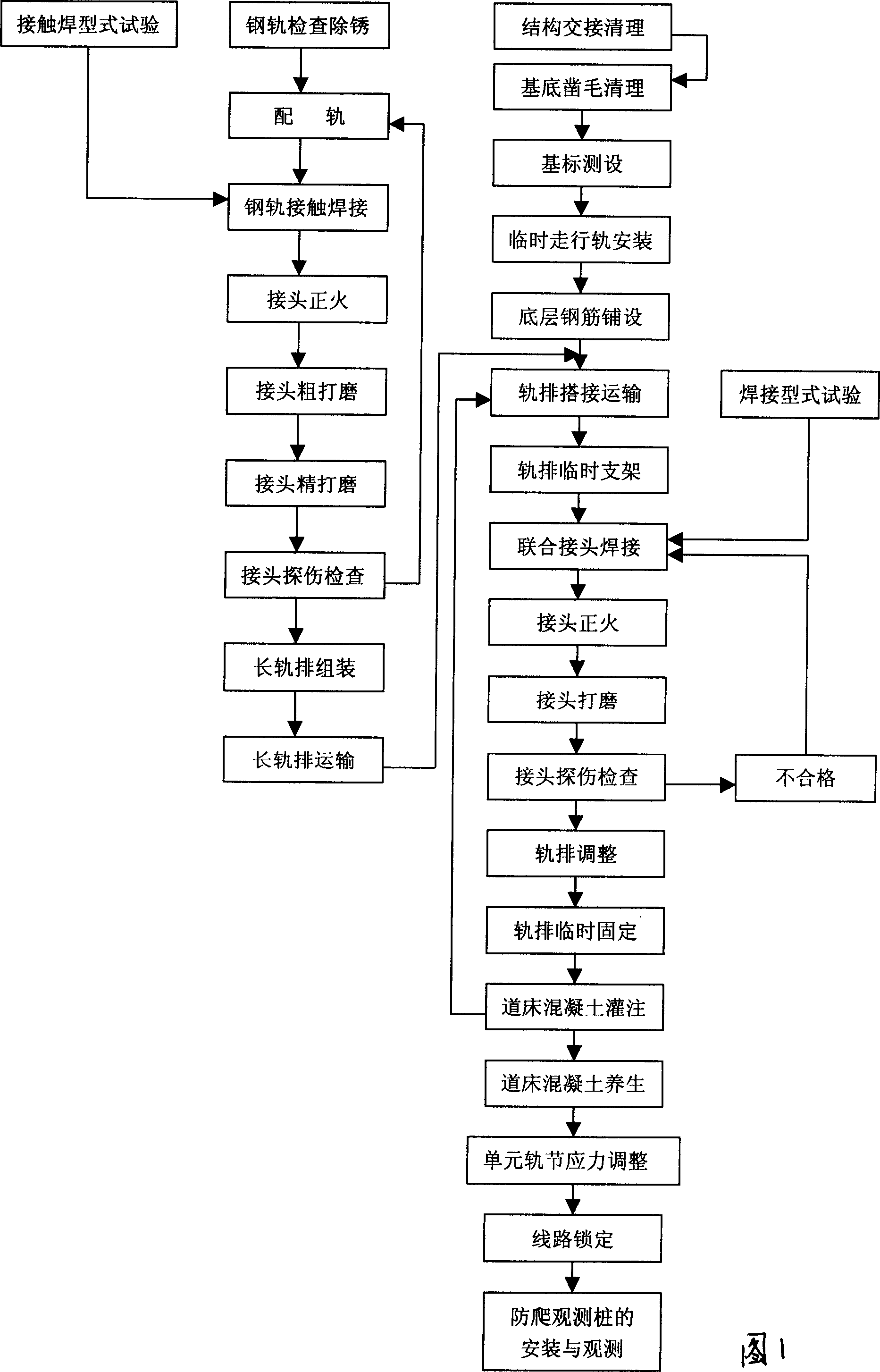

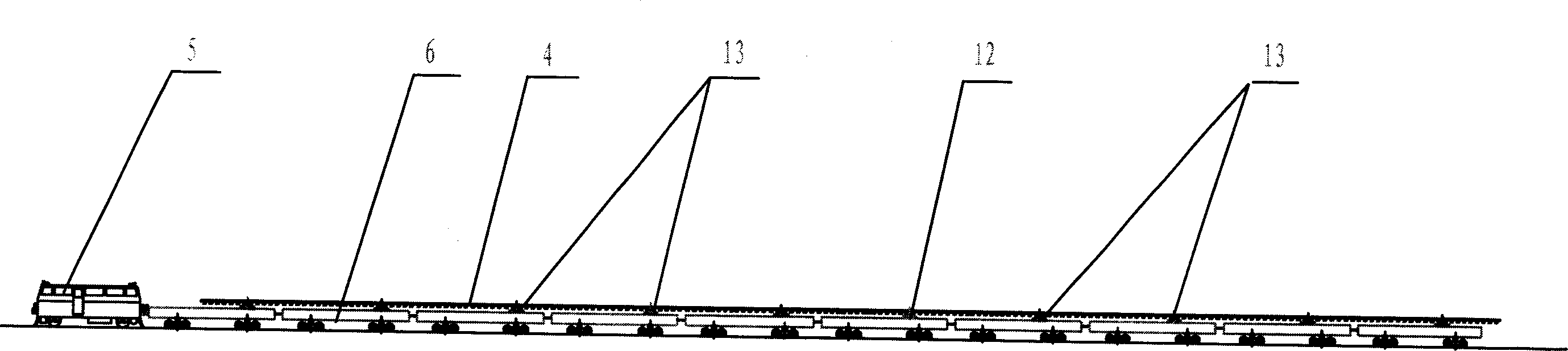

[0034] The short sleeper and long rail row monolithic track bed seamless track construction method of the present invention mainly includes long rail row base assembly, long rail row transportation, long rail row lifting installation and welding, long rail row fixing, monolithic track bed pouring and Lock several steps (detailed process steps are shown in Figure 1).

[0035] 1. Long rail platoon base assembly

[0036] 1.1 Carry out type test on the rails to be welded to determine the best parameters for the joint welding of this batch of rails;

[0037] 1.2 Match the welded rails according to the requirements of the rail matching table, conduct visual inspection of the selected rails, straighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com