Preparation method of magnetic activated carbon and magnetic activated carbon prepared thereby

A magnetic activated carbon and activated carbon technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of limited adsorption and removal of pollutants, easy scattering of activated carbon, and difficulty in recycling. Achieve the effect of increasing the specific surface area of the product, rich pore structure, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

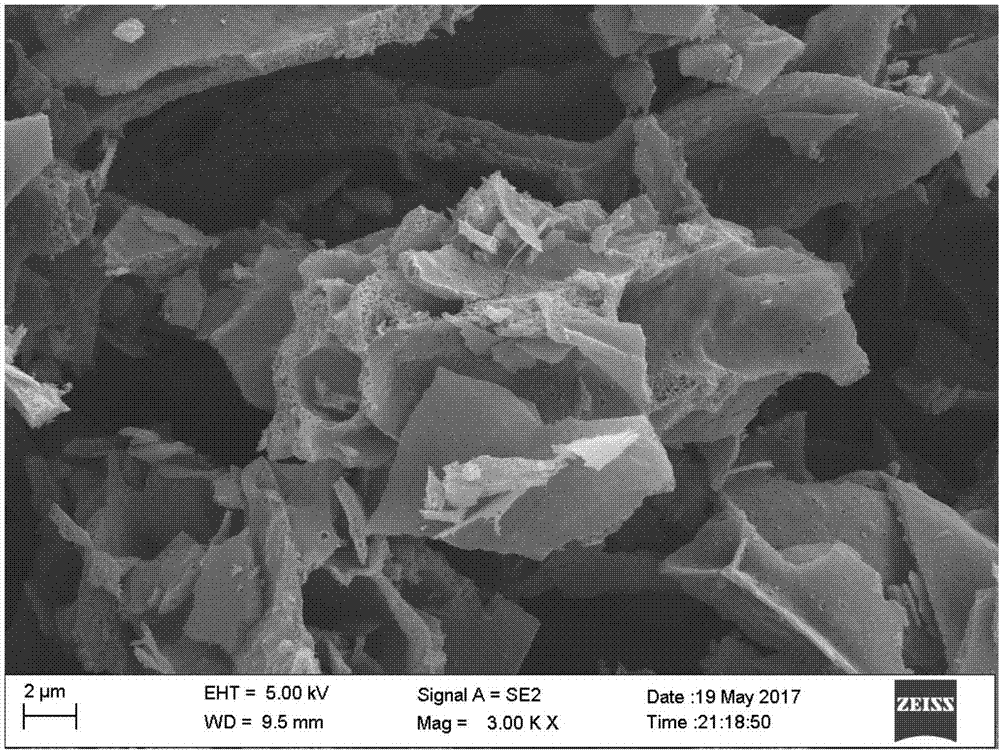

[0026] A preparation method of magnetic activated carbon, cellulose sol preparation: firstly take 16g of cellulose and 0.5g of urea in a 100ml beaker, add 60ml of zinc chloride aqueous solution with a mass fraction of 70%, and stir quickly and uniformly at a speed of 350r / min for 30min , to obtain a transparent sol; the use of cellulose as a carbon source is because cellulose is easy to form a transparent colloid after rapid stirring of zinc chloride, and activated carbon materials with high specific surface area can be prepared after high temperature activation. Vacuum freeze-drying: cut the above-mentioned transparent sol into 2cm thick slices, freeze in liquid nitrogen, and dry the frozen samples in a vacuum freeze dryer; vacuum freeze-drying makes the ice crystals in the samples sublimate directly, so that the product can keep Many tiny pore structures are conducive to high temperature activation to form a pore effect. High-temperature pyrolysis activation: put the freeze-...

Embodiment 2

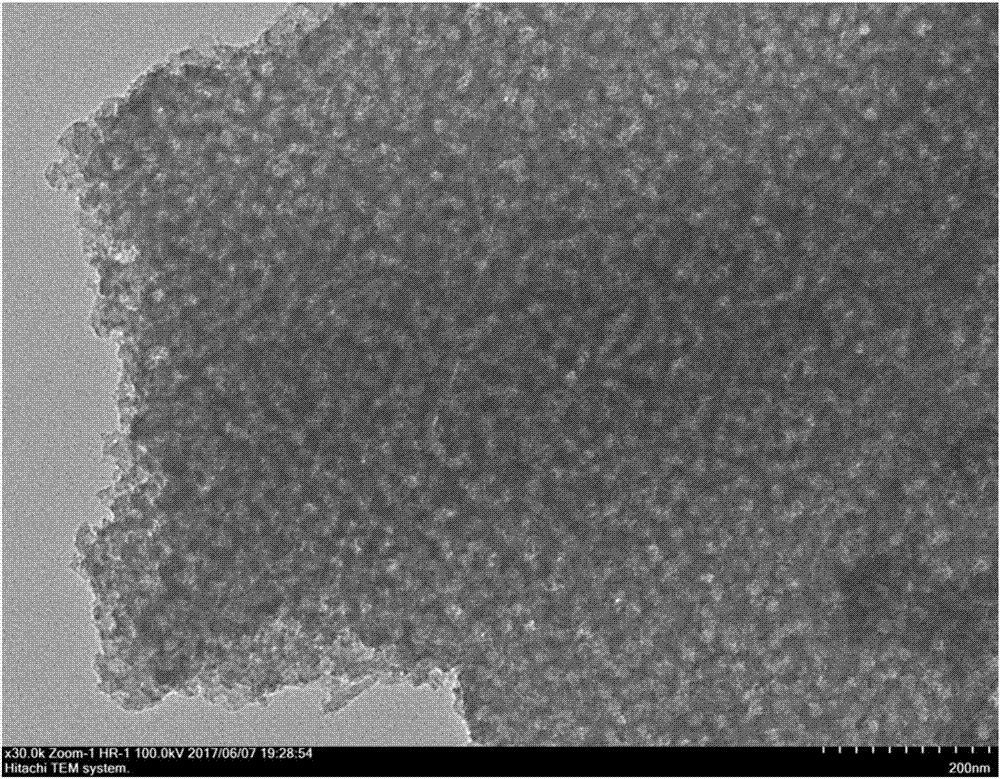

[0029] A preparation method of magnetic activated carbon, cellulose sol preparation: firstly take 16g of cellulose and 0.5g of urea in a 100ml beaker, add 60ml of zinc chloride aqueous solution with a mass fraction of 70%, and stir quickly and uniformly at a speed of 350r / min for 30min , to obtain a transparent sol. Vacuum freeze-drying: the above-mentioned transparent sol was cut into thin slices with a thickness of 2 cm, frozen in liquid nitrogen, and the frozen samples were dried in a vacuum freeze dryer. High-temperature pyrolysis activation: put the freeze-dried product in a porcelain boat and put it in the middle of the tube furnace, and pyrolyze it under the protection of nitrogen. The heating rate is 5°C / min, the temperature is raised to 700°C, heat treatment is carried out for 4 hours, and the flow rate of nitrogen gas is 30mL / min. °C in a vacuum oven for 12 hours to obtain an intermediate product of activated carbon with a high specific surface area. Ultrasonic ble...

Embodiment 3

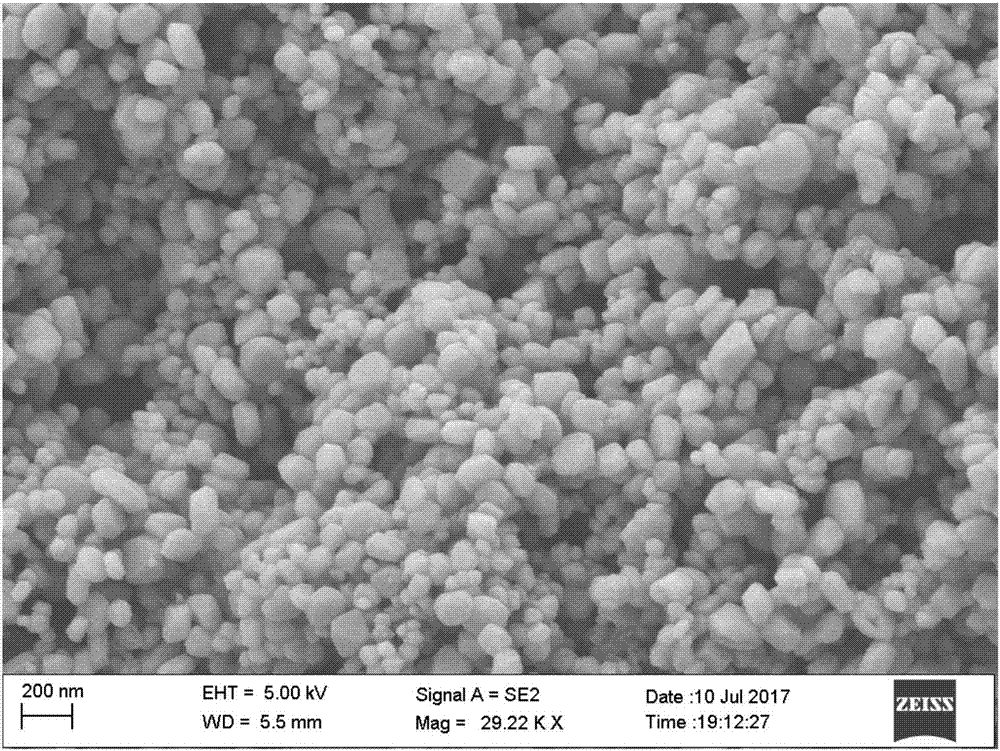

[0032] A preparation method of magnetic activated carbon, cellulose sol preparation: firstly take 16g of cellulose and 0.5g of urea in a 100ml beaker, add 60ml of zinc chloride aqueous solution with a mass fraction of 70%, and stir quickly and uniformly at a speed of 350r / min for 30min , to obtain a transparent sol. Vacuum freeze-drying: the above-mentioned transparent sol was cut into thin slices with a thickness of 2 cm, frozen in liquid nitrogen, and the frozen samples were dried in a vacuum freeze dryer. High-temperature pyrolysis activation: put the freeze-dried product in a porcelain boat and put it in the middle of the tube furnace, and pyrolyze it under the protection of nitrogen. The heating rate is 5°C / min, the temperature is raised to 800°C, heat treatment is performed for 2 hours, and the flow rate of nitrogen gas is 30mL / min. °C in a vacuum oven for 12 hours to obtain an intermediate product of activated carbon with a high specific surface area. Ultrasonic blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com