Drill bit seal and method of using same

a technology of drill bit and seal, which is applied in the field of drill bit, can solve the problems of high sealing interface speed, rapid heating, and increased surface speed of the seal against its seal land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The description that follows includes exemplary systems, apparatuses, methods, and instruction sequences that embody techniques of the subject matter herein. However, it is understood that the described embodiments may be practiced without these specific details.

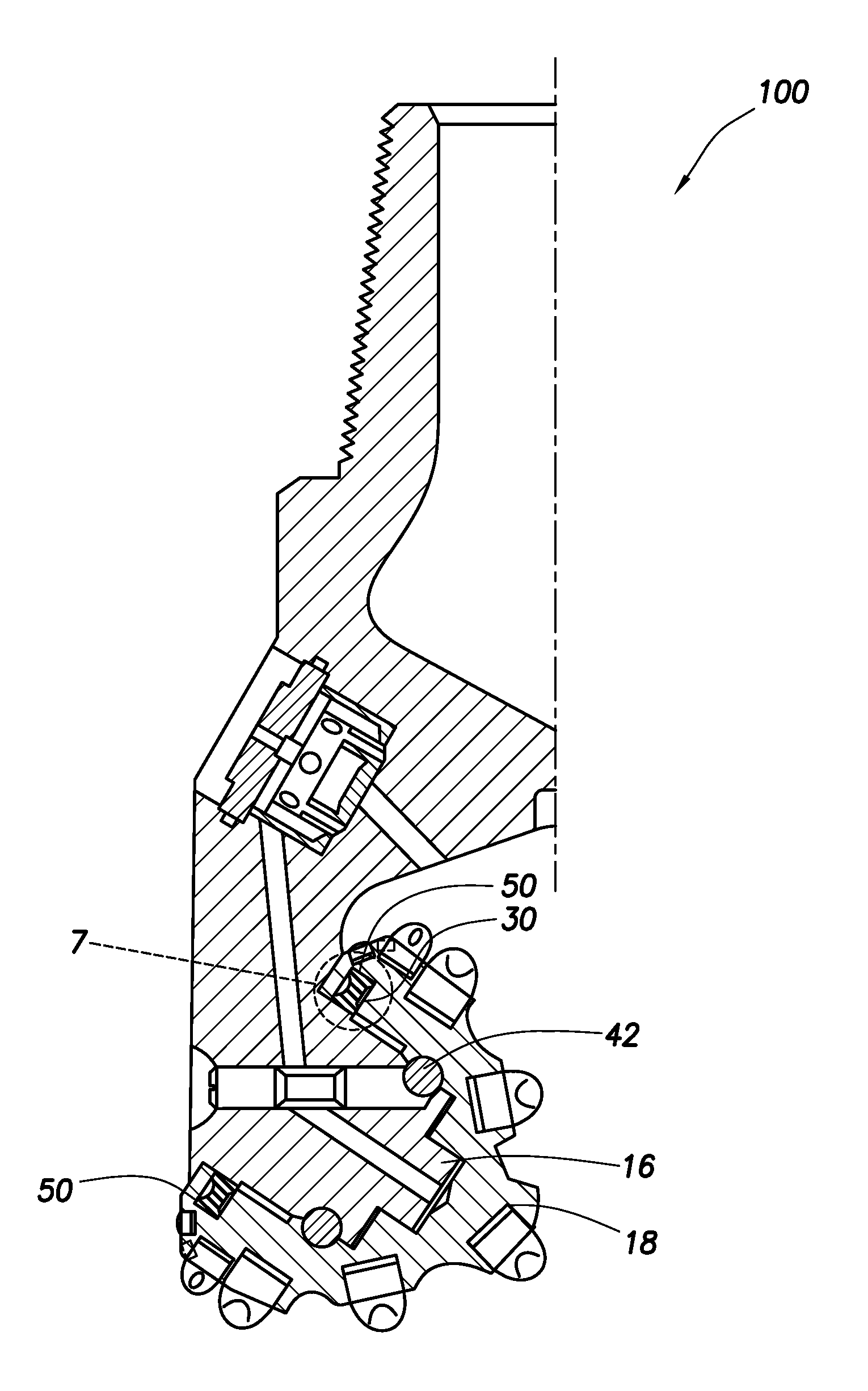

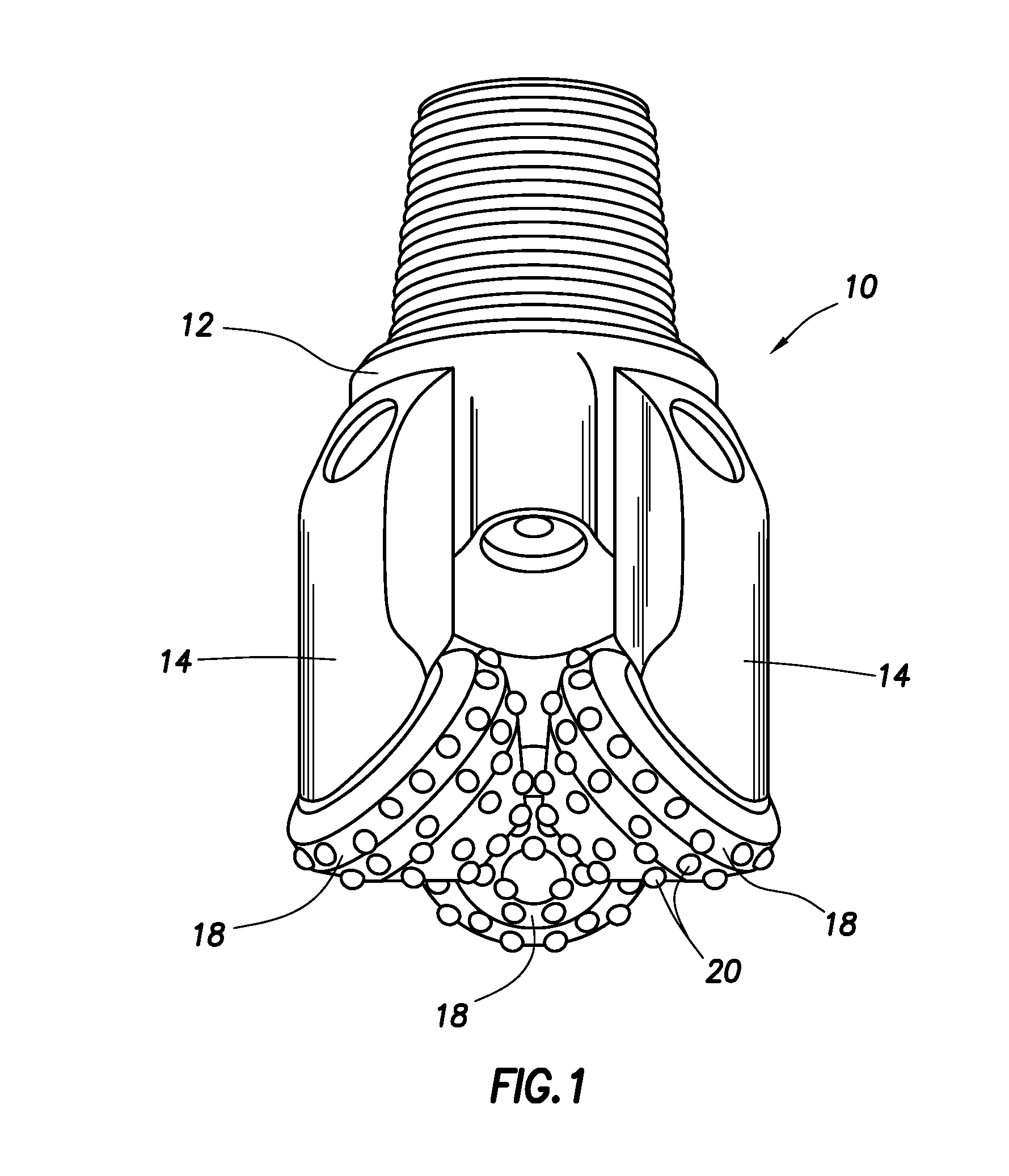

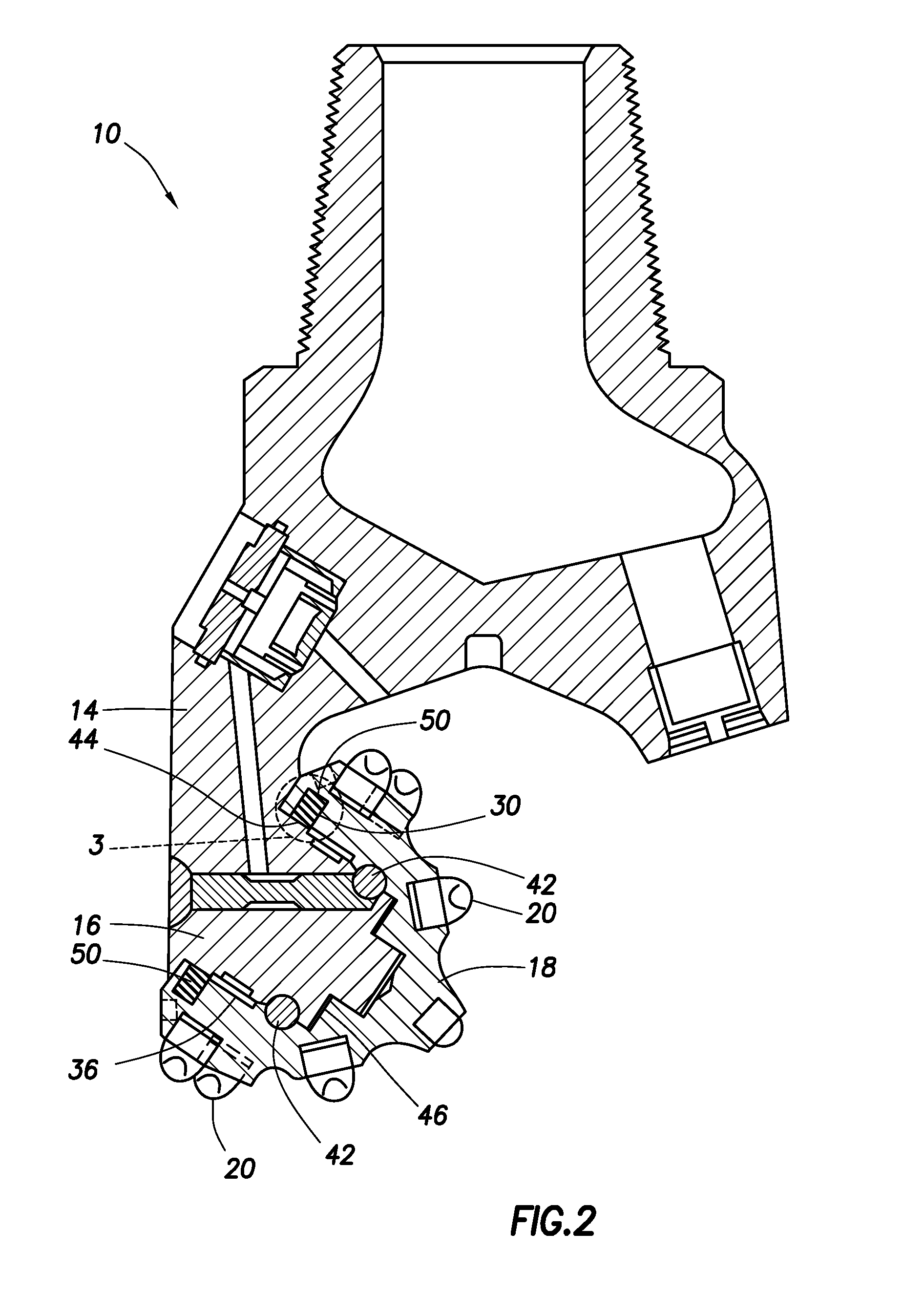

[0026]The present disclosure relates to a rolling cutter rock drill bit with a seal, such as a packing resistant type lip seal. The seal may be provided with an asymmetric configuration deformable within a seal groove of the drill bit under harsh conditions, such as downhole pressure (e.g., hydrostatic pressure, high hydrostatic pressure of greater than 1,000 kg / cm, and / or pressure from cuttings). The configuration may also be used to maintain a mud side lip of the seal in contact with a seal land of the seal groove. In some aspects, the seal may be provided with a spring to support the seal during operation, and / or a texturized pattern to trap lubricant and reduce running friction.

[0027]Referring now to FIG. 1, illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com