Rotary joint for single-point mooring system

A rotary joint and single-point mooring technology, applied in the direction of pipeline system, pipe/pipe joint/pipe fitting, adjustable connection, etc., can solve the problems of shortening life, increasing the gap between upper and lower pipe bodies, and crude oil leakage. , to prolong life and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

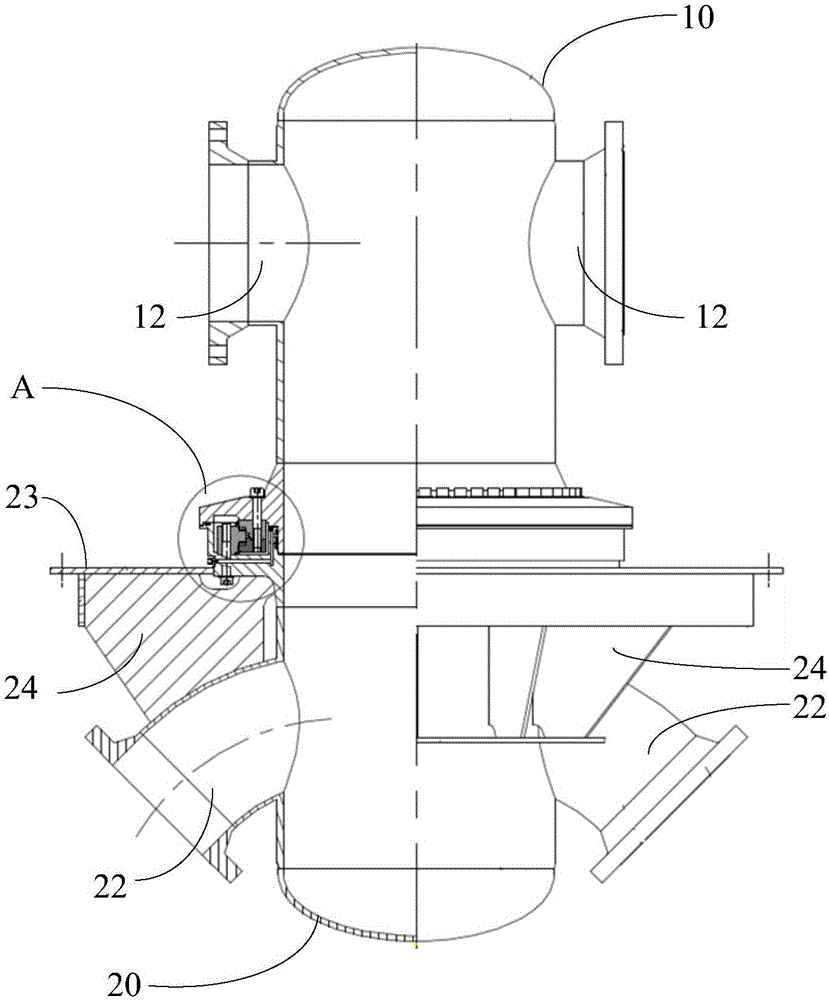

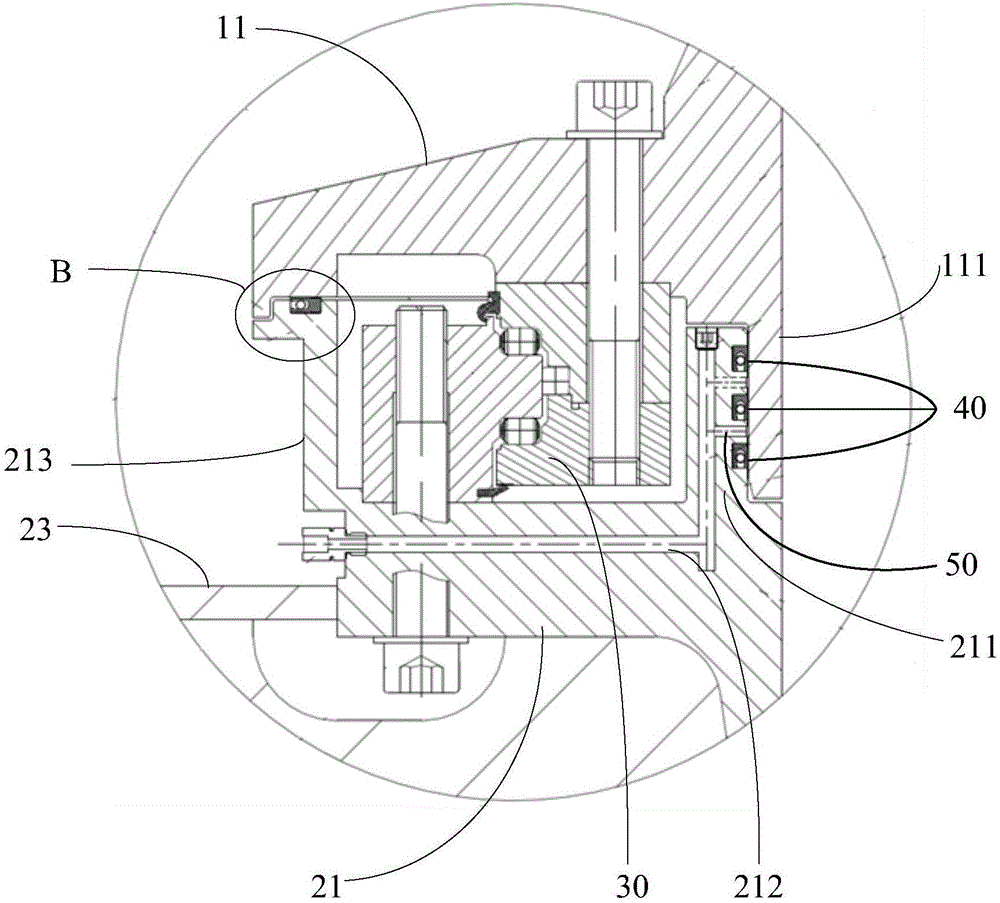

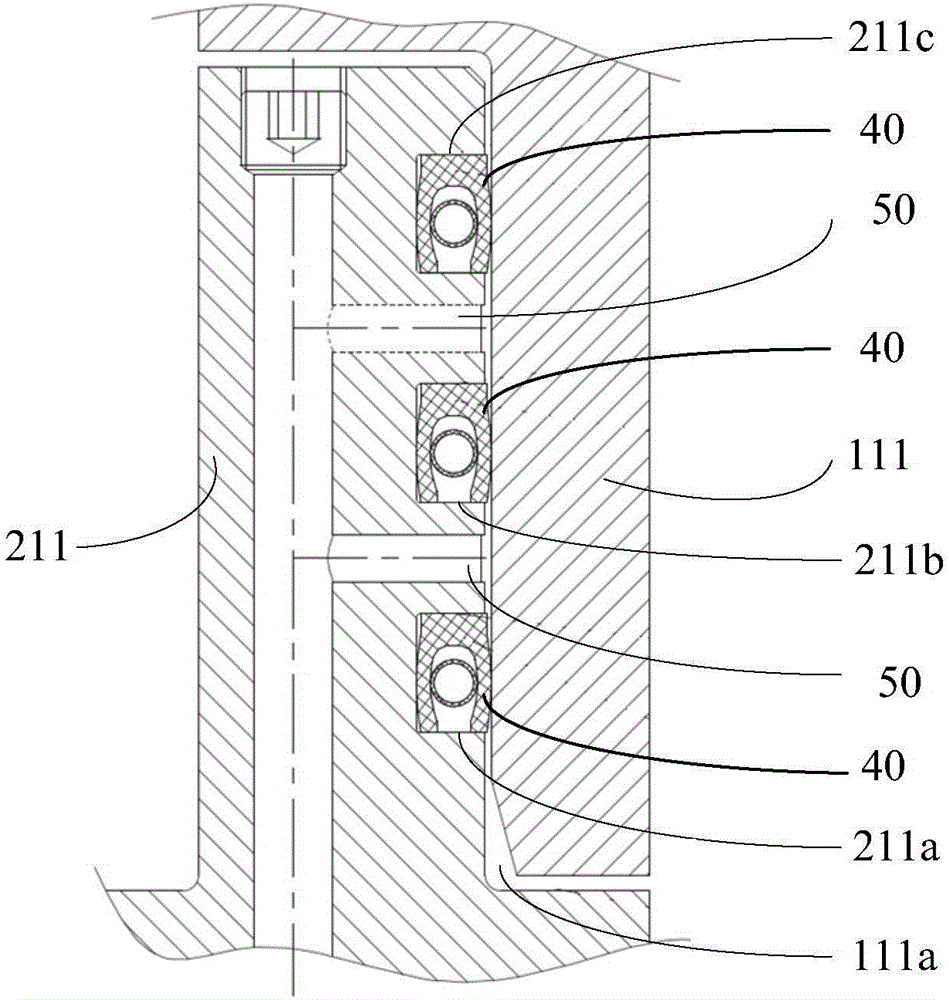

[0024] figure 1 is a structural schematic diagram of a rotary joint provided by an embodiment of the present invention, as shown in figure 1 As shown, the rotary joint includes a lower tubular body 20 and an upper tubular body 10 . figure 2 yes figure 1 The enlarged schematic diagram at A in the middle, such as figure 2 As shown, one end of the lower pipe body 20 is provided with a lower connecting flange 21, one end of the upper pipe body 10 is provided with an upper connecting flange 11, and the upper connecting flange 11 and the lower connecting flange 21 are rotatably butted through a slewing support 30. , the side of the lower connecting flange 21 opposite to the upper connecting flange 11 is provided with a first annular bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com