Vibration isolation buffer for resisting strong impact

A technology of buffers and vibration isolators, which is applied in the direction of inertial effect shock absorbers, non-rotational vibration suppression, etc., can solve the problems of large space, scattered reeds, and strong impact performance of vibration isolators without resonance peaks, etc., to achieve effective The effect of high cost, enhanced cushioning effect, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

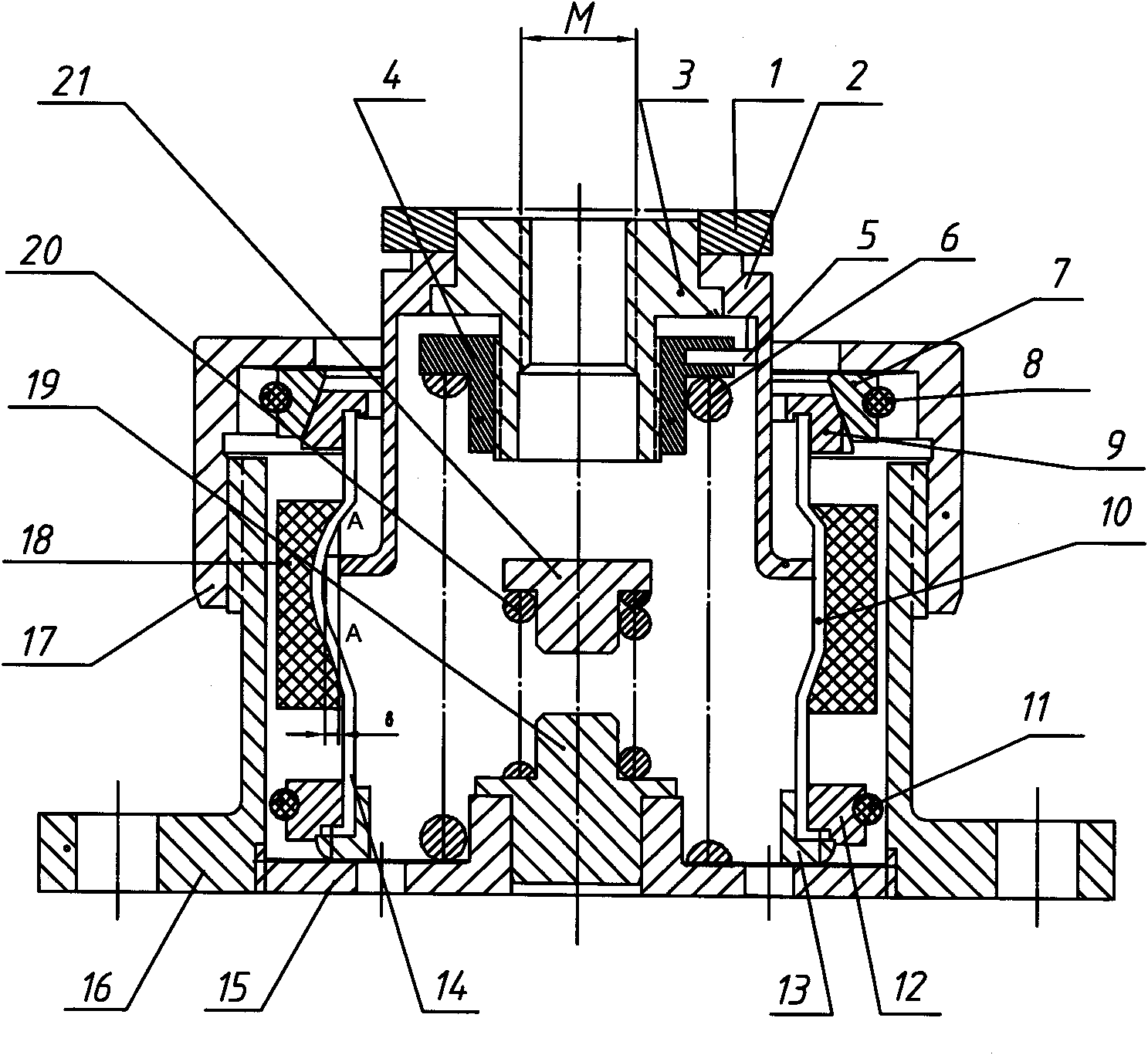

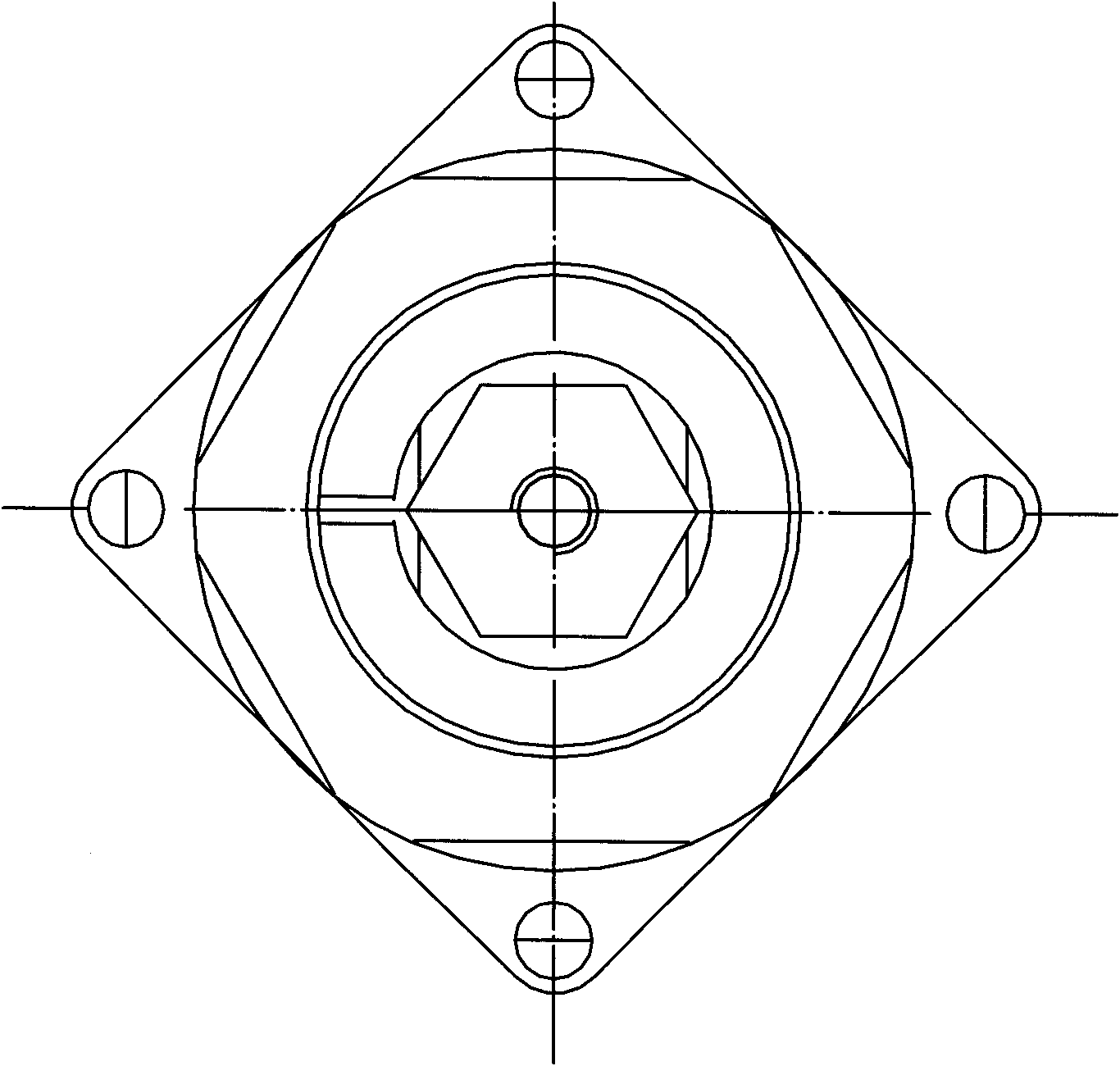

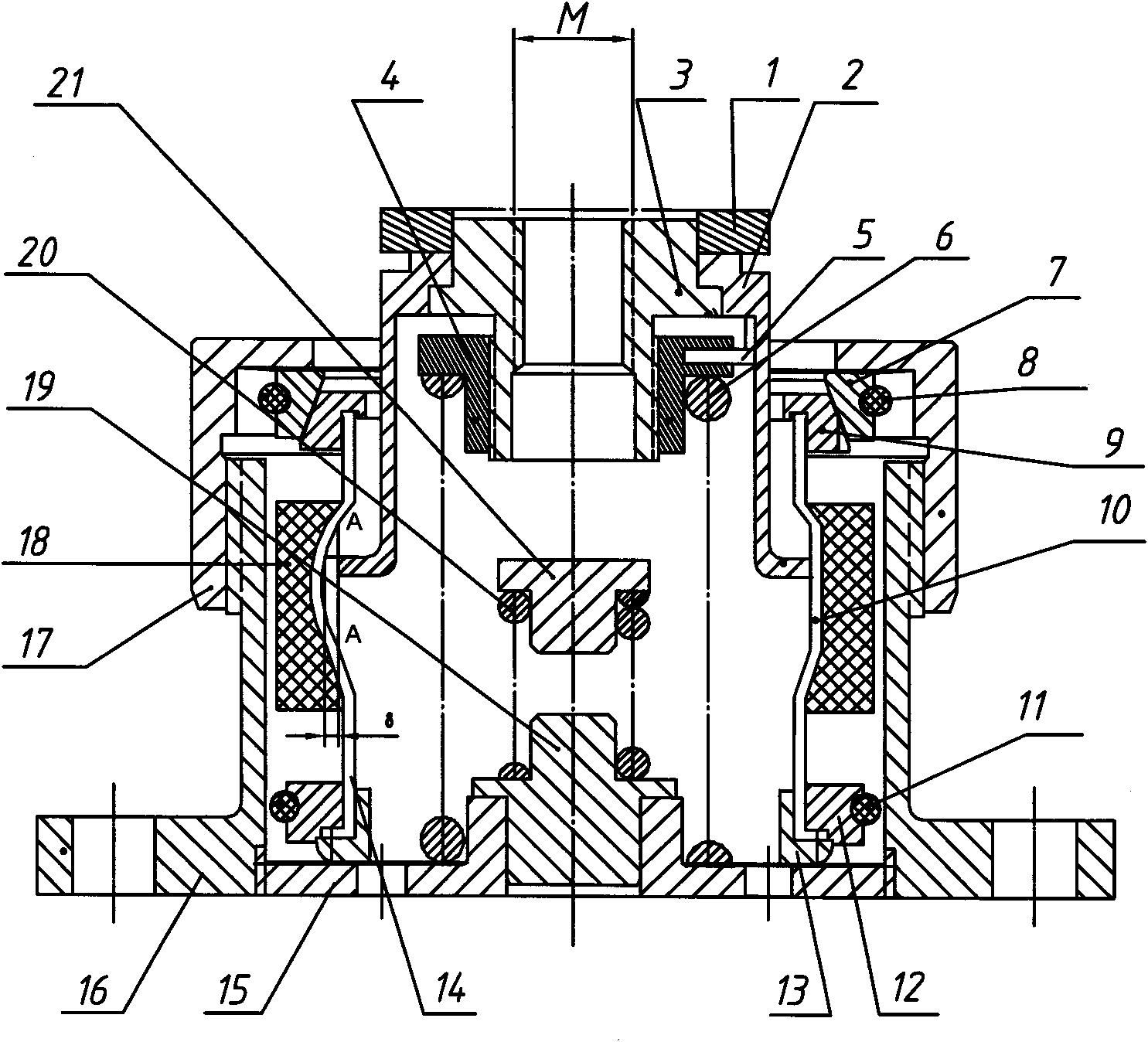

[0023] The present invention is an anti-strong shock vibration isolation buffer. The vibration isolator adopts a modular structure and is mainly composed of a main spring module, a damping buffer spring module and an installation and connection structure module; wherein,

[0024] The main spring module includes hexagon ring 1, adjusting bolt 3, adjusting nut 4, pin 5, main spring 6, damping buffer spring module includes cap 2, cone ring 7, first "O" ring 8, split ring 9, straight The reed 10, the second "O" ring 11, the lower ring 12, the pad cover 13, the bent reed 14, and the installation and connection structure module includes a bottom plate 15, a base 16, and an upper cover 17.

[0025] The base cover 16 is the main frame of the vibration isolator, the bottom plate 15 is fixed on the bottom of the inner circle of the base cover 16 through screw connections, and the upper cover 17 is fixed on the top of the base cover 16 through screw connections, thereby forming the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com