Quick automatic box sealer and box sealing method thereof

A sealing machine and automatic technology, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve problems such as low work efficiency, difficult maintenance, and difficulty in replacing tapes, and achieve the effect of improving sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

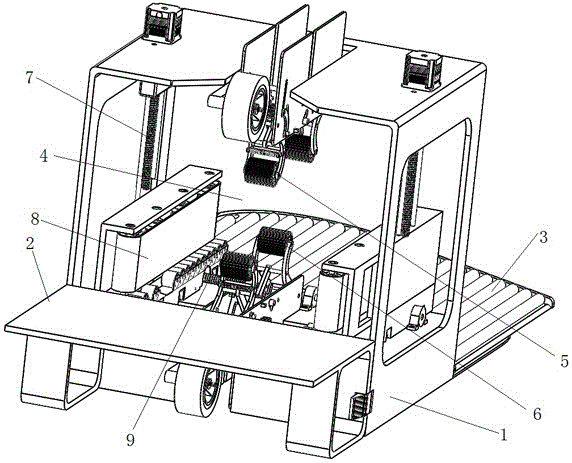

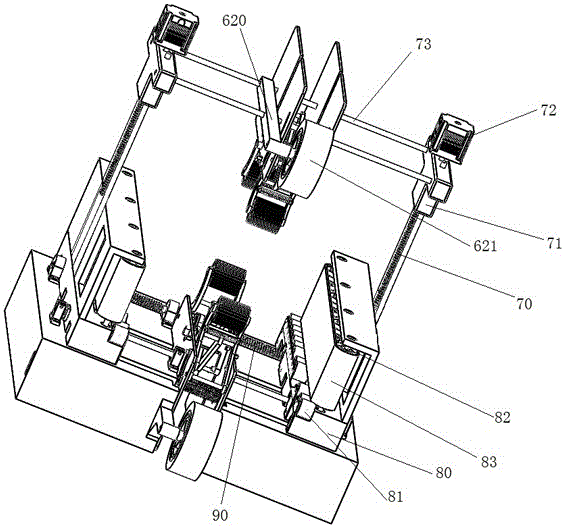

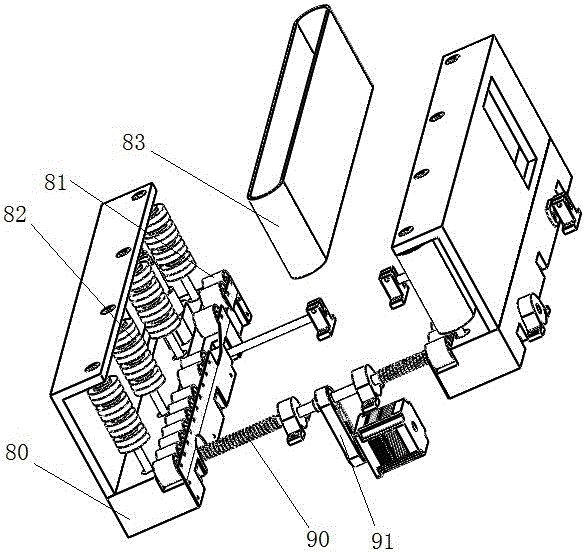

[0031] Such as Figure 1~6 As shown, a fast automatic box sealing machine of this embodiment includes a frame 1, a feed plate 2 and a discharge plate 3 joined to the front and rear ends of the frame 1, and the middle part of the frame 1 is from front to back A sealing channel 4 is provided through it, and an upper core 5 and a lower core 6 are arranged up and down in the middle of the sealing channel 4, and the upper core 5 and the lower core 6 are alternately arranged front and rear; the upper core 5 A height adjustment mechanism is arranged on the frame 1, and the left and right sides of the lower core 6 are respectively provided with a belt transmission mechanism 8 along the sealing passage 4, and two belt transmission mechanisms 8 are relatively arranged on the lower core 6 The two sides of the two-way screw mechanism are synchronously dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com