Electric direct reading test sealing checking tool

A tool and direct-reading technology, which is applied in construction and other fields, can solve the problems of large test errors, low efficiency, and poor real-time performance, and achieve the effects of safe and reliable setting and unsealing, high success rate of sealing inspection, and high efficiency of sealing inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

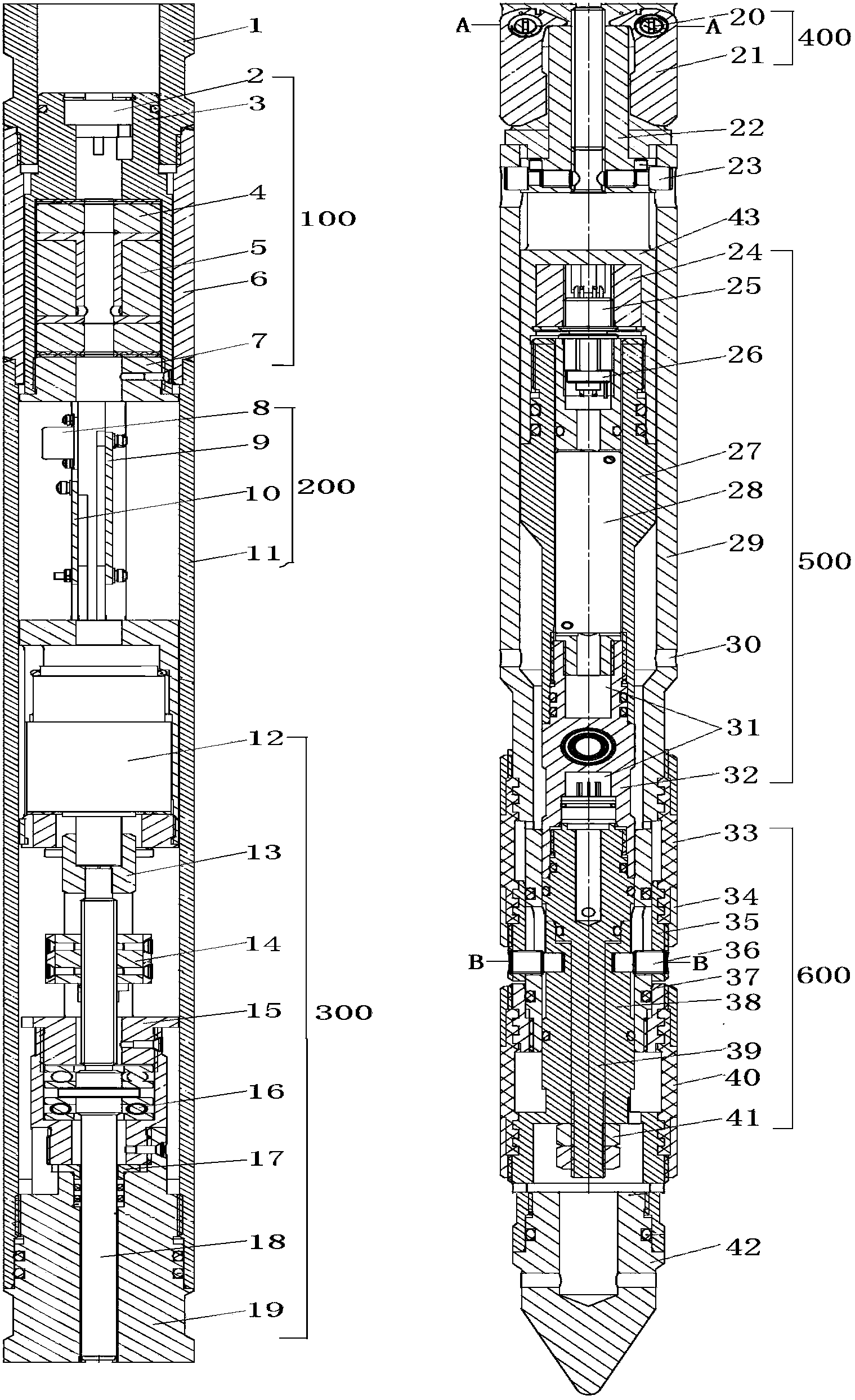

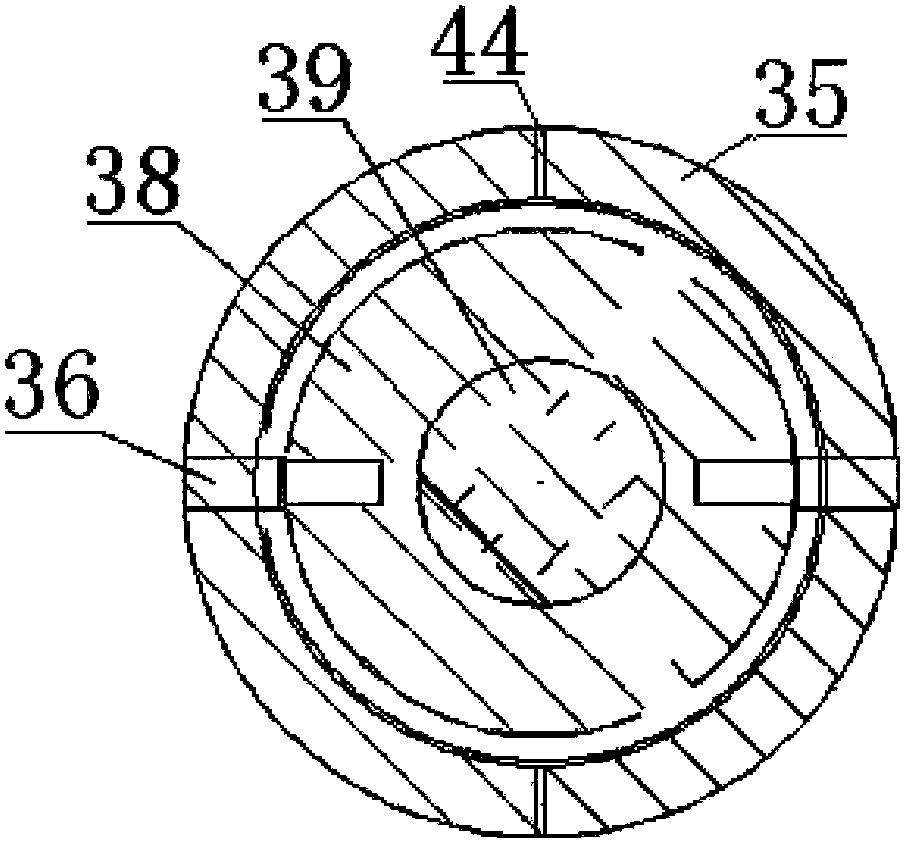

[0021] The electric direct-reading testing and sealing tool is composed of an upper joint 1, a magnetic positioning device 100, an integrated control device 200, a power transmission mechanism 300, a positioning mechanism 400, a pressure data acquisition device 500 and a testing sealing device 600:

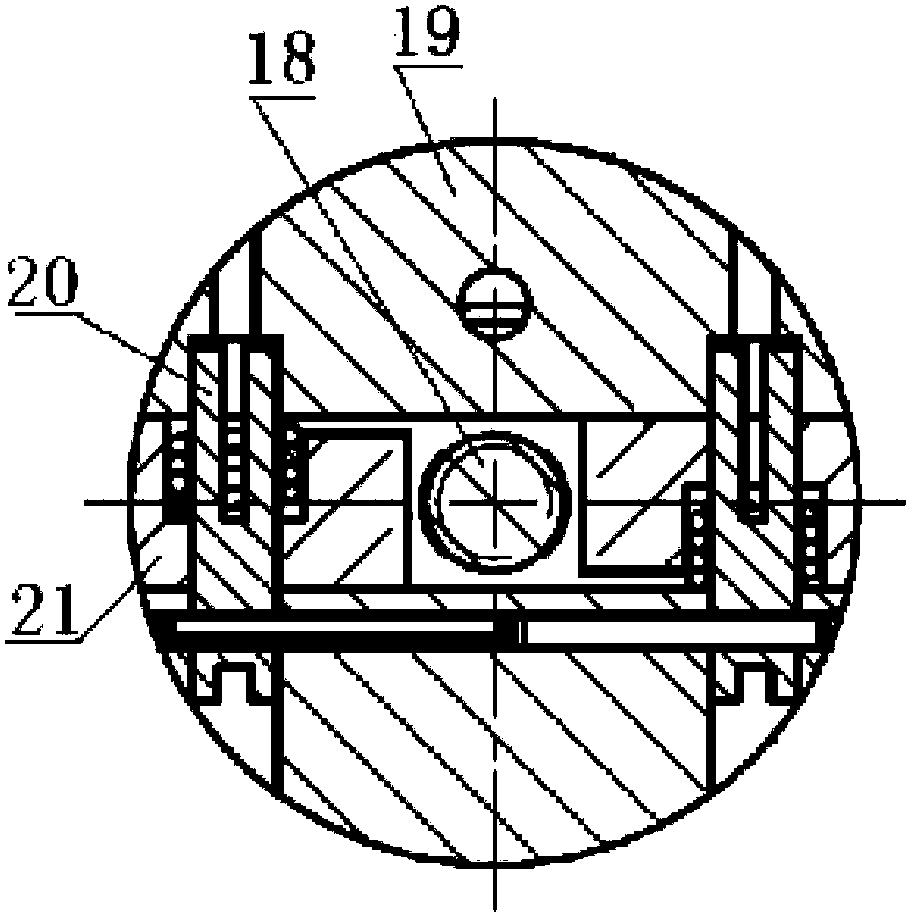

[0022] The outer thread of the sheath 3 of the magnetic positioning device 100 is connected to the upper joint 1, the upper part of the center hole of the sheath 3 is provided with a socket 2, and the inner and lower part of the center hole is provided with a coil assembly 5 and the magnetic steel 4 at both ends; the outer wall of the lower part of the upper joint 1 It is threadedly connected with the connection sleeve 6, and the bottom of the connection sleeve 6 is externally threaded to connect the casing 11.

[0023] The integrated control device 200 is set in the casing 11, the control frame 7 is connected to the lower end of the center hole of the sheath 3 by screws, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com