Advanced pre-grouting construction method using HSC grouting materials

A construction method and technology of grouting materials, which are applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve problems such as construction safety, impact on construction progress, unsatisfactory grouting effect, etc., and achieve water inrush problems and easy setting time Control and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The advanced pre-grouting construction method using HSC grouting material provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

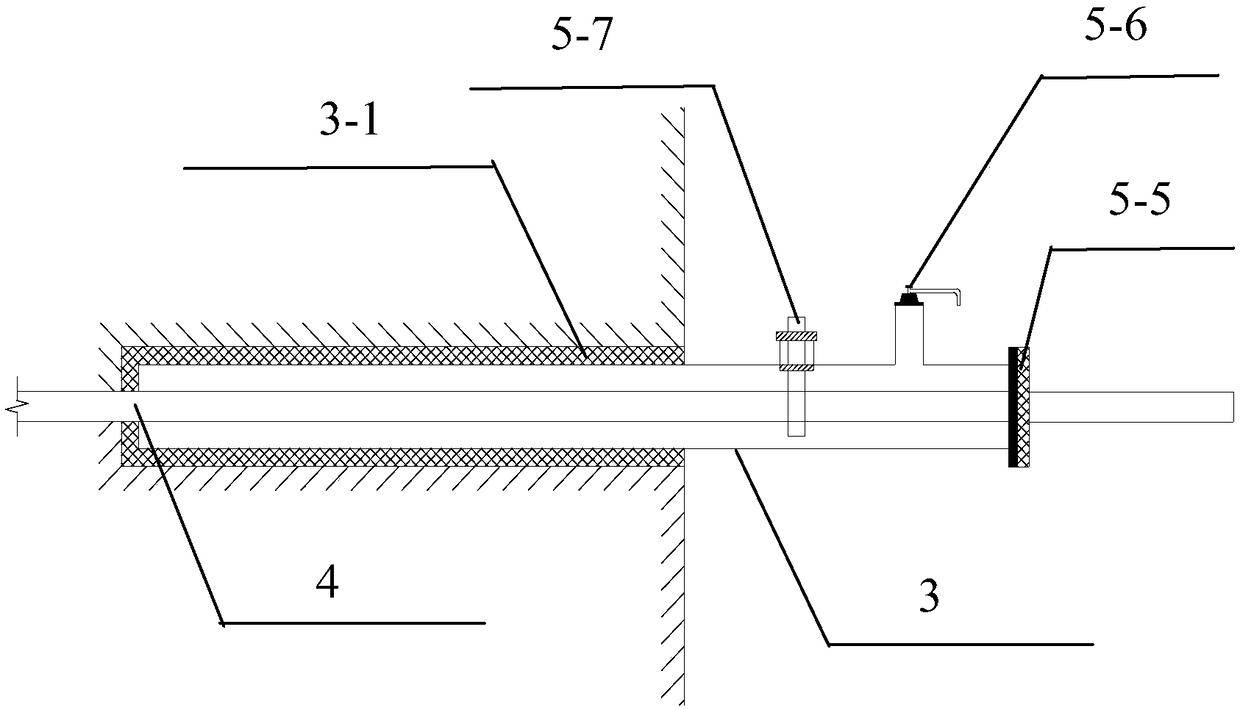

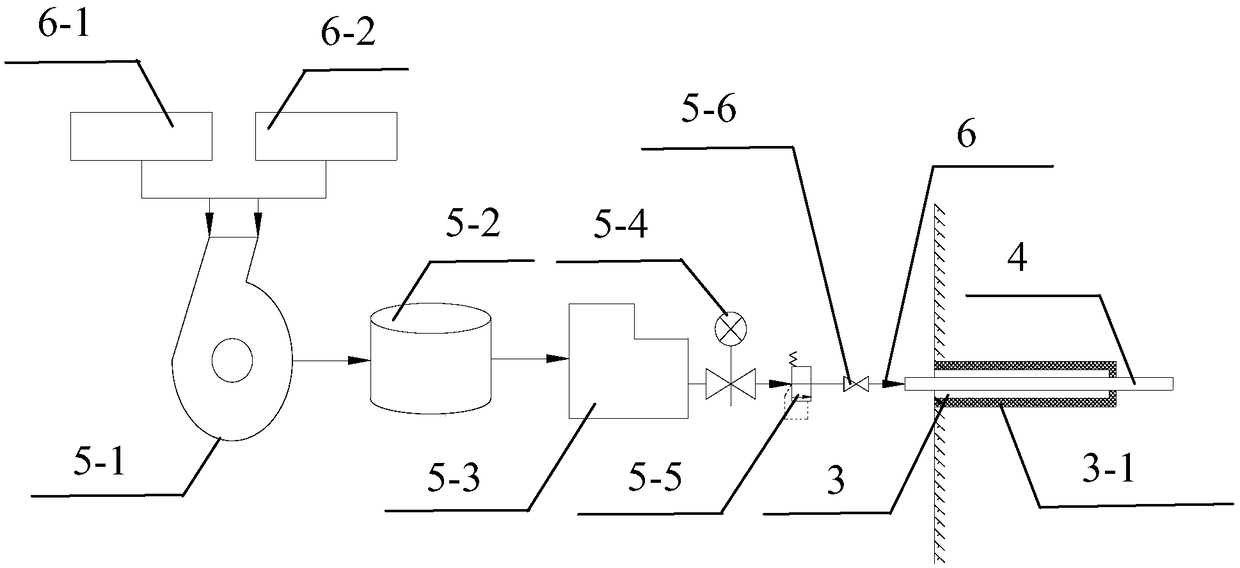

[0026] like figure 1 — Figure 4 As shown, the advanced pre-grouting construction method that adopts HSC grouting material provided by the invention comprises the following steps carried out in order:

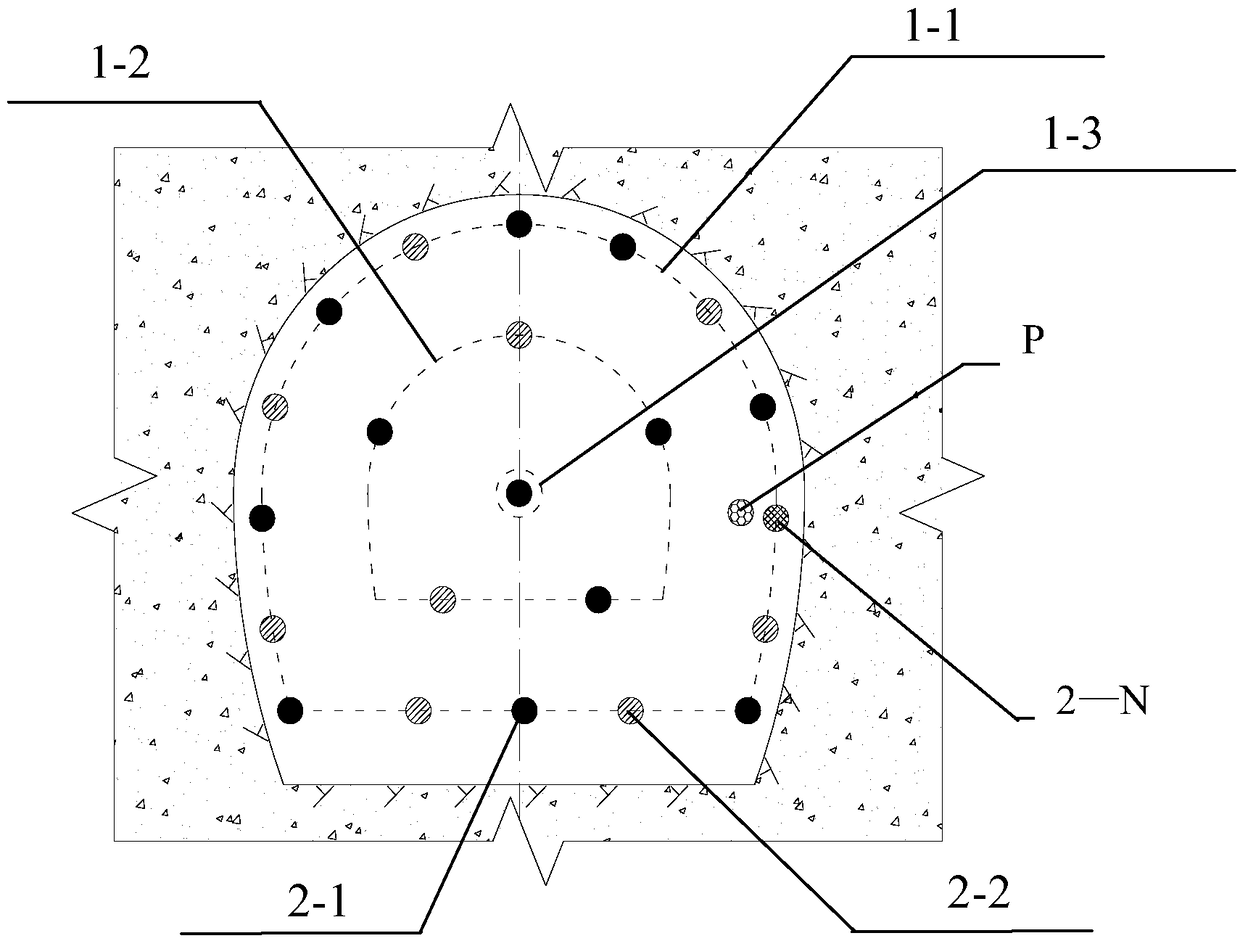

[0027] 1) When encountering water inrush caused by confined water when crossing geological faults or rich in groundwater during the construction of underground excavation tunnels, firstly, the construction personnel shall work from the outside to the inside on the tunnel surface within the outline of the underground excavation tunnel. Mark the multi-circle drilling rings 1-1-1-N. The position and quantity of these drilling rings shall be based on the section size of the tunnel excavated, the geological conditions of the surrounding rock, the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com