Patents

Literature

50results about How to "Improve wrapping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

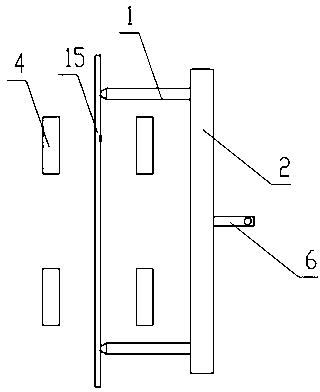

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

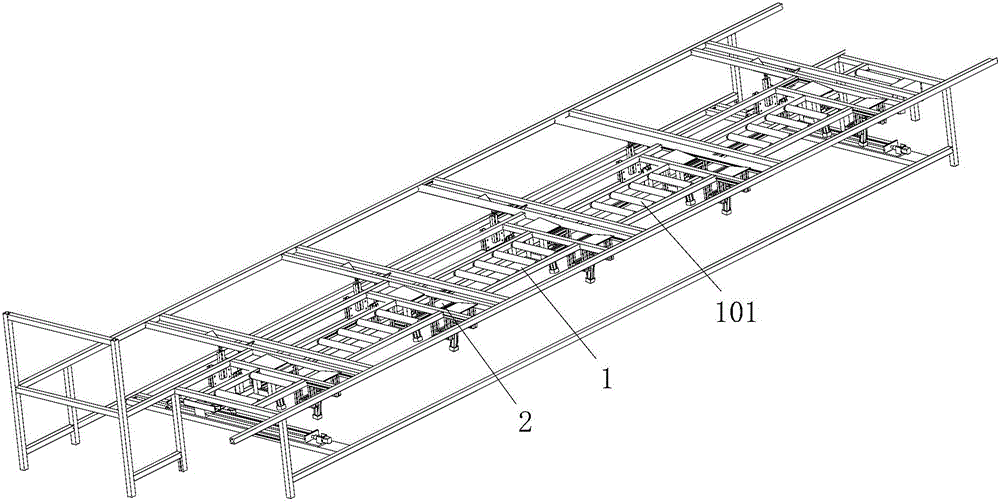

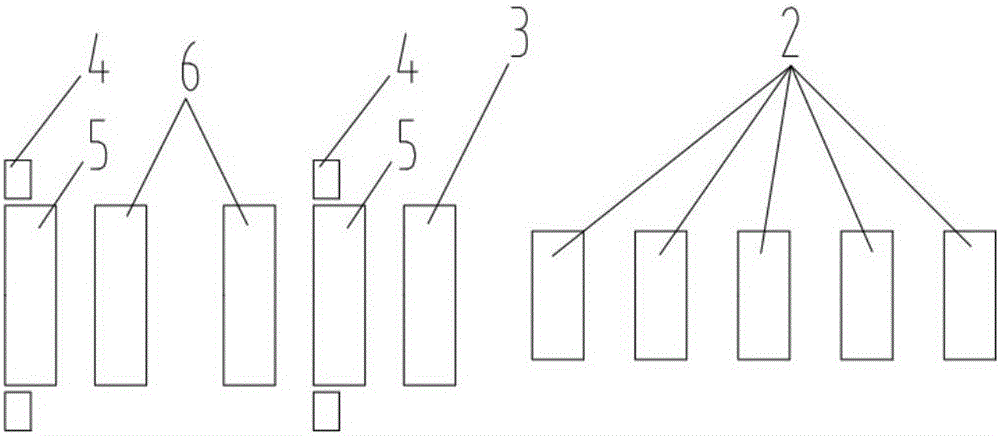

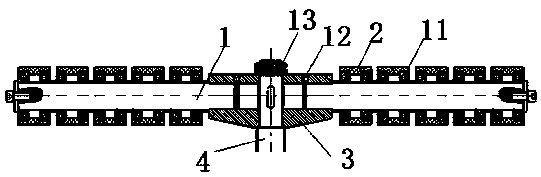

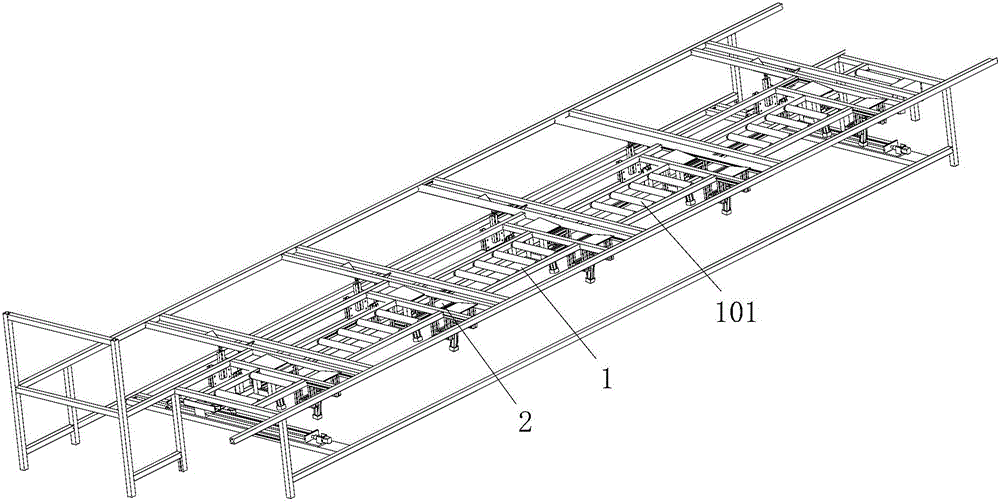

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

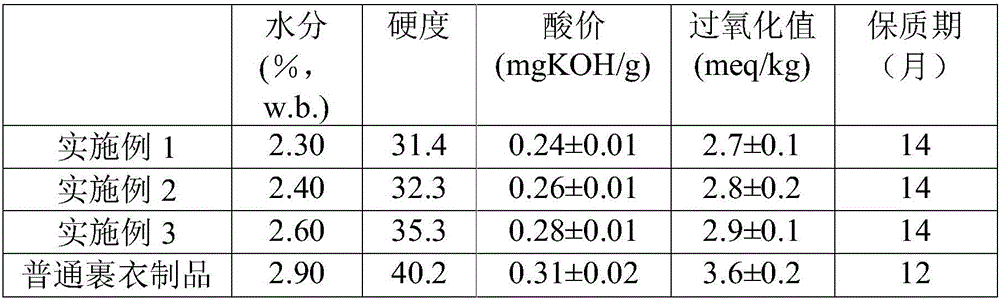

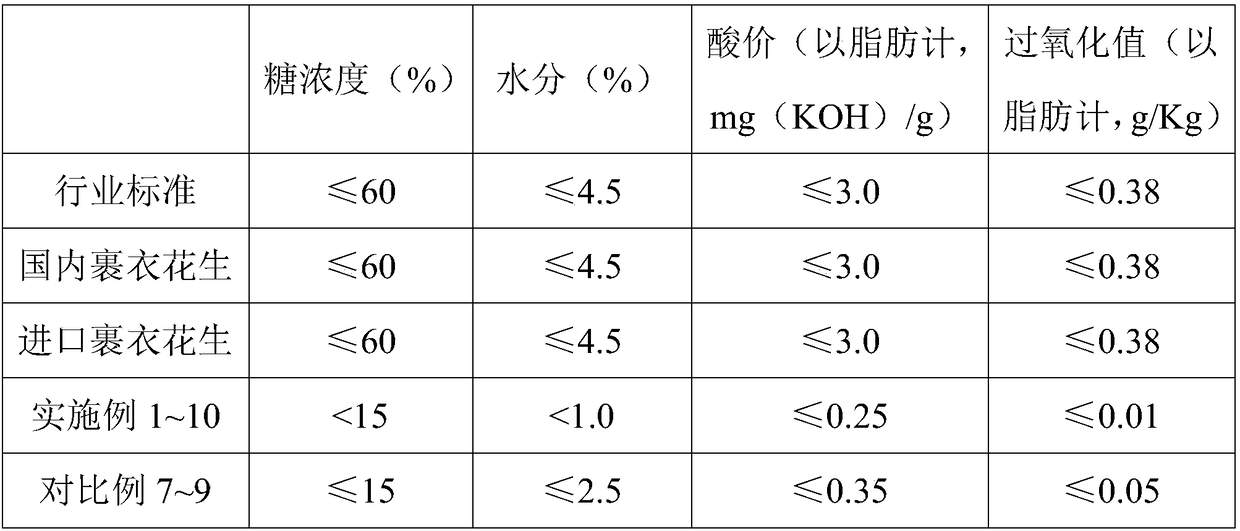

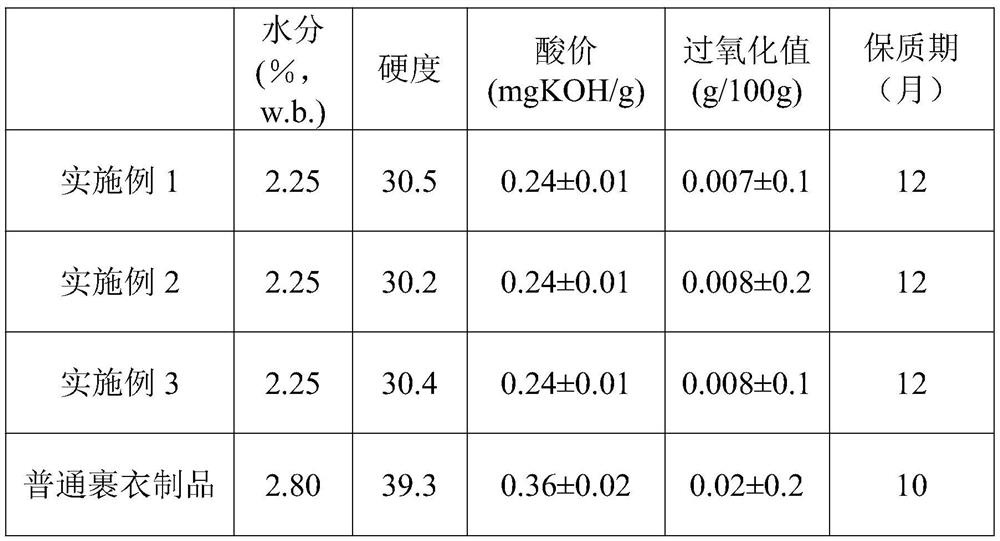

Processing technology of butter honey nuts

InactiveCN106174328AImprove uniformityImprove texture firmnessSugar food ingredientsFood coatingAdhesive materialsNutrient

The present invention discloses a processing technology of butter honey nuts. The processing technology specifically consists of the following steps: (1) wrapping liquid preparing; (2) pre-powder and post-powder preparing; (3) spraying and coating; (4) oil-frying and residue removing; (5) oil blowing; (6) cooling and beating; (7) butter spraying; and (8) nut finished product wrapping. The processing technology enriches the fragrant and sweet mouthfeel of the coated butter honey, effectively improves the uniformity of the powder wrapping, improves the texture tightness of the coating, and effectively prevents the falling of the coating, so that the product appearances, physicochemical indicators and other various performance indicators of the butter honey nuts are more stable. The processing technology effectively prevents the losses of the nuts, honey, butter and other nutrients, the low-temperature oil-frying reduces the destruction of the product nutrients, and the processing technology improves the nutritional values of the products, enables the coating to be translucent in appearances and uniform in color and luster, reduces the defective percentage to be 20-30%, improves the yields, and can well separate the adhesive materials. The oil blowing technology is conducive to the rapid drying of the surfaces of the butter honey nuts and prolongs the shelf life of the products.

Owner:青岛果果爸爸食品有限公司

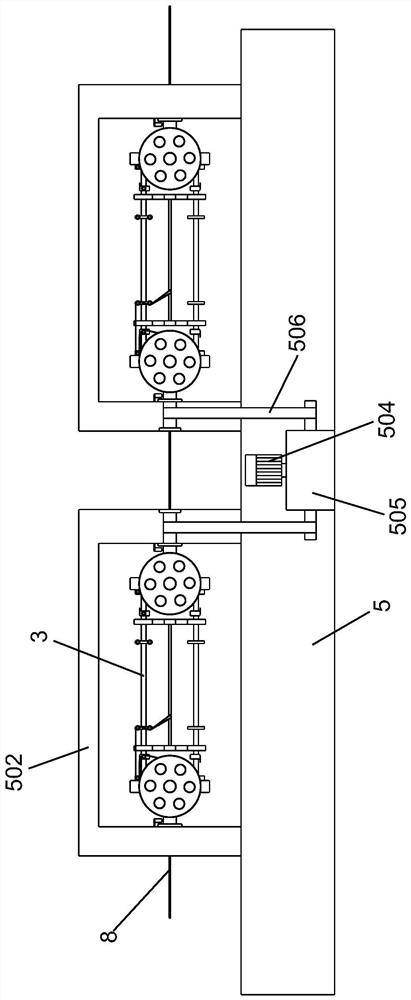

Wrapping machine

InactiveCN105711877ACompact structureOptimize layoutWrappingWrapper twisting/gatheringButt jointSmall footprint

The invention discloses a wrapping machine which comprises a lower-layer box sending assembly, a middle-layer film sending assembly, an upper-layer box sending assembly and an upper-layer film sealing assembly. The lower-layer box sending assembly, the middle-layer film sending assembly and the upper-layer box sending assembly are in butt joint in sequence from bottom to top. The upper-layer box sending assembly and the upper-layer film sealing assembly are in horizontal butt joint. The wrapping machine has the beneficial effects of being simple and compact in structure, reasonable in layout, small in occupied area and high in wrapping efficiency.

Owner:TRUKING TECH LTD

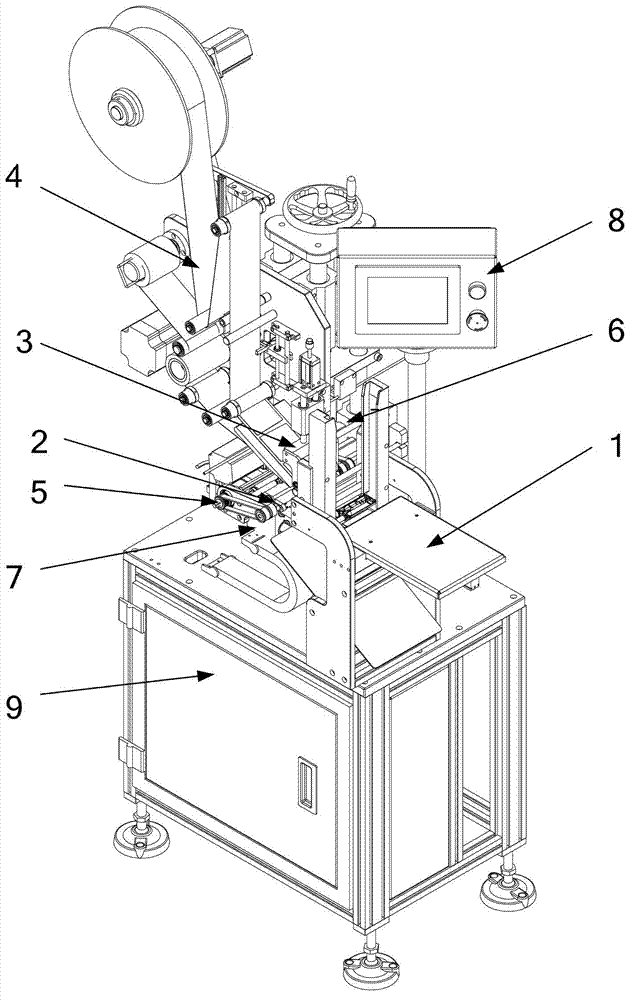

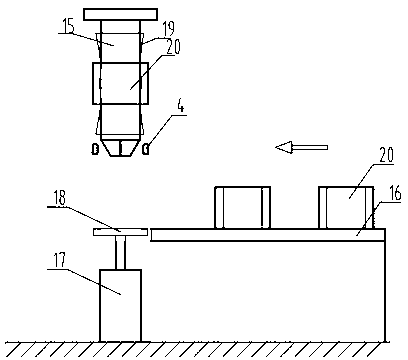

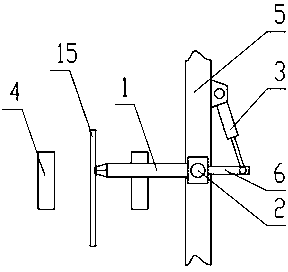

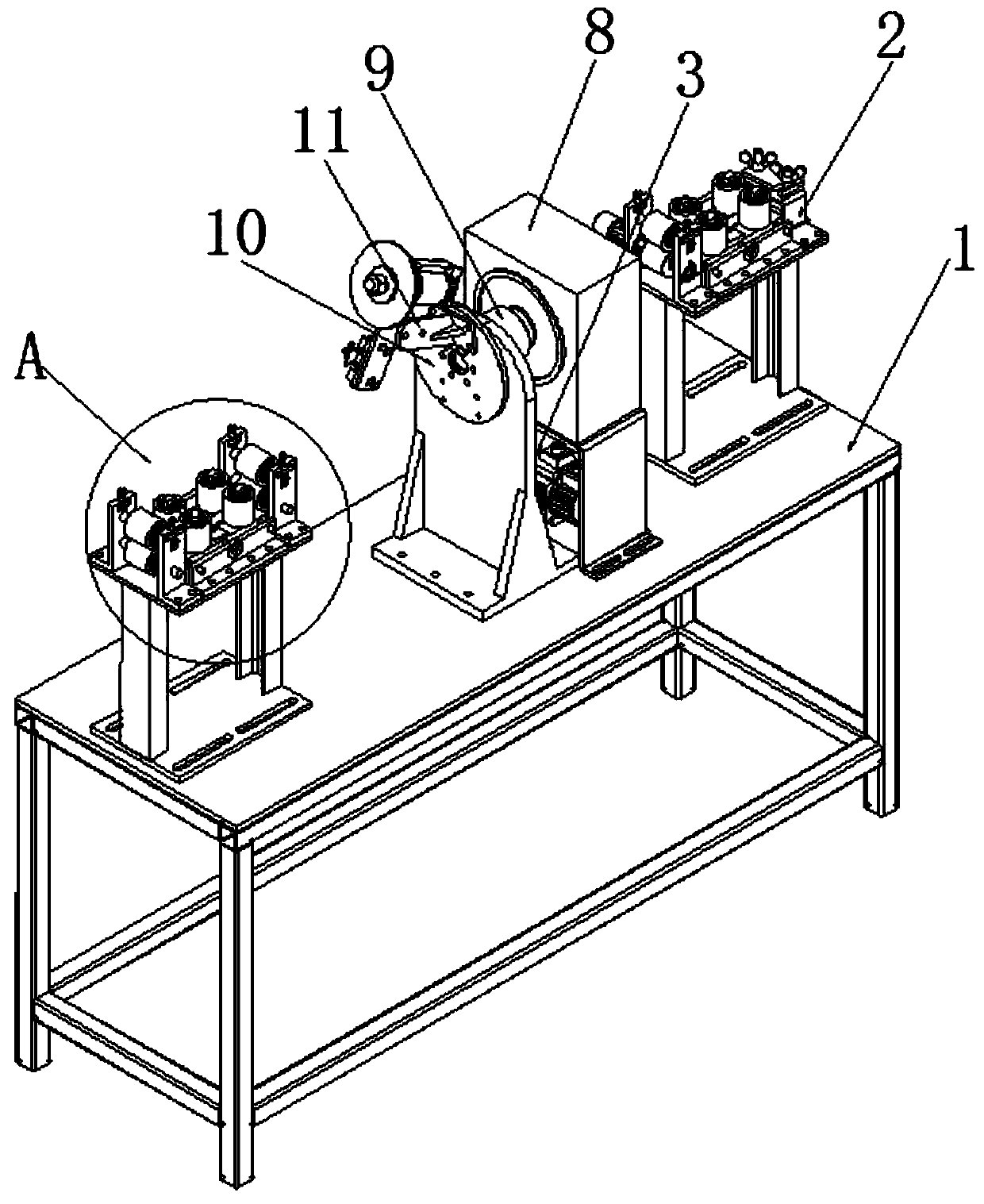

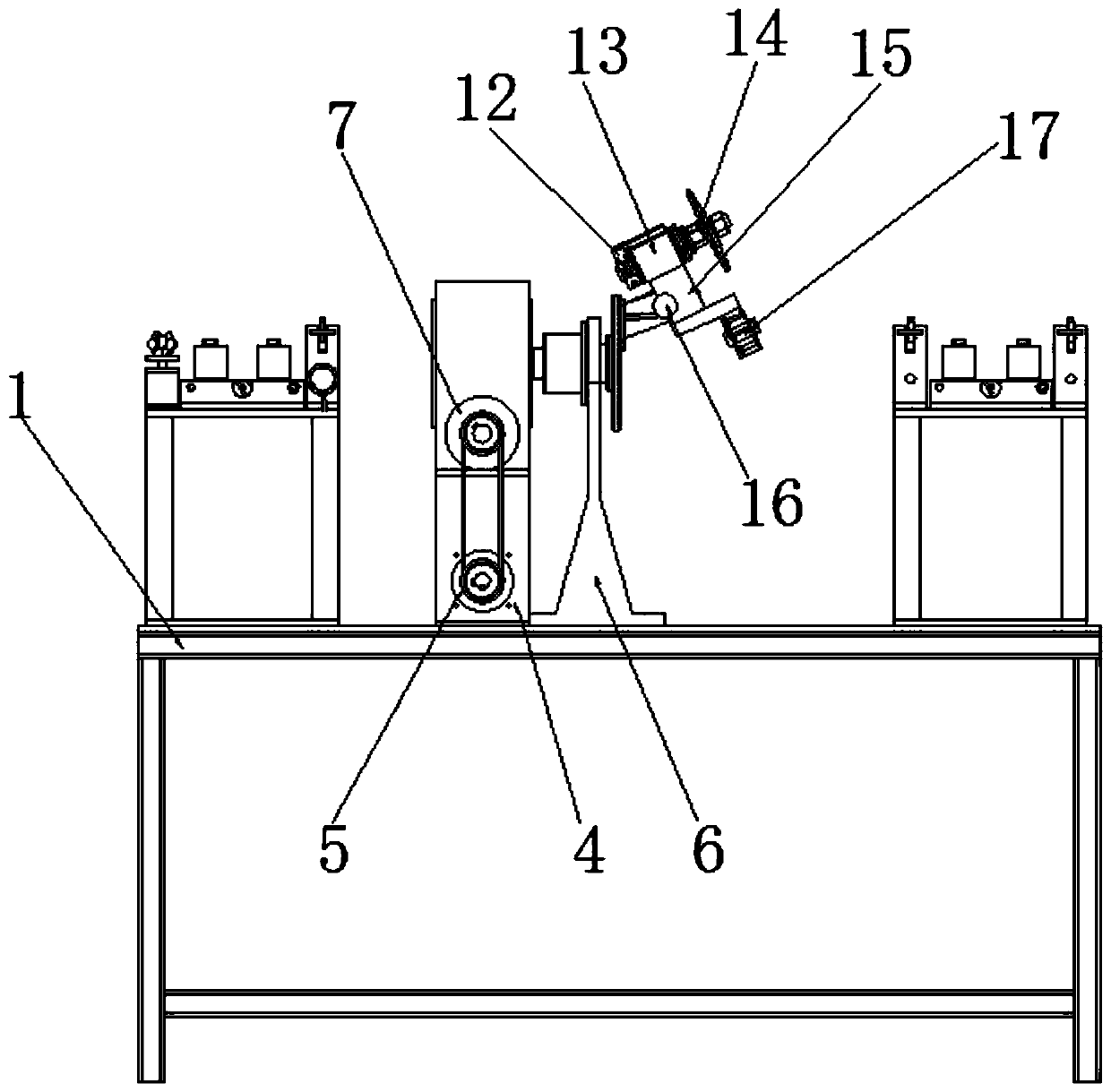

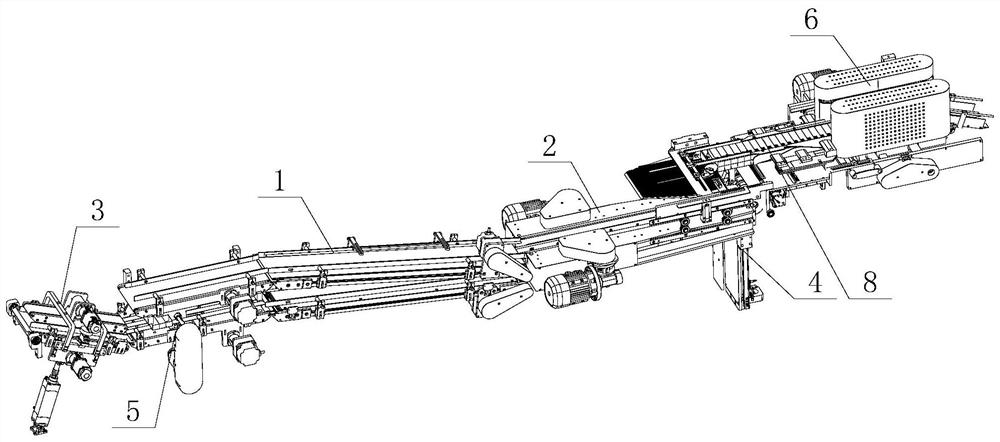

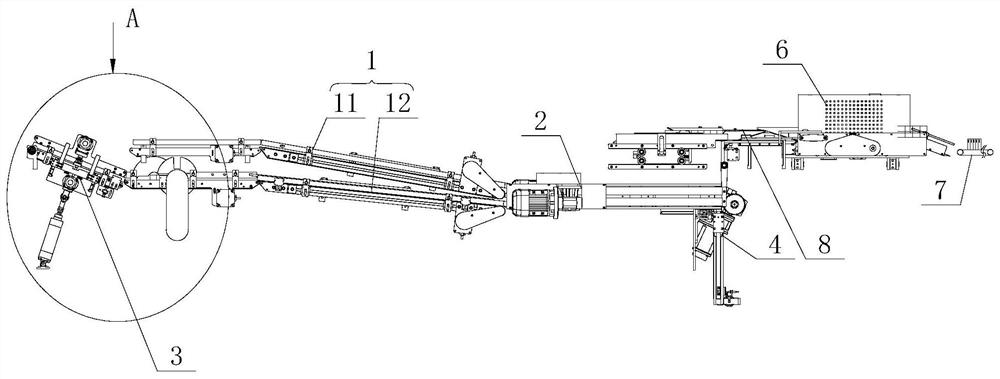

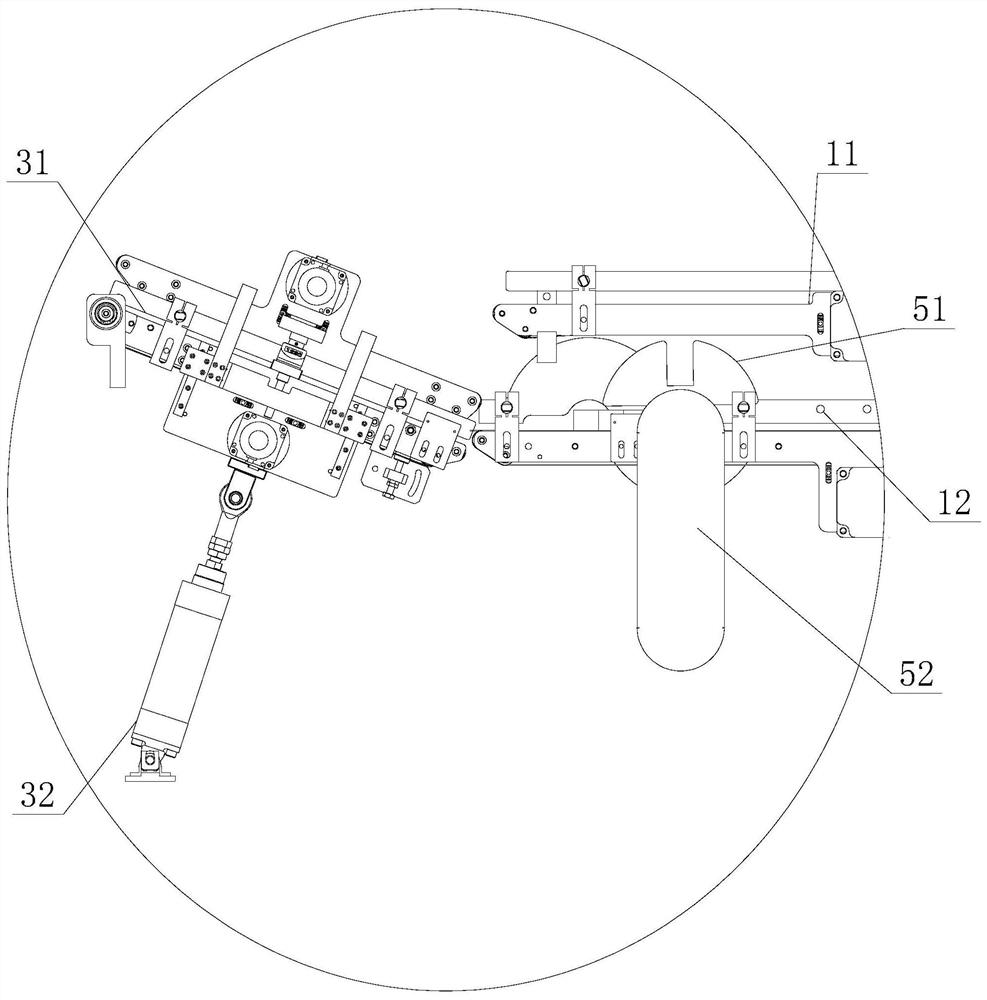

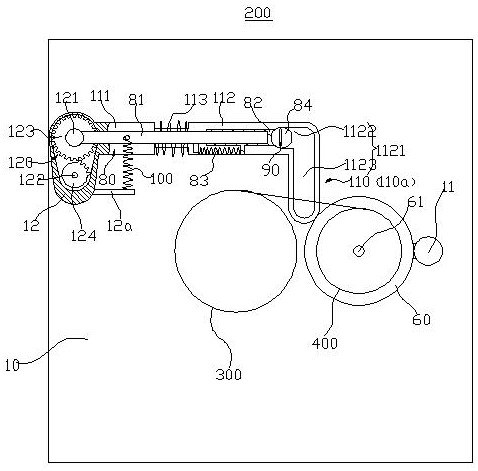

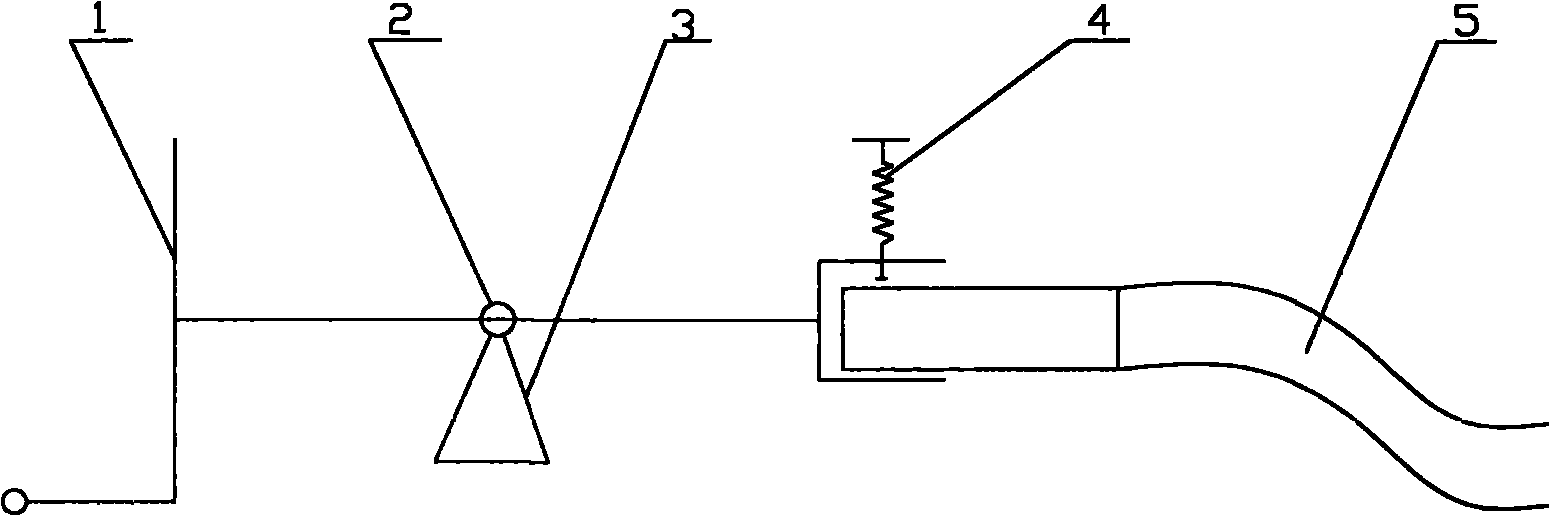

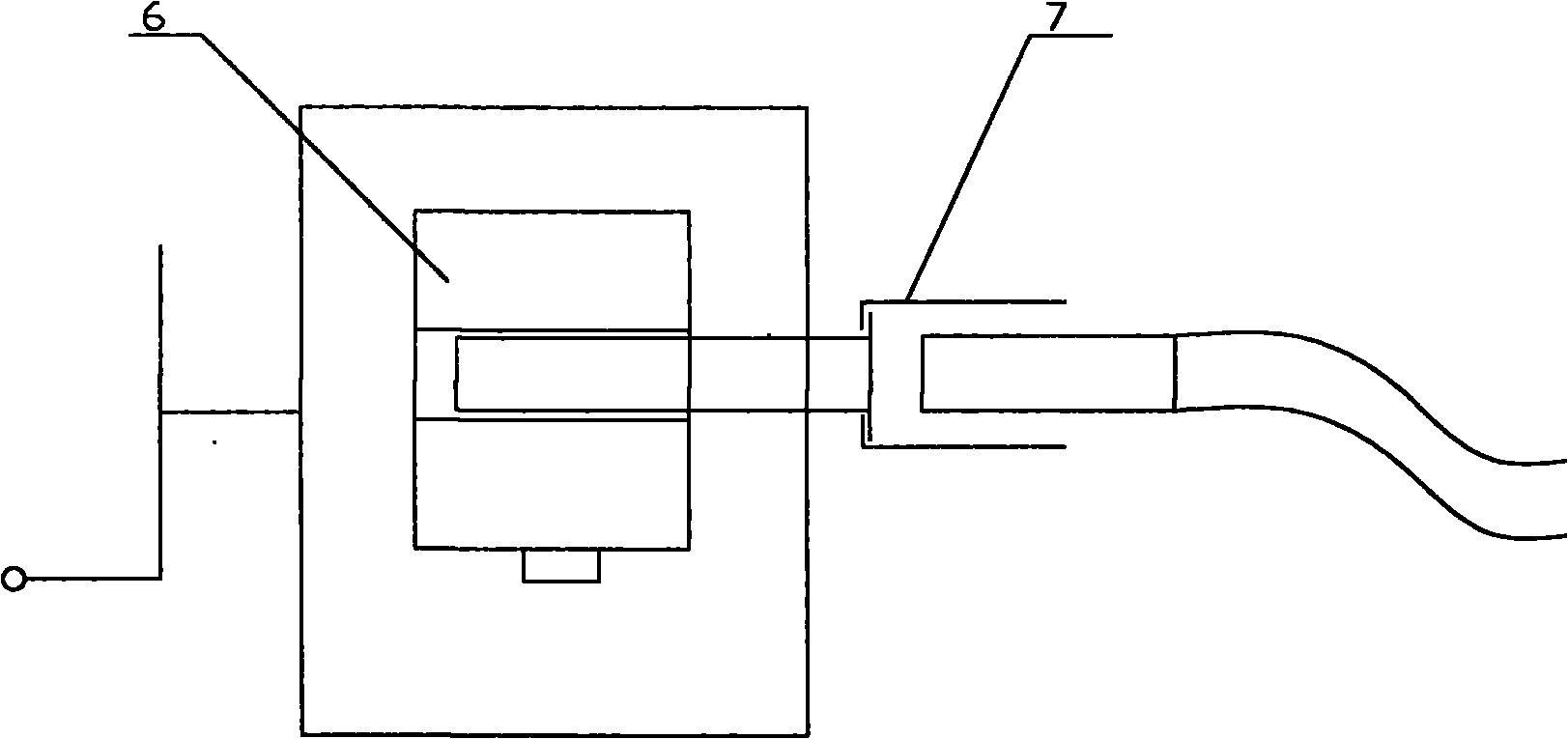

Paper wrapping machine and paper wrapping method

ActiveCN103043237AEliminate flatnessEliminates easy creasesWrapping with article rotationPulp and paper industryNumerical control system

The invention provides a paper wrapping machine which comprises a feeding device, a clamping device, a pressing device, a wrapping paper supply device, a rotating device, a lifting device, a transferring device and a numerical control system. The feeding device, the clamping device, the pressing device, the wrapping paper supply device, the rotating device, the lifting device and the transferring device are connected with the numerical control system. The feeding device, the clamping device, the pressing device, the wrapping paper supply device, the rotating device, the lifting device, the transferring device and the numerical control system are installed on a machine frame. A paper wrapping method is further provided. The paper wrapping machine and the paper wrapping method can effectively improve paper wrapping efficiency of a product, reduce labor intensity of workers, eliminate the defect that wrapping paper is uneven and easy to winkle and has bubbles and the like, reduce reject ratio of the product, and improve quality of the product.

Owner:XINHAI TECH GRP CO LTD

Automatic yarn package device and automatic yarn package process for mucilage glue yarn cake with long yarns

The invention discloses an automatic yarn package device for a mucilage glue yarn cake with long yarns. The automatic yarn package device for the mucilage glue yarn cake with the long yarns comprises a yarn cake conveying device and a yarn cake jacking device, wherein the yarn cake jacking device comprises a pushing plate which moves up and down. The automobile yarn package device for the mucilage glue yarn cake with the long yarns further comprises a bagging device and a packaging device. The yarn jacking device is placed at one end of the yarn cake conveying device, the packaging device is placed on the pushing plate, and the bagging device is placed between the pushing plate and the packaging device. The automatic yarn package device for the mucilage glue yarn cake with the long yarns can automatically package the yarns of the yarn cake which is automatically, continuously ad reliably produced by a spinning machine, manual operation is greatly reduced, labor intensity and labor cost are reduced, product quality and work efficiency are improved, and automation and continuity of yarn packaging of the yarn cake can be well achieved.

Owner:YIBIN HIEST FIBER +2

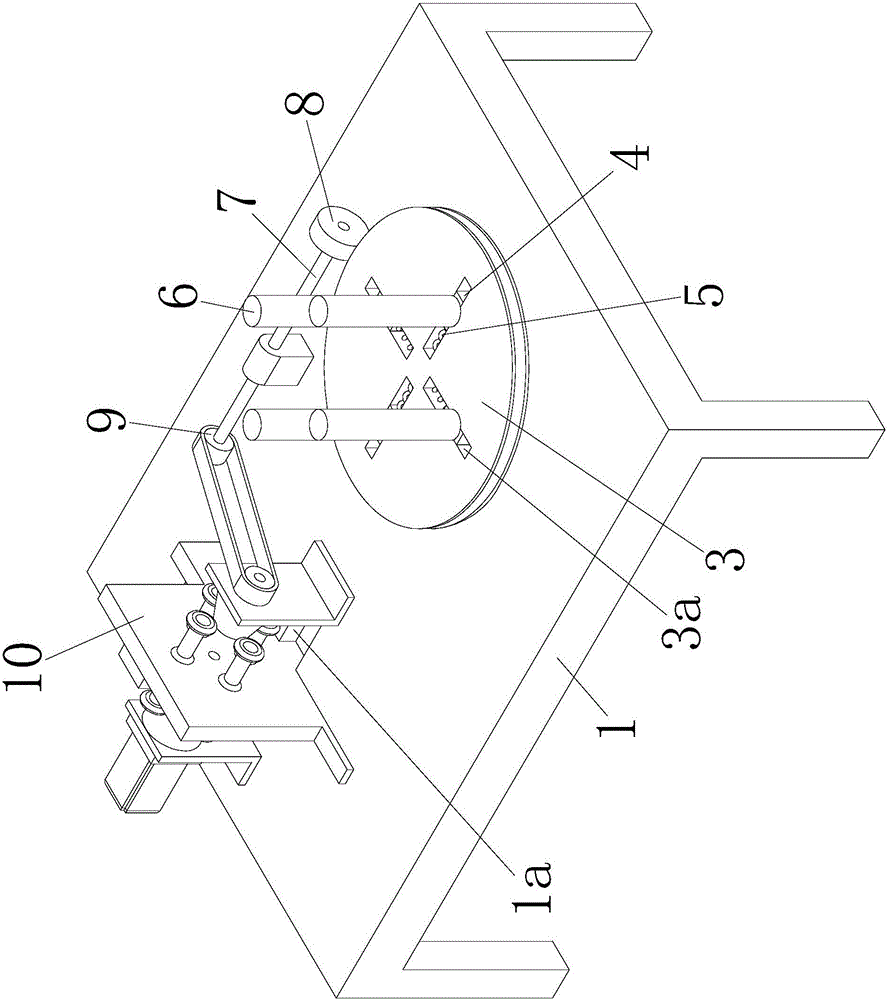

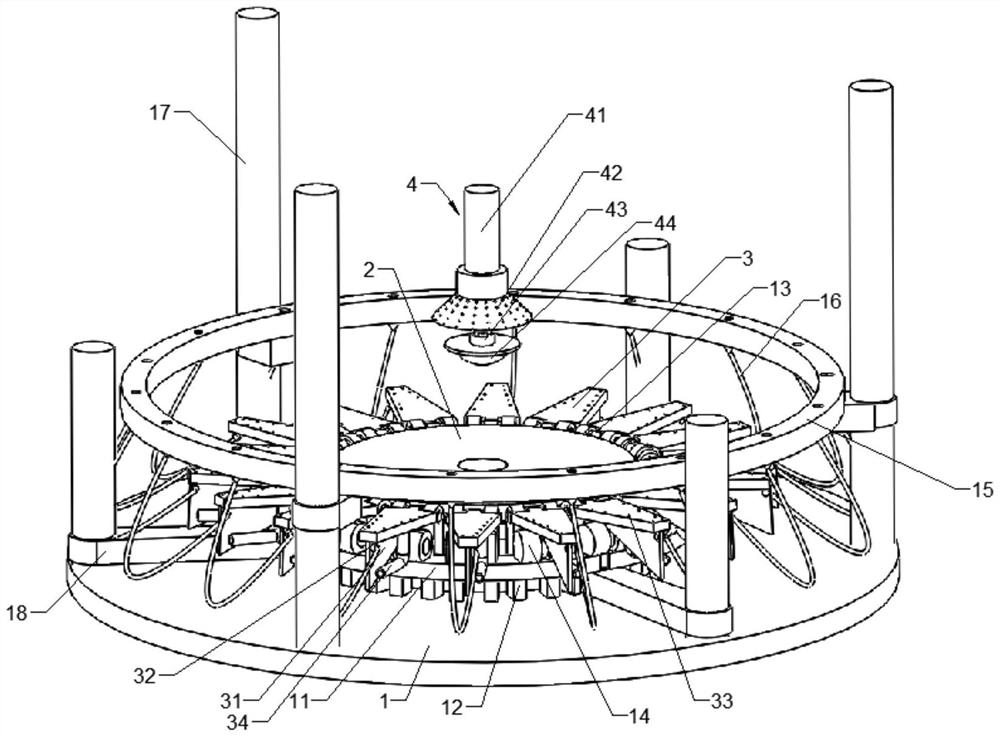

Regular hexagon packing device for Pu'er tea cake

The invention relates to a regular hexagon packing device for Pu'er tea cake, and belongs to the technical field of agricultural processing. The regular hexagon packing device comprises a folding device, a pneumatic compression device, a folding plate transmission device, a rotating table transmission device and a labeling device, wherein the folding device comprises folding plates and a rotating table. When tissue paper and the tea cake are sent to an assigned position of a workbench, certain positions of the tissue paper and the tea cake are folded with the folding plates, then the rotating table drives the tea cake and the tissue paper to rotate synchronously to change folding positions, and the whole folding process is fulfilled in such manner. The regular hexagon packing device has the advantages that a regular hexagon folding process can be fulfilled effectively; the manual tea cake packing technology can be replaced; the packing efficiency of the tea cake is improved to a great extent; the labor cost of personnel is reduced; the whole mechanical device is simple in structure and convenient to operate.

Owner:KUNMING UNIV OF SCI & TECH

Adhesive winding device for electrical adhesive tape

The invention discloses an adhesive winding device for an electrical adhesive tape. The adhesive winding device for the electrical adhesive tape comprises a bottom plate, wherein a bottom box and a vertical box are sequentially and fixedly connected to the top part of the bottom plate; a rotary plate is rotatably connected to the top part of the bottom box; a rotary rod is rotatably connected to one side of an inner wall of the vertical box through a base; a moving head is slidably connected to the surface of the rotary rod through a spiral groove; a sliding block is fixedly connected to one side of the moving head through a moving rod; a support frame is fixedly connected to one end of the sliding block; a lifting device is fixedly connected to one side of the top part of the vertical box; a lifting box is fixedly connected to the surface of the lifting device; a driving wheel is rotatably connected between the top part and the bottom part of an inner wall of the lifting box; a driving shaft is slidably connected to the center of the driving wheel; and a pressing plate is fixedly connected to the bottom part of the driving shaft. The adhesive winding device for the electrical adhesive tape provided by the invention relates to the technical field of electrotechnics. According to the adhesive winding device for the electrical adhesive tape provided by the invention, the problemof low efficiency brought by manual adhesive winding is solved, cables can be efficiently and uniformly winded with adhesives, and meanwhile, the labor intensity is reduced.

Owner:山东恒东实业集团有限公司

Flame-retardant and high-temperature-resistant computer cable and preparation process thereof

ActiveCN110364294AFlame retardantWith high temperature insulationInsulated cablesInsulated conductorsElectrical conductorCombustion

The invention discloses a flame-retardant and high-temperature-resistant computer cable. The cable comprises core wires, first wrapping layers, a second wrapping layer, a shielding layer, an armor layer and a sheath layer. Each core wire comprises tinned copper core conductors and insulating layers; the outer side of each tinned copper core conductor is wrapped with the corresponding insulating layer; every two core wires are twisted to form a pair wire set; and the outer side of each pair wire set is wrapped with the corresponding first wrapping layer. According to the invention, the quartz fiber maintenance sleeve layer on the outer side of the cable has the advantages of flame retardance, high-temperature resistance, insulationresistance, ablation resistance, corrosion resistance, heatinsulation ability, wave transmission ability, excellent dielectric property and the like; the cable can be protected from combustion in case of a fire; compared with polyethylene insulation, the performance of the the cross-linked polyethylene insulation is greatly improved after cross-linking modification; the comprehensive performance such as the mechanical performance, the environmental stresscracking resistance, the chemical corrosion resistance, the creep resistance and the electrical performance is remarkably improved; and the temperature resistance level is remarkably improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

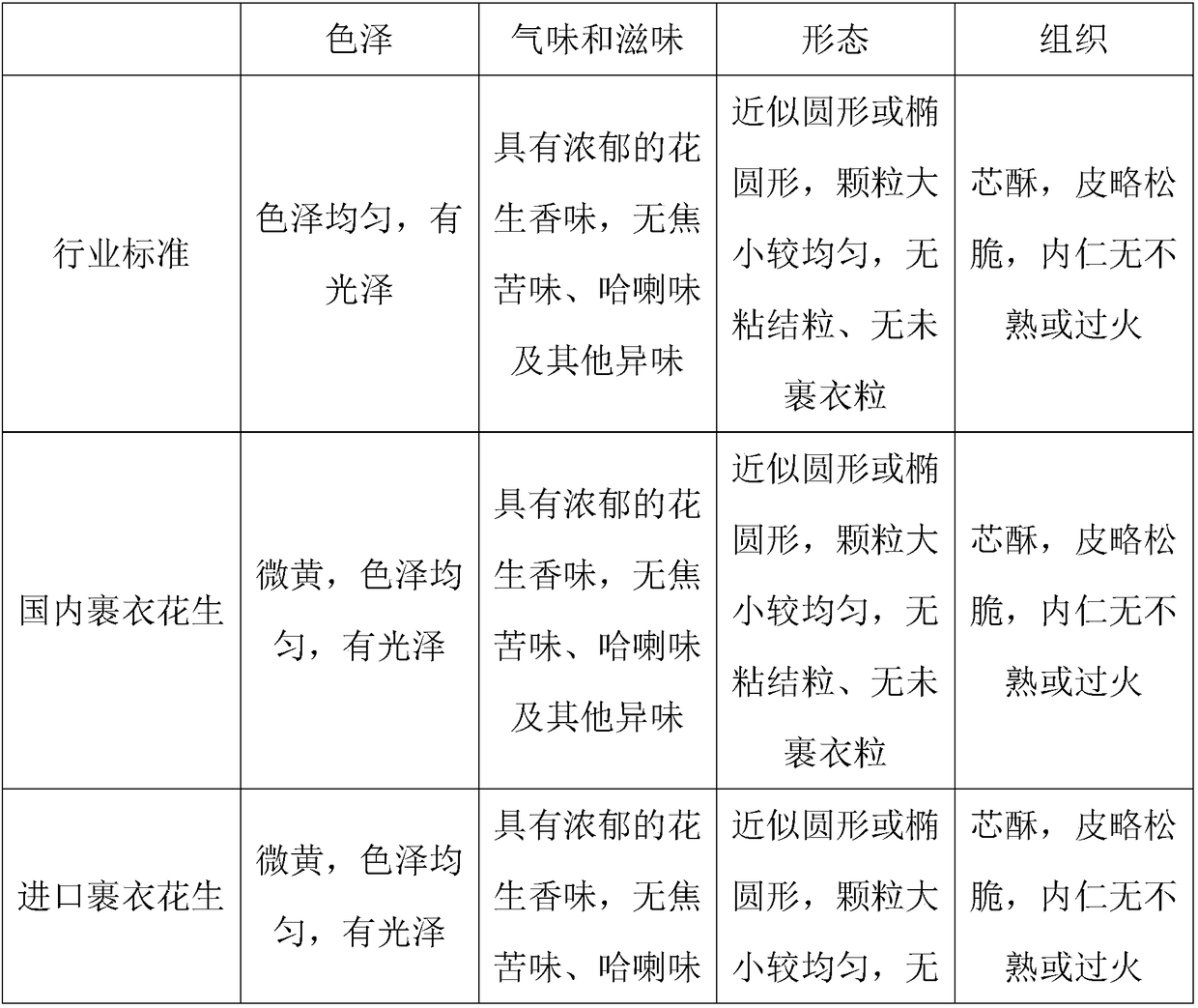

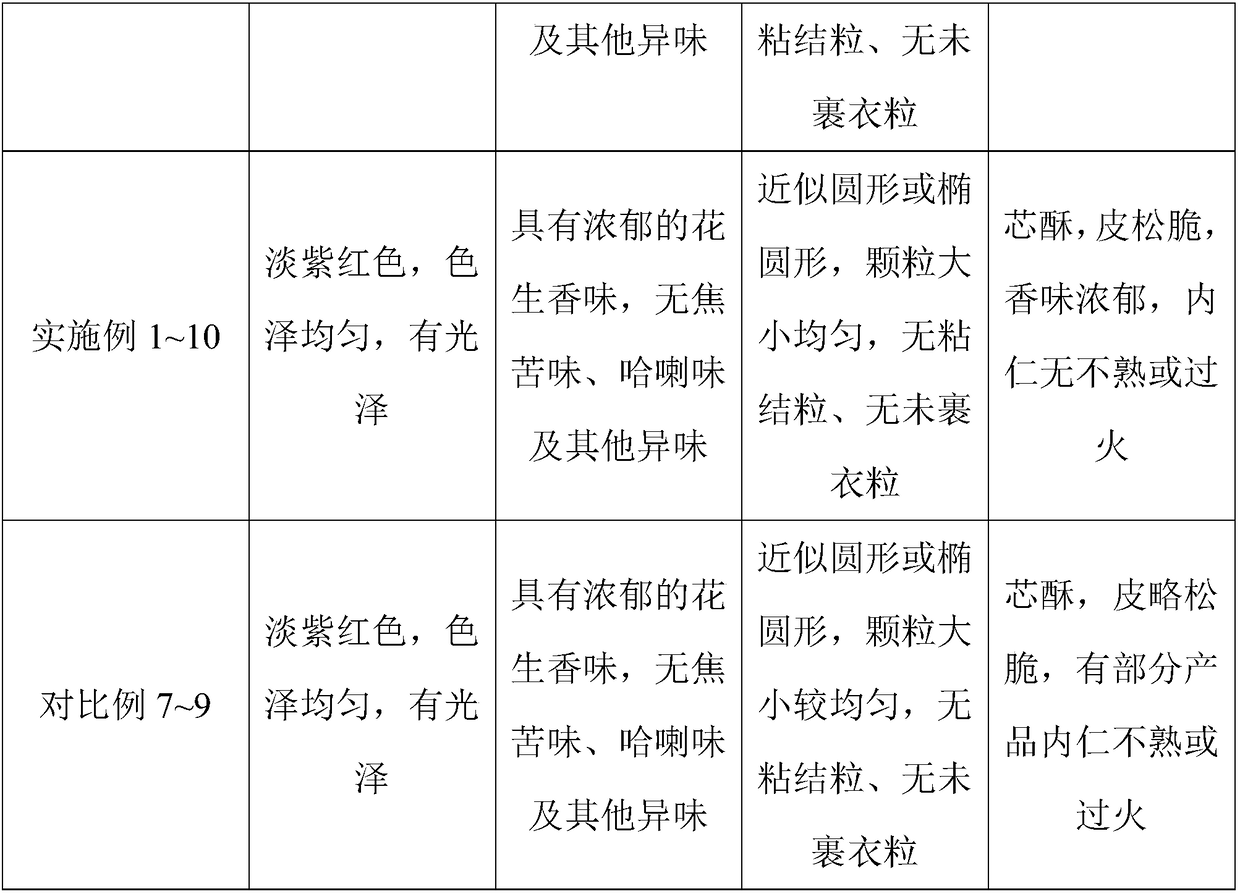

Coated peanut and preparation method thereof

InactiveCN109170763AHelp supplementRealize resource utilizationSeed preservation by coatingFood ingredient as colourWater ChestnutsVegetable oil

The invention discloses coated peanuts and a preparation method thereof, relating to the technical field of food processing. The coated peanuts are prepared from the following raw materials: 40-60 parts of peanut kernels, 5-15 parts of wheat bran, 3-6 parts of buckwheat, 2-5 parts of quinoa flour, 5-10 parts of pre-gelatinized starch, 2-7 parts of maltodextrin, 1-4 parts of corn starch, 0.5-1.5 parts of water-chestnut starch, 0.1-0.8 part of water-chestnut skin extract, 0.5-2 parts of whole egg powder, 0.2-1.8 parts of eggplant powder, 0.2-1 part of mushroom powder, 0.3-1.5 parts of pitaya skin powder, 0. 5-3 parts of fructose, 1-4 parts of maltitol, 0.01-0.1 part of sorbitol, 0.2-1 part of vegetable oil and 0.5-1.5 parts of feed powder. The coated peanuts have the beneficial effect that the added sweetening agent does not cause the increase in blood sugar, is rich in dietary fibers, and is conductive to supplementation of dietary fibers required by human bodies, and meanwhile does notcause the increase in blood pressure and blood fat.

Owner:江西普润食品有限公司

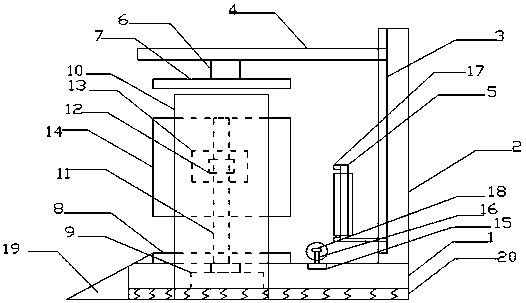

Automatic film winding machine

InactiveCN109131984AImprove the effectImprove wrapping efficiencyWrapping material feeding apparatusPackaging automatic controlTelescopic cylinderWinding machine

The invention provides an automatic film winding machine comprising a base, wherein the rear end of the base is provided with a bracket, a first longitudinal slide rail is arranged in the middle of the bracket, a support rod and a longitudinal film winding frame are arranged on the first longitudinal slide rail, the support rod is located above the longitudinal film winding frame, the front end ofthe support rod is provided with a first motor, the lower end of the first motor is provided with a top plate, the surface of the base is provided with a bottom plate, the top plate and the bottom plate are correspondingly arranged, the two sides of the base are respectively provided with fixing frames, the middles of the fixing frames are provided with second longitudinal slide rails, the secondlongitudinal slide rails are provided with telescopic cylinders, the front ends of the telescopic cylinders are provided with third motors, the front end of a rotary motor is provided with a suckingplate, the rear side of the base is provided with a horizontal slide rail, the horizontal slide rail is located between the bottom plate and the bracket, and the horizontal slide rail is provided witha horizontal film winding frame. The invention rotates a film around a product by setting the top plate and the bottom plate, and winds the upper and lower sides of the product with the film throughthe rotation of the sucking plate, thereby reducing labor and improving work efficiency.

Owner:WUHU YUANMA AUTOMATION EQUIP CO LTD

Coil wrapping tool

ActiveCN110660580AReduce maintenance costsEasy to wrapCoils manufacturePolyesterStructural engineering

The invention relates to a coil wrapping tool. The coil wrapping tool comprises a base and a support arranged on the base; the support is detachably connected with at least three supporting shafts which are arranged to form a structure in a horizontal star shape and are used for a supporting coil. In an actual wrapping process, the coil can be supported to a certain extent, so that a worker can wind the coil conveniently; the coil can rotate on the supporting shafts, so that the wrapping efficiency of the coil is effectively improved; manual processes such as the welding of a secondary outgoing line and the wrapping of a polyester film are facilitated, and labor intensity is low; and the supporting shafts are detachably connected with the support. With the above structure adopted, the coilwrapping tool has good overall structural stability and high strength in an actual operation process; and if the supporting shafts are bent and abraded, are break down or are subjected to other problems due to long-term pressing, the supporting shafts can be replaced at any time, and therefore, the maintenance cost of the tool is saved; and the structure of the tool is simple.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

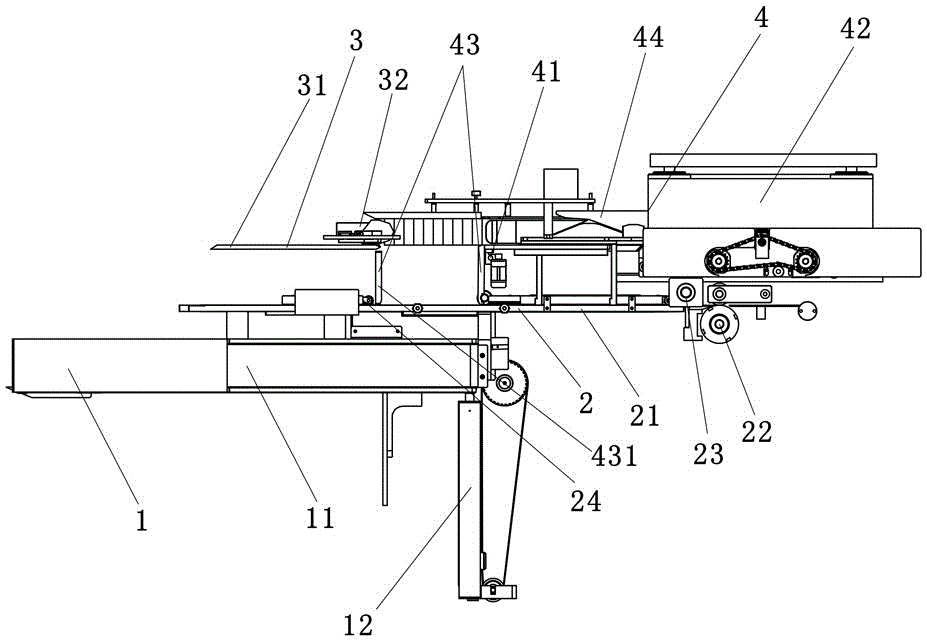

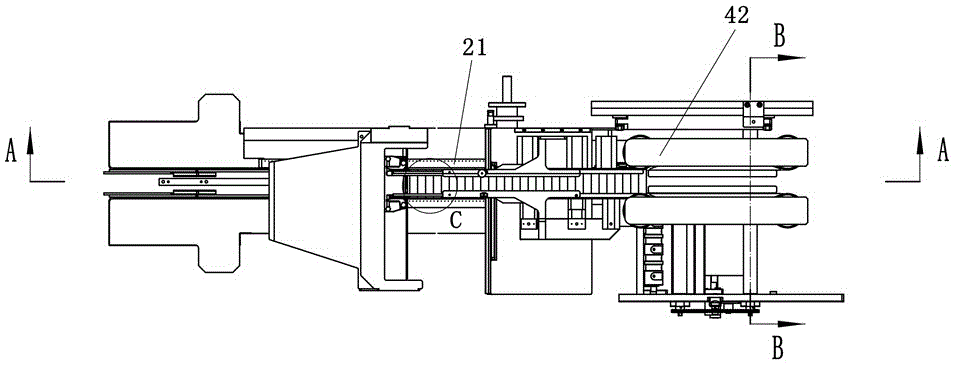

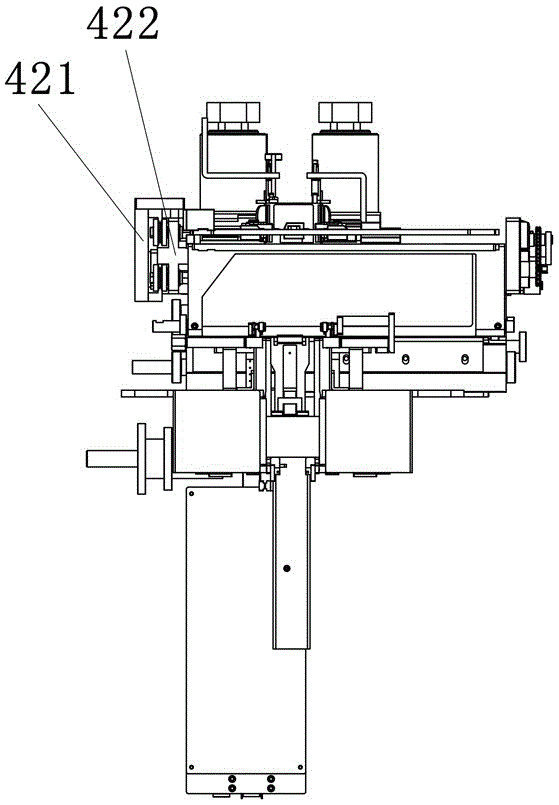

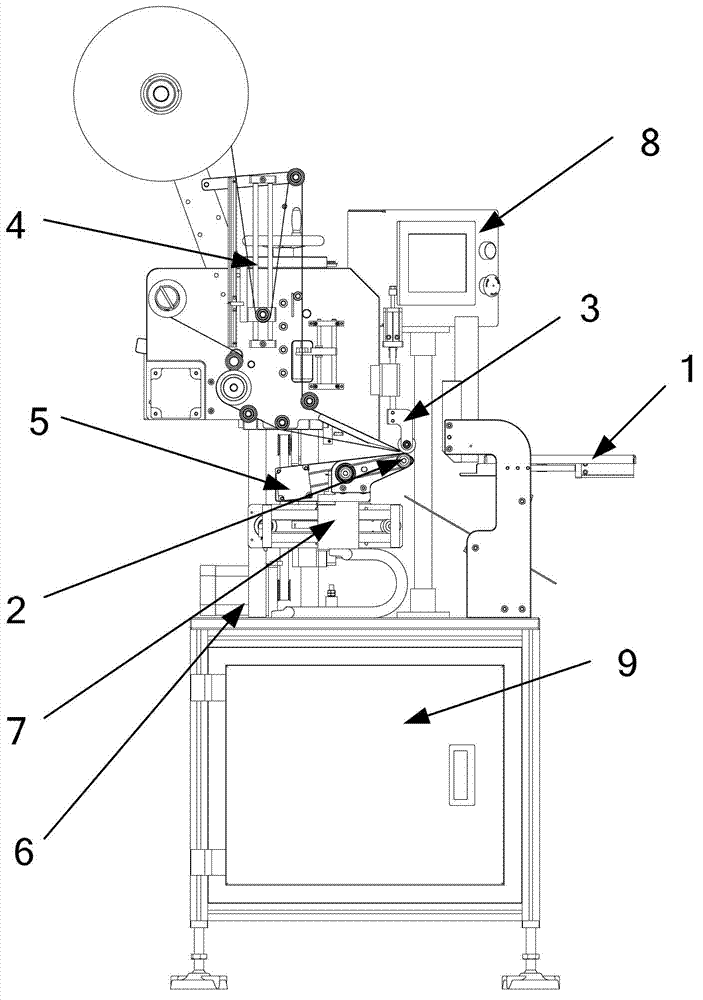

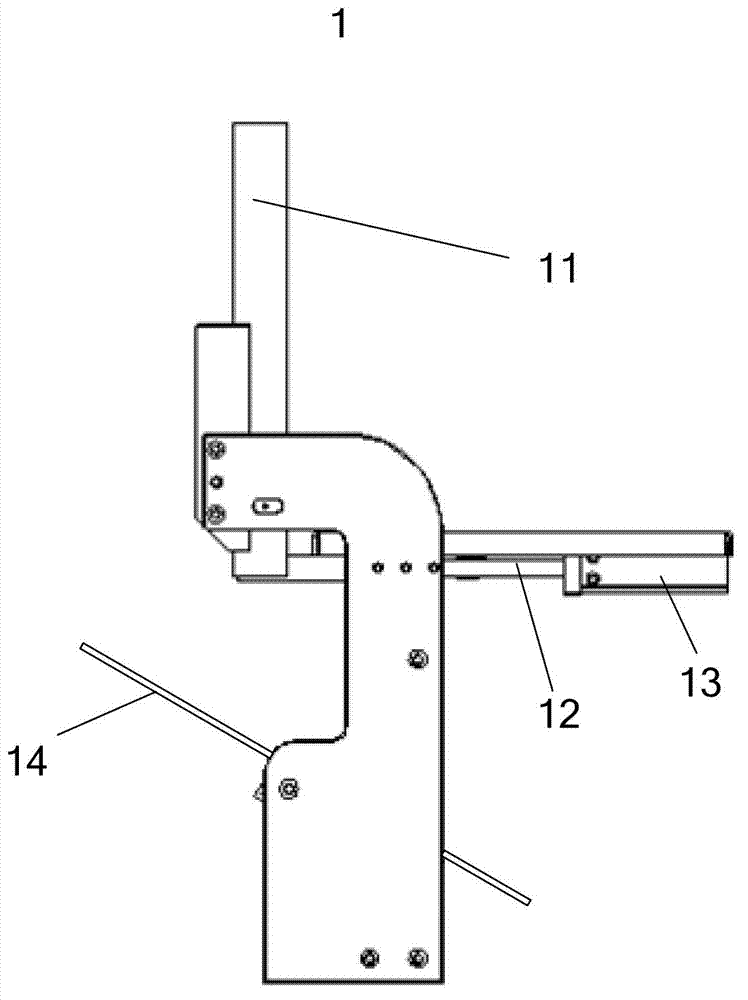

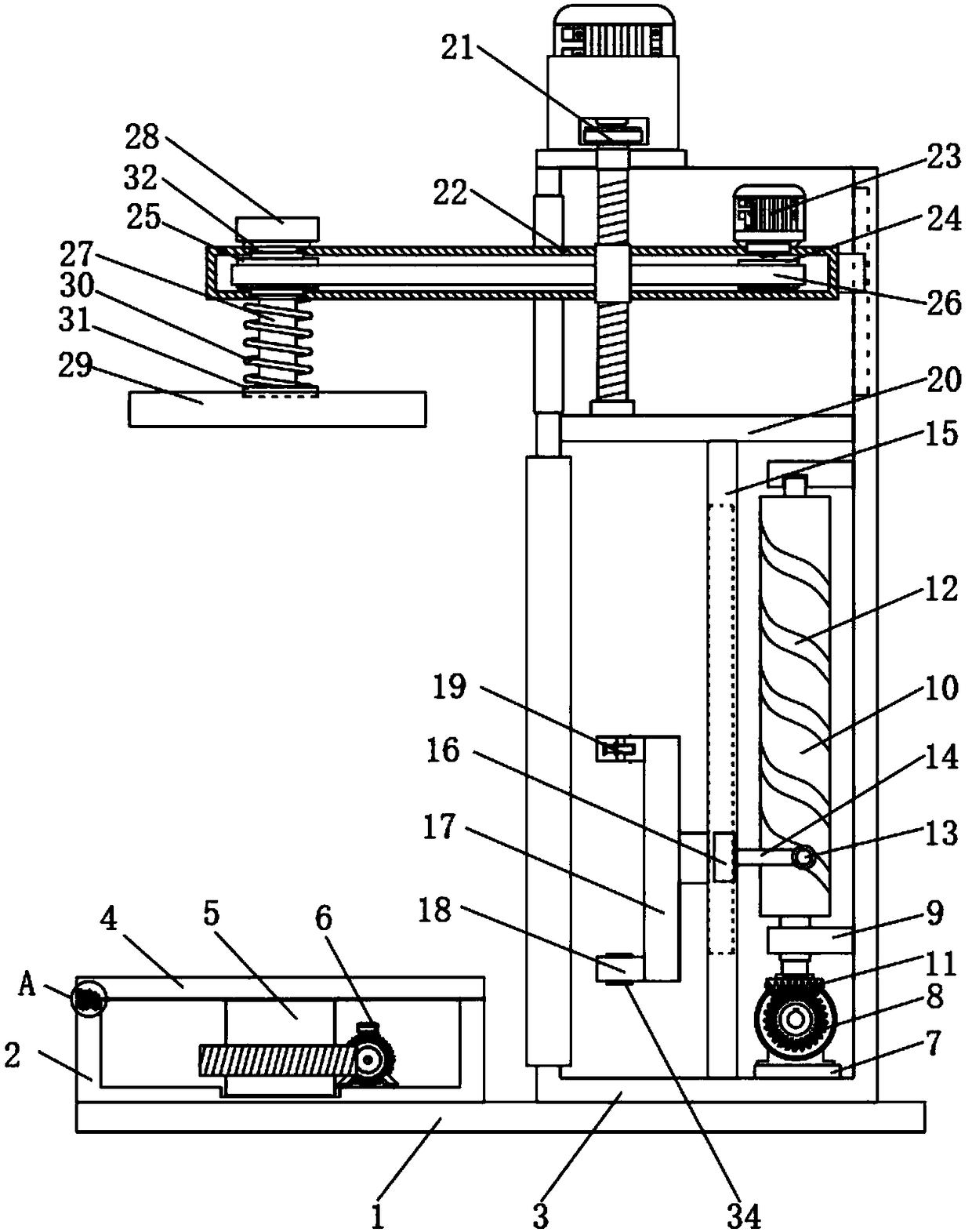

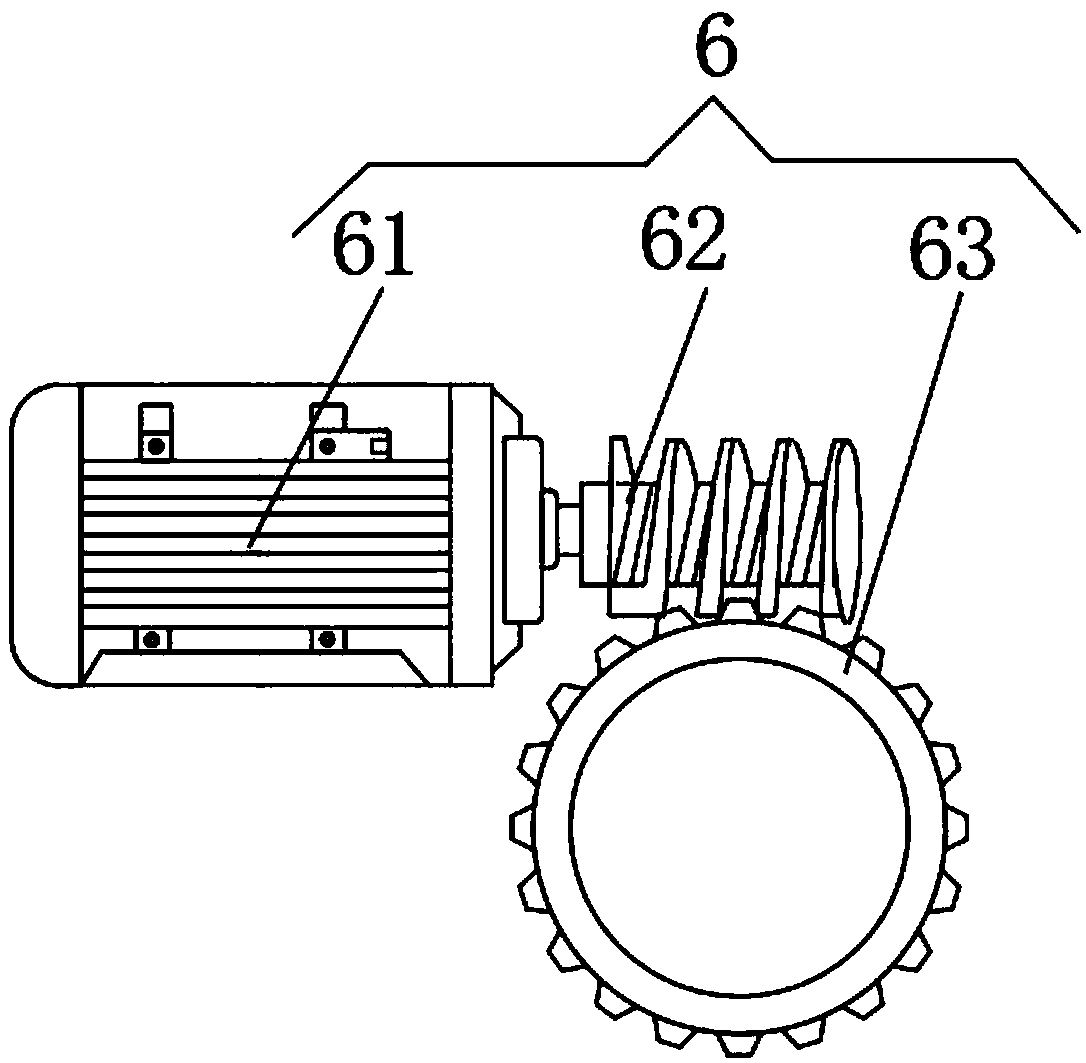

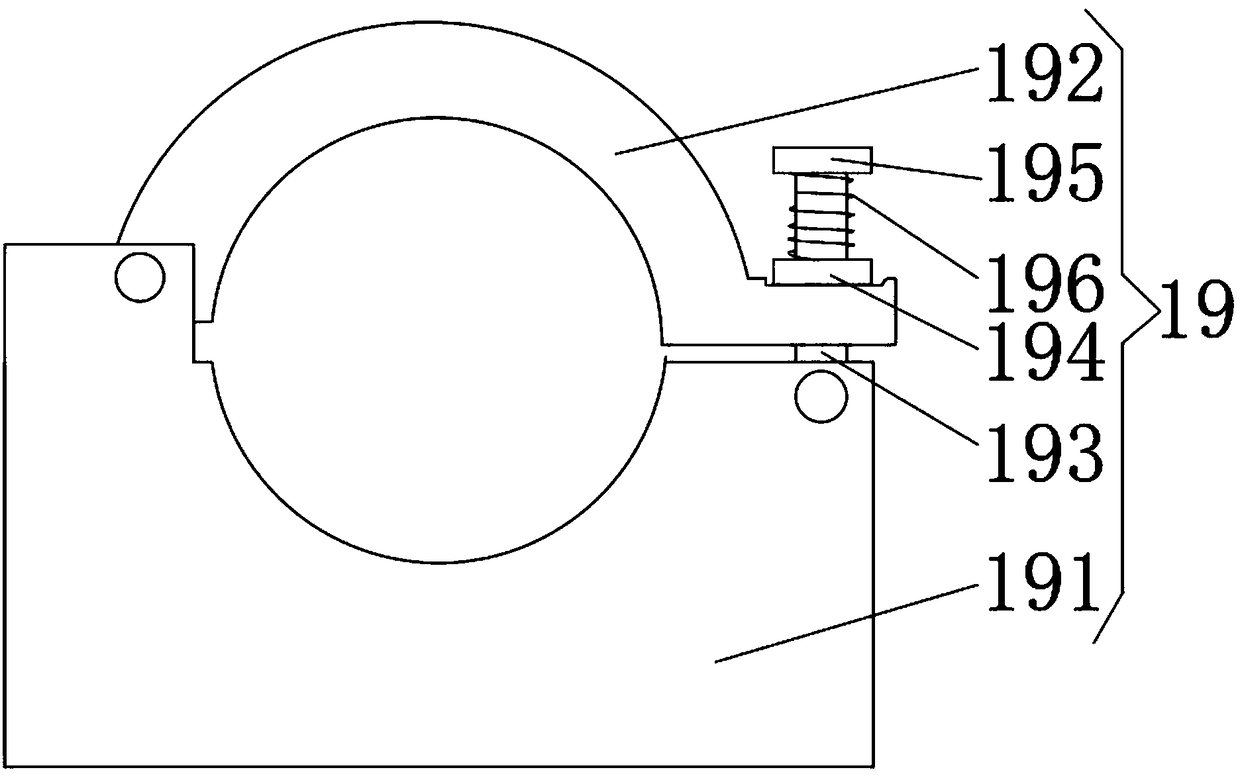

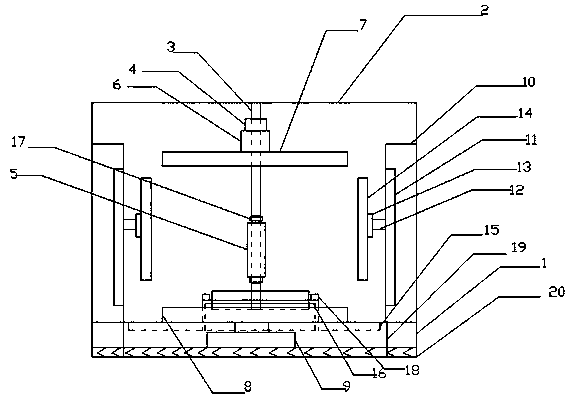

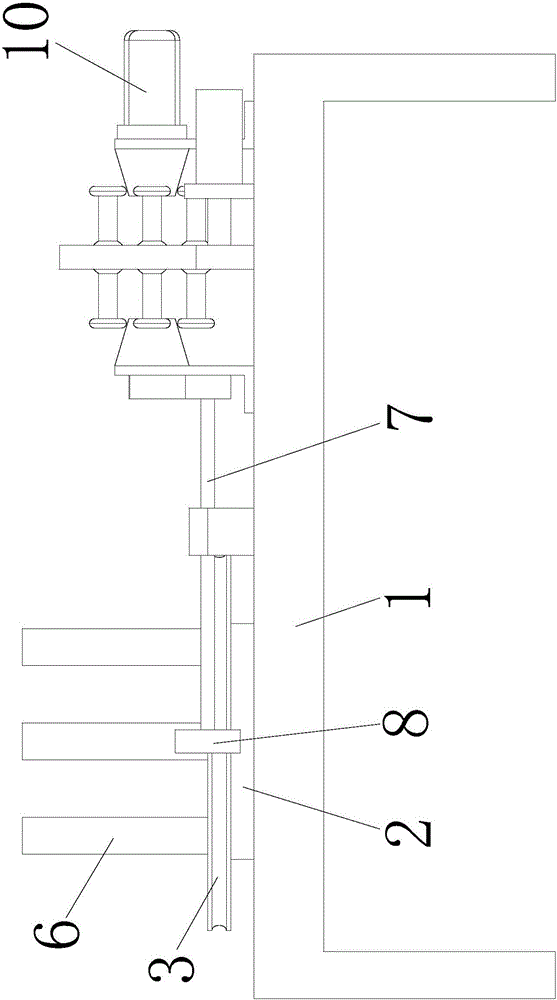

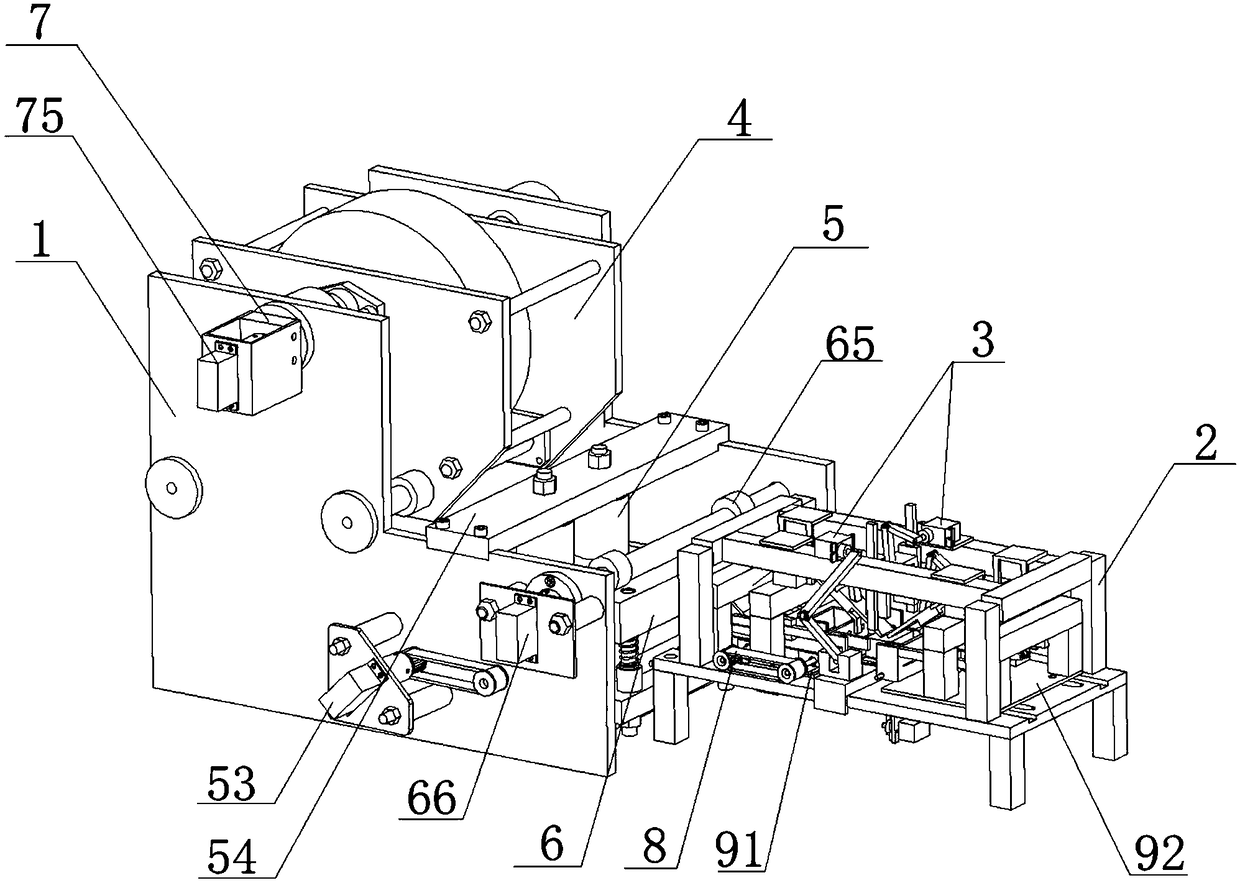

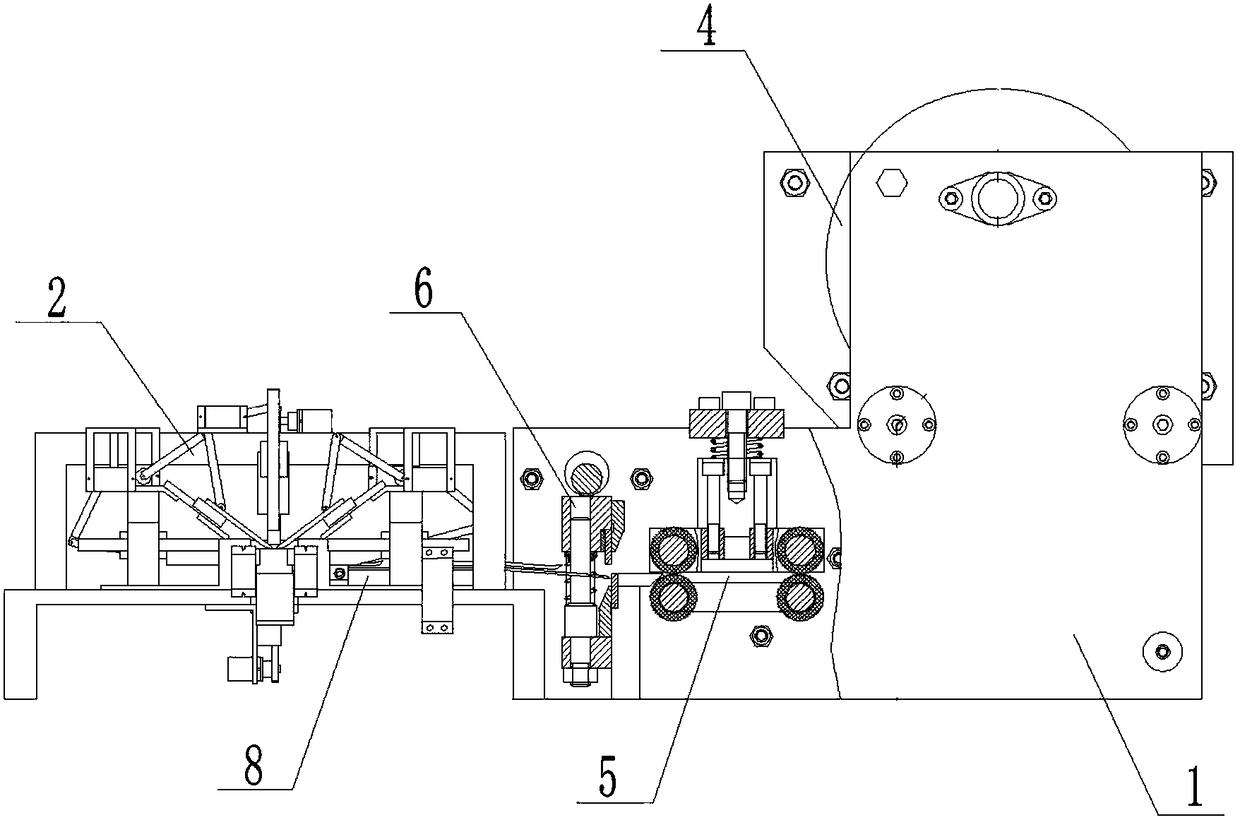

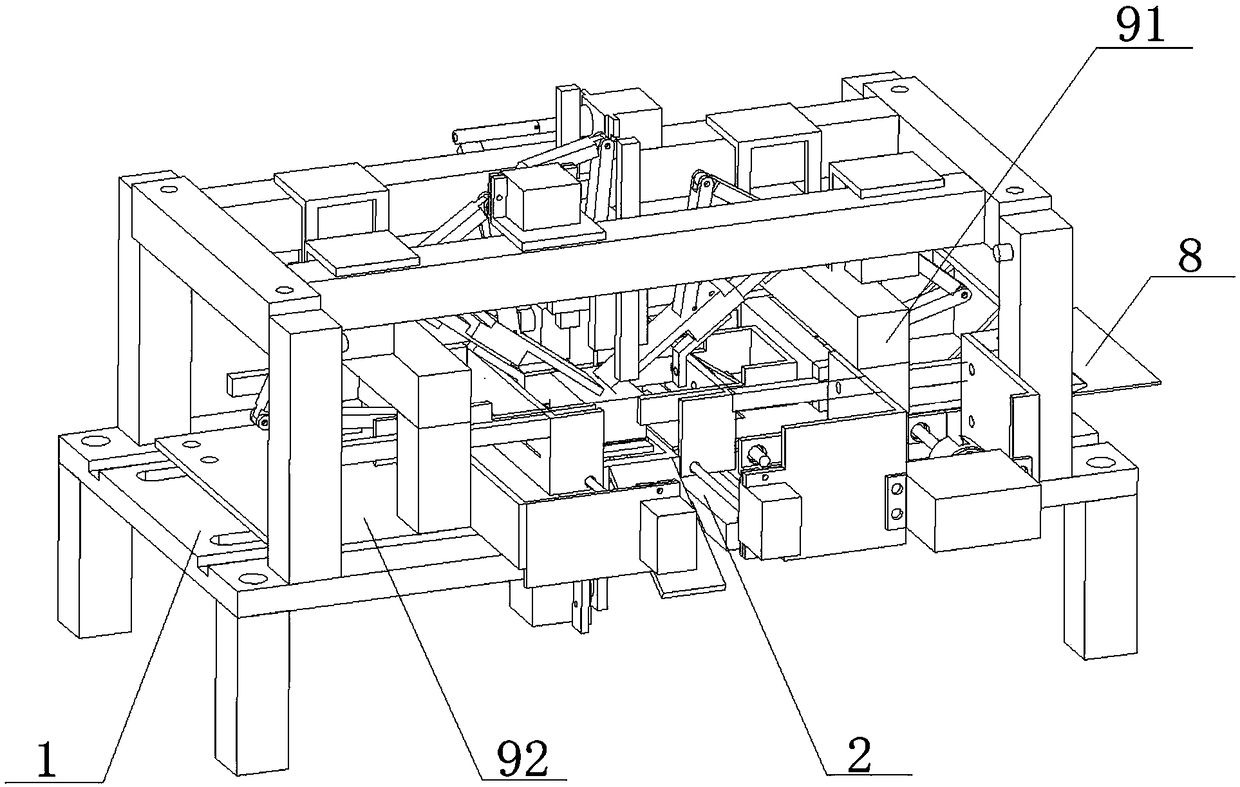

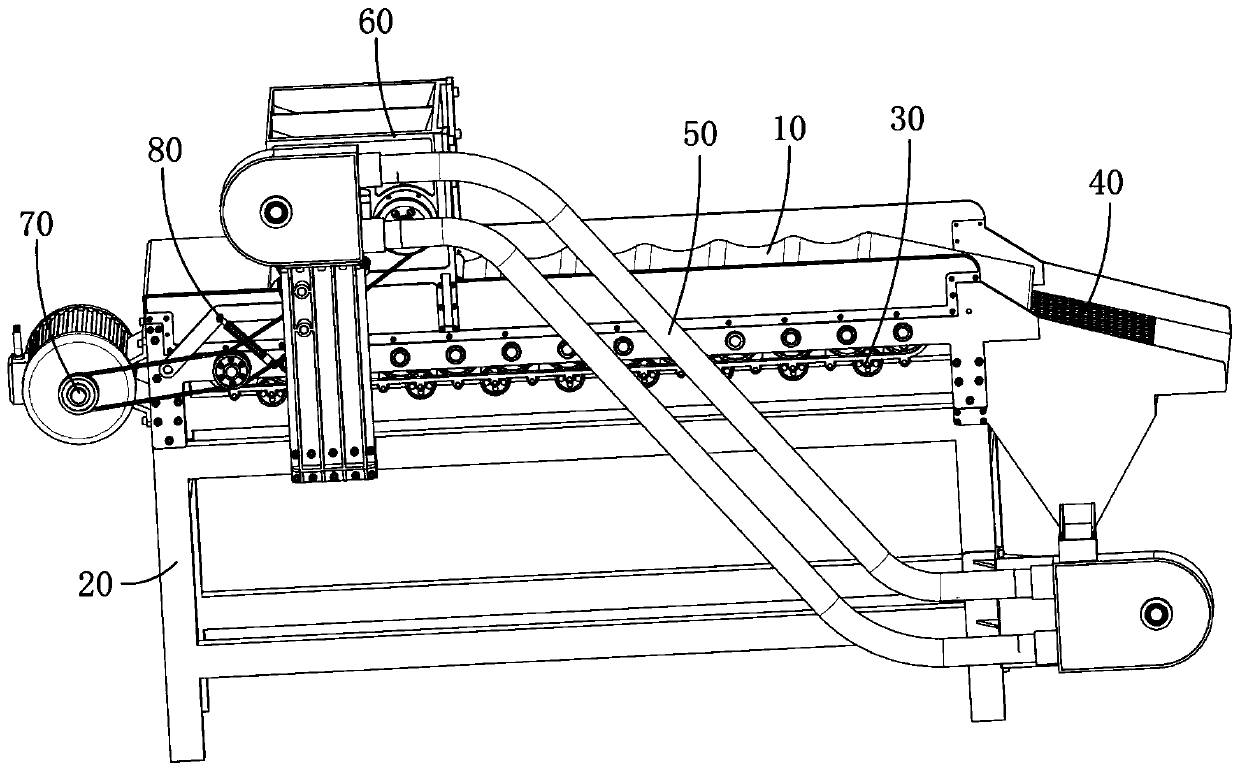

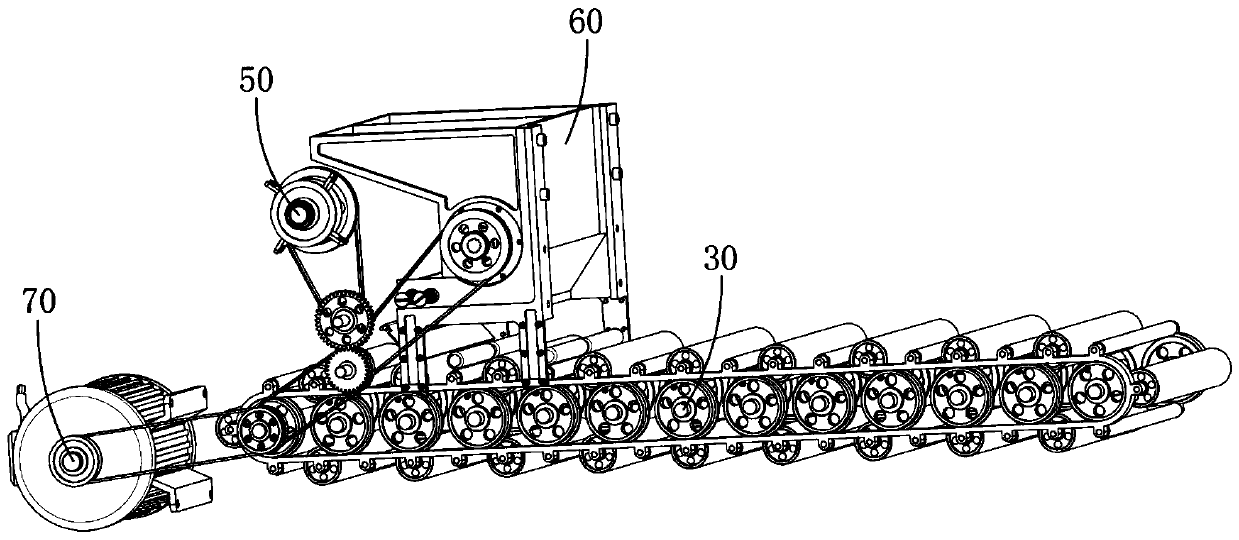

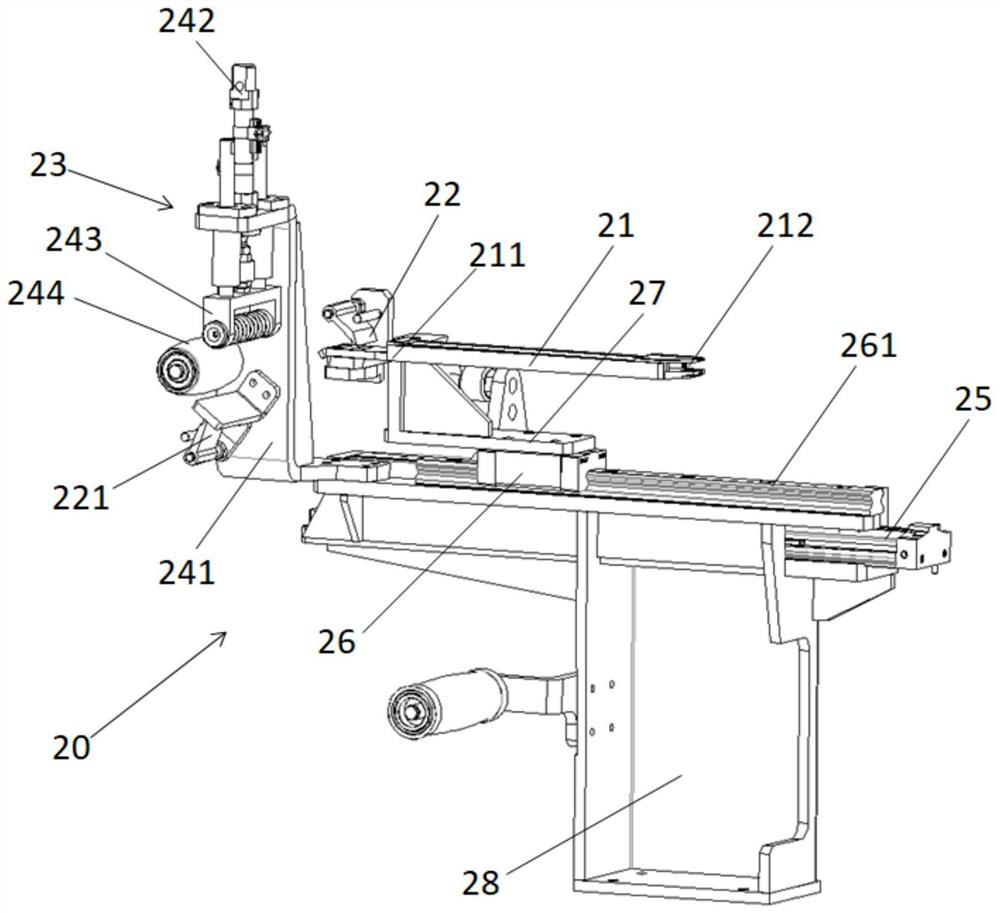

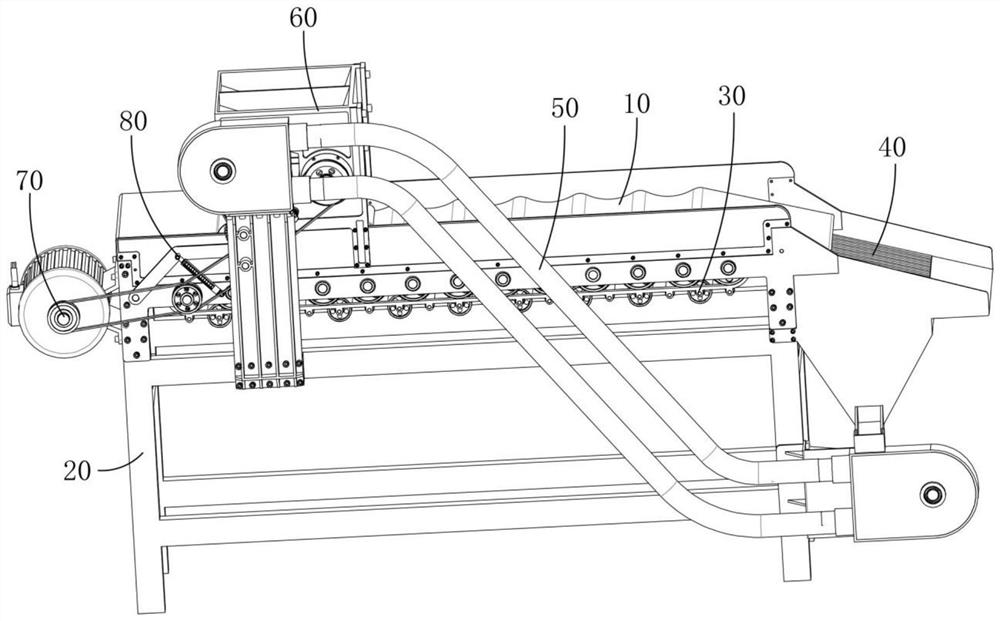

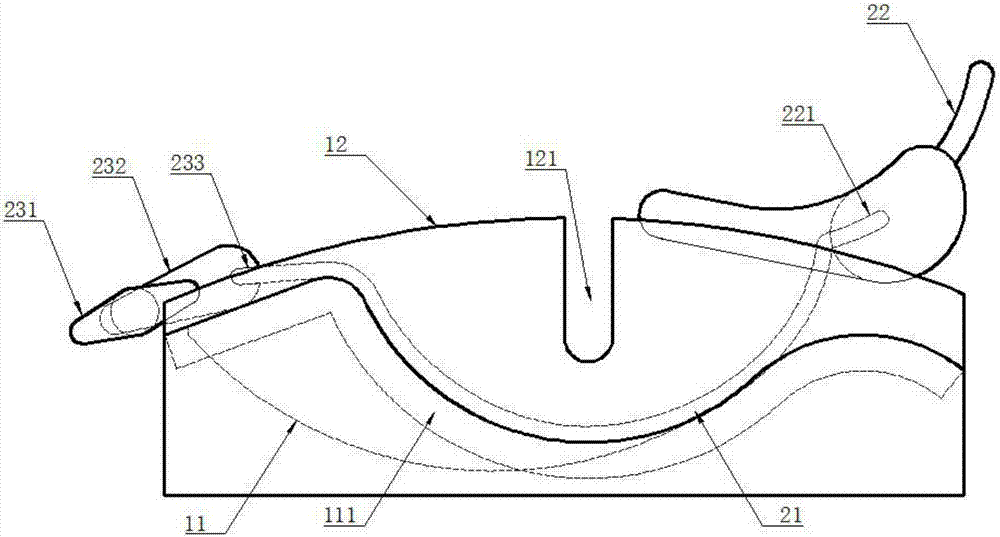

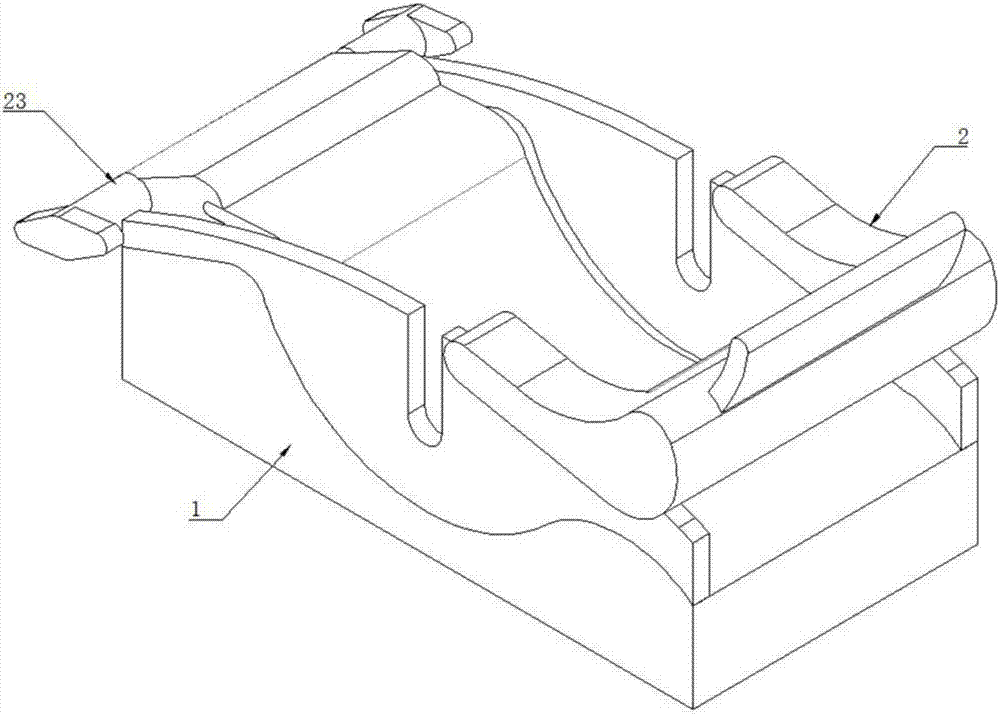

Automatic packaging machine with wrapping molding device

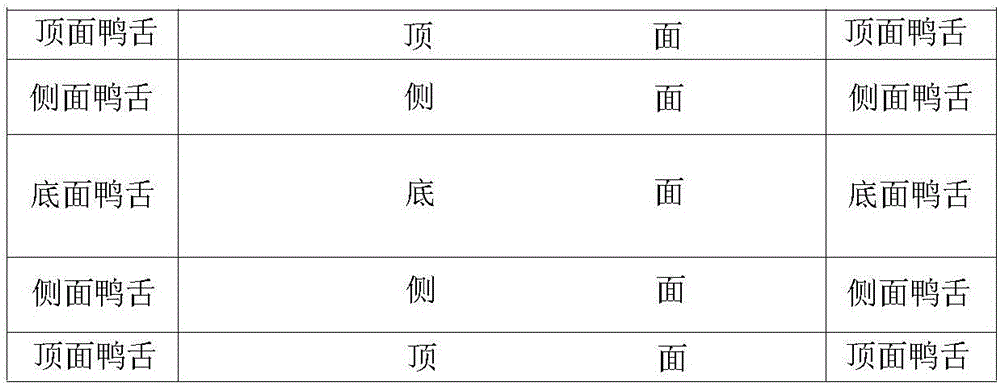

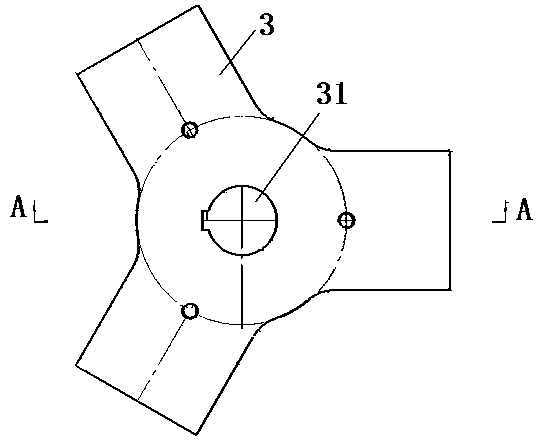

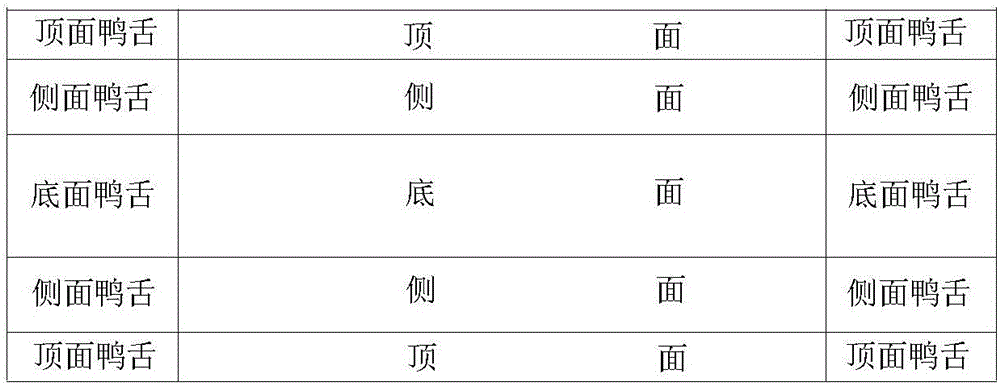

InactiveCN105711905AHigh degree of automationImprove wrapping efficiencyWrapper folding/bending apparatusEngineeringCardboard

The invention discloses an automatic packaging machine with a wrapping molding device. The automatic packaging machine comprises a rack and a control system, wherein a wrapping molding zone is arranged on the rack in the length direction of the rack, a carton placing zone is arranged in the wrapping molding zone, a top folding mechanism, a front end folding system and a bottom end folding system are sequentially arranged in the carton placing zone in the conveying direction of cartons, a side folding mechanism is arranged below the carton placing zone, each of the front end folding system and the bottom end folding system comprises a side duck tongue folding mechanism, a top duck tongue folding mechanism and a bottom duck tongue folding mechanism, and the side folding mechanism comprises a plurality of side folding units sequentially arranged in the length direction of the carton placing zone. By utilizing the automatic packaging machine, the side paperboards, top paperboards, side duck tongues, top duck tongues and bottom duck tongues of cartons can be sequentially folded, the whole folding process is sequentially carried out, the automation degree is high, and the wrapping efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

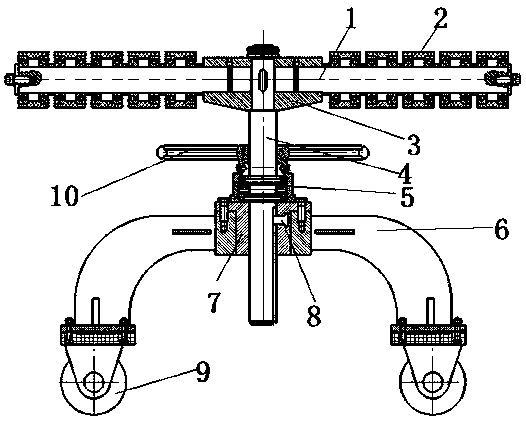

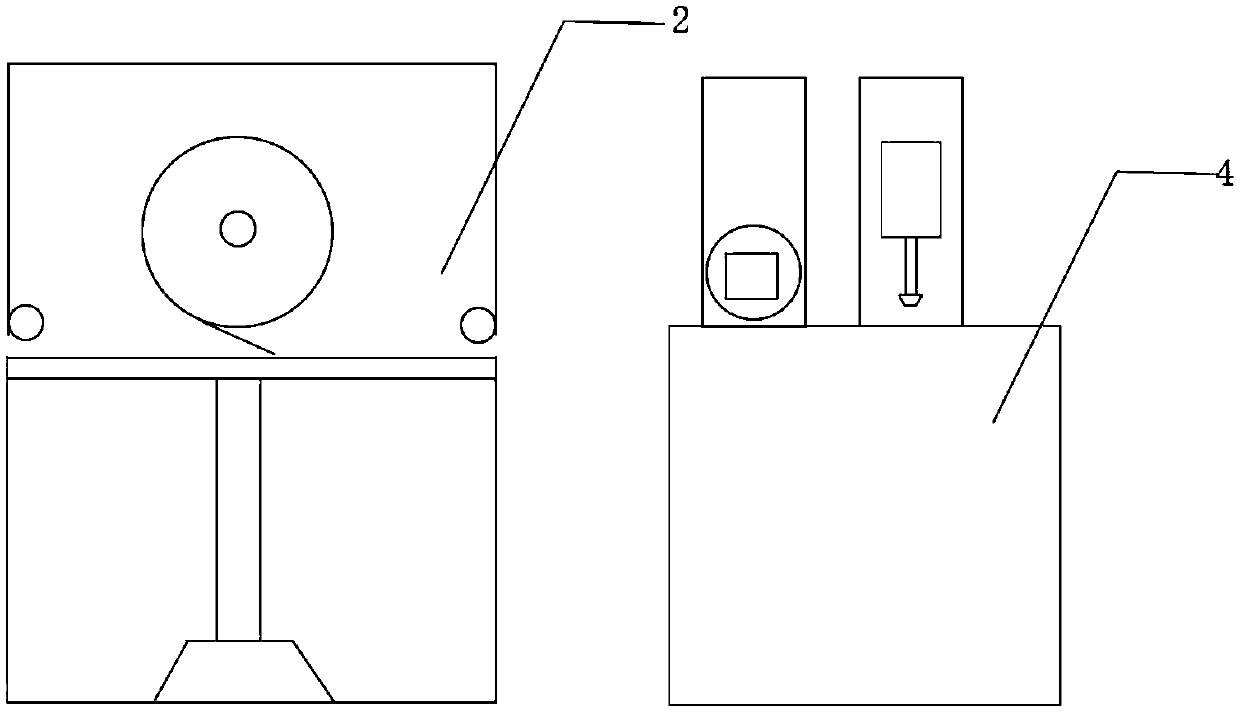

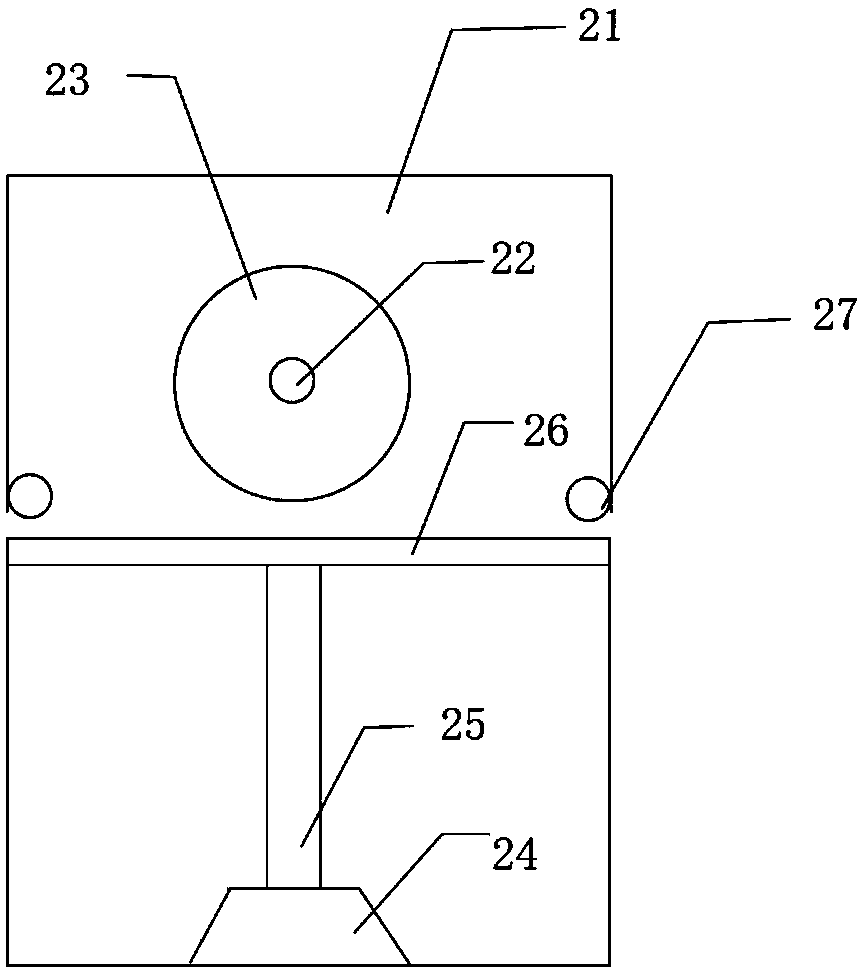

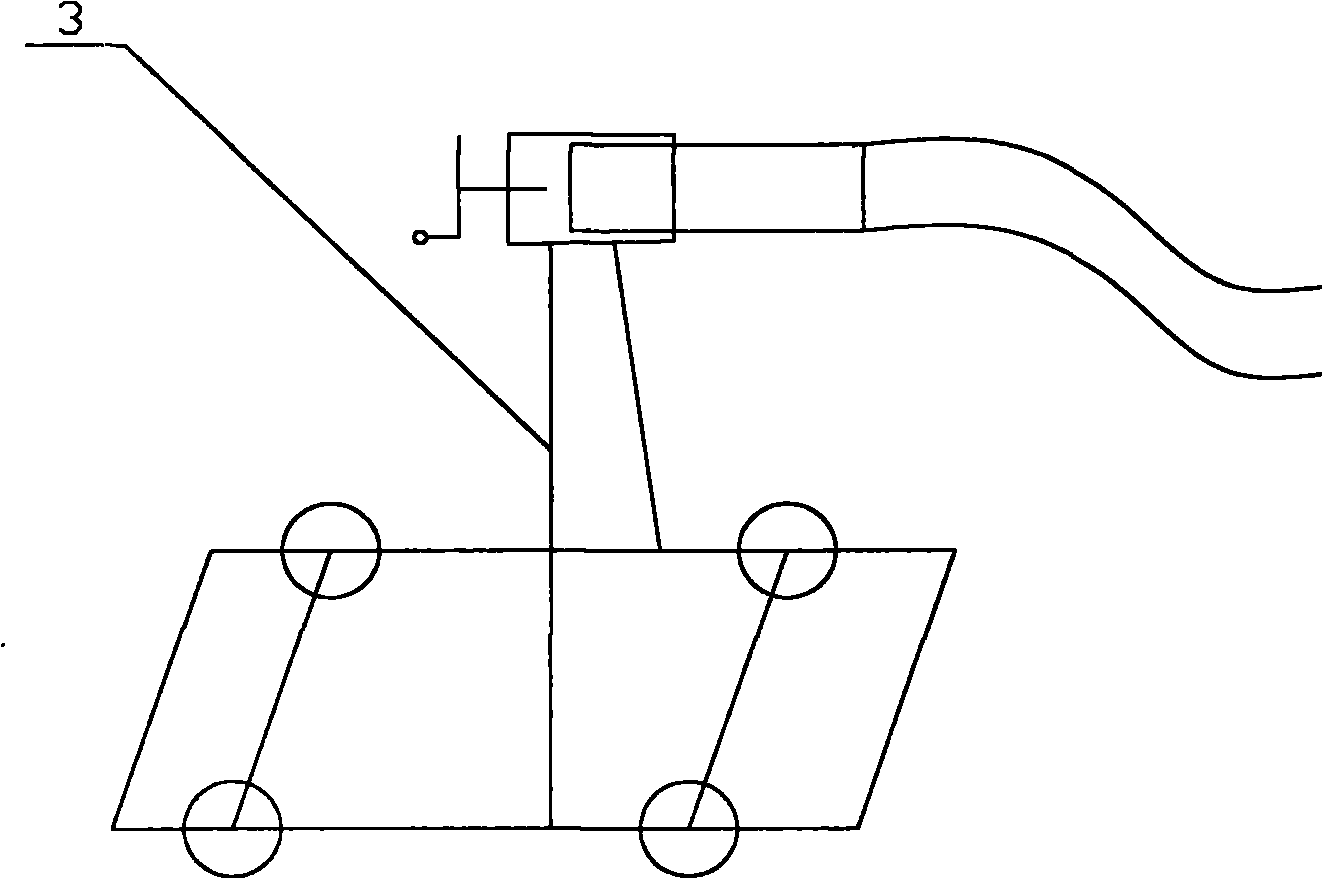

Fishing net winding device

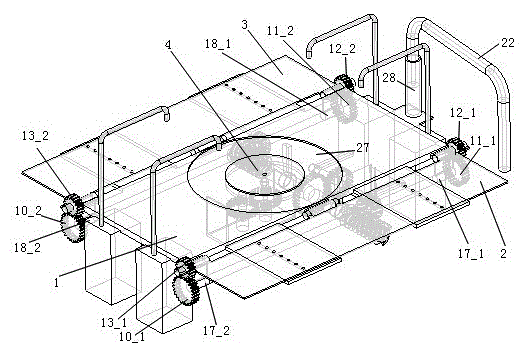

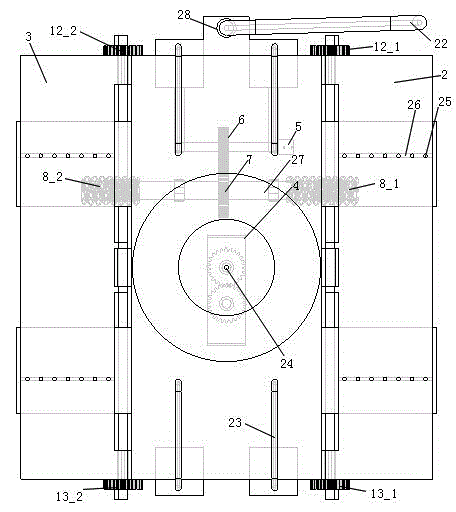

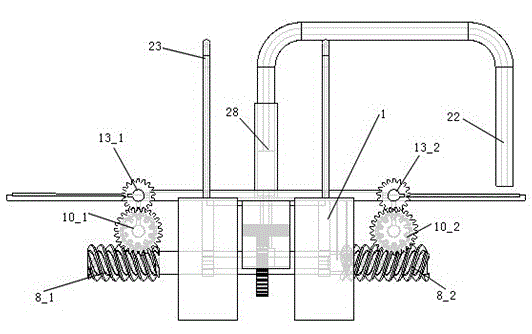

ActiveCN105923435ARealize automatic wrappingImprove wrapping efficiencyWebs handlingRotary stageEngineering

The invention discloses a fishing net winding device. The fishing net winding device comprises a support table; a rotating table is mounted at the left part of the support table; a worm wheel is fixed at the upper end of the rotating table; a chute 1 is formed in the right part of the support table; chutes 2 are uniformly formed in the upper end of the worm wheel; slide blocks are respectively mounted in the chutes 2; springs are respectively mounted on the slide blocks; positioning columns are respectively mounted at the upper ends of the slide blocks; a connecting shaft is mounted at the front part of the support table; a worm rod sleeve is mounted at the left end of the connecting shaft; a belt wheel 1 is mounted at the right end of the connecting shaft; and an adjustable driving device is mounted at the right part of the support table. The fishing net winding device has such advantages as reasonable structure design and convenience for use, realizes automatic fishing net winding, replaces manual winding, improves the fishing net winding efficiency, saves the manpower and material resources, uses the adjustable driving device for realizing adjustment of the fishing net winding speed, and guarantees the finishing net winding quality.

Owner:安徽省安国渔具有限公司

Winding package machine

The invention provides a winding package machine, and belongs to the field of package equipment. The winding package machine comprises a base, a rotating table, a first drive device, a trigger rod, afirst elastic piece, a moving frame, a second drive device, a swing arm, a cutter, a second elastic piece, a locking mechanism and a transmission mechanism. The first drive device is used for drivingthe rotating table to rotate around a first vertical axis relative to a base. The trigger rod is movably inserted in the center position of the rotating table vertically. The first elastic piece is used for enabling the trigger rod to be reset. The second drive device is used for driving the moving frame to move vertically. The swing arm can swing around a second vertical axis. The cutter is installed on the swing arm. The second elastic piece is connected between the swing arm and a second stand column. The locking mechanism is used for enabling the swing arm swinging to the first position tobe locked in a releasing manner. The swing arm and the trigger rod are in transmission connection through the transmission mechanism. According to the winding package machine with the structure, a thin film can be automatically cut off after being wound around to the top of a workpiece, the thin film does not need to be shorn off manually, and the film winding efficiency can be improved effectively.

Owner:安徽鸿韵彩印包装有限公司

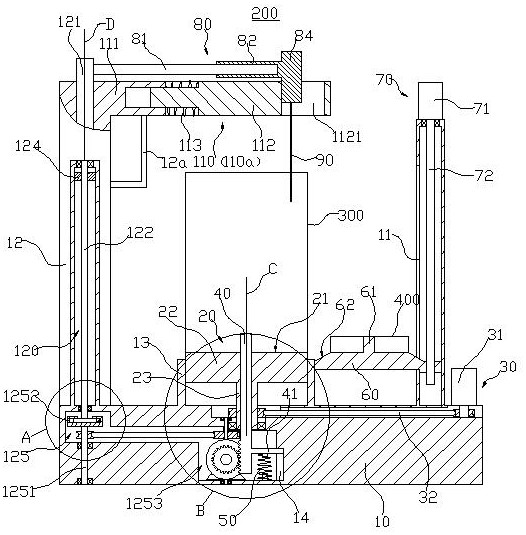

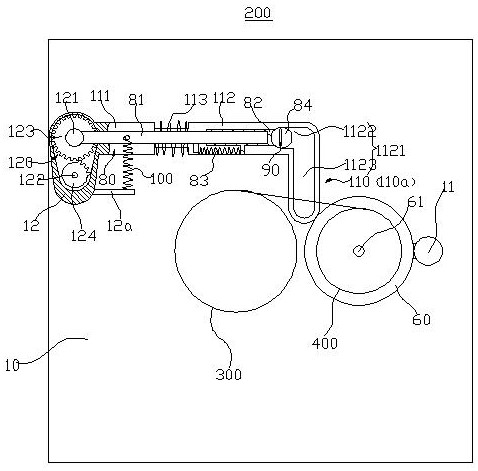

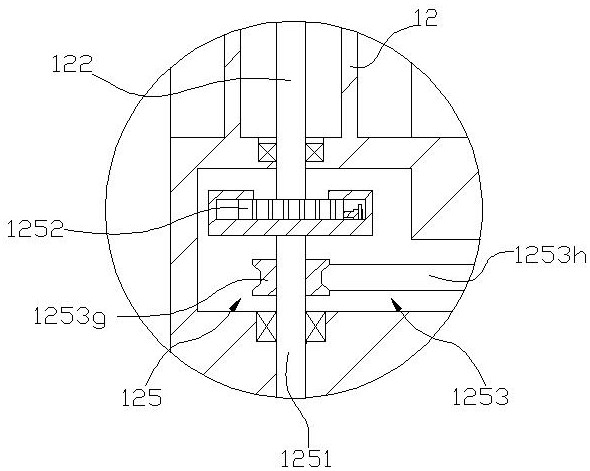

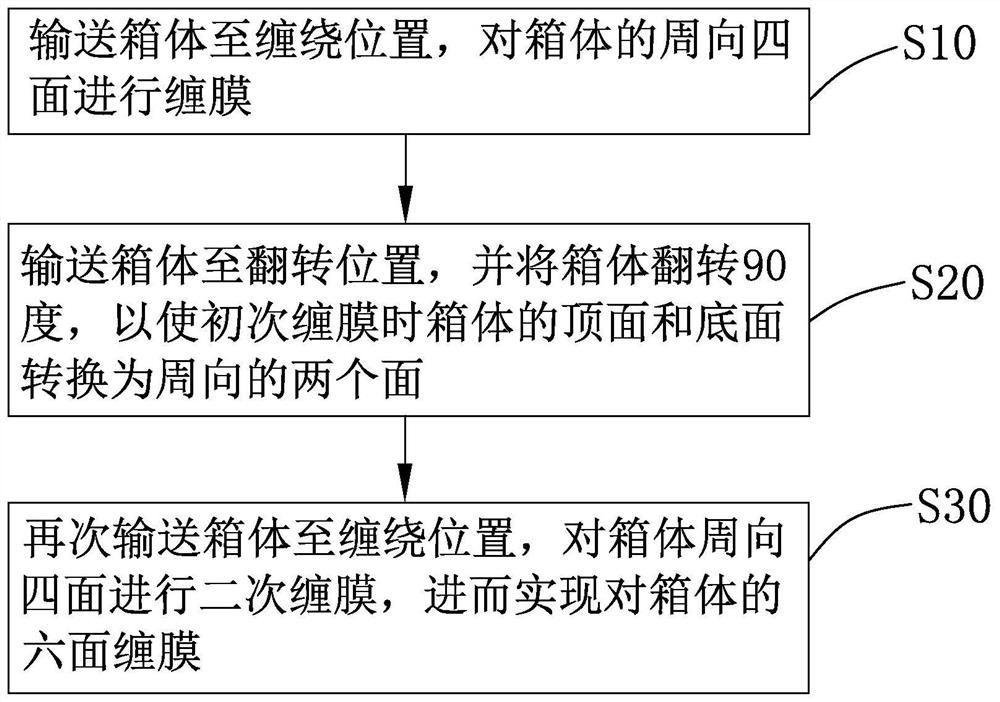

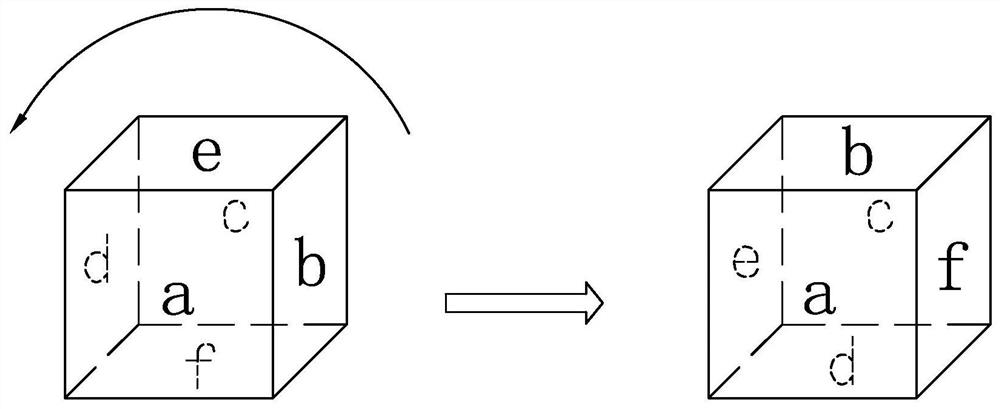

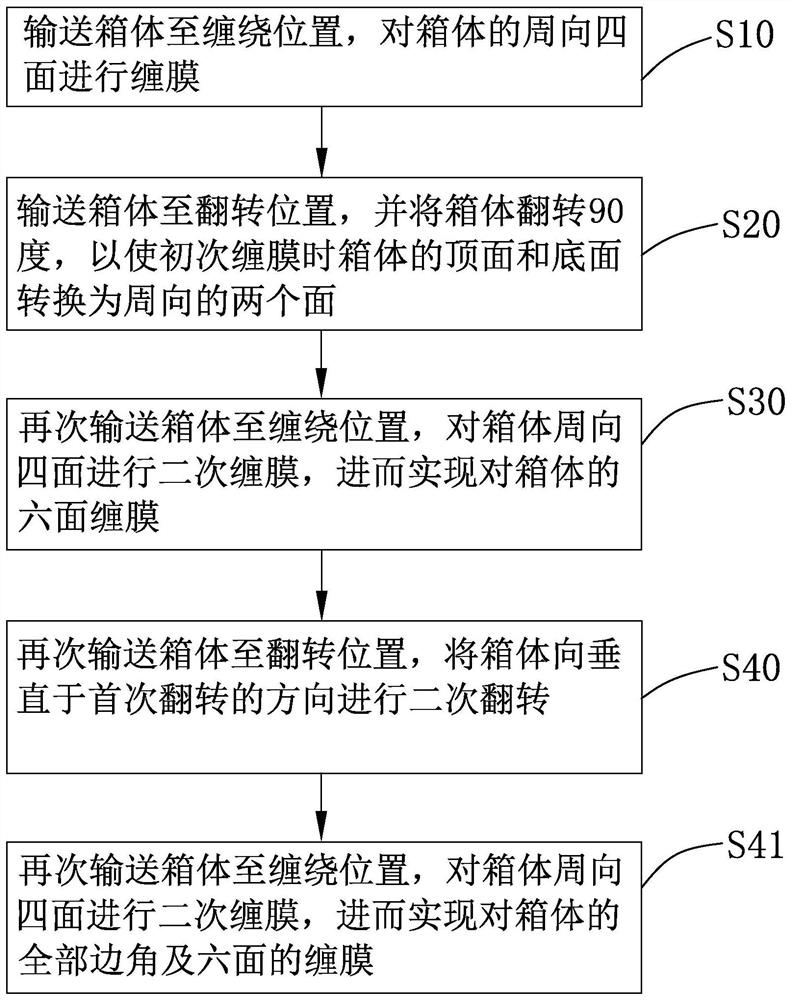

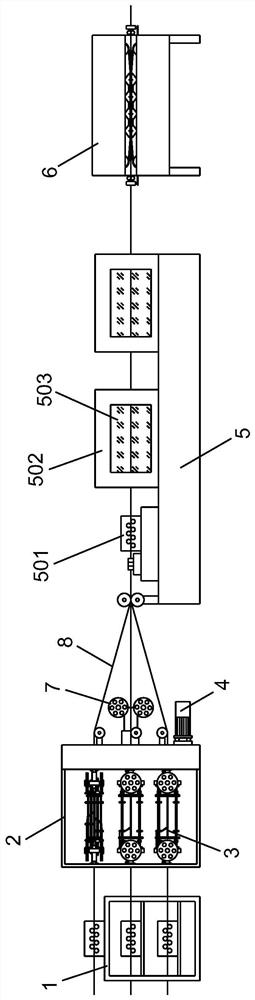

Film winding method and film winding machine

PendingCN112173207ASmall footprintImprove wrapping efficiencyConveyor wrappingWinding machineEngineering

The invention relates to the field of automatic packaging, in particular to a film winding method and a film winding machine which are used for winding a film on a box body. According to the film winding method, the film winding process is completed through one film winding machine, a box body is conveyed to a winding position, primary film winding is conducted on the four circumferential faces ofthe box body, then the box body is conveyed to an overturning position, the box body is overturned, the top face and the bottom face of the box body are converted into the two circumferential faces during primary film winding, then the box body is conveyed to the winding position again, and secondary film winding is conducted on the four circumferential faces of the box body, so that film windingof the six faces of the box body is independently completed through one film winding machine, and the occupied area of the film winding machine is reduced while the film winding efficiency is improved.

Owner:SHENZHEN FUYUNDI TECH

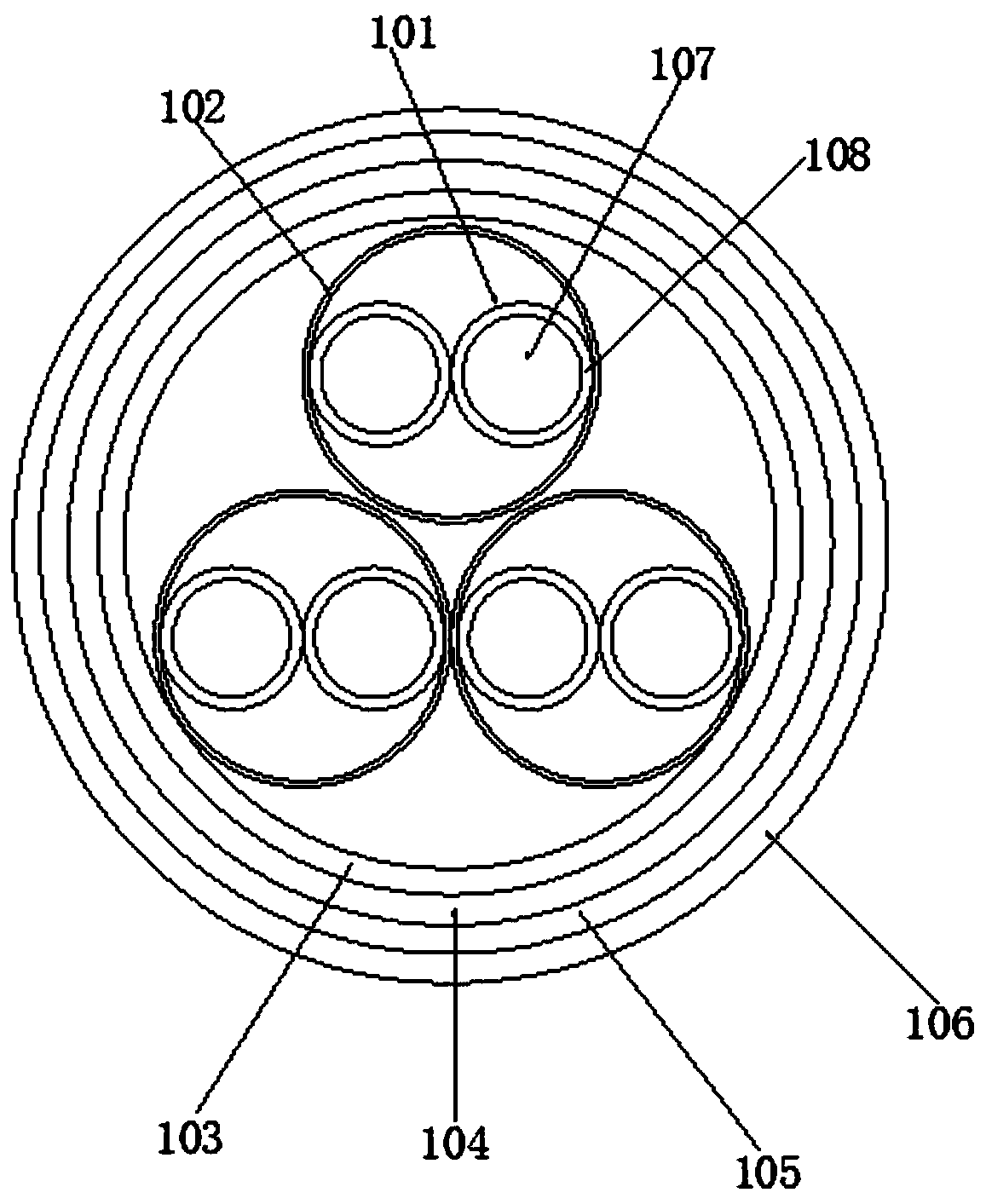

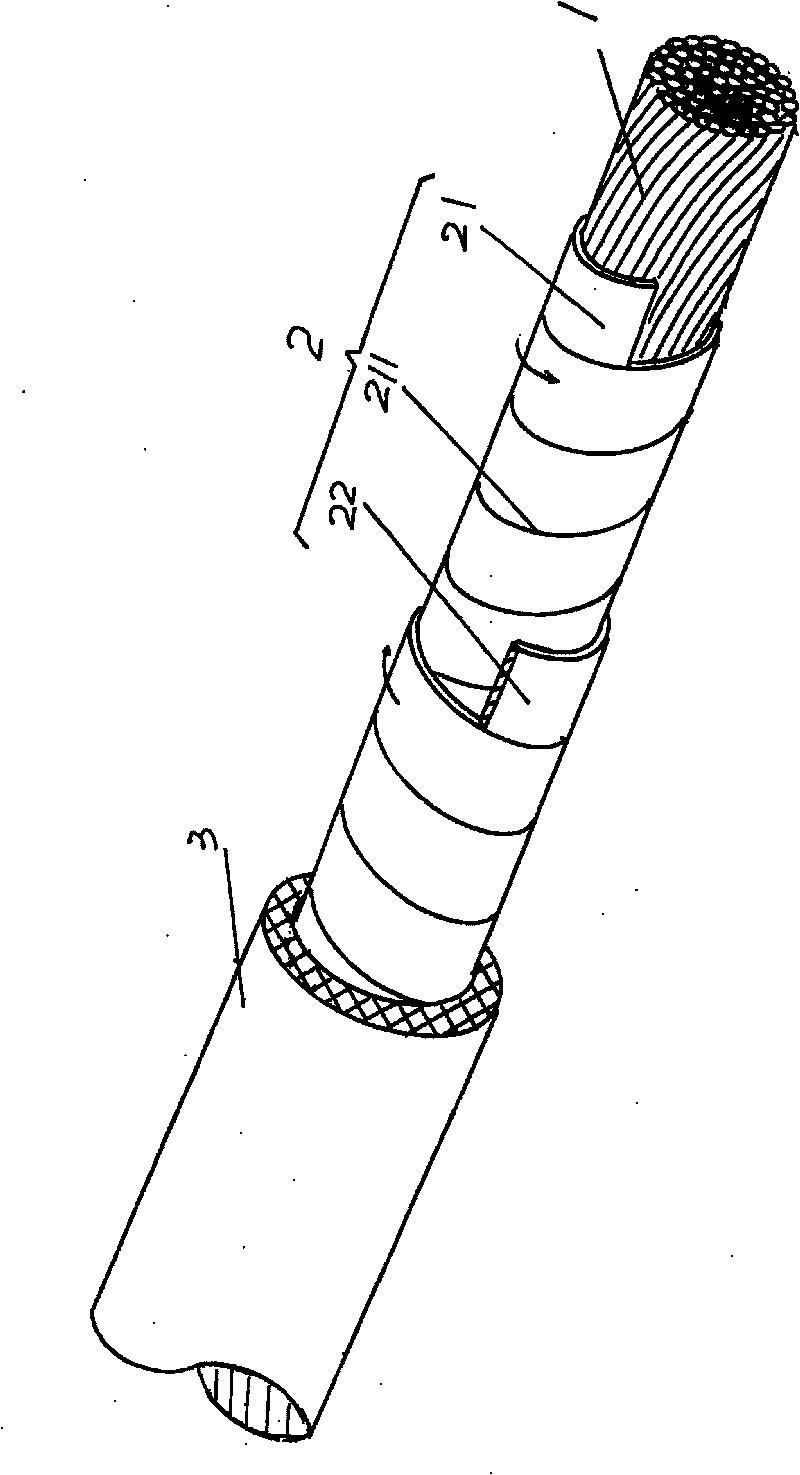

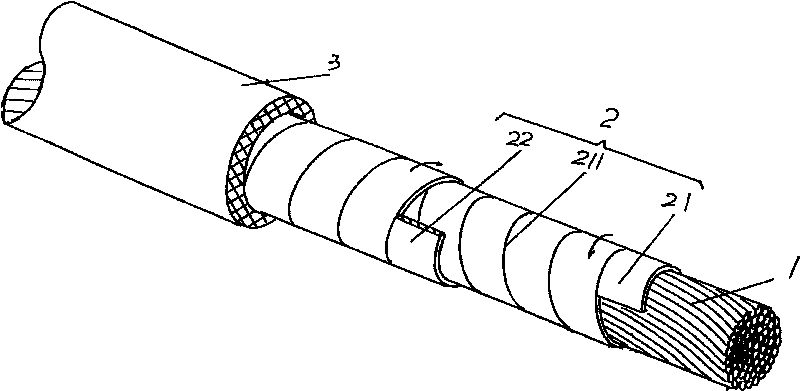

Fireproof cable

InactiveCN101707065AGood flexibilityImprove outer diameterInsulated cablesInsulated conductorsInsulation layerElectric wire

The invention relates to a fireproof cable, belonging to the technical field of wires and cables. The fireproof cable comprises a conductive wire core, a wrapping layer wrapped outside the conductive wire core and an insulation layer extruded outside the wrapping layer, wherein the wrapping layer comprises a first fireproof mica tape and a second fireproof mica tape which have opposite wrapping directions; the first fireproof mica tape is wrapped outside the conductive wire core in a connection mode; the second fireproof mica tape is wrapped outside the first fireproof mica tape in the same connection mode; and the insulation layer is extruded outside the second fireproof mica tape. The technical scheme replaces the traditional overlapping mode for wrapping the fireproof mica tapes with a connecting mode for wrapping the first fireproof mica tape and the second fireproof mica tape which have opposite wrapping directions, thereby not only improving the fireproof effect and saving the fireproof mica tapes, but also improving the flexibility and the external diameter of the fireproof cable and the wrapping efficiency.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

Golden fragrant nut and preparation method thereof

The invention discloses a golden fragrant nut and a preparation method thereof. The preparation method specifically comprises the following steps: (1) performing baking; (2) performing cooling; (3) preparing a coating liquid; (4) preparing a pre-powder; (5) performing coating; (6) performing wrapping with the powder; (5) performing baking; (6) performing cooling; (7) performing scattering; (8) performing vibrating to remove slag; and (9) preparing a golden fragrant nut finished product. According to the golden fragrant nut, the fragrance of a nut raw material is further stimulated, the productis endowed with natural smoking flavor and crispy taste, the smoking flavor and a marinating flavor are naturally fused to form unique golden-fragrant flavor, and the content range of the series of products is expanded. According to the invention, the appearance of the nut coating layer is transparent and bright and uniform in color, the defective rate is reduced by 25-35%, meanwhile, the half-grain rate of the product is reduced by 20%, the yield is increased, the problem of adhesion of the product after being taken out of an oven is solved, the adhered materials can be well separated, a quick cooling process is beneficial to quick drying of the surface of the golden fragrant nut, and the shelf life of the product is prolonged.

Owner:青岛众创味来食品科技有限公司

Small food wrapping machine

PendingCN108313356ASmall footprintSimple structureWrapping material feeding apparatusConveyor wrappingSingle chipMechanical engineering

The invention relates to a small food wrapping machine. The small food wrapping machine comprises a frame body, a wrapping assembly, a wrapping steering engine and a single chip microcomputer; the wrapping assembly, the wrapping steering engine and the single chip microcomputer are arranged on the frame body, the wrapping assembly comprises a wrapping table, a lower turning plate, an upper slidingplate, a transverse fork plate and a vertical fork plate. The wrapping machine is simple in structure, small in occupied space, high in wrapping efficiency and suitable for package of small cakes.

Owner:JILIN UNIV

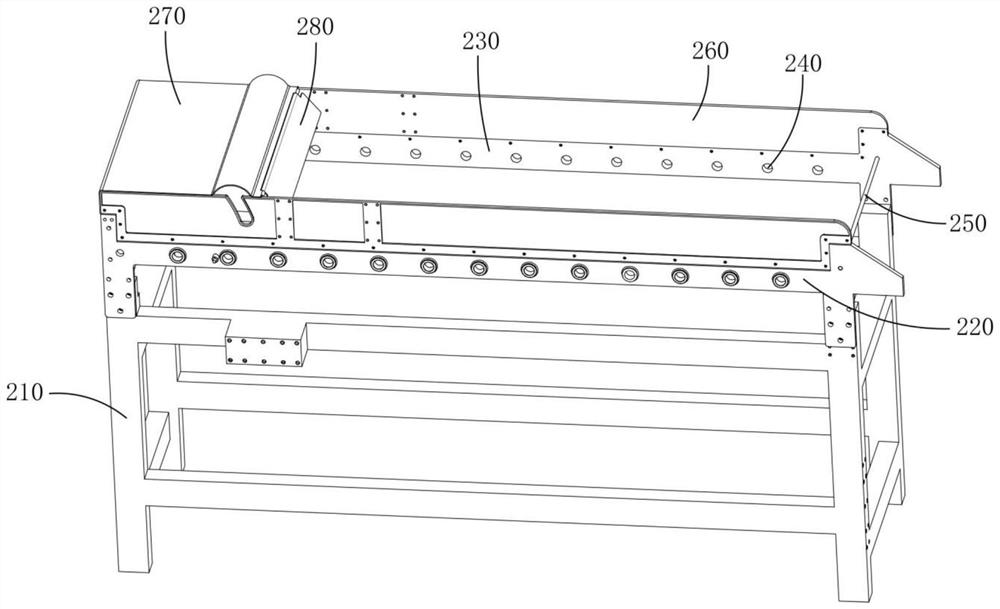

Surface wrapping machine for puffed foods

InactiveCN109820220AEvenly wrappedImprove wrapping efficiencyFood coatingEngineeringMechanical engineering

The invention discloses a surface wrapping machine for puffed foods. The surface wrapping machine comprises an installation rack, a conveying belt, a transmission conveying mechanism and a power supply mechanism, wherein the transmission conveying mechanism is used for transmitting conveying power to the conveying belt; the power supply mechanism is used for supplying power to the transmission conveying mechanism; the conveying belt, the transmission conveying mechanism and the power supply mechanism are installed on the installation rack; the conveying belt is used for conveying rod-like foods or particles. The installation rack is further provided with a falling device and a particle conveying device, wherein the falling device is used for making the rod-like foods fall off; the particleconveying device is used for conveying the particles. The installation rack is of a rectangular frame structure, the conveying direction of the conveying belt is parallel to the length direction of the installation rack, the conveying belt is a wave-propelled conveying belt, the falling device is arranged at the position, close to the conveying starting end of the conveying belt, above the conveying belt, and the particle conveying device is arranged on one side in the width direction of the installation rack.

Owner:潘声田

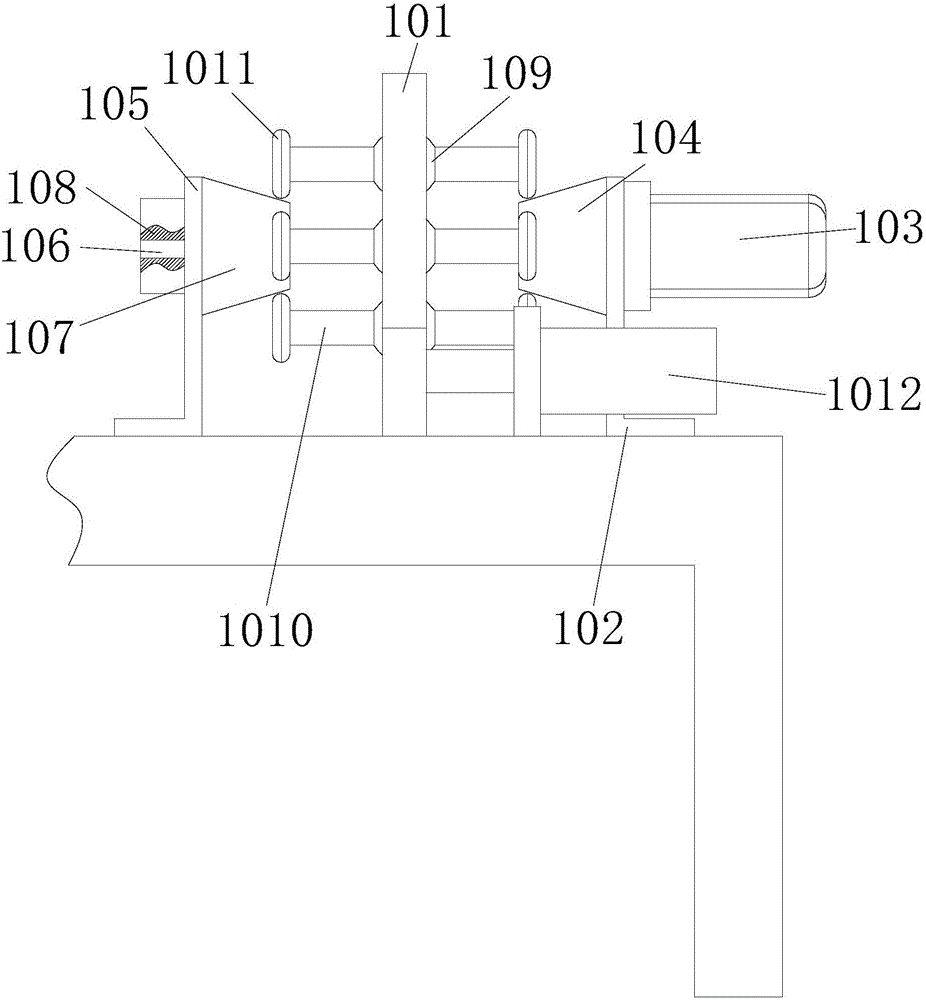

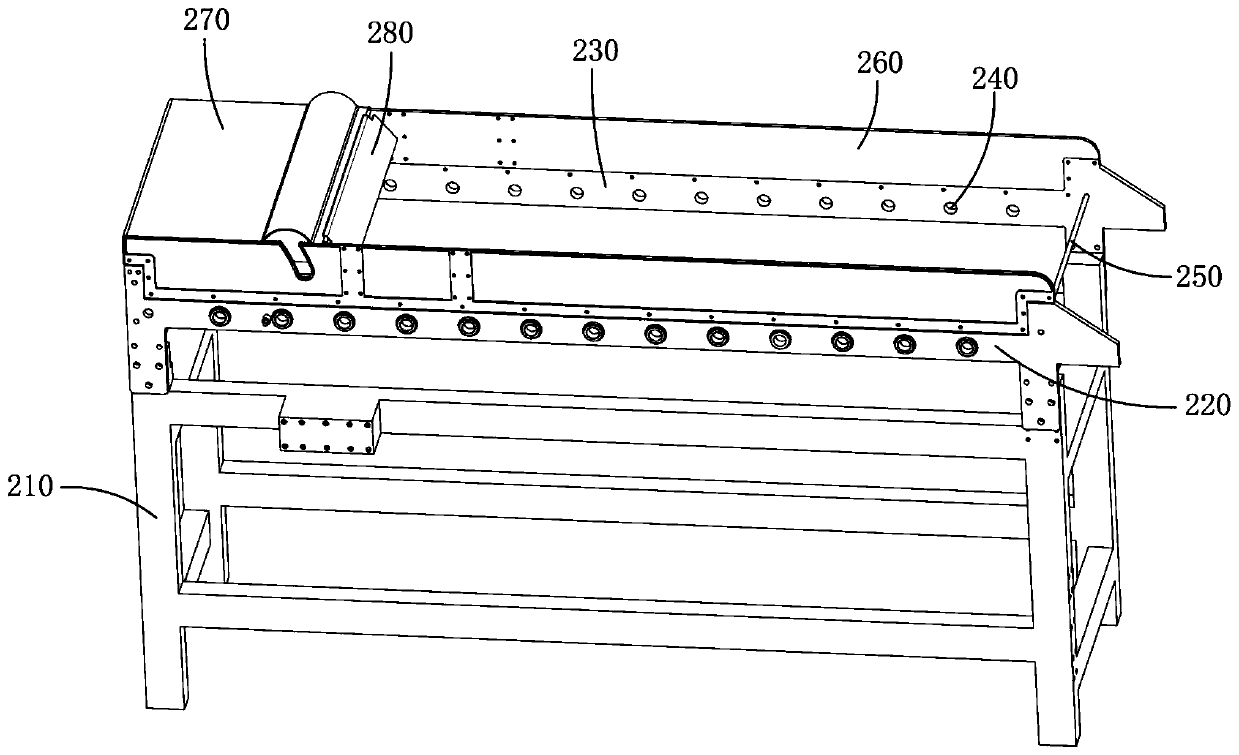

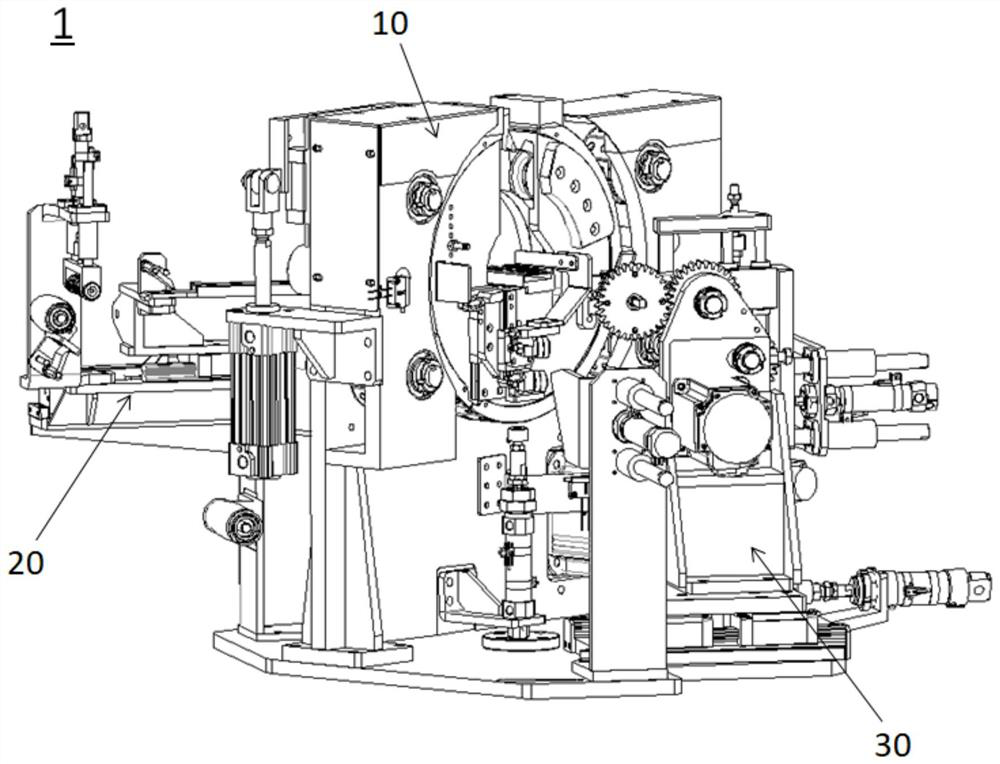

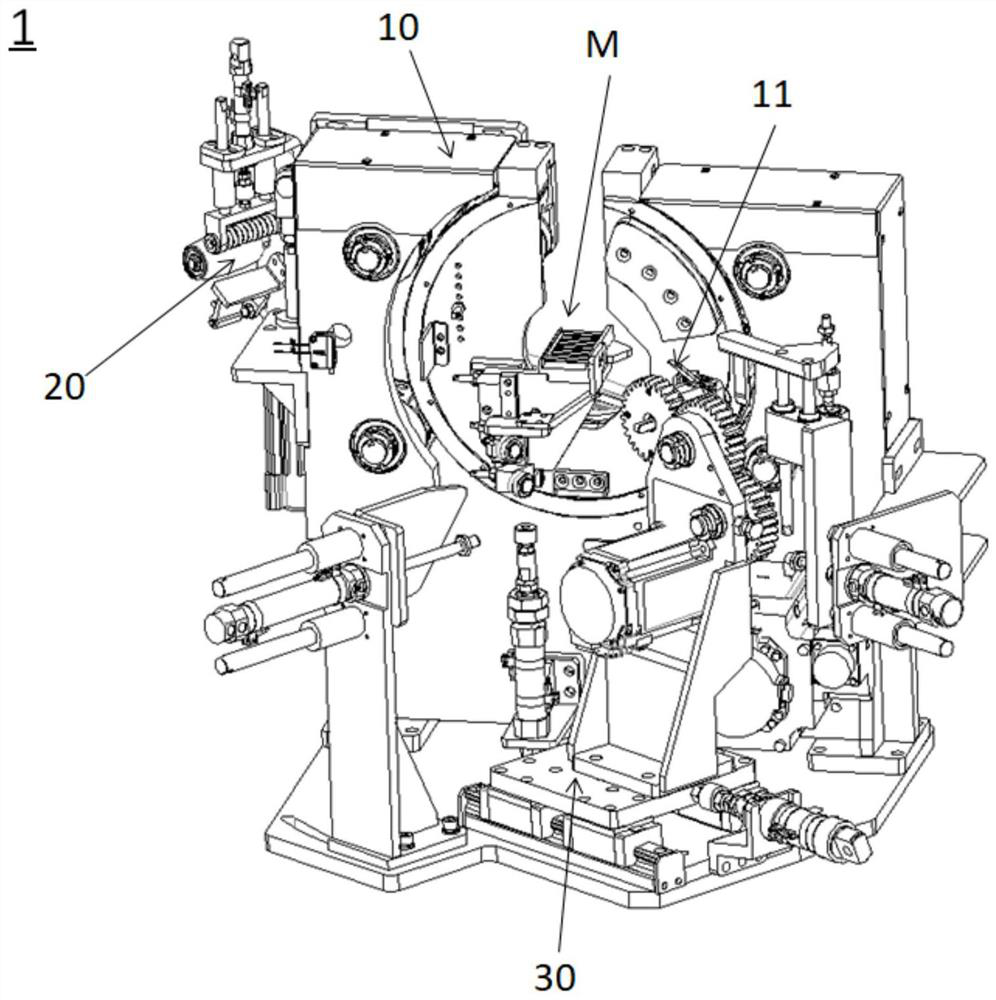

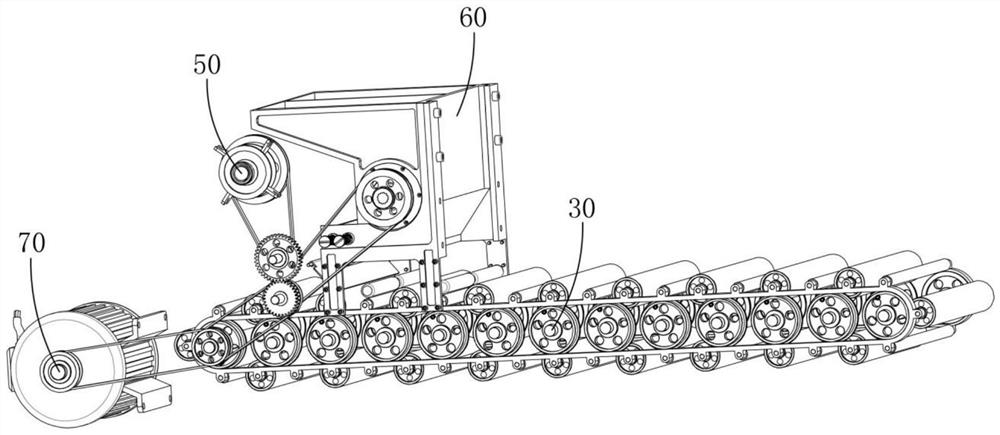

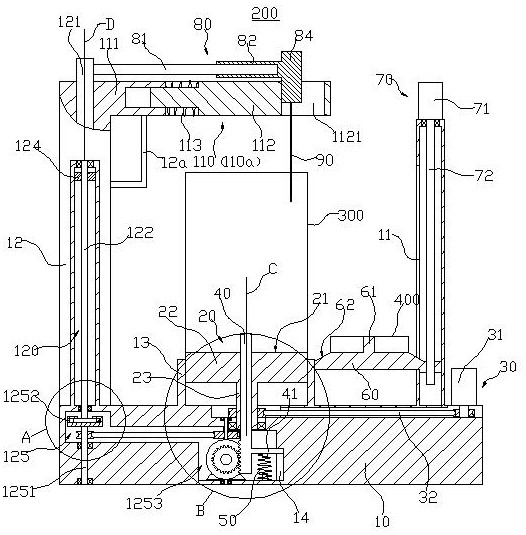

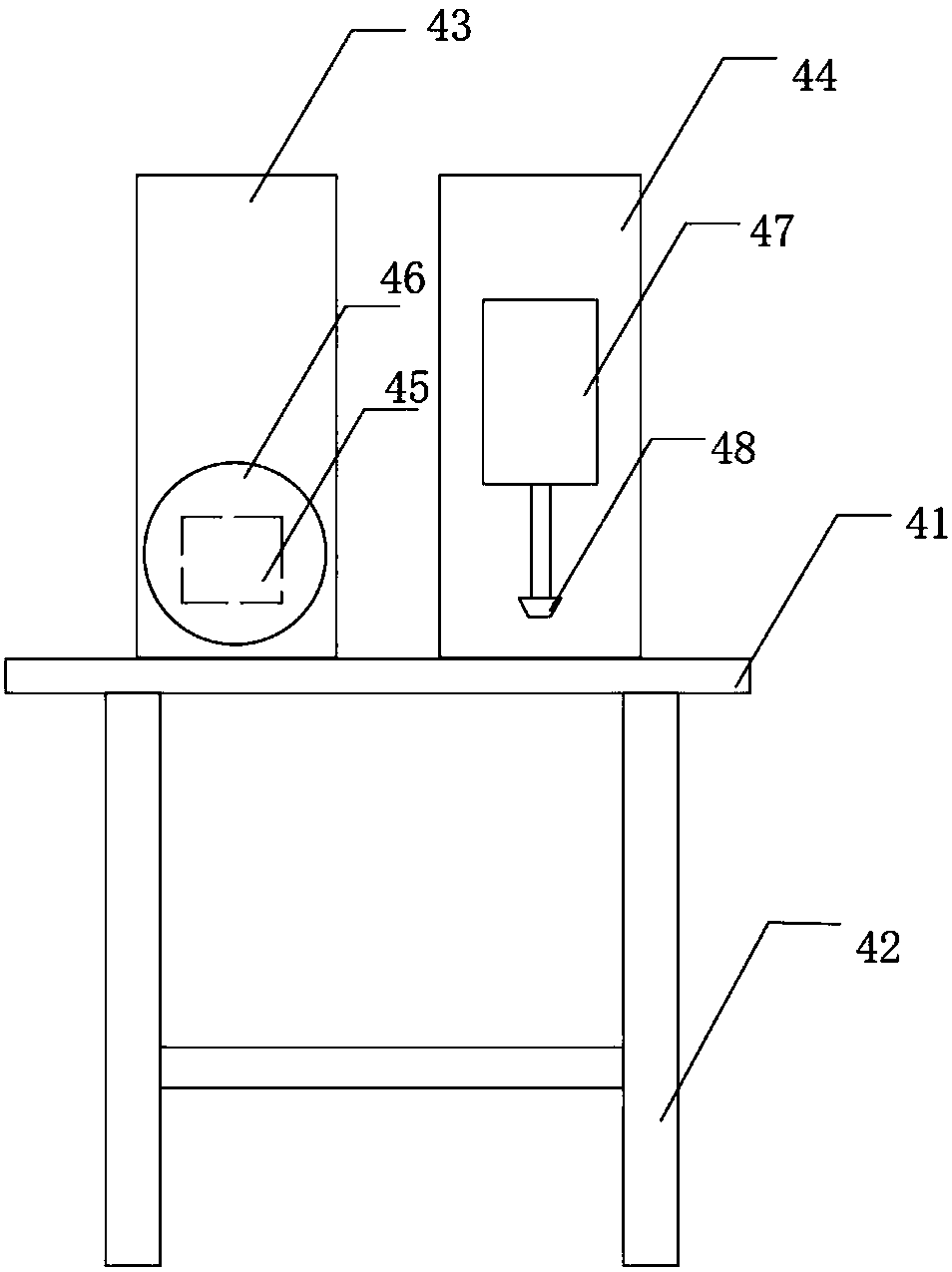

Electromagnetic wire wrapping device

InactiveCN112489892AImprove wrapping efficiencySmall footprintInsulating conductors/cablesClutchElectric machinery

The invention provides an electromagnetic wire wrapping device which sequentially comprises a first straightening assembly, a wrapping machine frame, a wrapping machine table and a crawler-type traction machine, a plurality of wrapping frames are vertically distributed in the wrapping machine frame and driven by a first motor to rotate synchronously, and a second straightening assembly and two wrapping frames are sequentially and horizontally distributed on the wrapping machine table. A second motor and a clutch gearbox are arranged in the wrapping machine table, and output shafts are arrangedat the two ends of the clutch gearbox and connected with the hollow shafts of the two wrapping frames through tooth-shaped chains respectively; and the first motor, the second motor, the clutch gearbox, the rotating speed sensor and the self-reset switch are all electrically connected with the controller. The four paper discs can be placed on the single wrapping frame at the same time for wrapping, the wrapping efficiency is greatly improved, multi-layer wrapping can be achieved without multiple devices, the occupied area and the device investment are effectively reduced, and the production cost is reduced; and the two wrapping frames on the wrapping machine table can rotate reversely, so that wrapping in different rotating directions is realized, and different requirements of customers can be met.

Owner:江西九星铜业有限公司

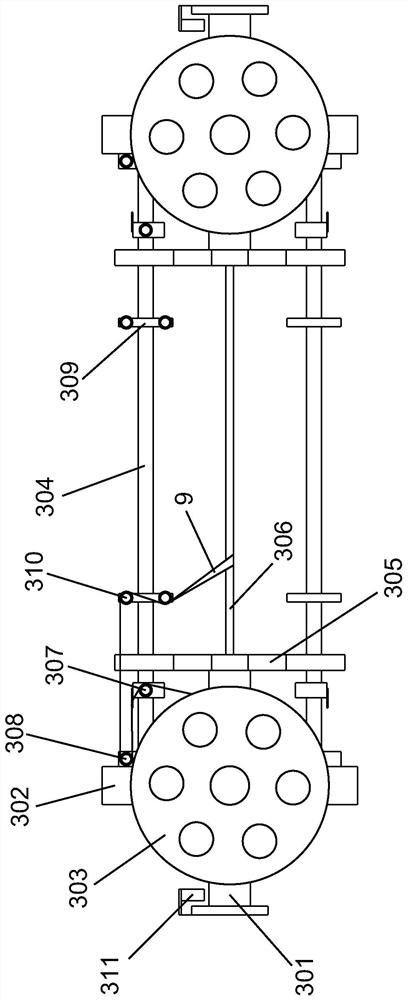

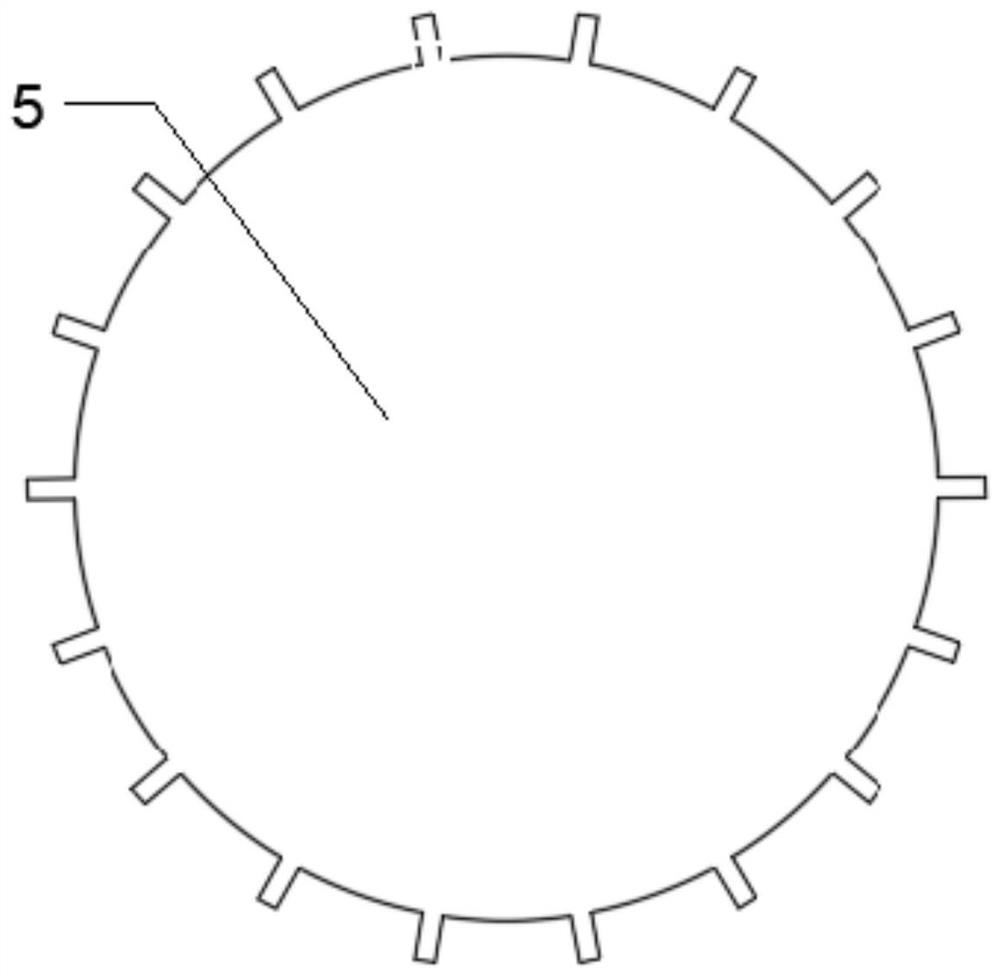

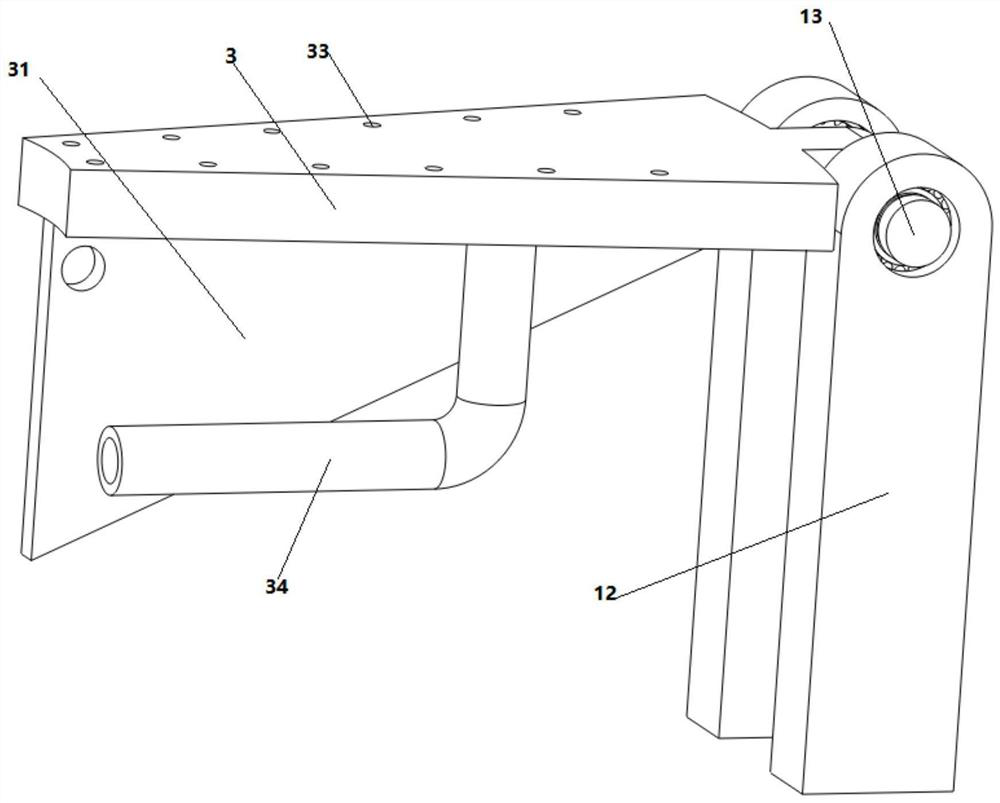

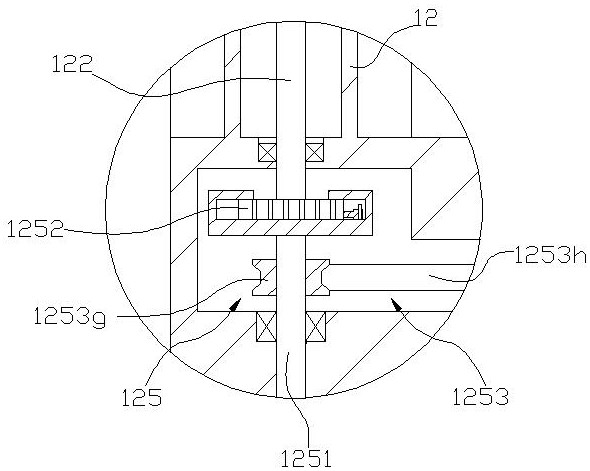

Winding head for steel wire ring cloth wrapping machine and steel wire ring cloth wrapping machine

ActiveCN114347533AImprove wrapping efficiencySolve the situation of breaking away from the material head clamping structureTyresRing deviceEngineering

The invention discloses a winding head for a steel wire ring cloth wrapping machine. The winding head comprises a winding ring device provided with a material storage roller, a material conveying device and a material storage driving device. The material conveying device is used for conveying a cloth wrapping strip belt to the material storage roller; the material storage driving device is used for driving the material storage roller to rotate so as to wind the cloth wrapping strip with the preset length onto the material storage roller for temporary storage; the winding ring device is used for winding the wrapping cloth strip temporarily stored on the storage roller onto a steel wire ring; wherein the material conveying device comprises a material conveying plate, a first retaining element and a cloth wrapping strip temporary storage device, the cloth wrapping strip temporary storage device is arranged on the upstream of one side of a feeding port of the material conveying plate, and the first retaining element is arranged between the cloth wrapping strip temporary storage device and the feeding port of the material conveying plate. The problem that the stub bar of the cloth wrapping strip is easily separated from a stub bar clamping structure when rotating after being clamped is mainly solved by arranging the first retaining element and the cloth wrapping strip temporary storage device, and then the cloth wrapping efficiency of the steel wire ring cloth wrapping machine is improved.

Owner:LINK-ASIA SMART TECH (SUZHOU) CO LTD

1-methylcyclopropene inclusion complex for fruits, vegetables and flowers and preparation method thereof

InactiveCN101971875BImprove the efficiency of encapsulationImprove wrapping efficiencyDead plant preservationFruit and vegetables preservationActive componentCyclodextrin

The invention relates to a 1-methylcyclopropene inclusion complex for fruits, vegetables and flowers and a preparation method thereof. The inclusion complex is prepared by carrying out inclusion reaction on 1-methylcyclopropene and a cyclodextrin copper complex, and is a novel solid antistaling agent material for fruits, vegetables and flowers. The active component of the inclusion complex is 1-methylcyclopropene gas accounting for 0.001%-4.5% of the weight of the antistaling agent. The inclusion complex is used for refreshment of fruits, vegetables and flowers with climacteric after-ripeningand senescence, has high active component content, convenient use and low cost, is uneasy to oxidize and is apt to reserve, store and transport. The preparation method is performed at an ordinary pressure, has the advantages of simple process, safety and reliability, high product yield and low cost, and is easy to implement.

Owner:浙江欣衢环境科技有限公司

Multi-layer wrapping conveying line

PendingCN114132568AImprove work efficiencySave time at workWrappingWrapper twisting/gatheringStructural engineeringWork time

Owner:TRUKING TECH LTD

Surface wrapping technology of puffed food based on sine wave push

ActiveCN109965329BEvenly wrappedImprove wrapping efficiencyConfectionerySweetmeatsElectric machineryConveyor belt

The invention discloses a sine wave push-type puffed food surface wrapping process. The method includes: stick food enters the wrapping machine and drops onto the conveyor belt of the wrapping machine, and the conveyor belt is conveyed by a transmission set on the wrapping machine. The mechanism transmits power, and the power is provided by the power supply mechanism installed on the wrapping machine. When the conveyor belt conveys the stick food, the motor is turned on, and the output shaft of the motor rotates to drive the driving wheel to rotate and drive the first driven wheel to rotate around its own axis. , the movement of the transmission roller makes a particle on the conveyor belt do a simple harmonic motion up and down, the movement of the transmission roller and the adsorption rod makes the contact interface between the conveyor belt and the transmission roller always at the peak position, and the contact interface between the conveyor belt and the adsorption rod The contact interface is always in the trough position, and the bar-shaped food is placed at the beginning of the conveyor belt and in the trough position between two adjacent driving rollers.

Owner:山东大树达孚特膳食品有限公司

Tea cake paper wrapping machine

The invention discloses a cake tea paper wrapping machine which comprises a bottom plate, a paper wrapping mechanism and a paper wrapping mechanism. The supporting plate is movably arranged below the through hole; one end of each vacuum suction plate is hinged to the outer side of the bottom plate, and the vacuum suction plates can suck the outer side of the tea paper; a first driving structure; the second driving structure can be matched with the first driving structure to enable the non-hinged end of the vacuum suction plate to be suspended above the bottom plate; the paper driving structure is used for driving the part, between every two adjacent vacuum suction plates, of the tea paper to form a crease when the non-hinged ends of the vacuum suction plates are suspended above the bottom plate; the paper pressing component is movably arranged above the through hole; wherein at least one of the supporting plate and the paper pressing component can drive the tea cake to rotate when the tea cake is pressed by the paper pressing component. The problem that in the prior art, the efficiency is low due to the fact that tea cakes are wrapped with paper manually can be solved.

Owner:北京秋果科技有限公司

A wrapping machine

The application provides a winding packaging machine, which belongs to the field of packaging equipment. The wrapping packaging machine includes a base, a turntable, a first driving device, a trigger lever, a first elastic member, a movable frame, a second driving device, a swing arm, a knife, a second elastic member, a locking mechanism and a transmission mechanism. The first driving device is used to drive the turntable to rotate relative to the base around the first vertical axis. The trigger lever is vertically movably inserted in the center of the turntable. The first elastic member is used to reset the trigger lever. The second driving device is used to drive the movable frame to move vertically. The swing arm can swing around the second vertical axis. The tool is mounted on the swing arm. The second elastic member is connected between the swing arm and the second column. The locking mechanism is used to releasably lock the swing arm swinging to the first position. The swing arm and the trigger lever are connected in transmission through a transmission mechanism. The wrapping packaging machine with this structure can automatically break the film after wrapping the film to the top of the workpiece, without manual cutting of the film, which can effectively improve the wrapping efficiency.

Owner:安徽鸿韵彩印包装有限公司

1-methyl-3-(2-methyl cyclopropane)-1-cyclopropylene stable inclusion compound and preparation method thereof

ActiveCN101990936ALow costGood fresh-keeping effectDead plant preservationFruit and vegetables preservationMethyl groupMethylcyclopropane

The invention discloses a 1-methyl-3-(2-methyl cyclopropane)-1-cyclopropylene stable inclusion compound for preserving freshness of fruits, vegetables and flowers. The inclusion compound is characterized by being formed by inclusion reaction of 1-methyl-3-(2-methyl cyclopropane)-1-cyclopropylene and cyclodextrin copper complexes. The inclusion compound is a novel solid material used as a preservative agent for preserving the freshness of fruits, vegetables and flowers. The effective component in the inclusion compound is 1-methyl-3-(2-methyl cyclopropane)-1-cyclopropylene gas of which the weight percent accounts for 0.001%-4.5% of the preservative agent. The product is mainly used for preserving the freshness of climacteric after-ripening fruits, vegetables and flowers, has high content of effective components, can not be oxidized easily, can be used conveniently, can be kept, stored and transported easily, is prepared at the normal pressure, and has the advantages of simple processes, easy implementation, safety, reliability, high product yield and low cost.

Owner:XI AN JIAOTONG UNIV

Wrapping and winding mechanism for audio cable production

The present invention proposes a wrapping and take-up mechanism for the production of audio cables, including a wrapping part and a take-up and cutting part, the wrapping part is located on the left side of the take-up and cutting part; the wrapping part It includes a chassis, a first fixed shaft screwed to the upper part of the chassis, a first reel sleeved on the first fixed shaft, and a second base screwed to the bottom of the chassis , the first lifting rod screwed to the second base along the axial direction of the second base, the first fixing plate screwed to the top of the first lifting rod and welded to the chassis Limiting pieces on both sides of the middle part. The invention has high wrapping efficiency and good shearing effect, and is beneficial to improving production efficiency.

Owner:嘉兴凯达电子有限公司

Food packaging and rolling device

InactiveCN107874653AShorten the cooking processImprove wrapping efficiencyKitchen equipmentAdditive ingredientEngineering

The present invention relates to the field of food making tools, in particular to a food wrapping device, comprising: a base and a drawing roller blind, the drawing roller blind is located in the workbench of the base, and the base is mainly composed of a workbench and an inserting plate , the inserting board is embedded in the crack of the workbench. During implementation, lay the drawable roller blind on the workbench of the base, insert the groove block of the drawable roller blind into the plug-in board, and place and stick the prepared food outsourcing roll on the drawable roller blind Then add your favorite fillings and ingredients, and control the pull block and the slot block of the rolling curtain with both hands to form a cylindrical roll shape, so that the wrapped food can be shaped. The invention has the beneficial effects of providing a convenient and fast auxiliary tool for food production through the shape fit and material selection of the base and the pull-out roller blind, and improving the wrapping efficiency.

Owner:SONGLI GUANGDONG ELECTRONICS TECH CO LTD

Winding method for fireproof asbestos cloth

ActiveCN102062275AEasy alignmentImprove stuckPipe elementsPipe protection against damage/wearMechanical engineeringAsbestos

The invention relates to a winding method for fireproof asbestos cloth, which belongs to the technical field of rubber-hose overhauling. The winding method comprises the following processes of: connecting and fixing the rotating ends of rubber hoses needing to be wound, connecting the driven ends of the rubber hoses needing to be wound, regulating the distance according to the length of the rubber hoses and winding the fireproof asbestos cloth. The method provided by the invention has the advantages that compared with a purely manual method, by adopting the wrapping method, the labor force can be saved by one person, the wrapping efficiency is high, and the quality is good.

Owner:BEIJING SHOUGANG CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com