Winding package machine

A packaging machine and driving device technology, applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems affecting the wrapping efficiency, etc., and achieve the effect of improving wrapping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

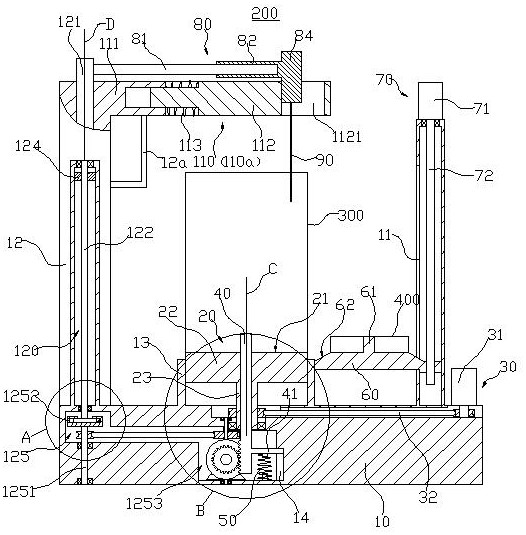

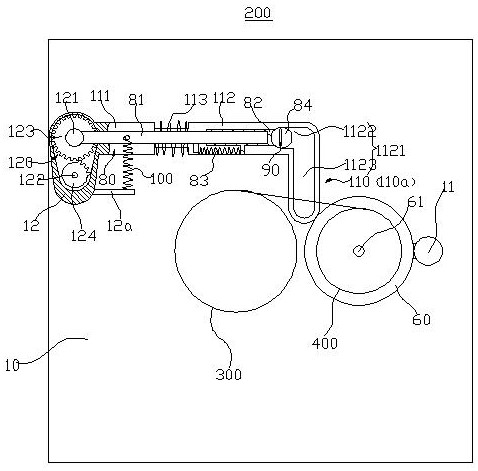

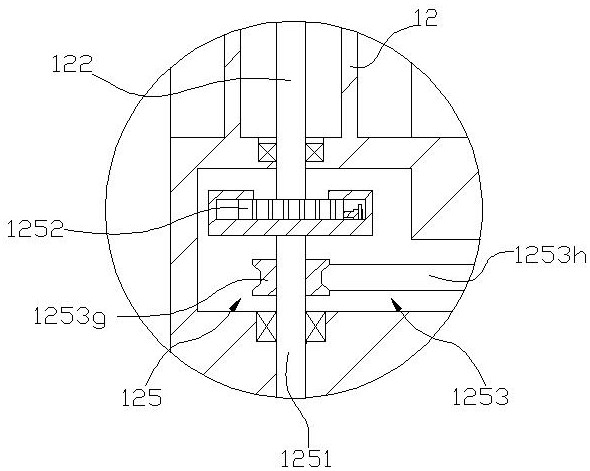

[0054] Such as figure 1 , figure 2 As shown, the embodiment of the present application provides a wrapping packaging machine 200, including a base 10, a turntable 20, a first driving device 30, a trigger lever 40, a first elastic member 50, a movable frame 60, a second driving device 70, a pendulum Arm 80 , knife 90 , second elastic member 100 , locking mechanism 110 and transmission mechanism 120 .

[0055] The base 10 is fixed with a first column 11 and a second column 12 arranged at intervals. The turntable 20 is rotatably disposed on the base 10 , and the turntable 20 has a placing surface 21 for placing the workpiece 300 . The first driving device 30 is connected between the turntable 20 and the base 10 , and the first driving device 30 is used to drive the turntable 20 to rotate around the first vertical axis C relative to the base 10 . The trigger rod 40 is vertically movably inserted at the center of the turntable 20 , and the top end of the trigger rod 40 protrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com