Winding method for fireproof asbestos cloth

A technology of asbestos cloth and wrapping cloth is applied in the field of wrapping fire-resistant asbestos cloth, which can solve the problems of low labor productivity, low efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Processing step of the present invention is:

[0023] 1. The connection and fixation of the rotating end:

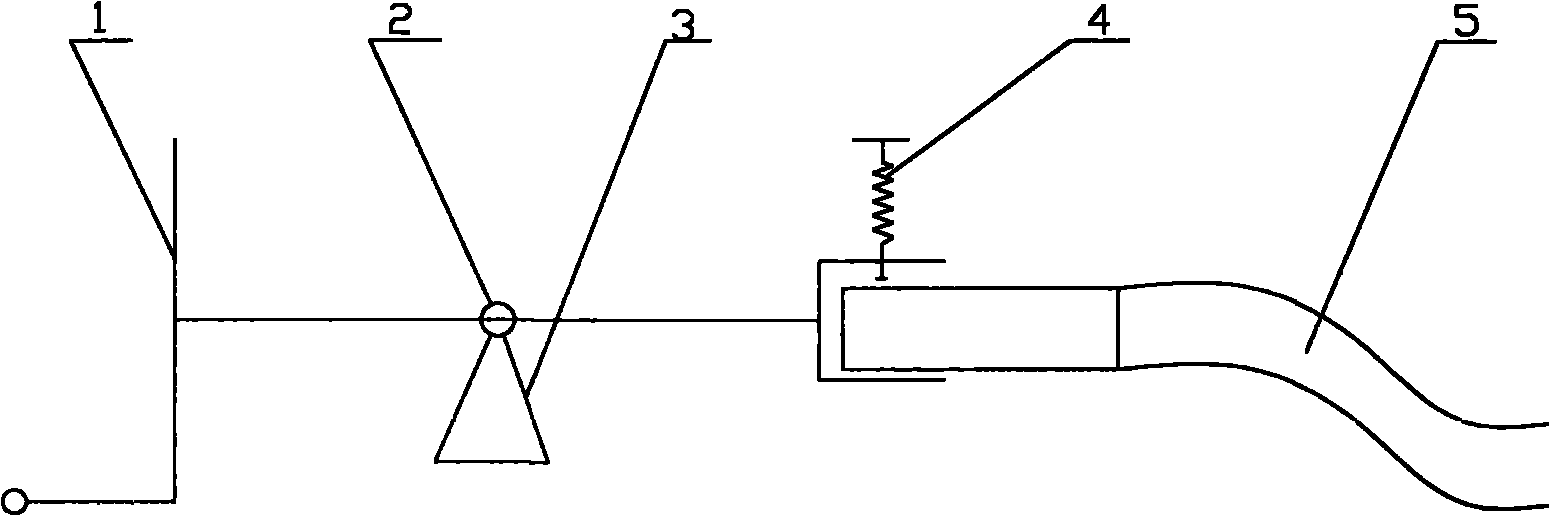

[0024] Pull up the end of the hose that has been bolted, and insert it into the figure 1 In the cylinder on the side of the rotating end shown, turn the locking handle to fix this end. In this operation, when turning the locking bolt to lock one side of the hose, the force point of the locking switch must be on the side of the nut on the hose crimping, not on the crimping iron piece, so as to prevent the sealing structure from being damaged. destroy.

[0025] 2. Connection of the driven end of the rubber hose:

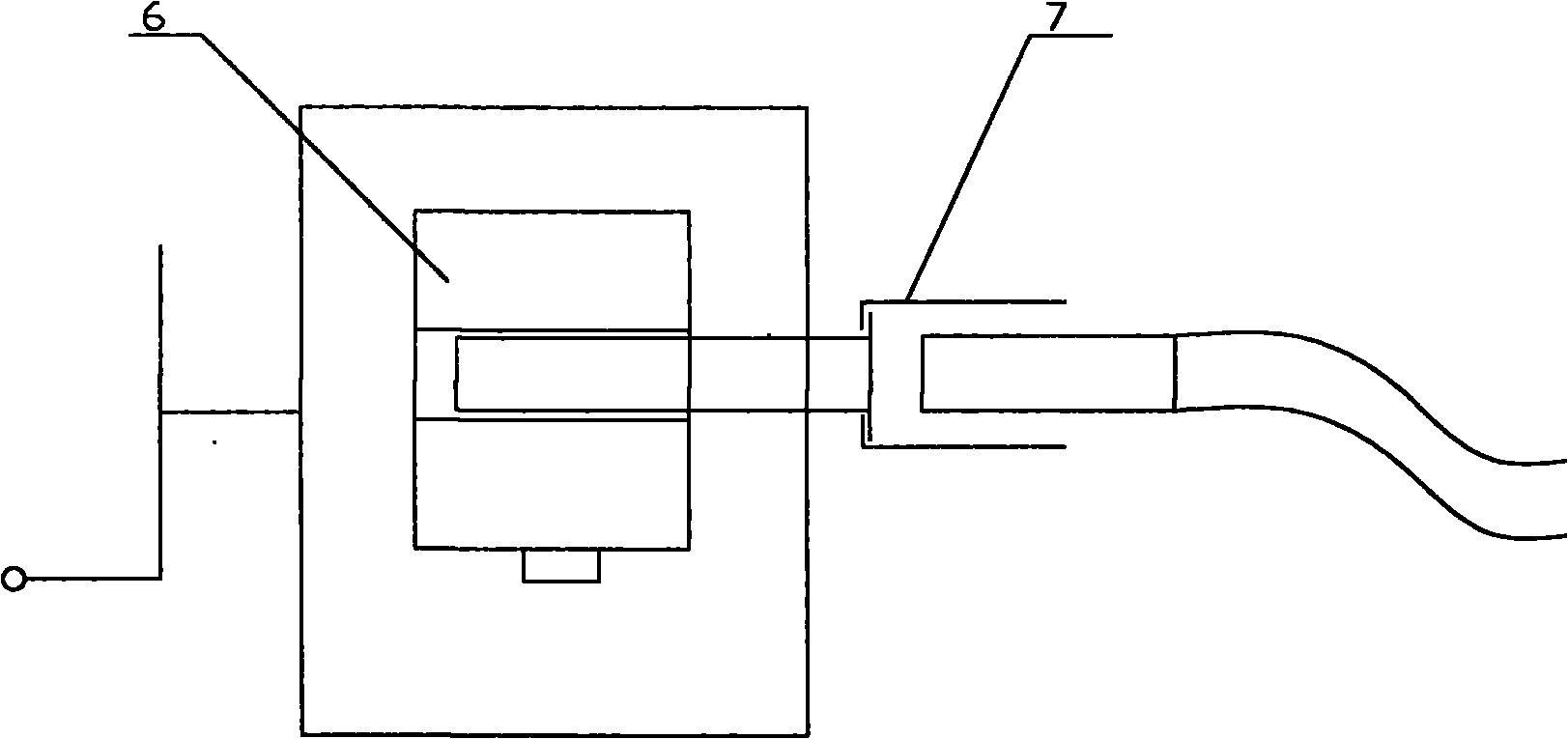

[0026] Remove the nut at the other end of the hose, screw the bolt on the nut side of the matching pre-prepared structure, and fasten the other end of the structure with a vise, such as figure 2 shown.

[0027] 3. Adjust the distance according to the length of the hose:

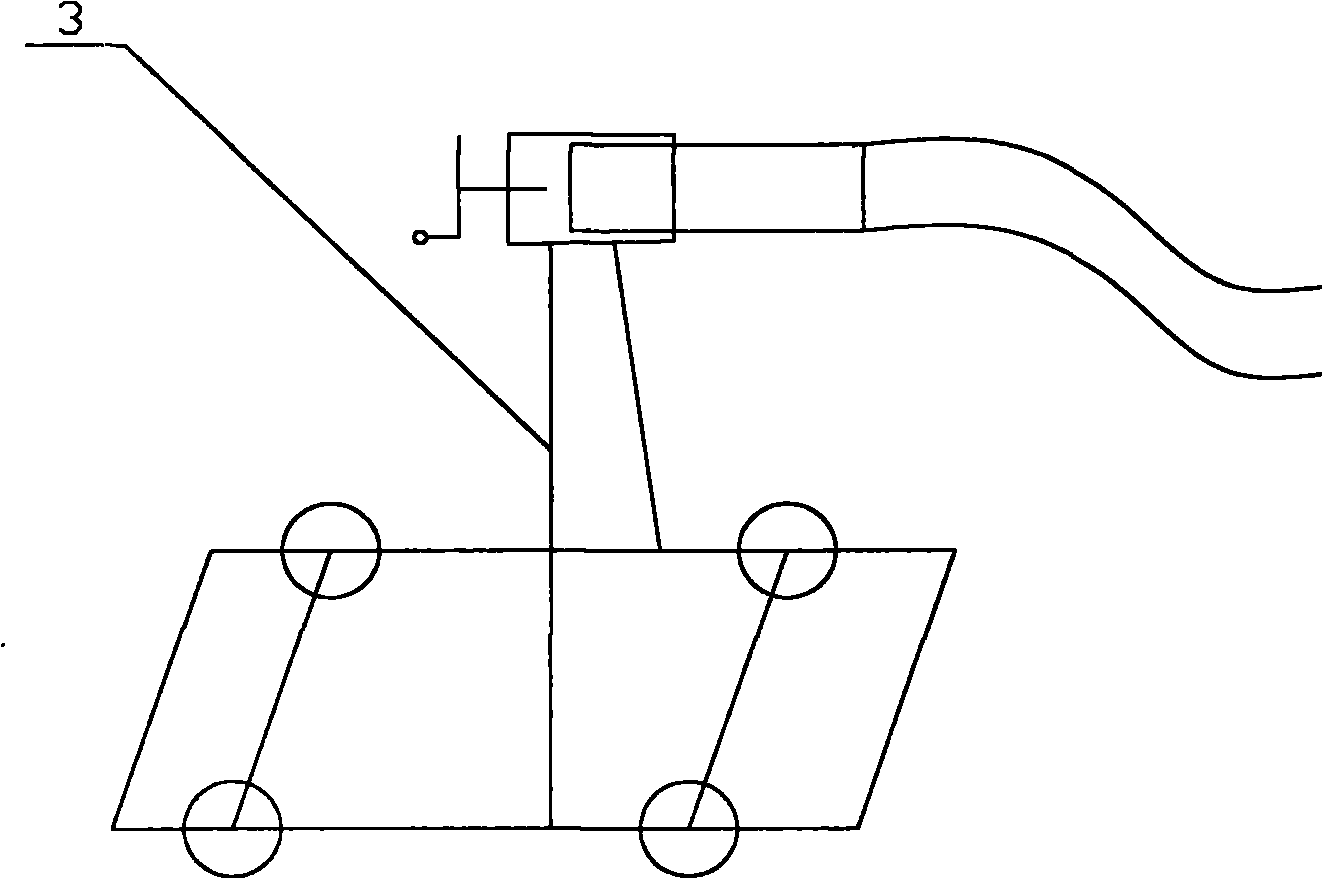

[0028] Move the trolley at the rotating end and the driven end according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com