Patents

Literature

35results about How to "Realize automatic wrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

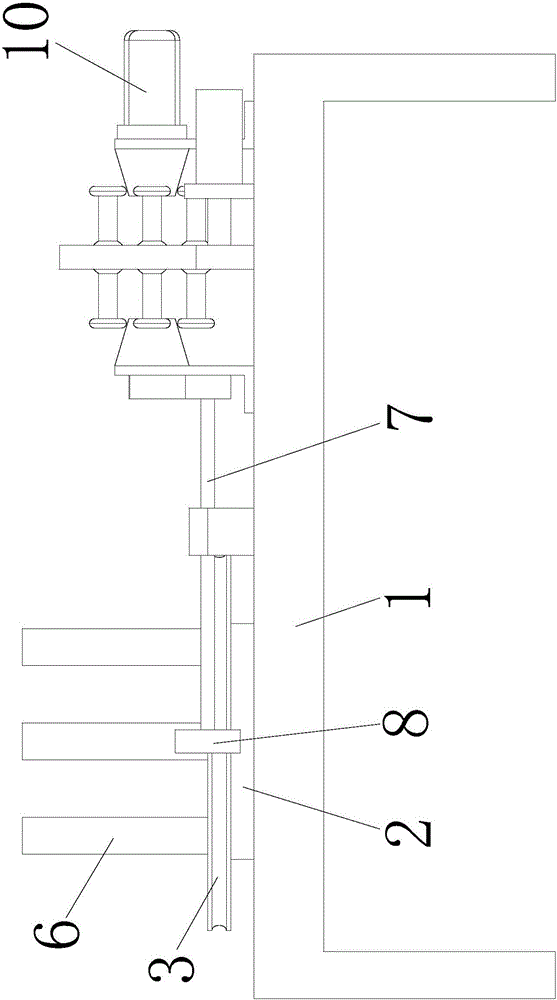

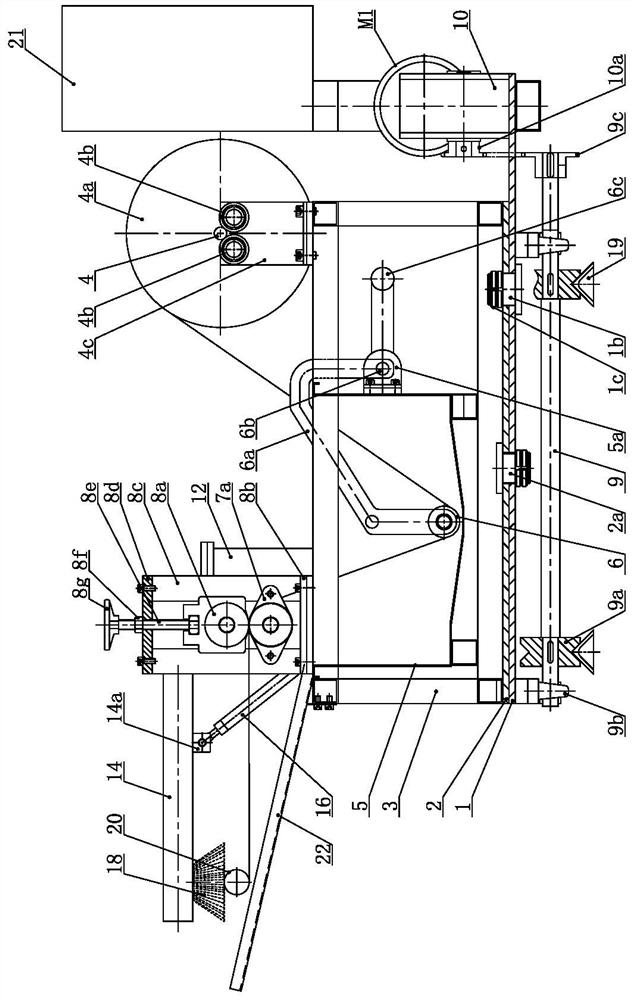

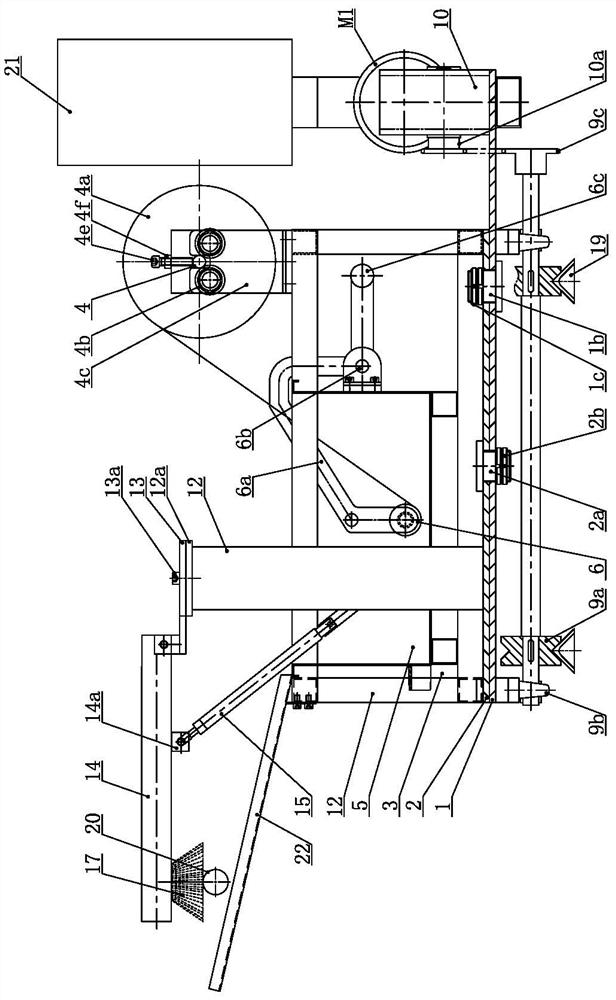

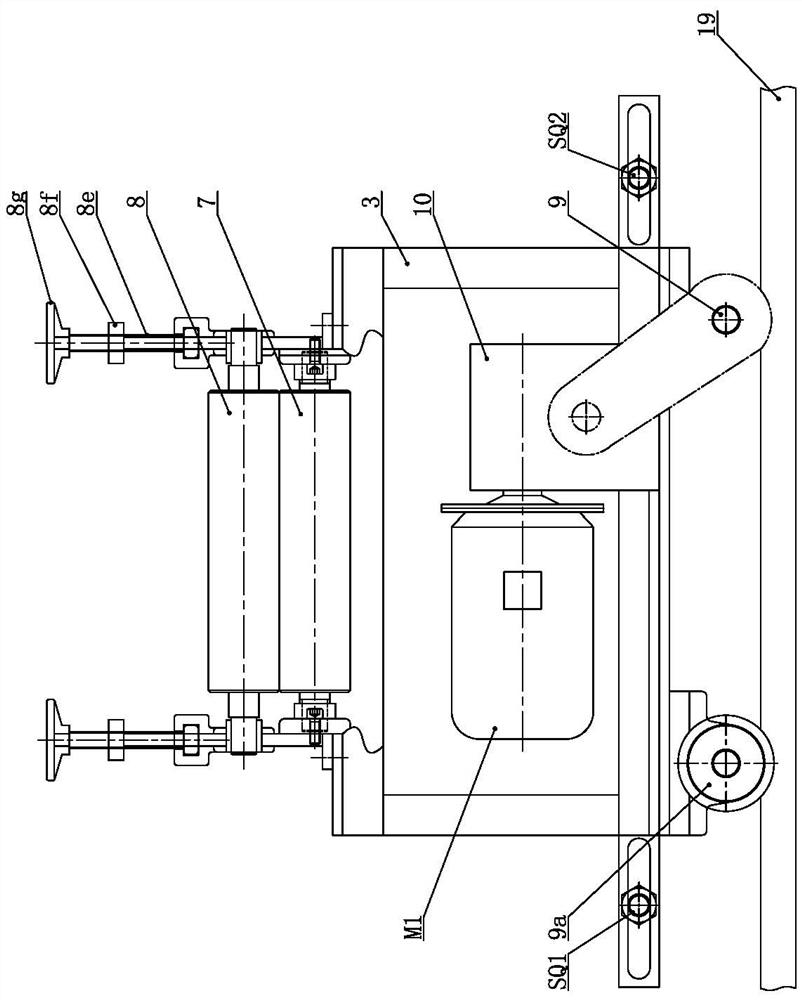

Paper wrapping and pasting device of full-automatic hamburger packaging machine

ActiveCN105857702ARealize automatic paper wrappingThe process is complete and smoothWrapper folding/bending apparatusWrapper supporting apparatusMeat burgerPulp and paper industry

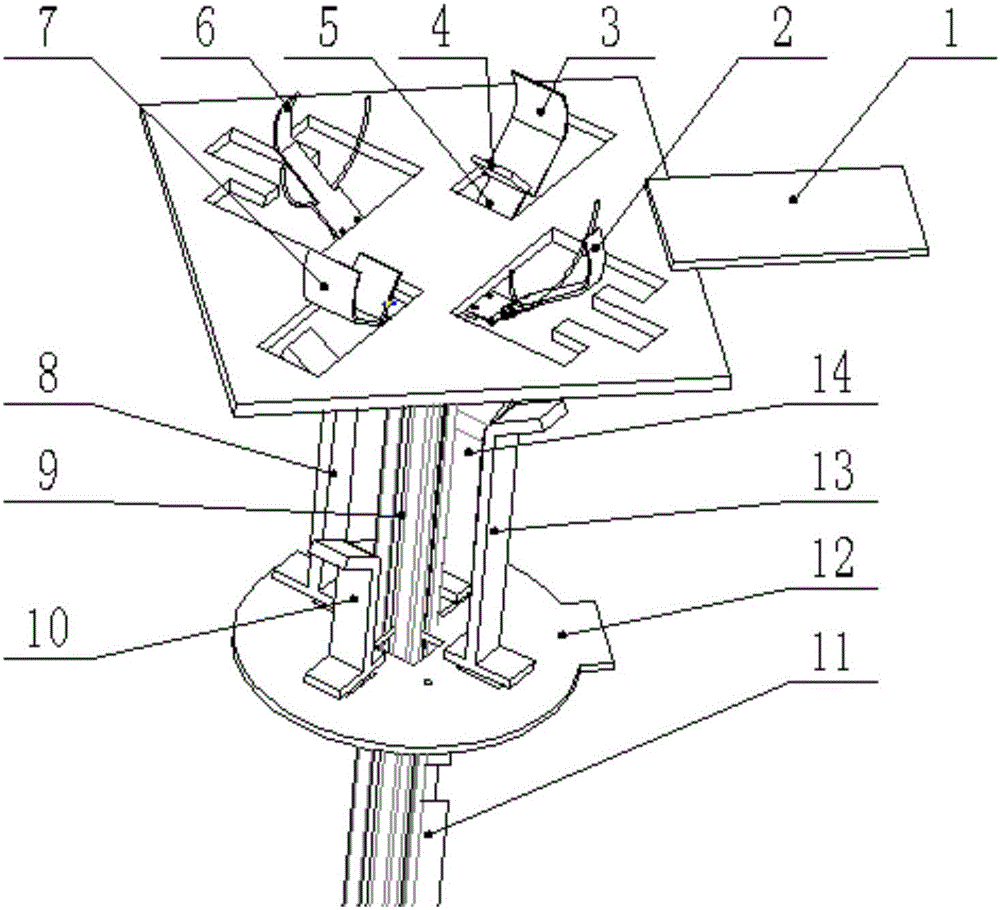

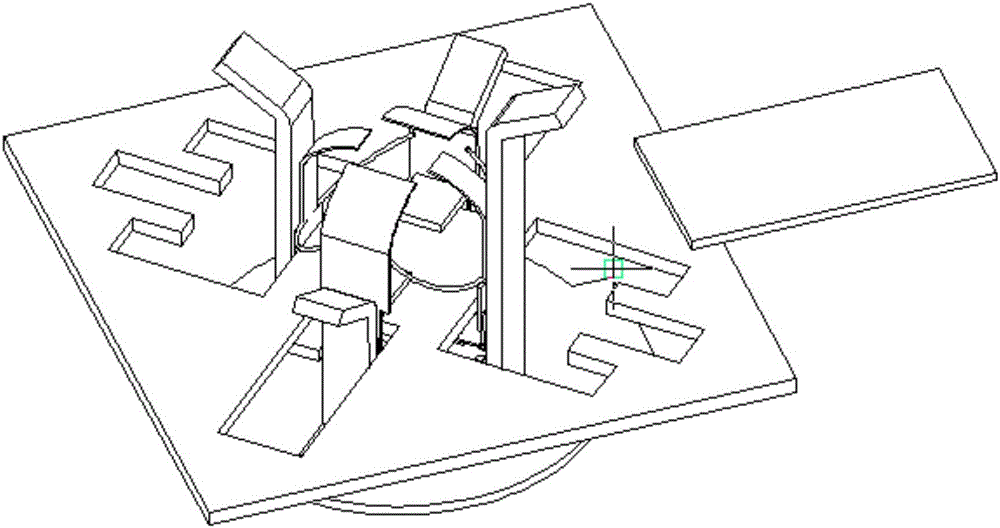

The invention discloses a paper wrapping and pasting device of a full-automatic hamburger packaging machine. The paper wrapping and pasting device comprises a rack, wherein a working platform is arranged on the rack; four mechanical claw arms are respectively arranged on the working platform; the four mechanical claw arms comprise two groups of front claw arms and rear claw arms arranged oppositely; sponge strips are arranged in the middle of the rear claw arms; the sponge strips face to a paper wrapping station; compression springs are arranged at the connecting parts of the four mechanical claw arms and the working platform; push rods are mounted on a push platform; the push platform is connected with a lifting driving component; through holes through which the mechanical claw arms are turned downwards and the push rods penetrate are formed in outer sides of the four mechanical claw arms on the working platform; a paper pressing cylinder and a pressing block are arranged above the paper wrapping station; a paper pasting mechanism is arranged on a side above the paper wrapping station; the moving end of the paper pressing cylinder is connected with a paper belt plate; an upper paper coiling wheel is mounted on the rack; a paper pasting piece is mounted on a roller of the upper paper coiling wheel in a sleeving manner; and the paper pasting piece penetrates through the end part of the paper belt plate and penetrates through a lower paper coiling wheel. The paper wrapping and pasting device is automatic in operation, saved in time and labor and relatively high in working efficiency, and automatic paper wrapping of hamburgers can be achieved.

Owner:ZHEJIANG UNIV OF TECH

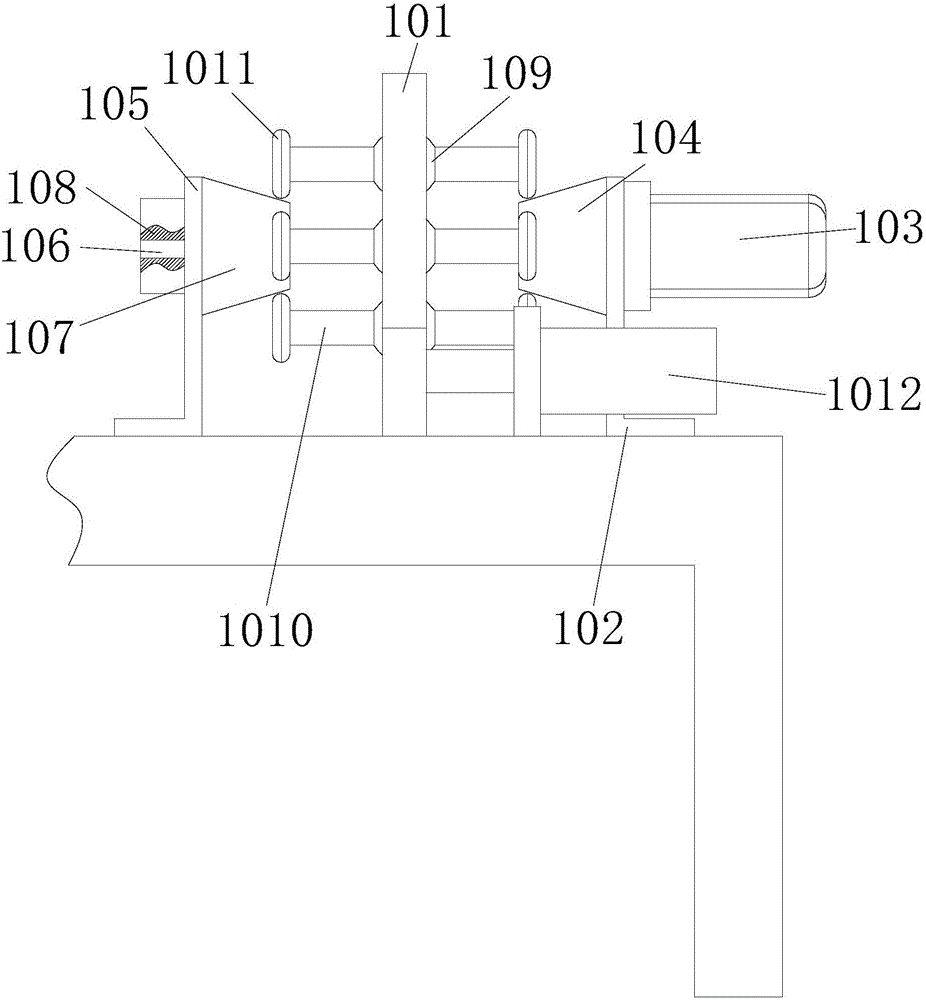

Automatic coating tooling equipment for automobile headrest and automatic coating method

InactiveCN102529770ASimple structureIncrease productivityUpholstery manufactureVehicle seatsInterior spaceHeadrest cover

The invention relates to automatic coating tooling equipment for automobile headrest and an automatic coating method, wherein the automatic coating tooling equipment comprises a worktable on which a direct-push air cylinder is arranged; the head part and the tail part of the direct-push air cylinder are respectively connected with an electromagnetic valve through an air pipe; a stationary fixture is arranged on a piston rod of the direct-push air cylinder; a headrest foam assembly is fixed on the stationary fixture; a reinforced cloth fixing seat is arranged on the worktable; a piece of reinforced cloth for coating the headrest foam assembly is fixed on the reinforced cloth fixing seat; the worktable is connected with the electromagnetic valve and a vacuum pump respectively through the air pipe; and the electromagnetic valve and the vacuum pump are respectively connected with a control box. The method comprises steps of: installing the headrest foam assembly on the stationary fixture and coating the headrest foam assembly by the reinforced cloth; vacuumizing the internal space wrapped by the reinforced cloth; nesting a headrest cover into the headrest foam assembly; stopping vacuumizing; starting the direct-push air cylinder to push the headrest upwards to realize the separation of the coated headrest and the reinforced cloth. The invention is simple in structure and high in production efficiency and is capable of automatically coating.

Owner:NINGBO JIFENG AUTO PARTS

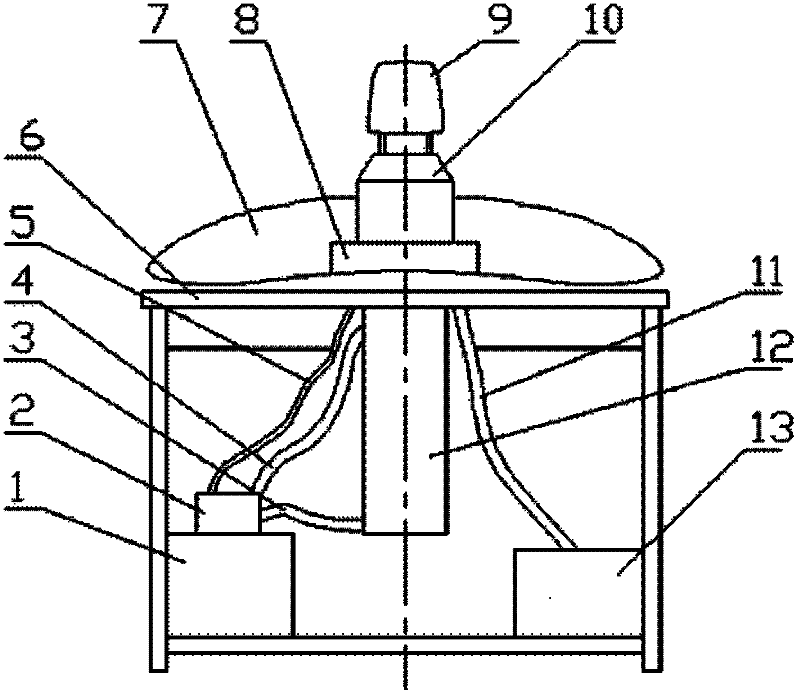

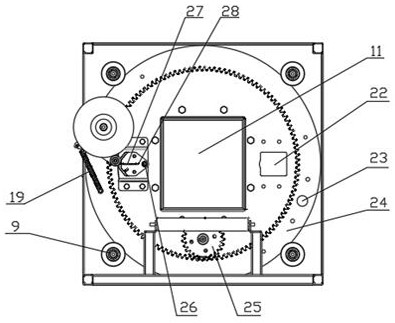

Full-automatic film winding mechanism and using method thereof

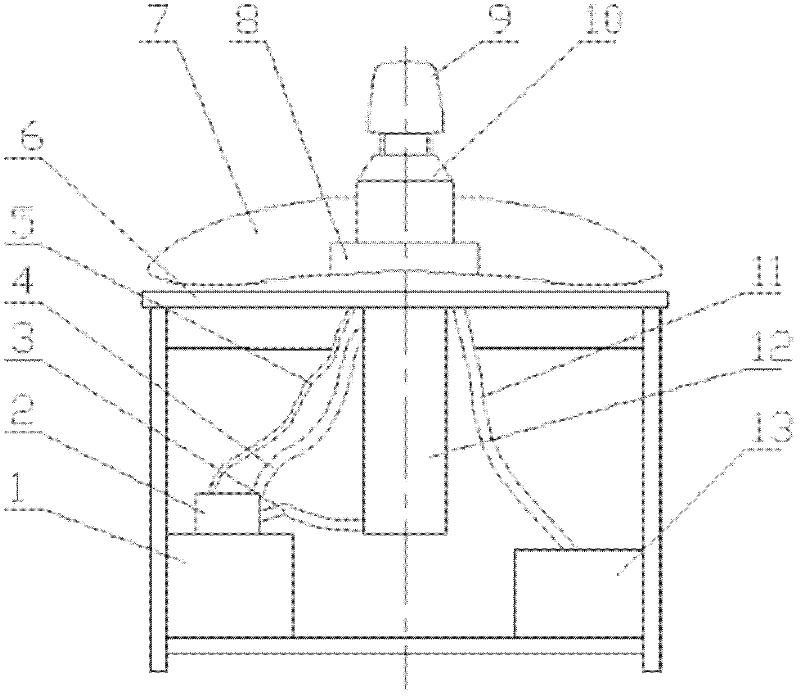

The invention relates to a full-automatic film winding mechanism and a using method thereof, and belongs to the technical field of compacted straw packaging equipment. According to the technical scheme, a discharging horn mouth (11) penetrates out of a gear ring and is fixedly arranged on a rack (8) through an upper fixing rib plate (16), a lower fixing rib plate (19) and a fastening screw (12), the gear ring and the discharging horn mouth are coaxial, and compacted straw is pushed out of the discharging horn mouth; a film winding device is installed on the gear ring (24) through a film winding device installation hole (23); a hydraulic motor (10) drives a straight gear (25) to rotate, the straight gear (25) drives the gear ring to rotate, a net roll rotates around the compacted straw along with the gear ring, and a winding film on the net roll is wound on the compacted straw; and a film pulling device is arranged between the gear ring and the discharging horn mouth. The full-automaticfilm winding mechanism and the using method thereof have the beneficial effects that automatic film winding of the compacted straw is achieved, labor force is reduced, the production cost is reduced,and the working efficiency is improved.

Owner:TANGSHAN XINWANDA IND

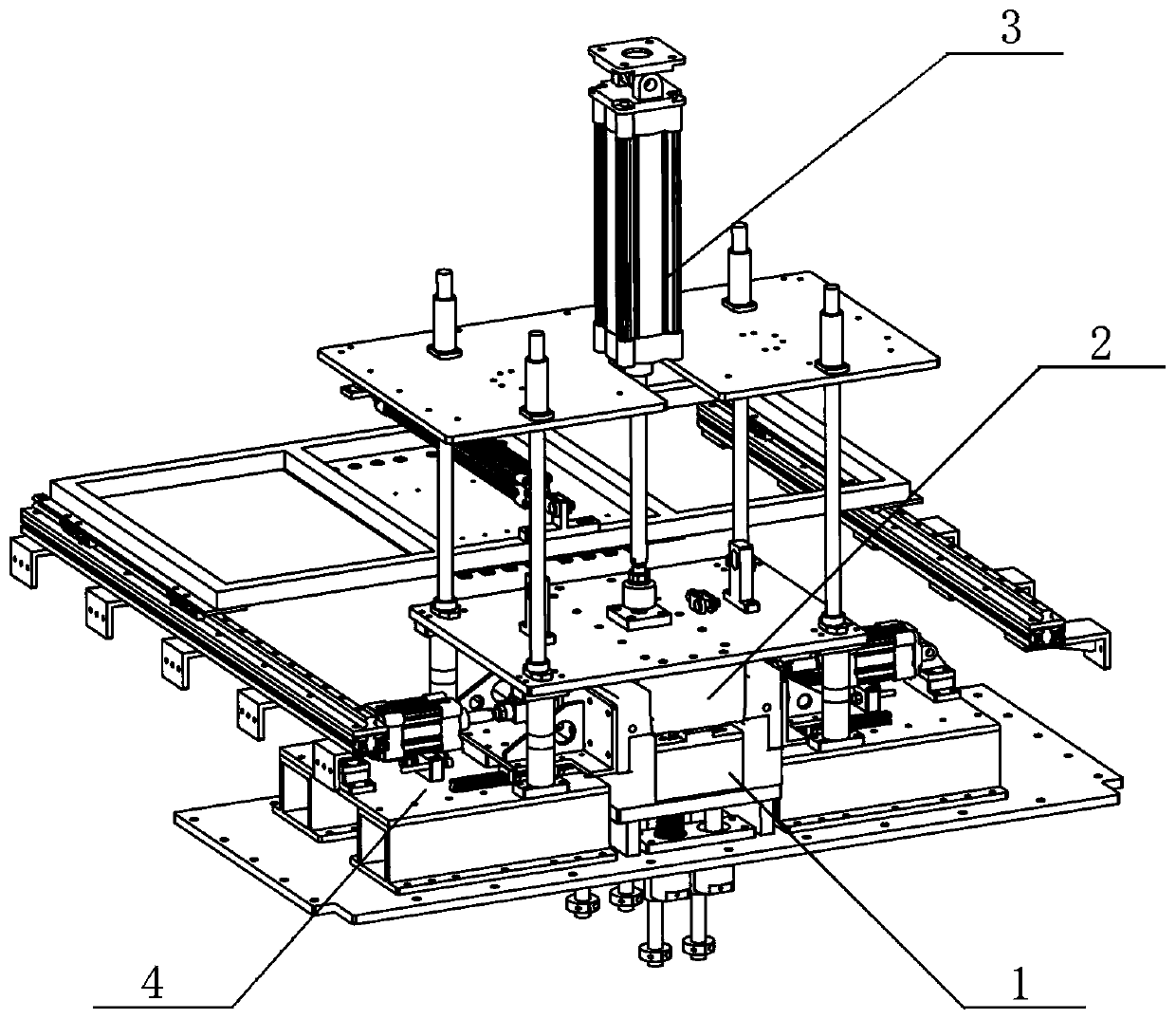

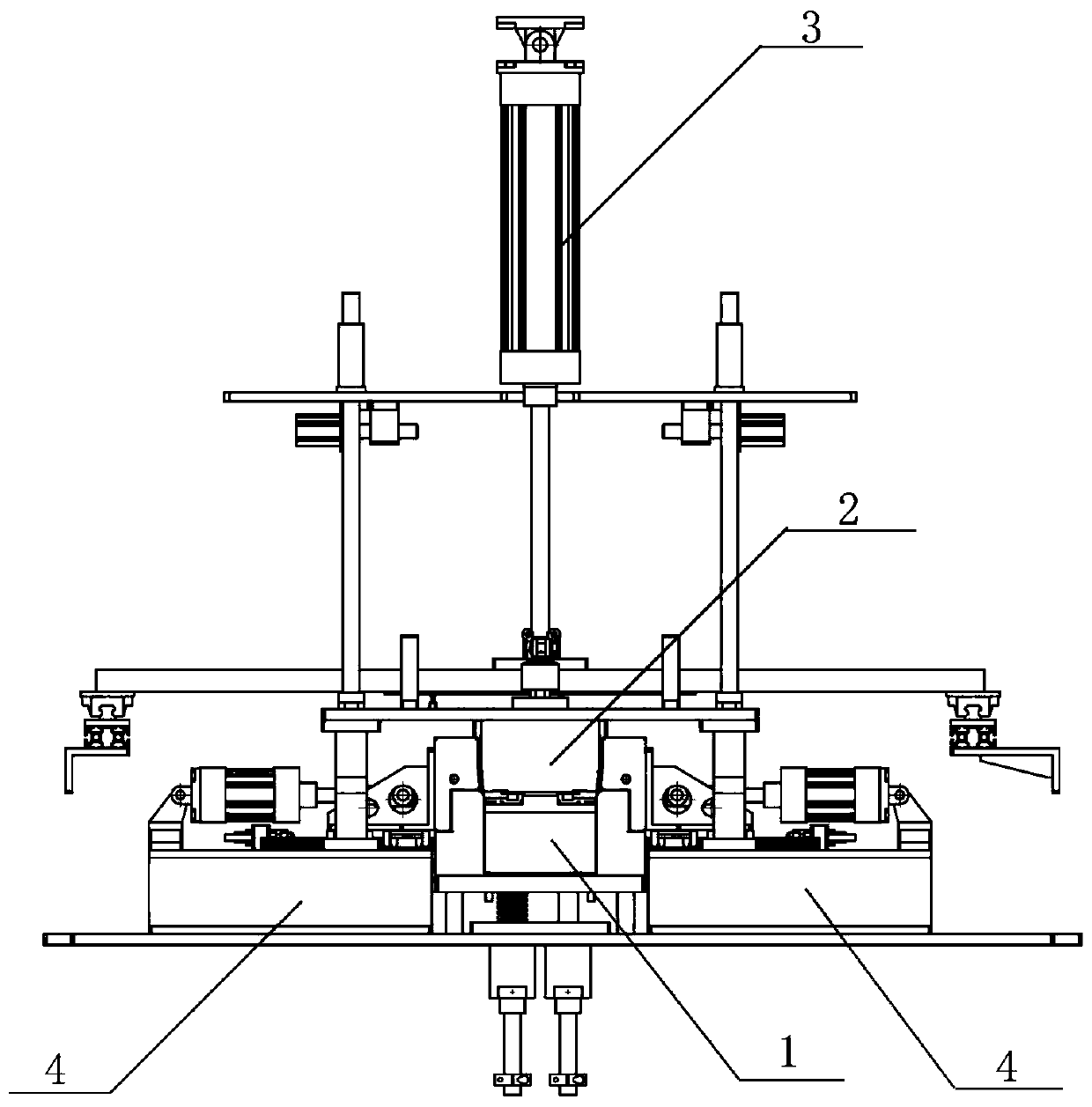

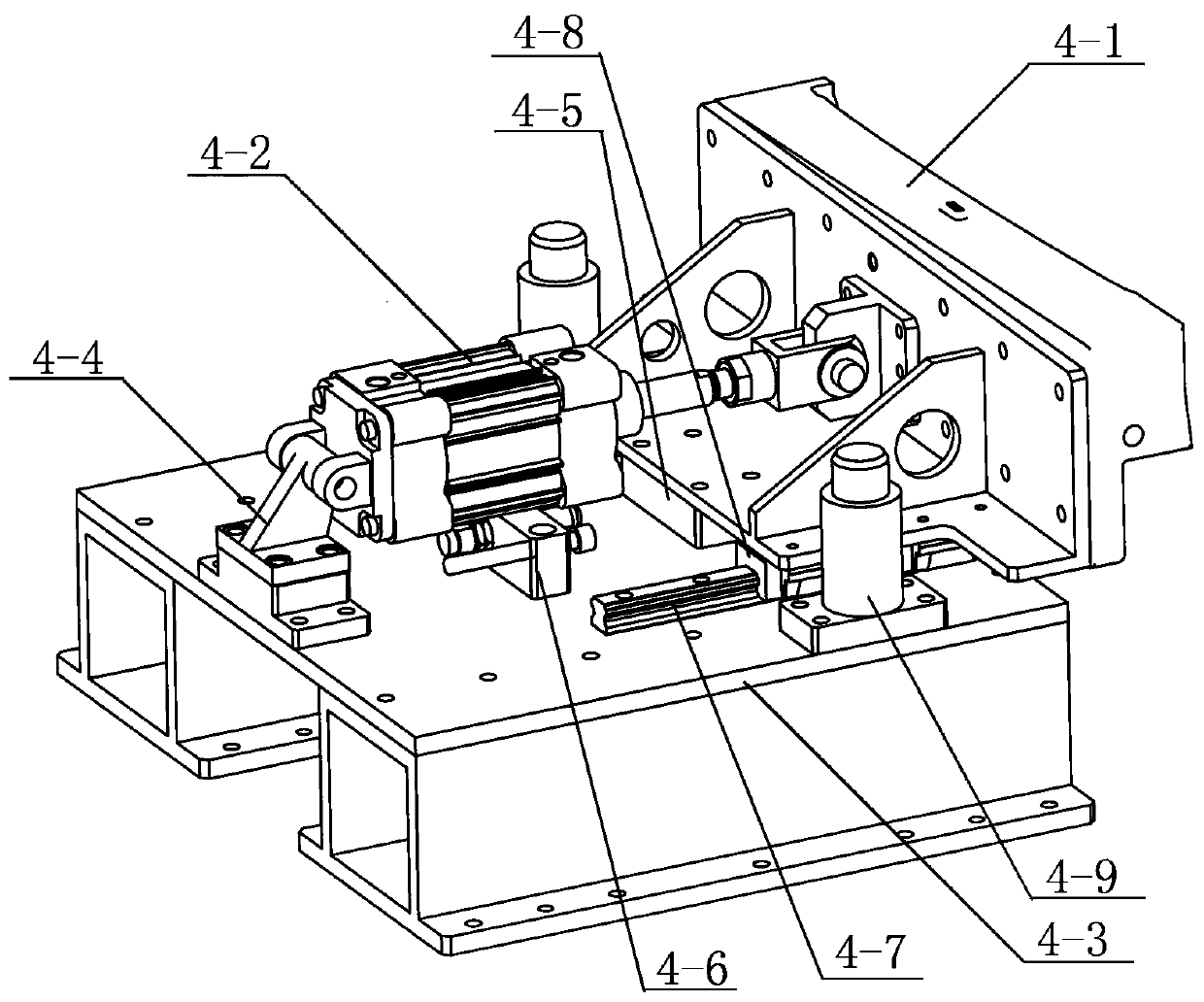

Automatic automobile trim coating device with sewing thread

PendingCN110219105AGuaranteed positionWarranty requirementsThread-break detectorsMechanical engineeringQuality standard

The invention provides an automatic automobile trim coating device with a sewing thread. The coating device comprises a lower mold and an upper mold. The upper mold is provided with a lifting mechanism, and side pushing mechanisms for clamping workpieces on the lower mold are arranged on both sides of the lower mold. The lower mold comprises a lower mold body, lateral lower molds, a lower mold mounting plate, sewing thread middle jacking molds, a main spring component and an auxiliary spring component. Two symmetrical sewing thread middle jacking mold mounting grooves are formed in edge positions, close to both sides, of the lower mold body. The sewing thread middle jacking molds are mounted in the sewing thread middle jacking mold mounting grooves. The automatic automobile trim coating device has the advantages that the sewing thread middle jacking molds with positioning and suction functions and the side pushing mechanisms are added to the lower mold, automatic coating of trim products can be realized; front and back edges of a cover are sucked by vacuum suckers to guarantee the shape stability of the sewing thread during coating, the position degree and flatness of the sewing thread after coating are also ensured, and accordingly, the products meet quality standards.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

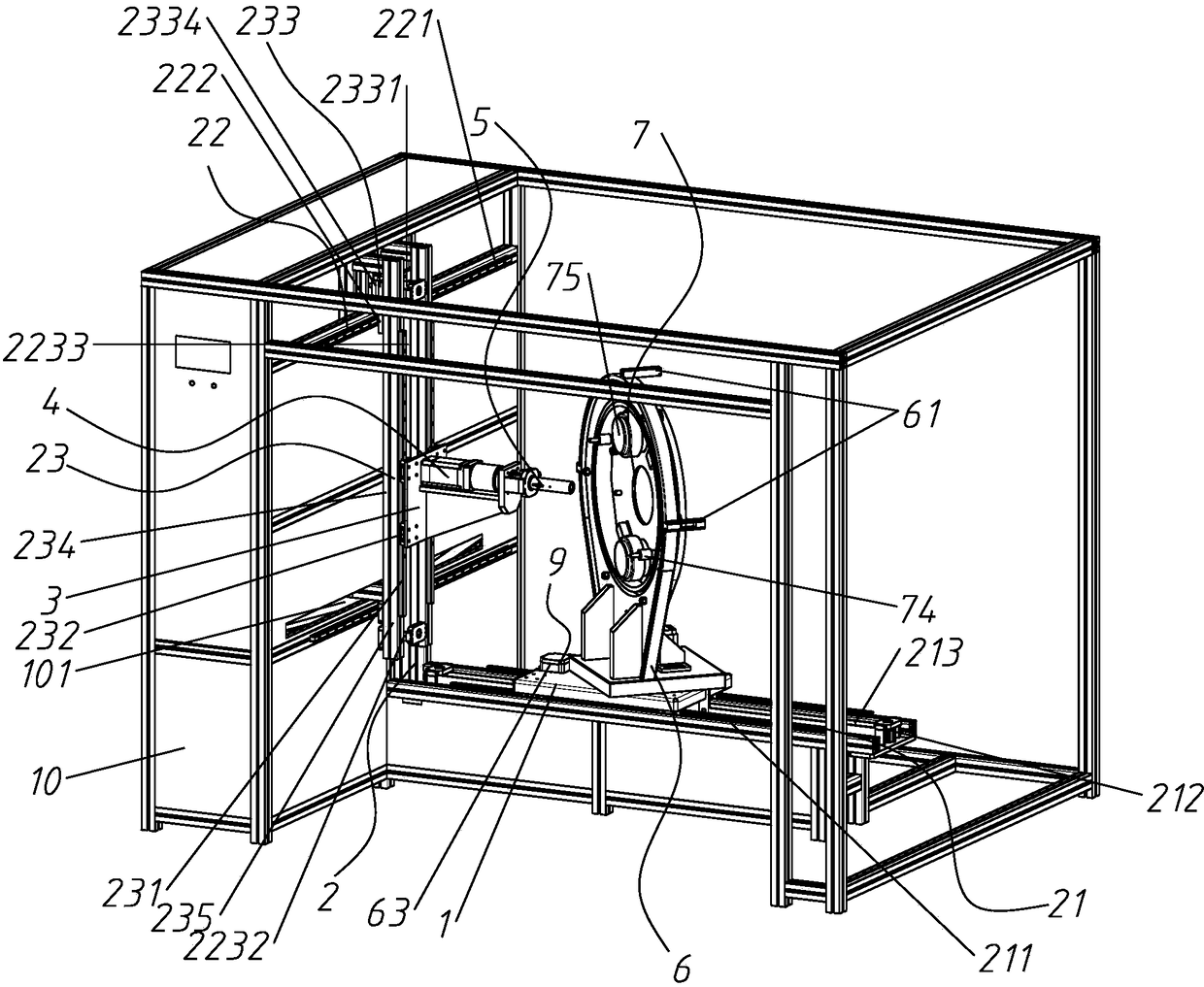

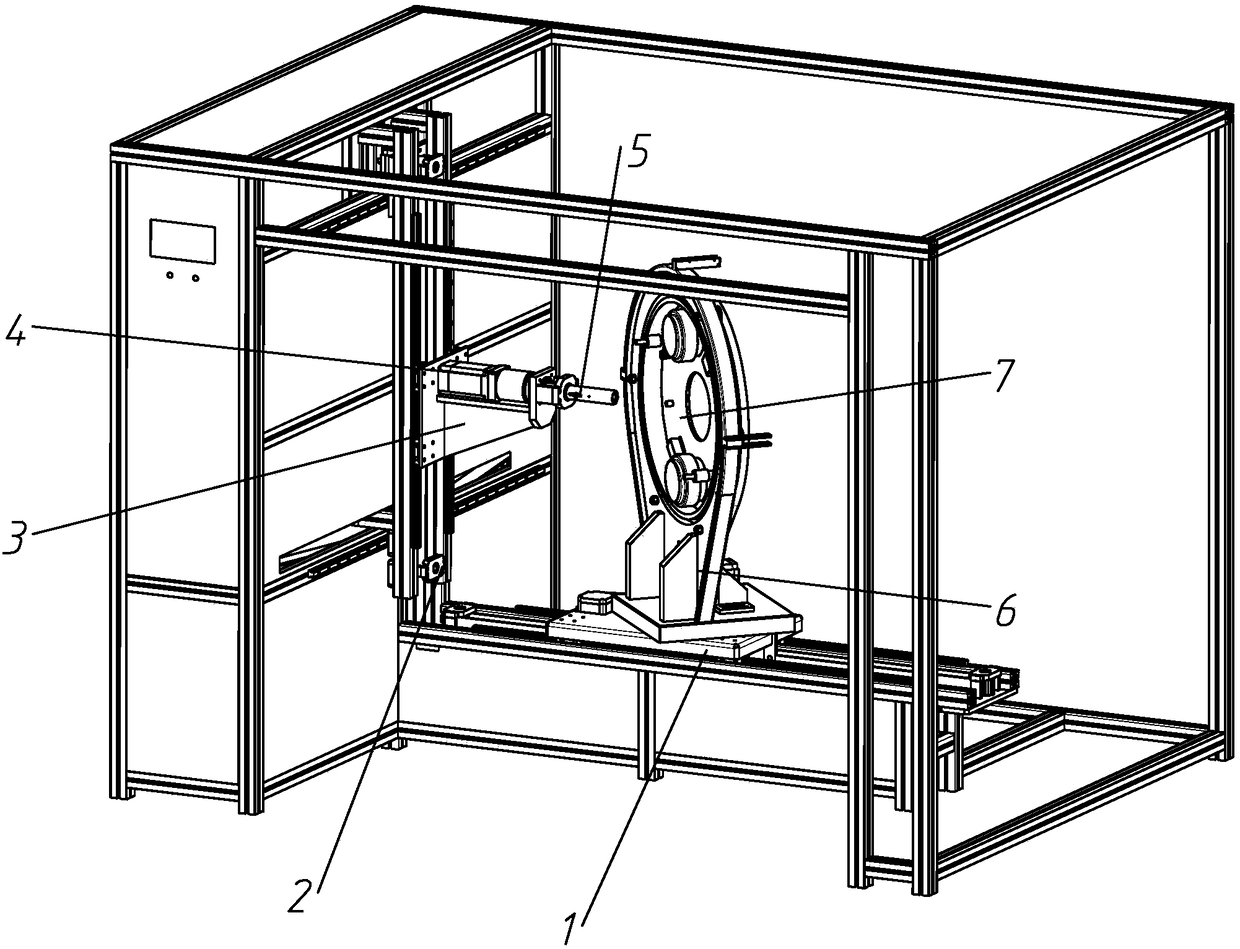

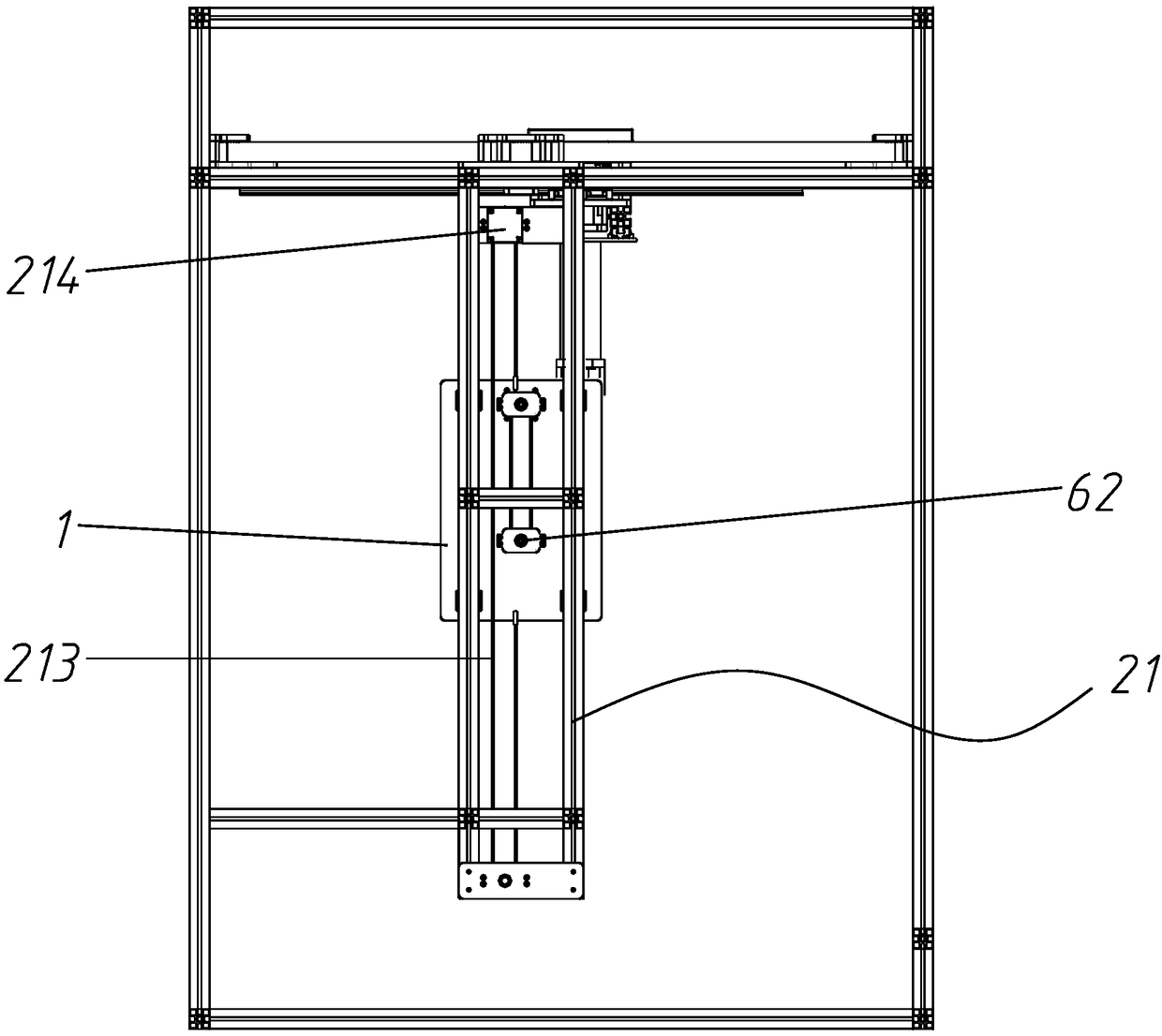

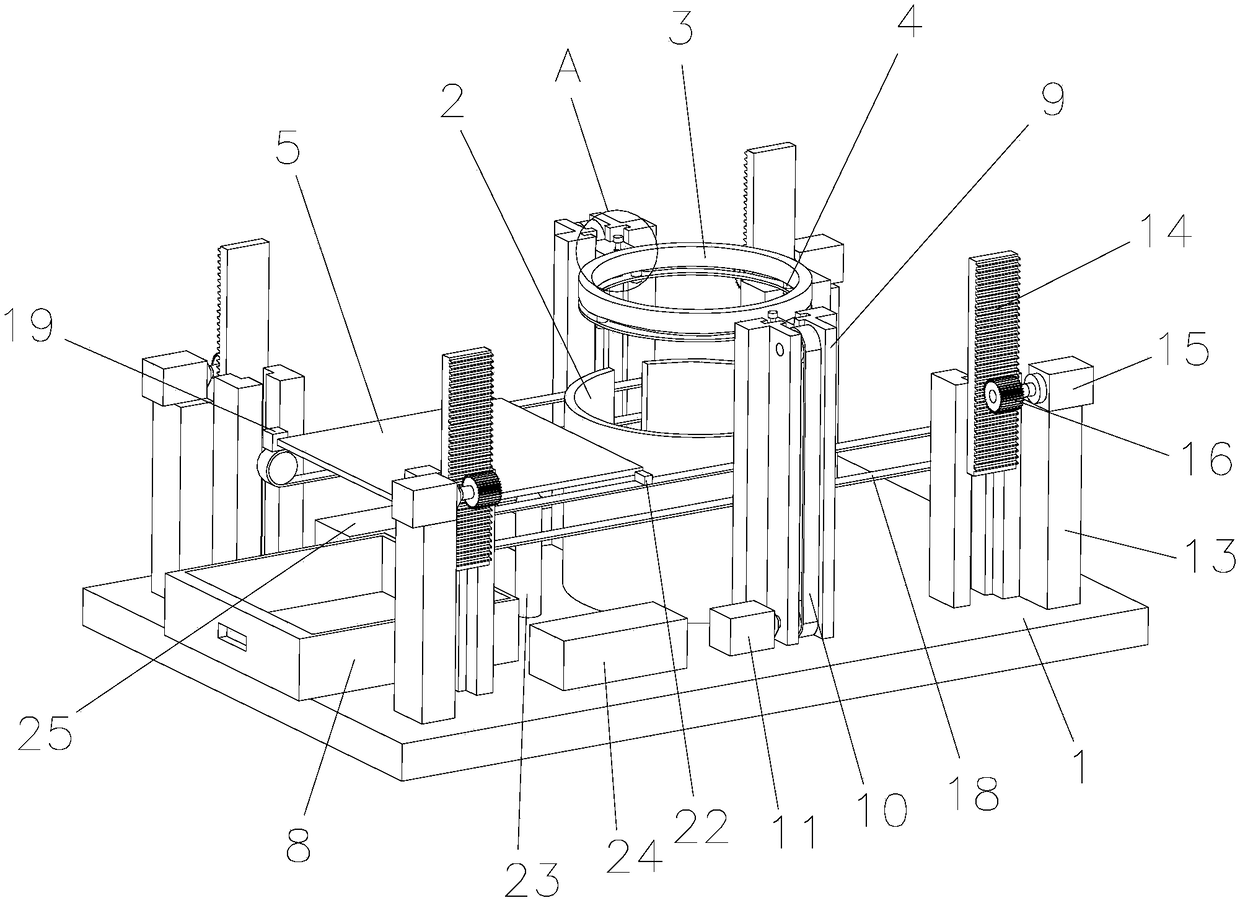

Multi-axis linkage winding machine for wrapping irregular pipe body

ActiveCN108423220AGuaranteed normal windingGuaranteed wrappingWrapping with article rotationWinding machineMulti axis

The invention belongs to the technical field of a winding machine, and provides a multi-axis linkage winding machine for wrapping an irregular pipe body. The multi-shaft linked winding machine comprises a foundation support, wherein the foundation support is connected with a clamping support by virtue of a moving apparatus, the clamping support makes the translation movement in a three-dimensionalspace relative to the foundation support by virtue of the moving apparatus, the clamping support is provided with a clamping portion in a rotating manner by virtue of a rotating apparatus I, the foundation support is provided with a winding frame in a rotating manner by virtue of a rotating apparatus II, a rotating shaft of the winding frame is perpendicular to a rotating shaft of the clamping support, the winding frame is provided with a winding disc in a rotating manner, and the winding disc is provided with a supporting apparatus for supporting a wound strip coil. By virtue of the technical scheme, the technical problems in the prior art that no winding machine for winding the irregular tubular article is provided can be solved.

Owner:河北海赞自动化科技有限公司

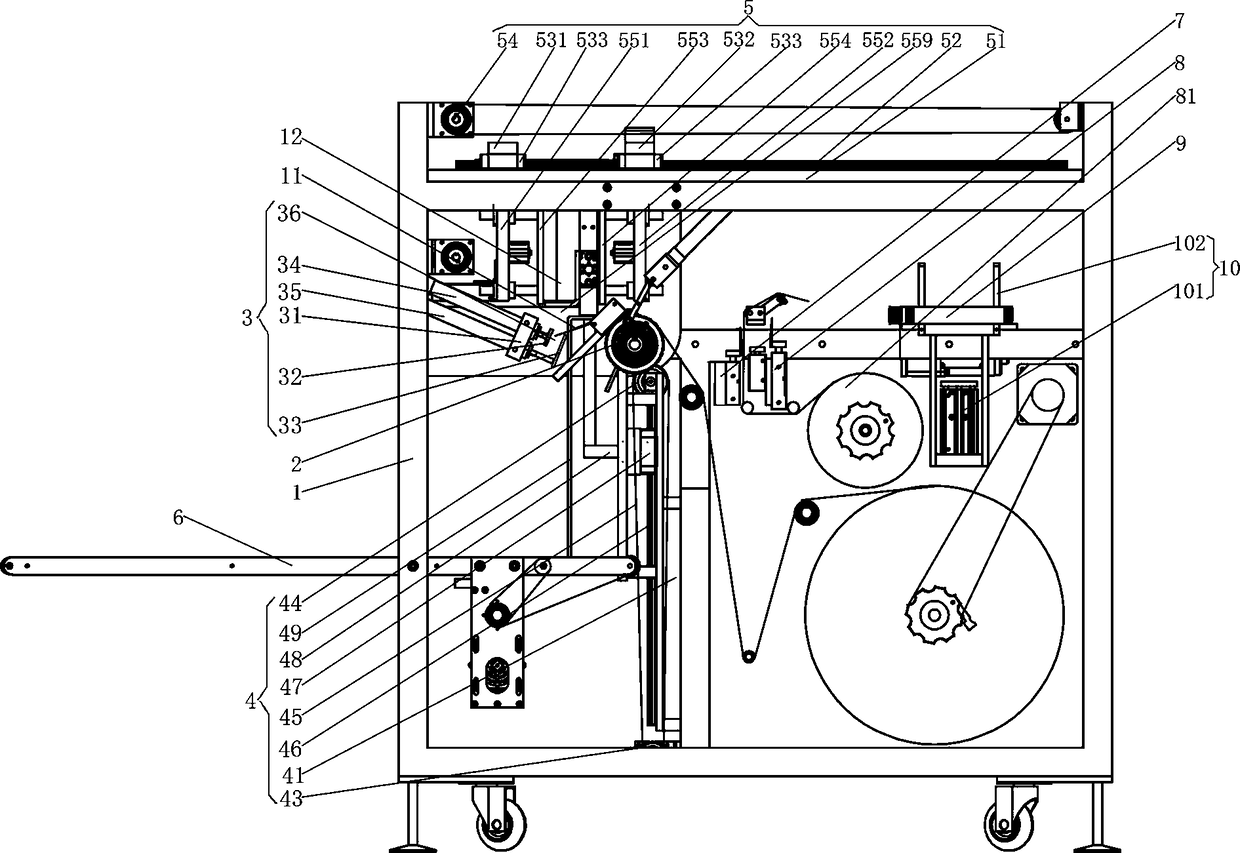

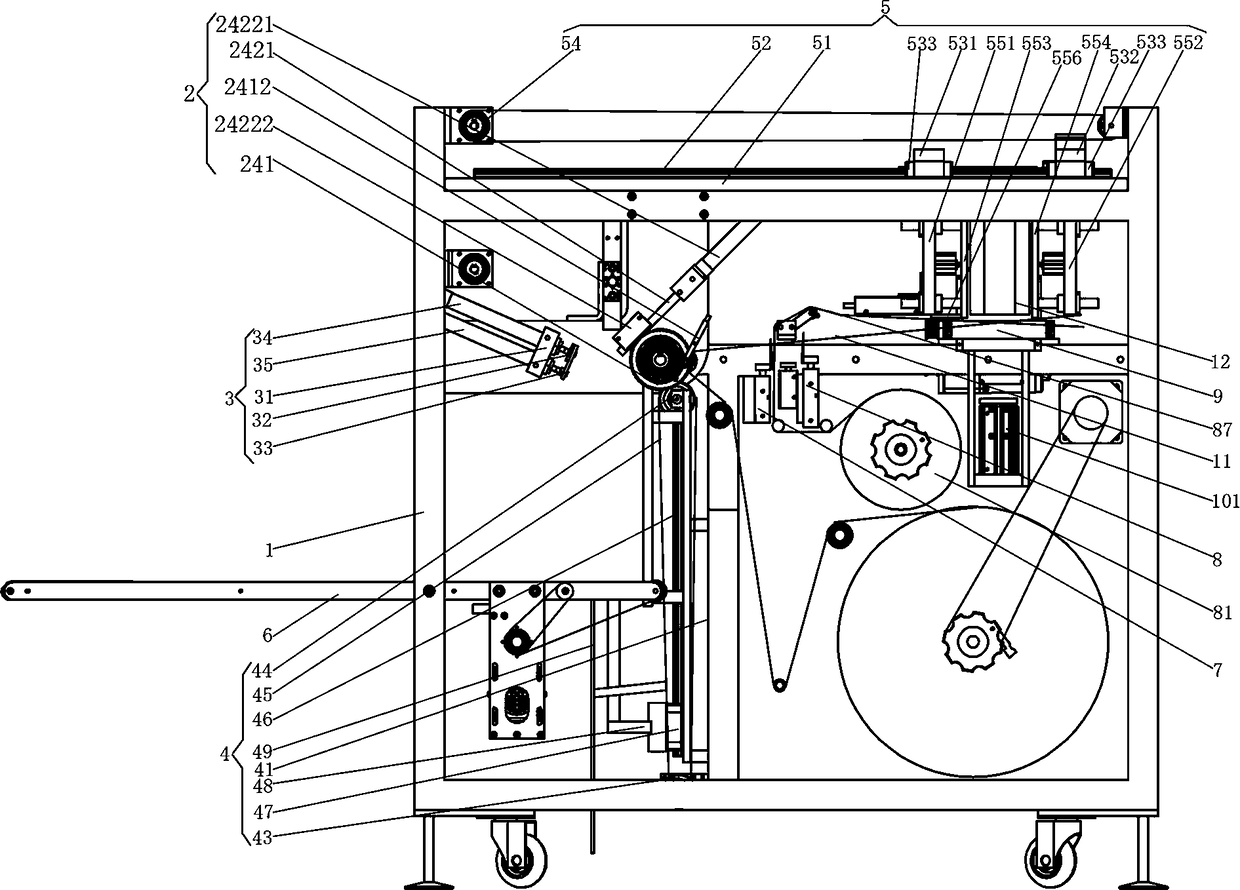

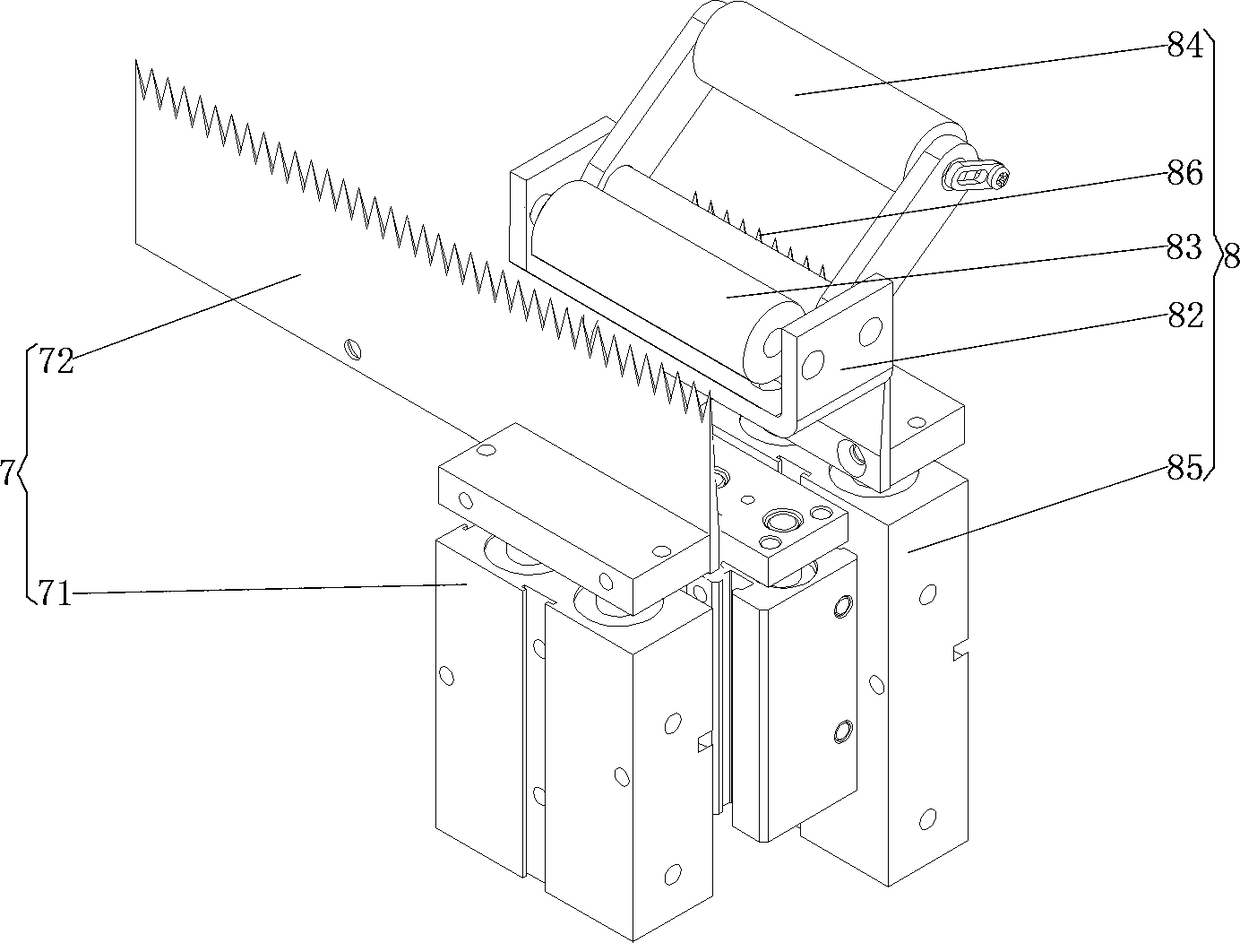

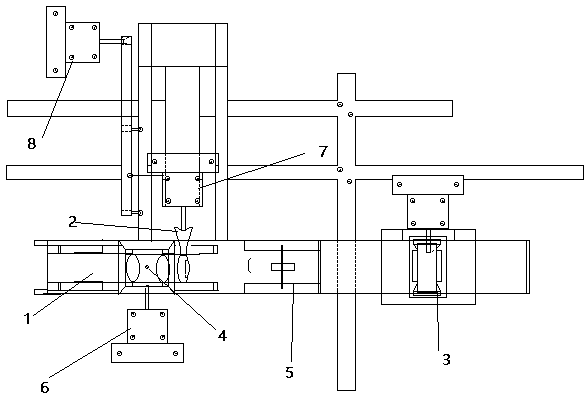

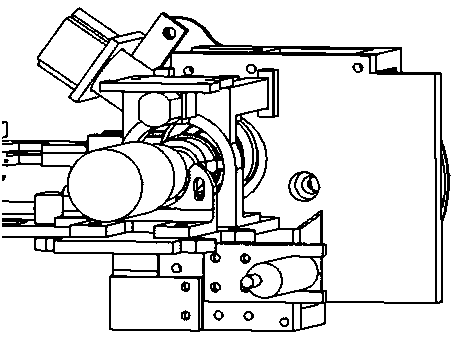

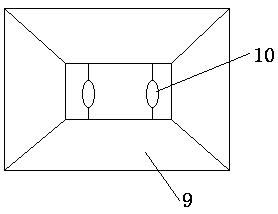

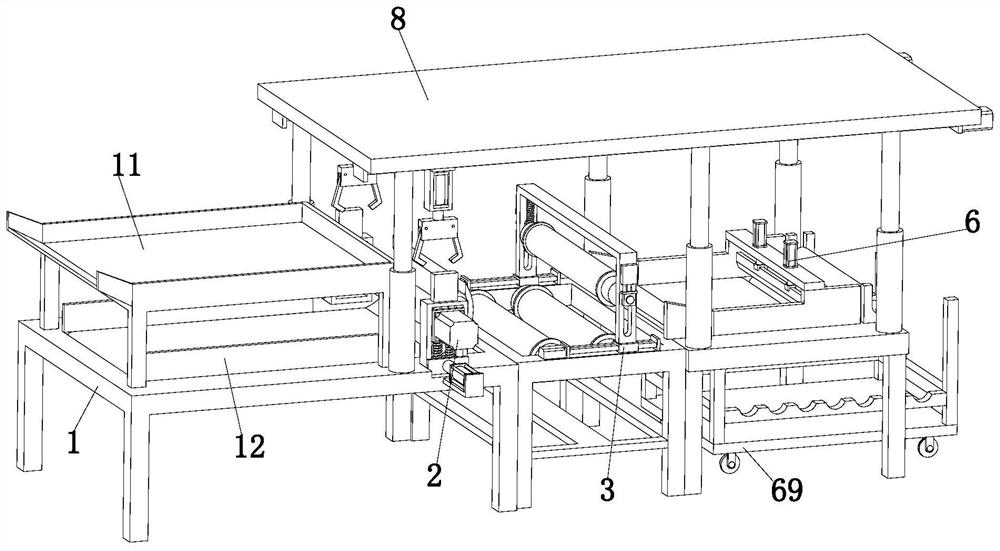

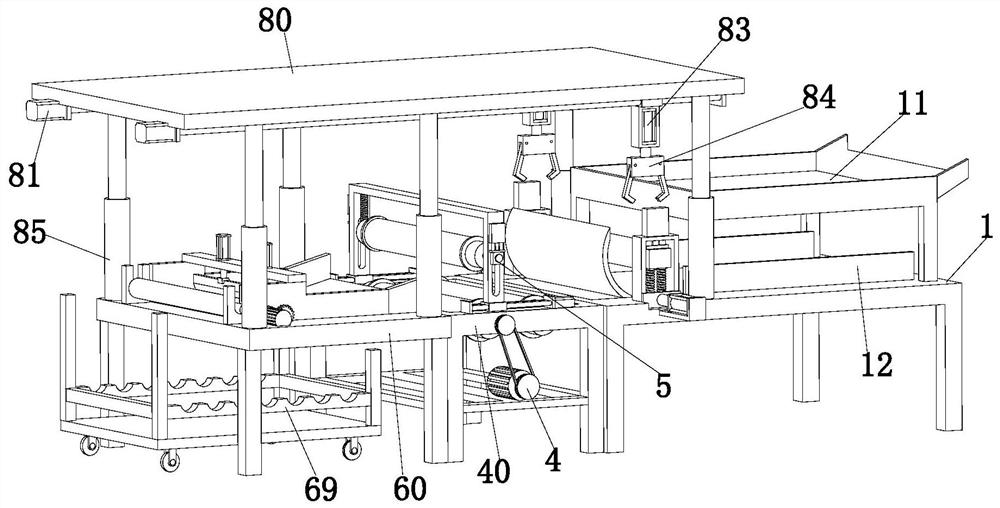

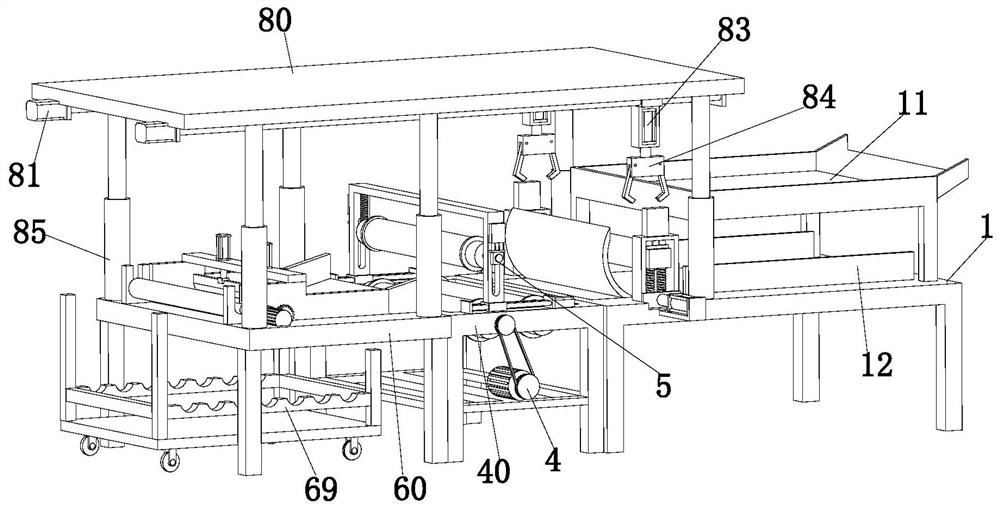

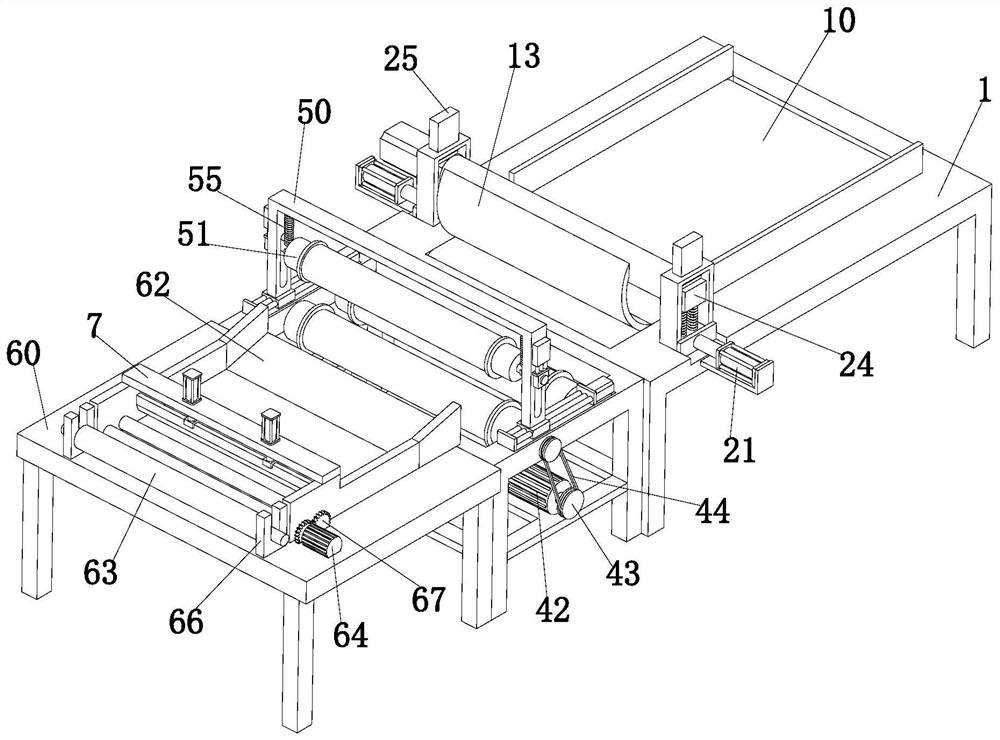

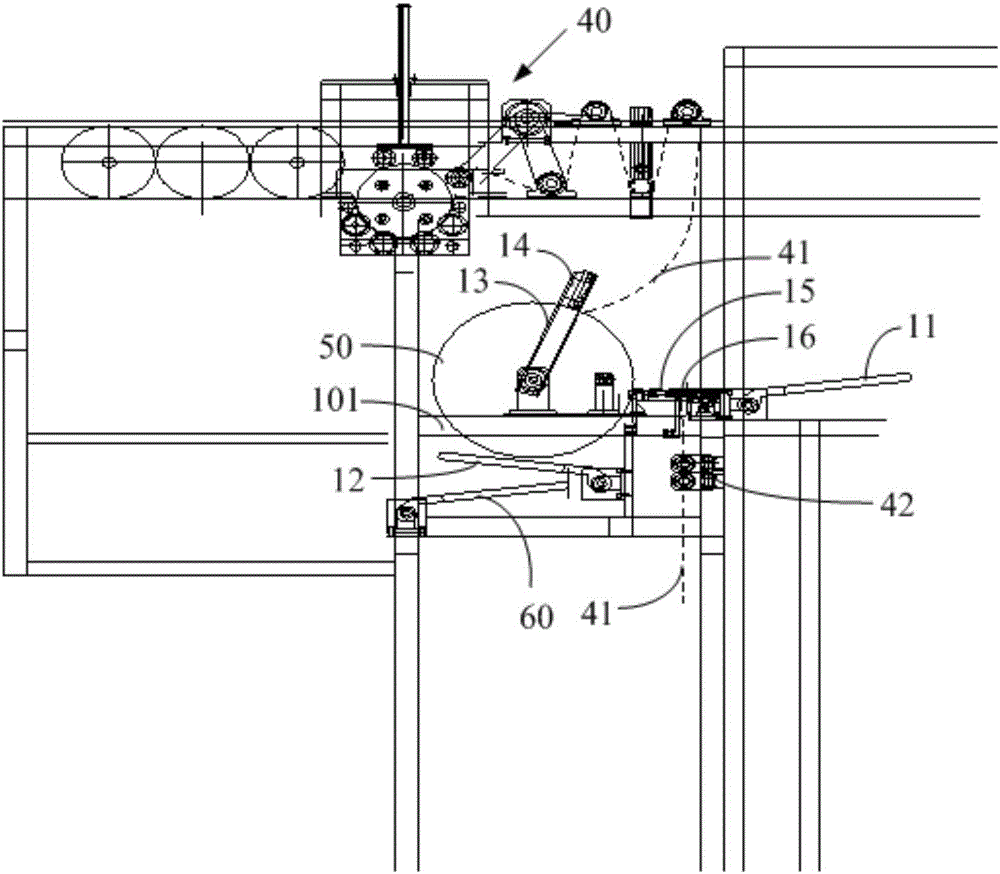

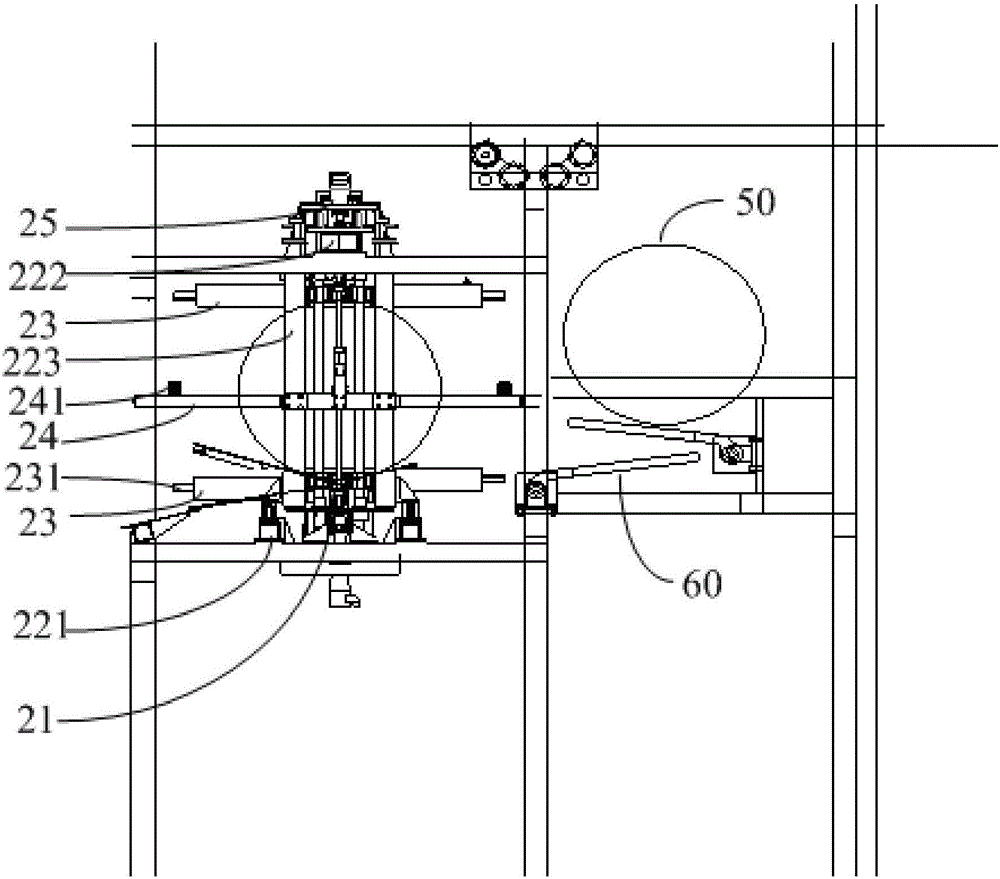

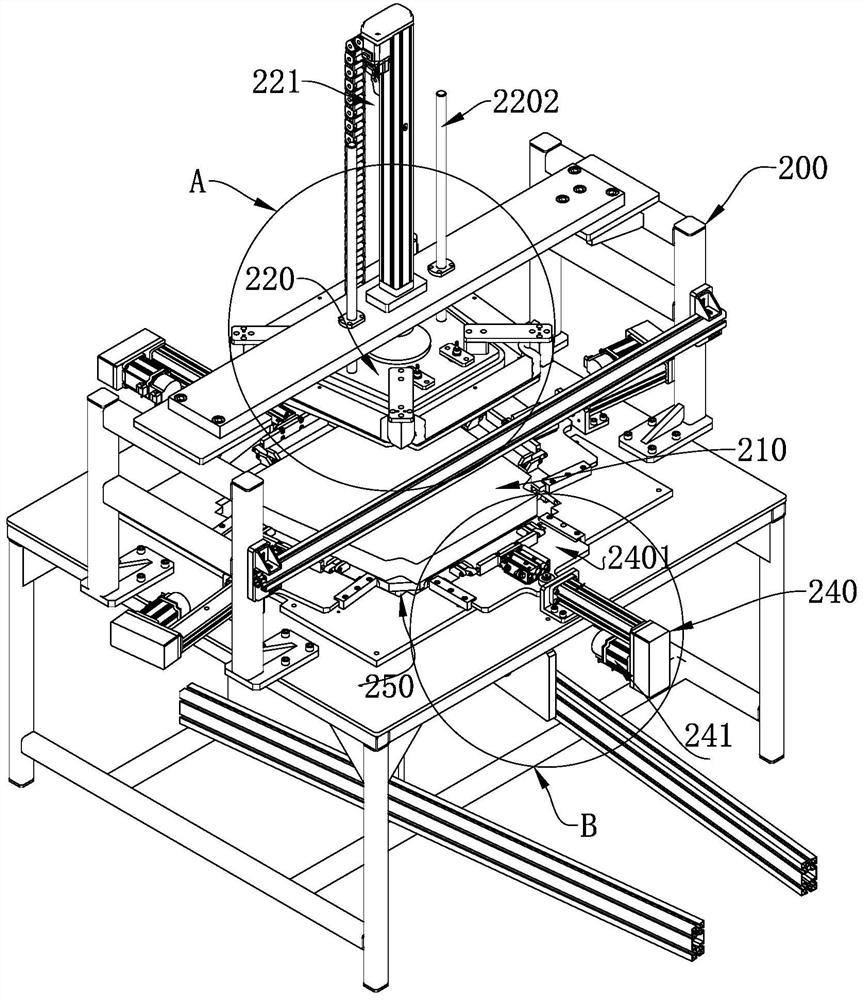

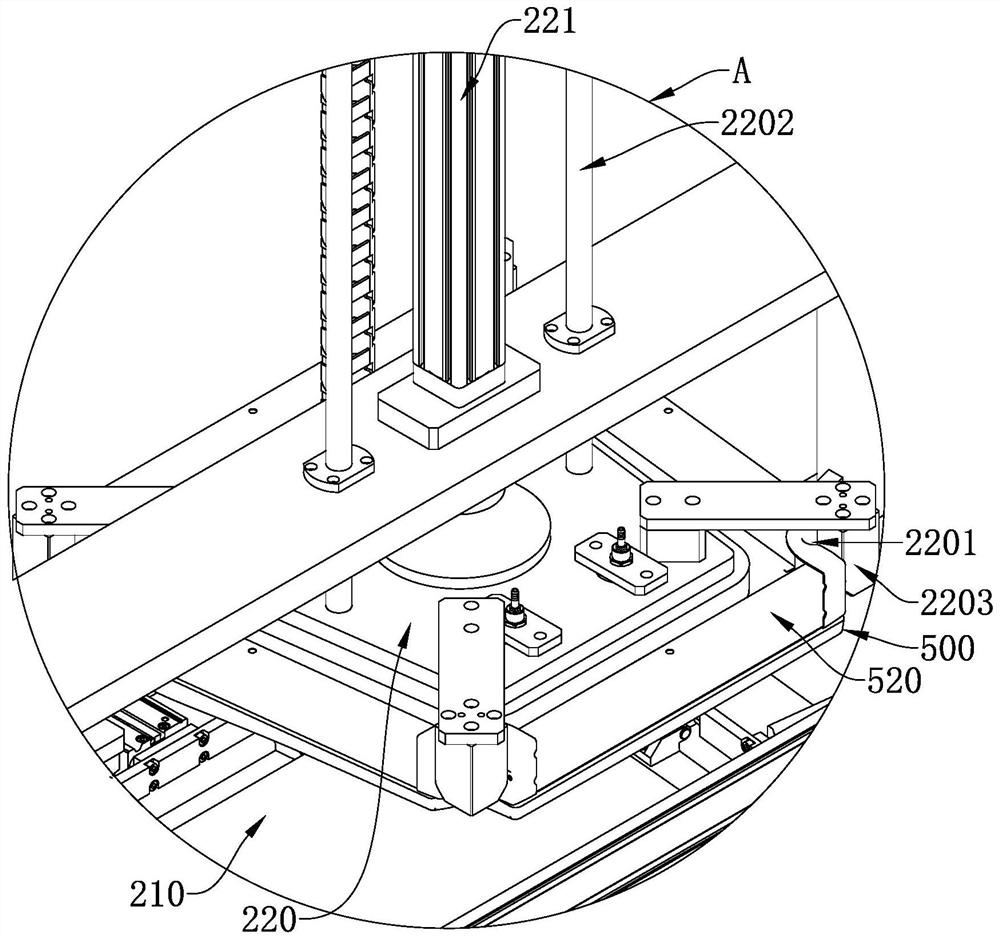

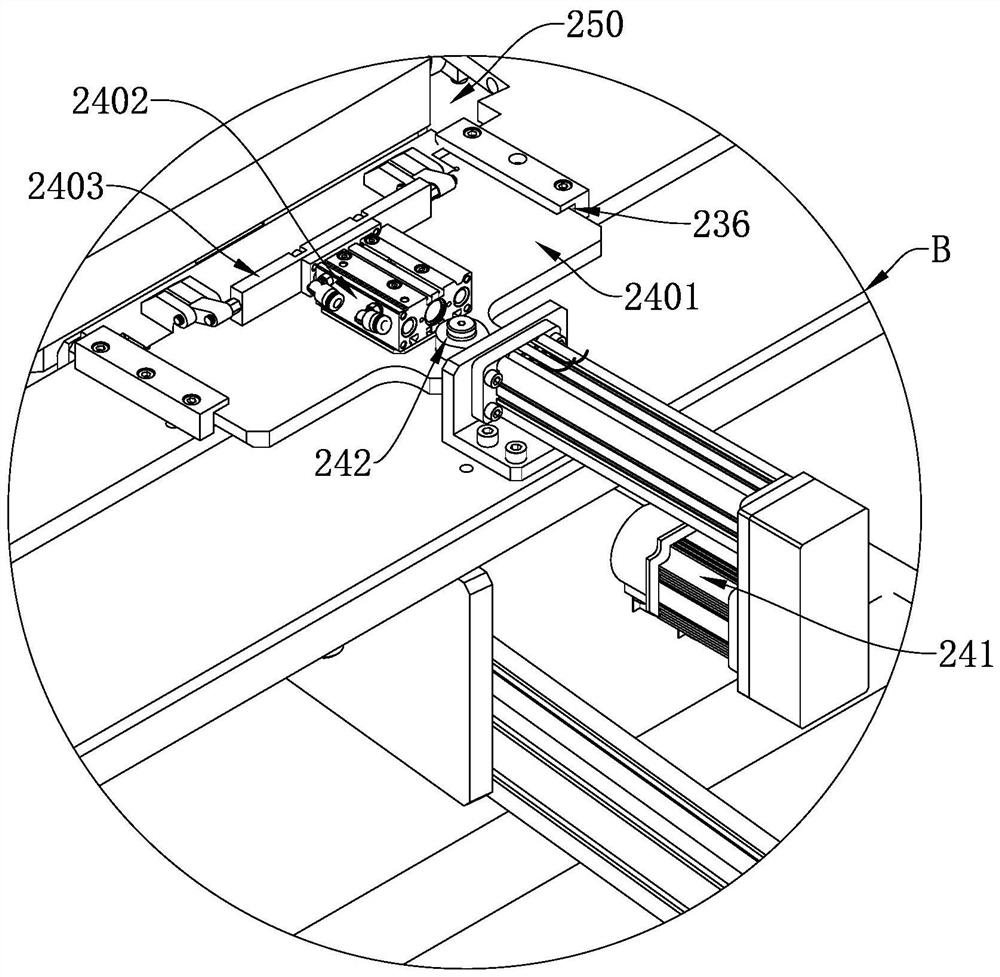

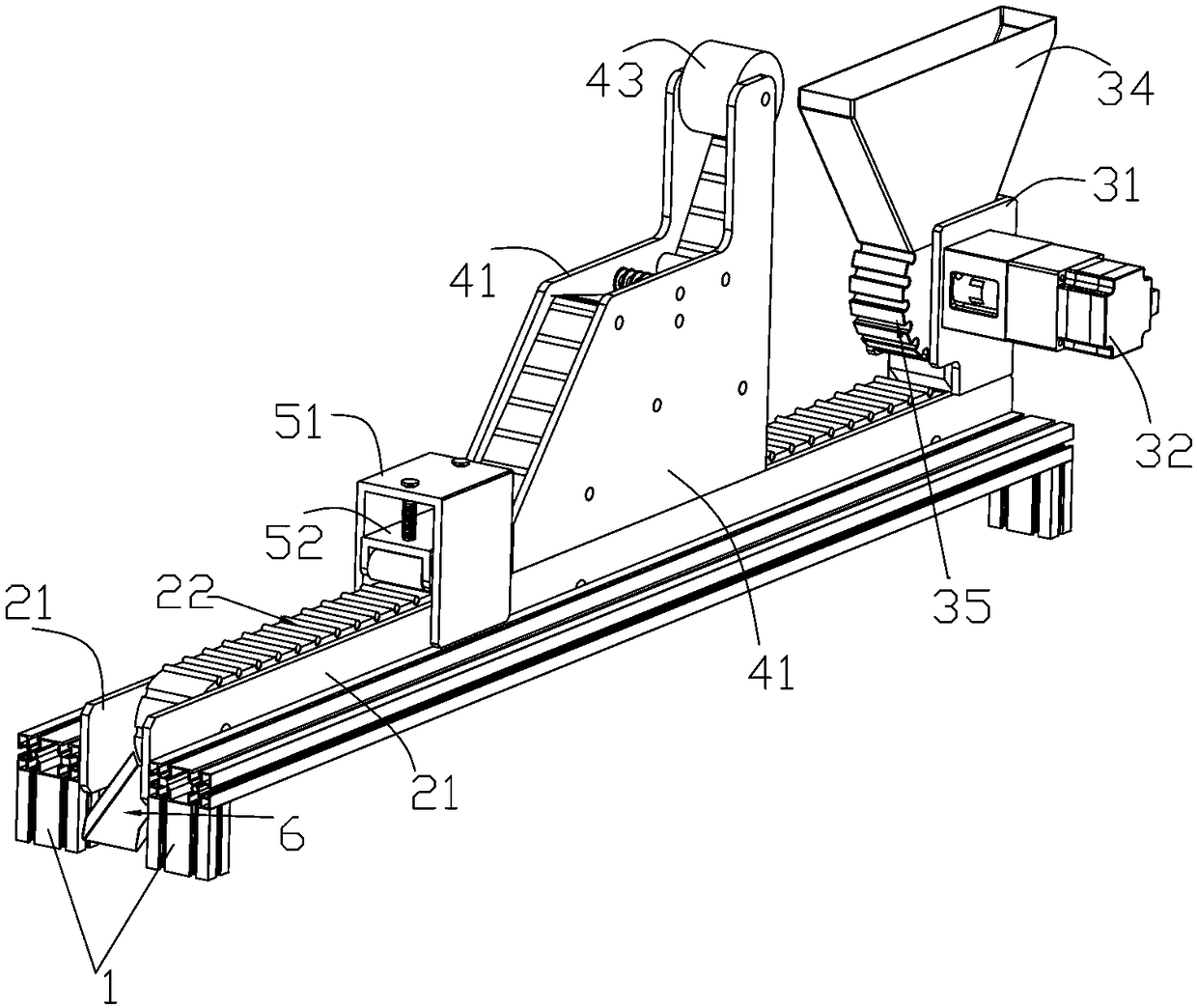

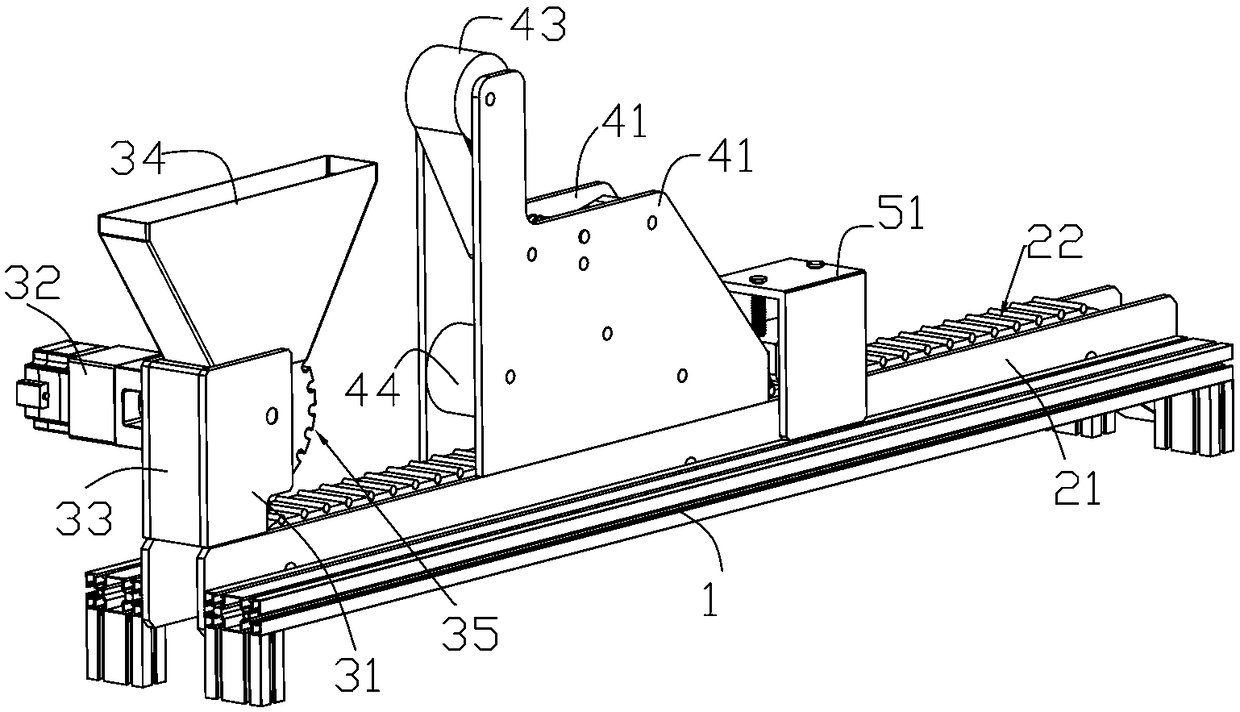

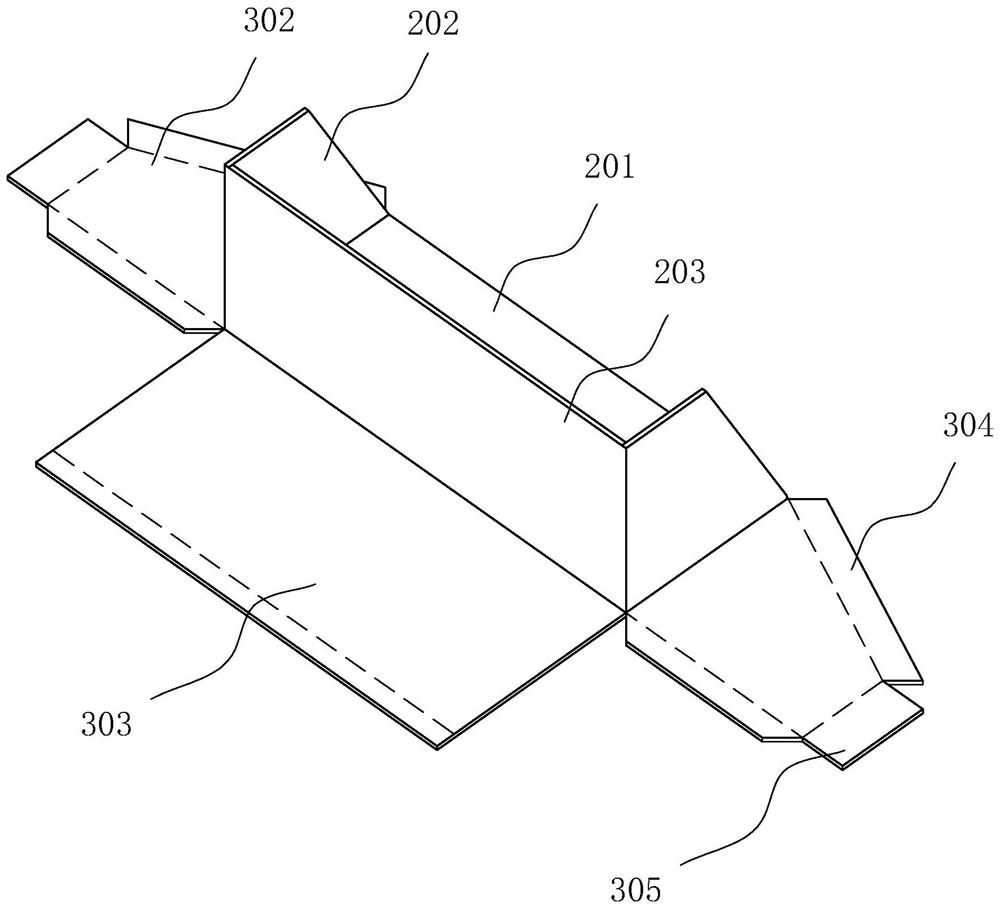

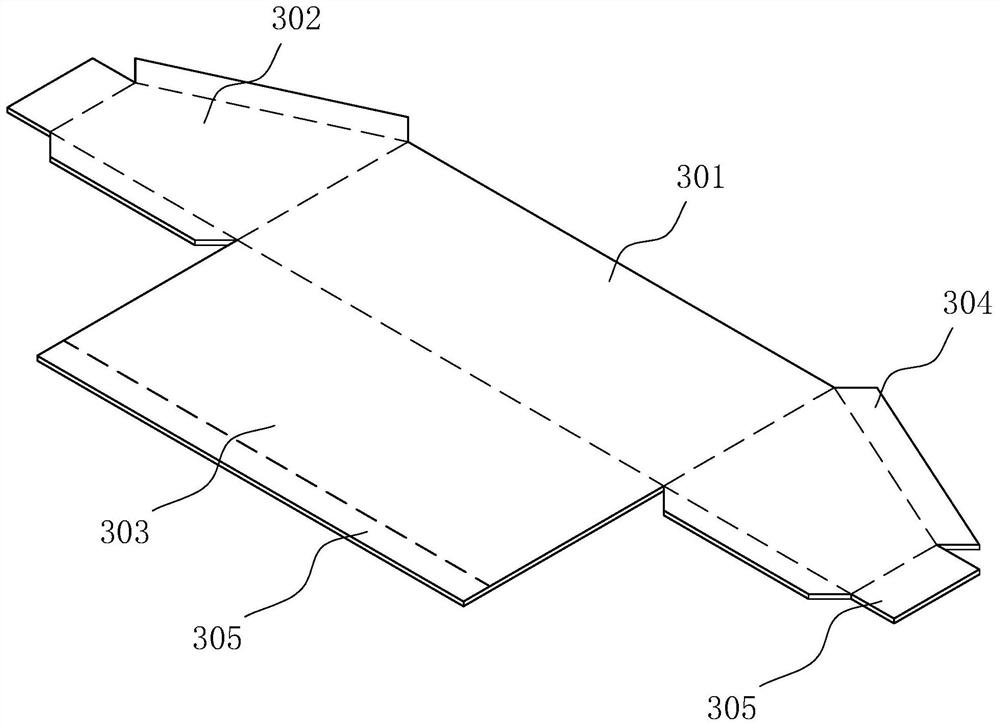

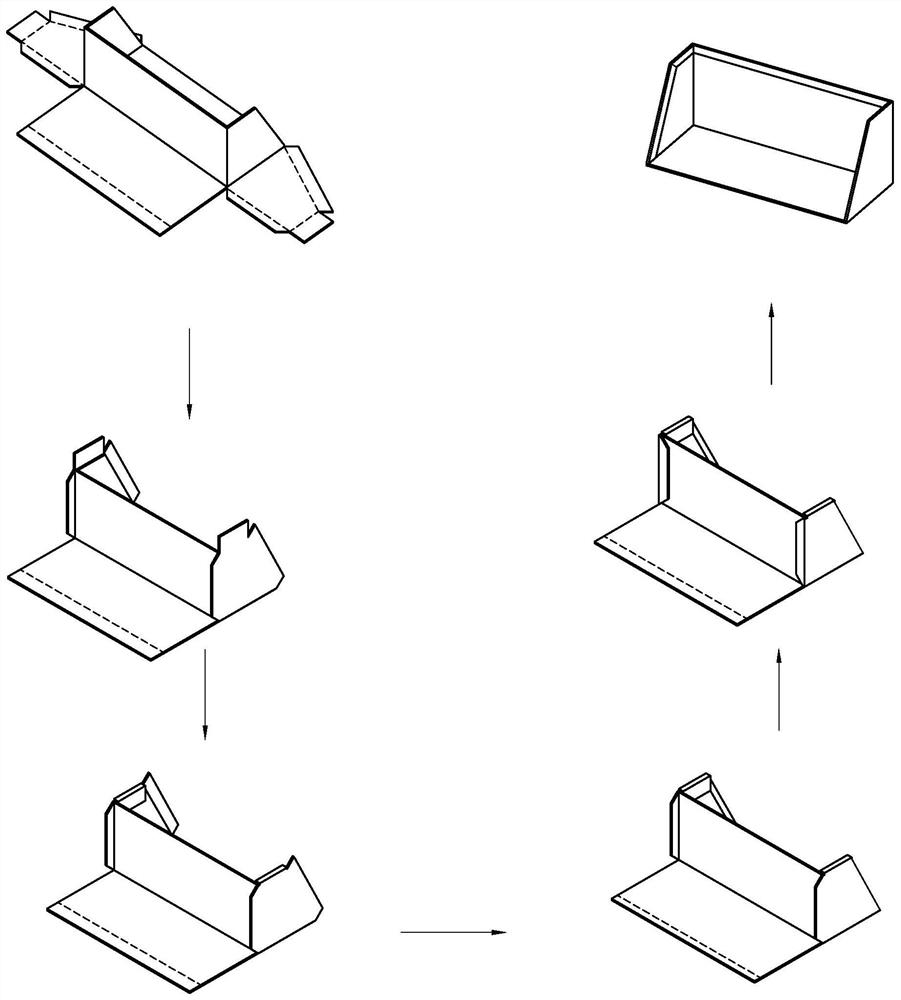

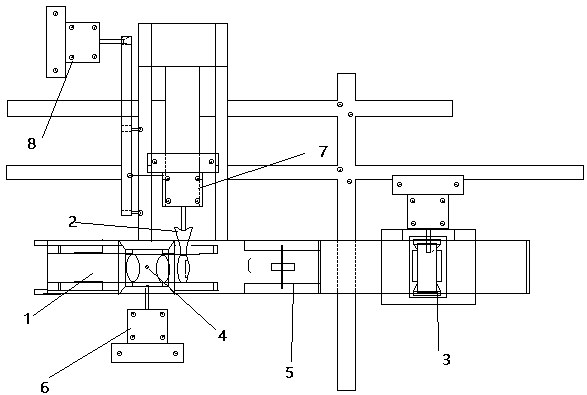

Printed product packing machine

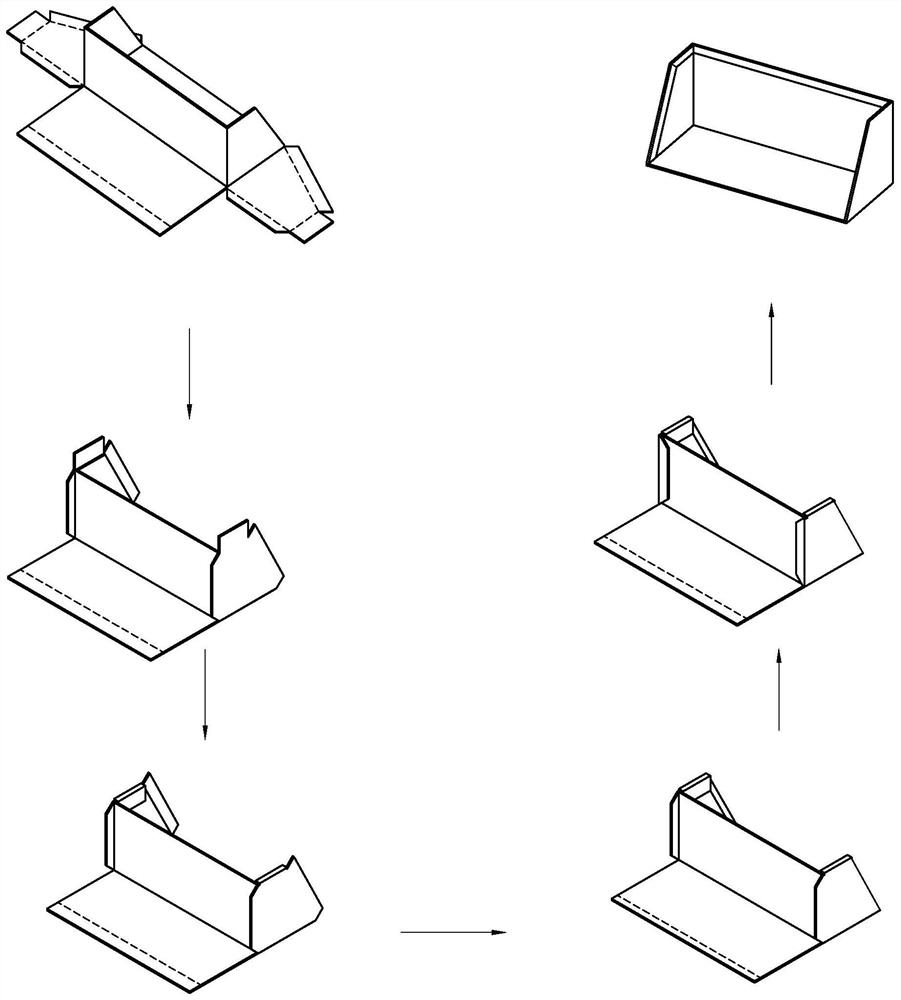

PendingCN109178384ANeatly packedRealize automatic wrappingWrappingPulp and paper industryKraft paper

The invention discloses a printed product packing machine which comprises a rack, a loading and conveying mechanism, a paper packing mechanism, a kraft paper tailoring mechanism, an adhesive tape attaching and tailoring mechanism and an unloading and conveying mechanism. The paper packing mechanism comprises a paper feeding mechanism, a paper taking mechanism, a jacking mechanism and a clamping mechanism. The paper taking mechanism is arranged on the left side of the paper feeding mechanism, the jacking mechanism is arranged below the part between the feeding mechanism and the paper taking mechanism, and the clamping mechanism is arranged above the paper feeding mechanism, has a clamping opening formed downward and can move above the paper feeding mechanism in a reciprocating manner; and both the kraft paper tailoring mechanism and the adhesive tape attaching and tailoring mechanism are arranged between the paper feeding mechanism and the clamping mechanism, and the kraft paper tailoring mechanism is located on the left side of the adhesive tape attaching and tailoring mechanism. The printed product packing machine can feed paper automatically in a turning manner to hide sealed edges and keeps the tensity of the kraft paper all the way, so that the printed products are packaged orderly and are packed automatically.

Owner:汕头市顺鑫隆印刷机械有限公司

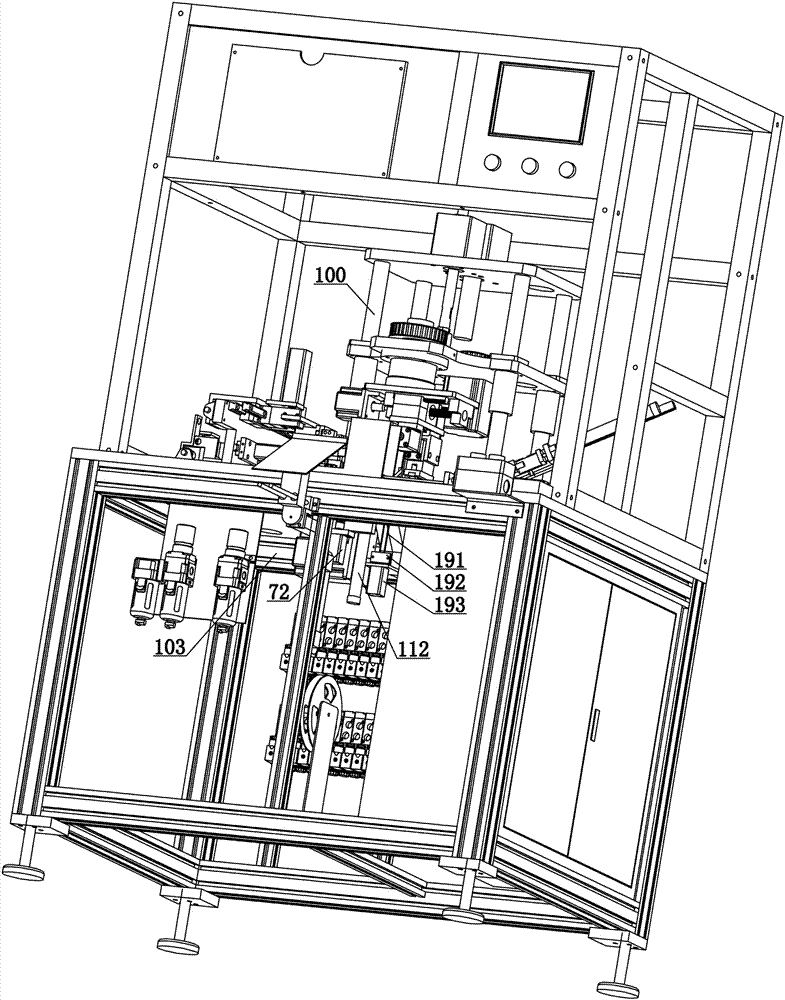

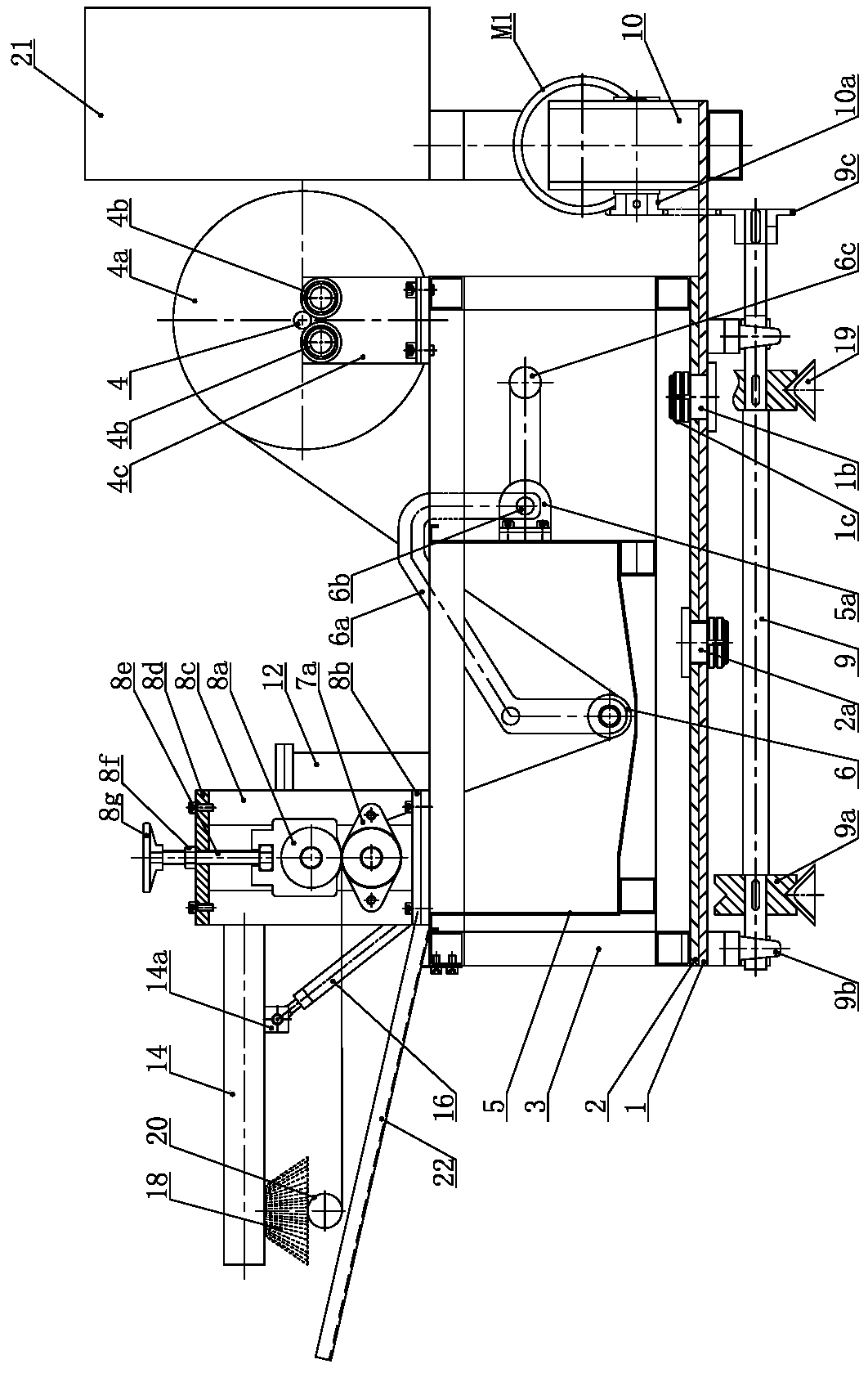

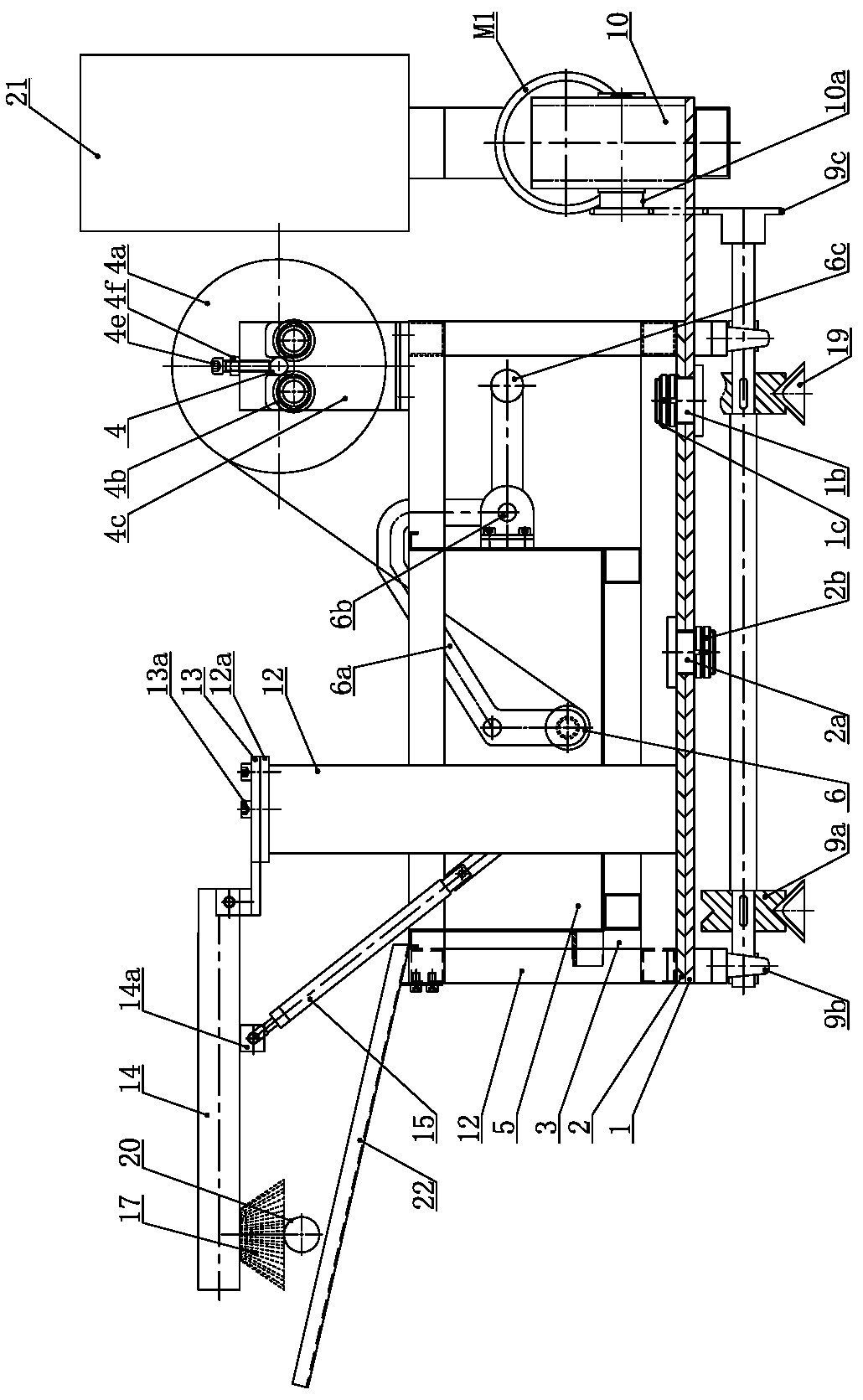

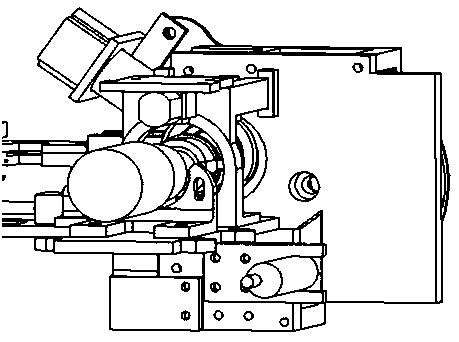

Lead sheet wrapping machine

The invention discloses a lead sheet wrapping machine, and belongs to the field of machinery. The lead sheet wrapping machine aims to solve the problems that lead sheet strips are usually packaged bymanual winding at present, production efficiency is low and labor intensity of workers is high. The lead sheet wrapping machine includes reels, a support frame, a lead sheet conveying unit for conveying lead sheets, a reel conveying unit for conveying reels, a wrapping unit, a visual positioning unit and a control system. The lead sheet conveying unit and the wrapping unit are correspondingly disposed on the support frame, and the reel conveying unit is disposed above the wrapping unit. The reels each include a central shaft and two end plates, the central shafts are provided with positioninggrooves, and the end plates are arranged at both ends of the central shafts. The lead sheet wrapping machine can realize automatic wrapping of the lead sheets on a lead weight, greatly improves the production efficiency, and effectively reduces the production cost. The lead sheet wrapping machine is ingenious in concept and reasonable in design, can greatly improve the efficiency of lead sheet wrapping, and has higher application value and wider application prospects.

Owner:SOUTHWEAT UNIV OF SCI & TECH

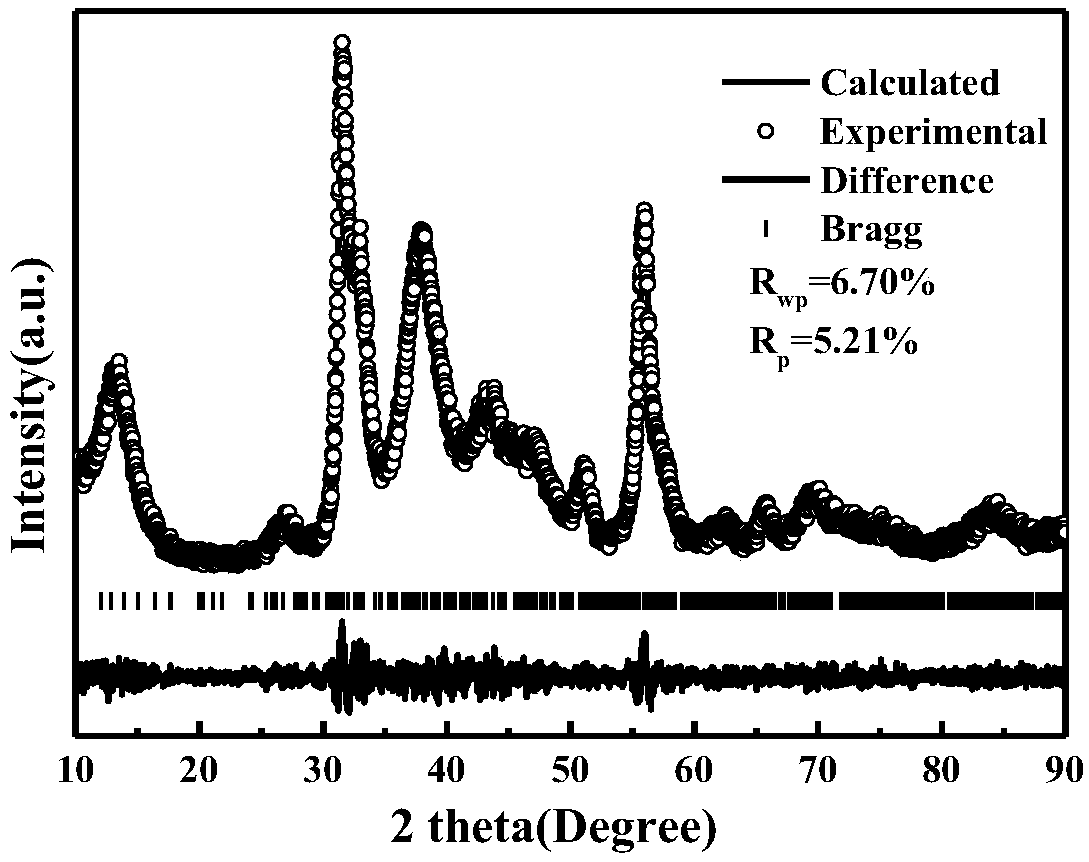

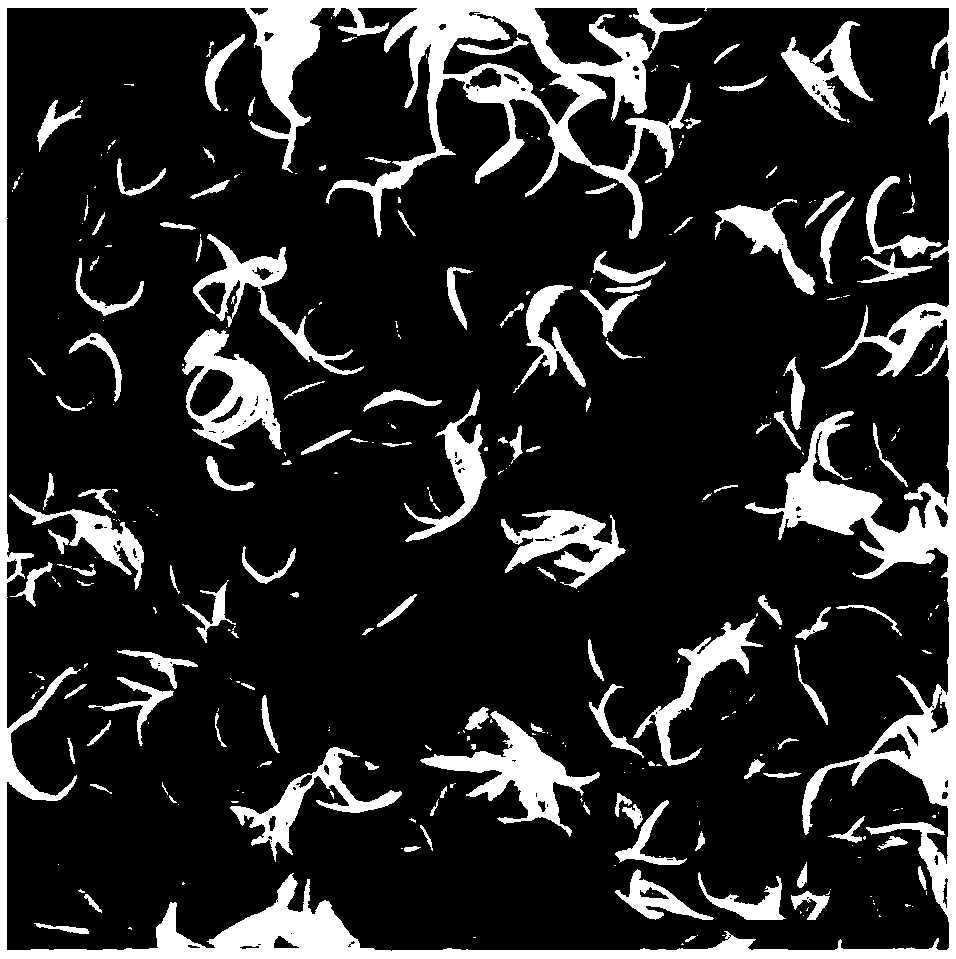

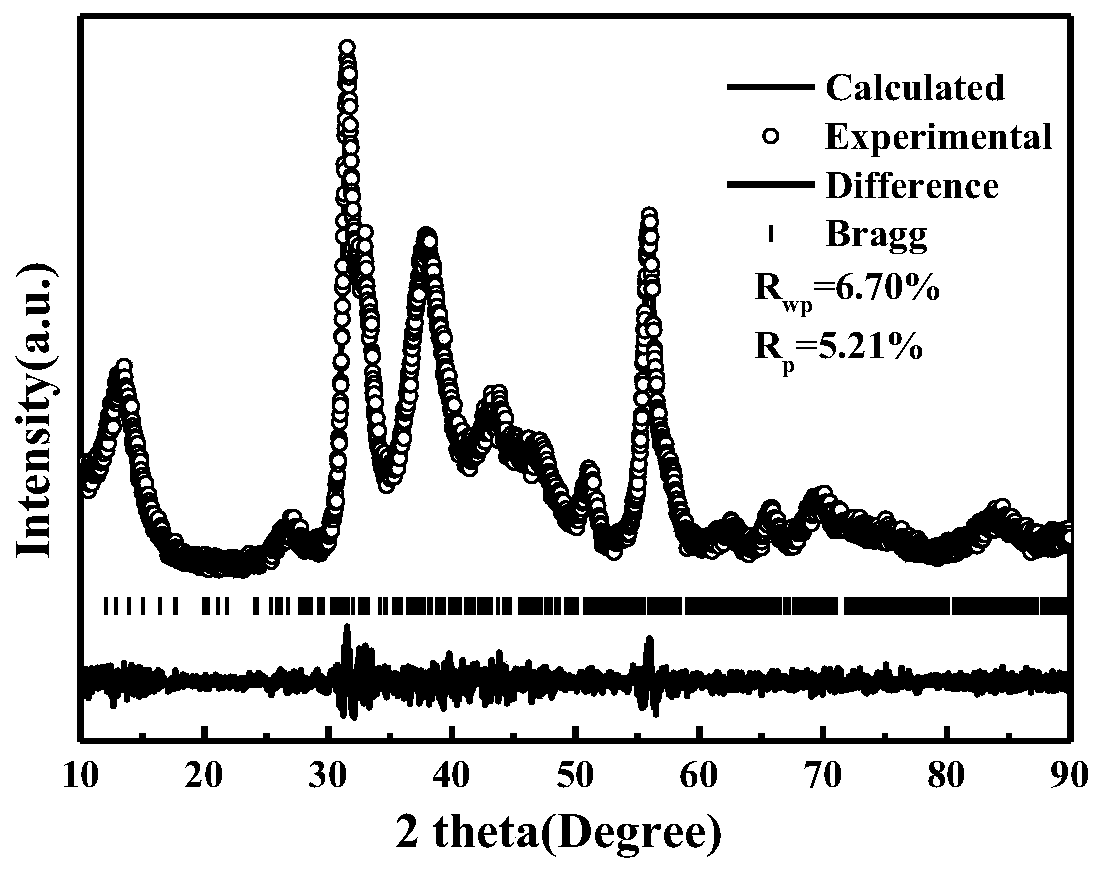

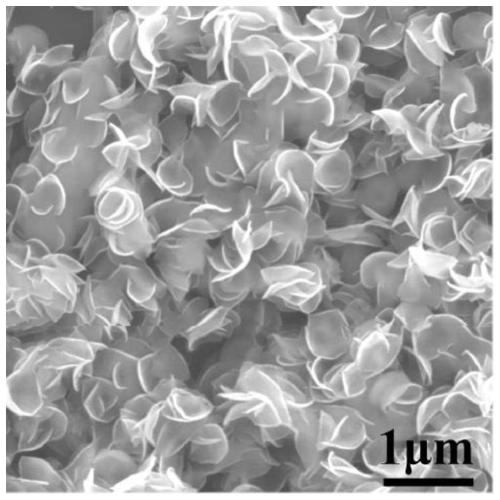

A prepartion method of a carbon-coated ultrathin FeMoSe4 nanometer potato chip-like potassium ion negative electrode material

ActiveCN109244426AGood lookingSimple methodNegative electrodesSecondary cellsVacuum dryingOleic Acid Triglyceride

The invention relates to a preparation method of carbon-coated ultrathin FeMoSe4 nanometer potato chip-like potassium ion negative electrode material, and belongs to the functional nanometer materialand electrochemical field. The method comprises the following steps: adding ferric chloride hexahydrate and molybdic acid into a single-necked flask filled with oleamine and oleic acid and placing theflask in a heating sleeve for pre-dissolution; after cooling to room temperature, adding selenium powder into the flask and heating the flask to the target temperature for a period of time; cooling that final solution to room temperature, cleaning, centrifuge and vacuum drying to obtain black powder; Finally, the obtained powder is transferred to a crucible and heated in an inert protective atmosphere in a tubular furnace to obtain carbon-coated ultrathin FeMoSe4 nano-potato chip-like potassium ion battery negative electrode material. The potassium ion battery negative electrode material synthesized by the invention has simple process, short production cycle, low cost, strong repeatability, has an important reference to the preparation of selenium-based nanocomposites, and has high intrinsic conductivity and large interlayer spacing, excellent rate performance and cycle performance, but also in the semiconductor, energy storage and catalytic fields have broad application prospects.

Owner:UNIV OF SCI & TECH BEIJING

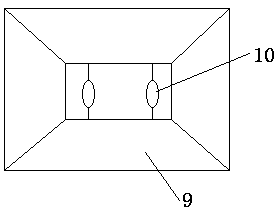

Fishing net winding device

ActiveCN105923435ARealize automatic wrappingImprove wrapping efficiencyWebs handlingRotary stageEngineering

The invention discloses a fishing net winding device. The fishing net winding device comprises a support table; a rotating table is mounted at the left part of the support table; a worm wheel is fixed at the upper end of the rotating table; a chute 1 is formed in the right part of the support table; chutes 2 are uniformly formed in the upper end of the worm wheel; slide blocks are respectively mounted in the chutes 2; springs are respectively mounted on the slide blocks; positioning columns are respectively mounted at the upper ends of the slide blocks; a connecting shaft is mounted at the front part of the support table; a worm rod sleeve is mounted at the left end of the connecting shaft; a belt wheel 1 is mounted at the right end of the connecting shaft; and an adjustable driving device is mounted at the right part of the support table. The fishing net winding device has such advantages as reasonable structure design and convenience for use, realizes automatic fishing net winding, replaces manual winding, improves the fishing net winding efficiency, saves the manpower and material resources, uses the adjustable driving device for realizing adjustment of the fishing net winding speed, and guarantees the finishing net winding quality.

Owner:安徽省安国渔具有限公司

Garbage bin capable of automatically wrapping sputum

PendingCN108891822ARealize automatic wrappingPrevent volatilizationPaper recyclingRefuse receptaclesPulp and paper industryPaper sheet

The invention relates to a garbage bin capable of automatically wrapping sputum. A wrapping paper storage cylinder is fixedly mounted on a base, and wrapping paper is stacked in the wrapping paper storage cylinder. A wrapping paper sticking ring capable of moving in the wrapping paper storage cylinder is installed right above the wrapping paper storage cylinder in the lifting mode. The wrapping paper sticking ring and the wrapping paper storage cylinder are coaxially arranged. The lower surface of the wrapping paper sticking ring is circumferentially and uniformly provided with a plurality ofpressure sensitive rubber columns. The base is provided with a linear reciprocating mechanism in the lifting mode. The linear reciprocating mechanism is rotatably provided with a wrapping paper receiving plate, and the base is further provided with a wrapping paper receiving plate turning mechanism. A casing is further detachably arranged on the base in the covering mode and provided with a sputumopening coaxially arranged with the wrapping paper sticking ring, a collecting box is mounted on the casing in the sliding mode, and the collecting box is located below the linear reciprocating mechanism. The garbage bin can achieve automatic wrapping of the sputum and completely wrap the sputum, so that the sputum is not exposed, the volatilization of bacteria is prevented, and the spread of thedisease is effectively prevented.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

Alignment tool and alignment method thereof

InactiveCN111844792ARealize automatic wrappingShorten the timeDomestic articlesEngineeringVacuum pump

The invention relates to an alignment tool and an alignment method thereof. The tool is provided with a first face and a second face, wherein the first face is matched with the contour of an inner trim frame, a vacuum cavity is formed between the first face and the second face, a wire groove is formed in the first face, a plurality of vacuum holes are formed in the first face, the vacuum holes communicate with the vacuum cavity, and the vacuum cavity further communicates with a vacuum pump. According to the alignment tool and the alignment method thereof, automatic wrapping of a product with no obvious step characteristics on a wrapping surface cover is achieved, and products with different configurations can share a same automatic wrapping forming die. Meanwhile, the time for laying skinin equipment is omitted, the equipment rhythm is reduced, and the equipment productivity is saved.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

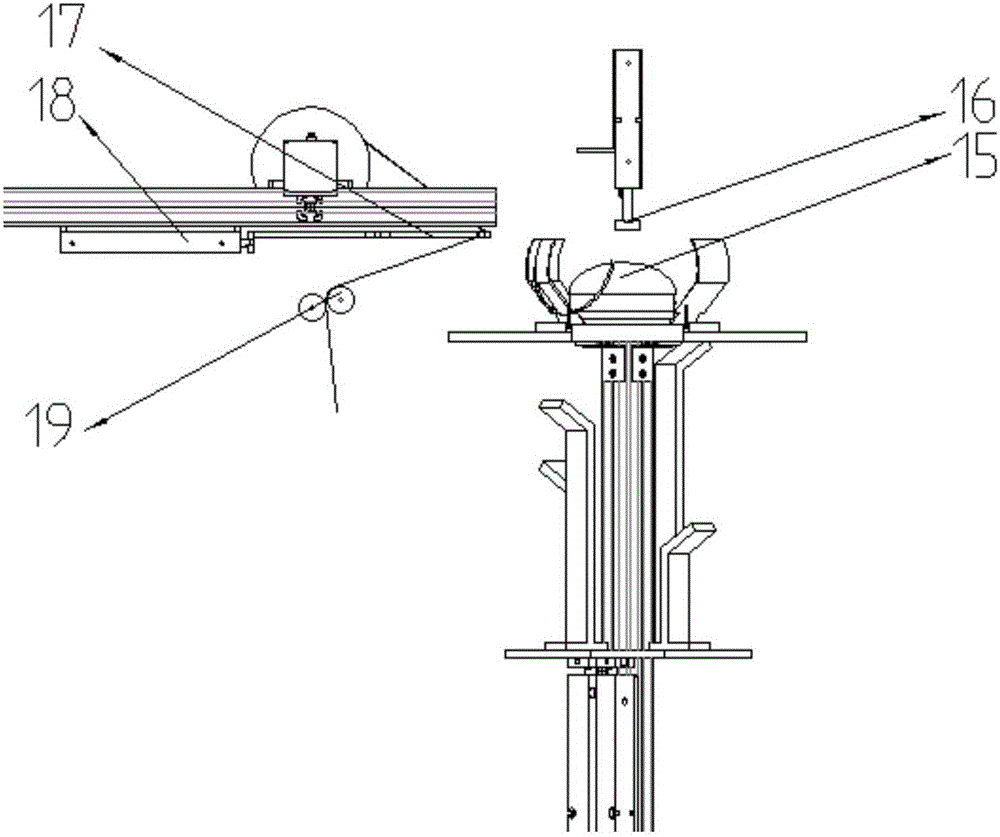

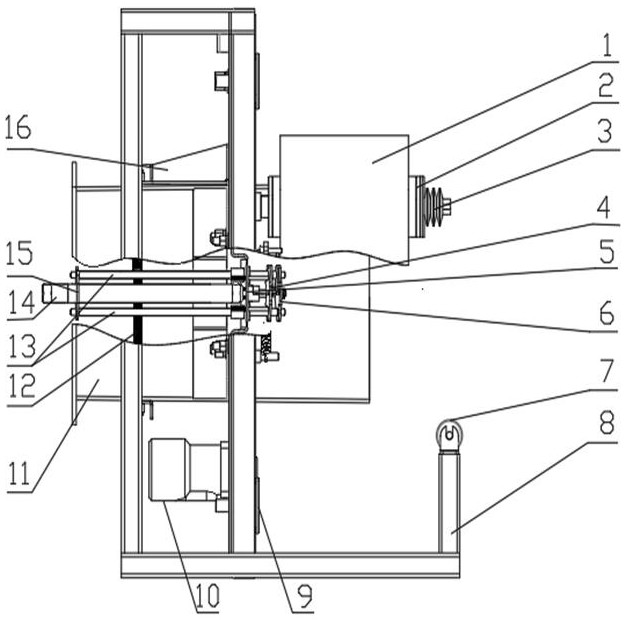

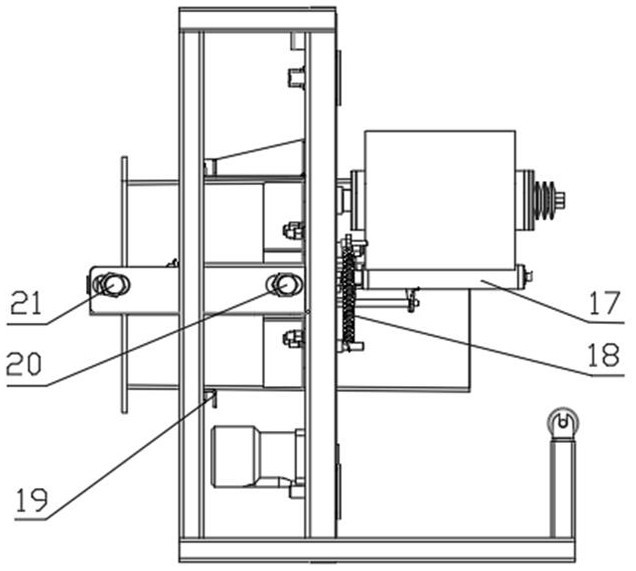

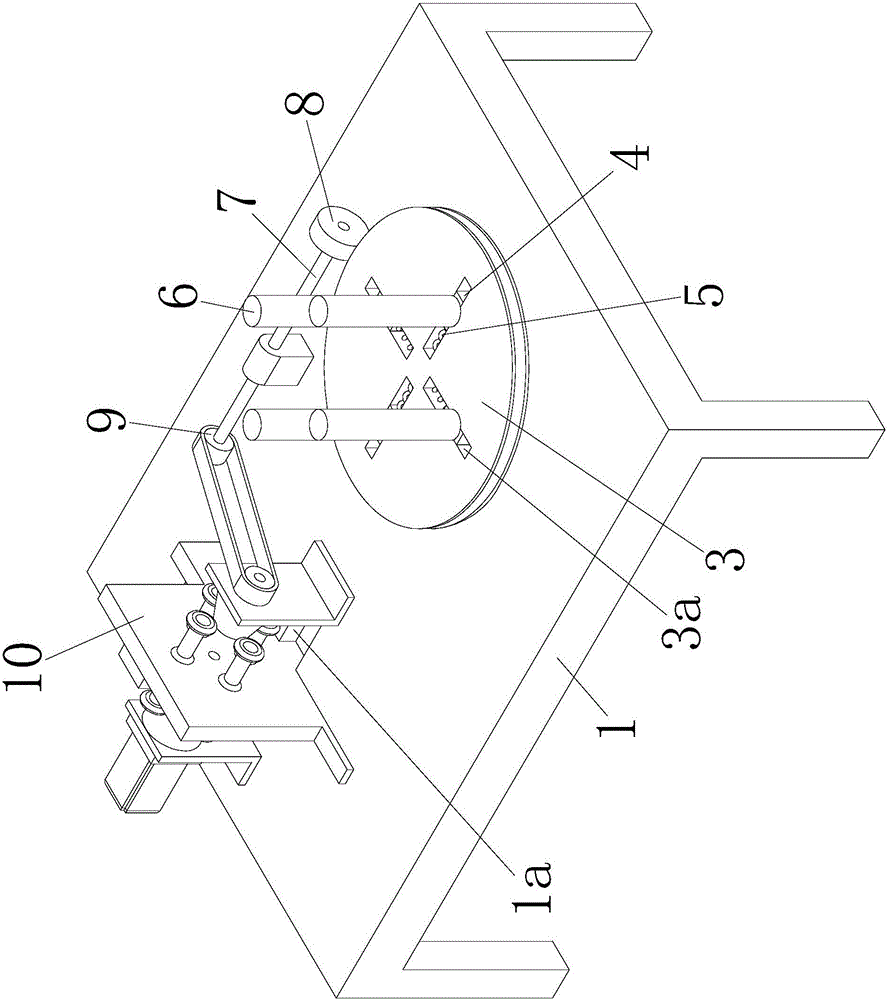

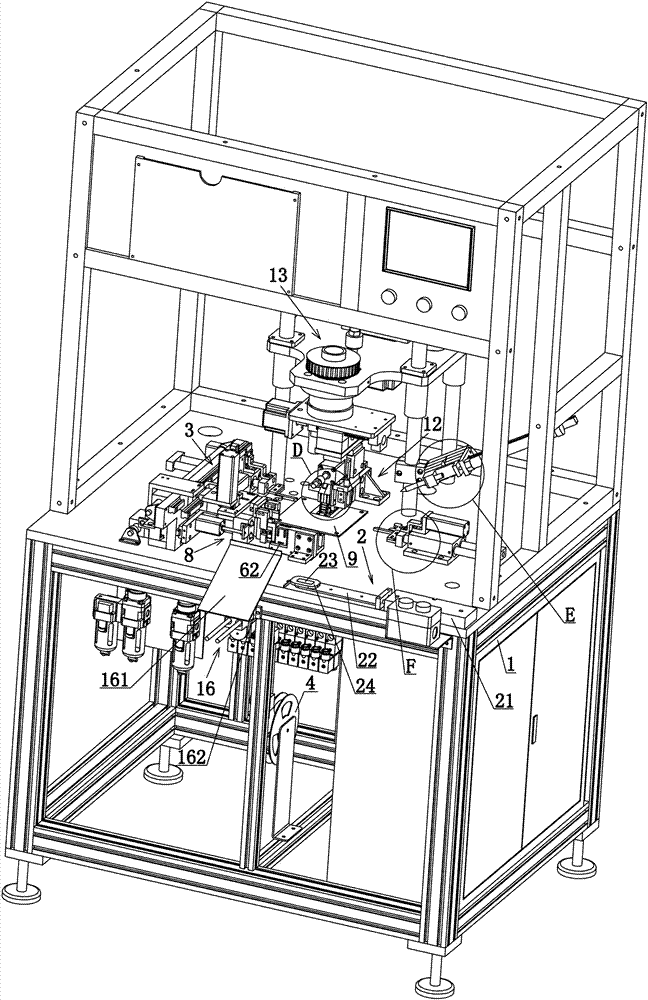

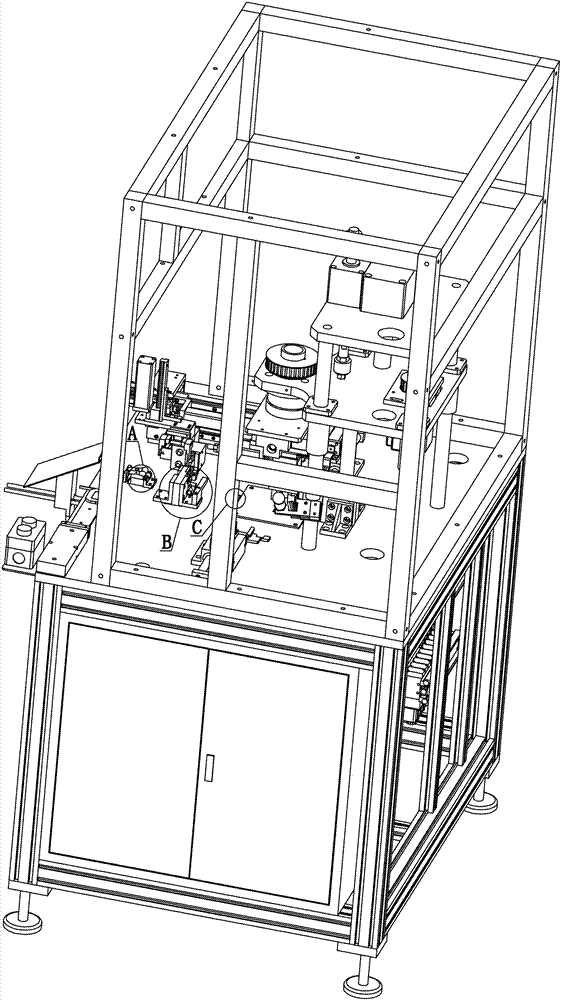

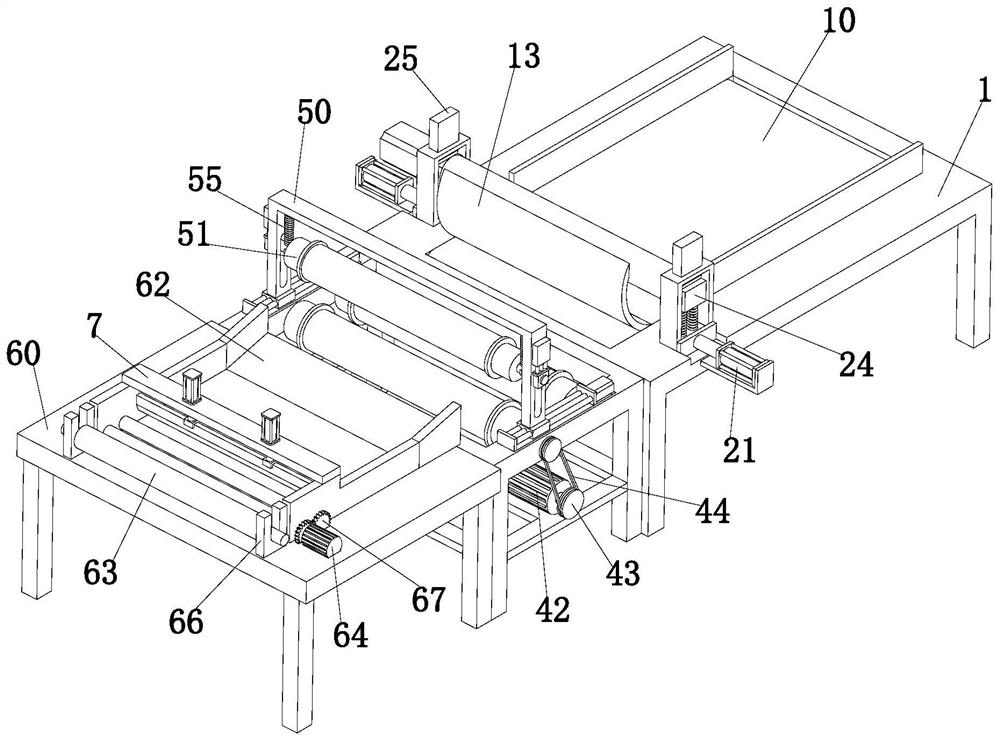

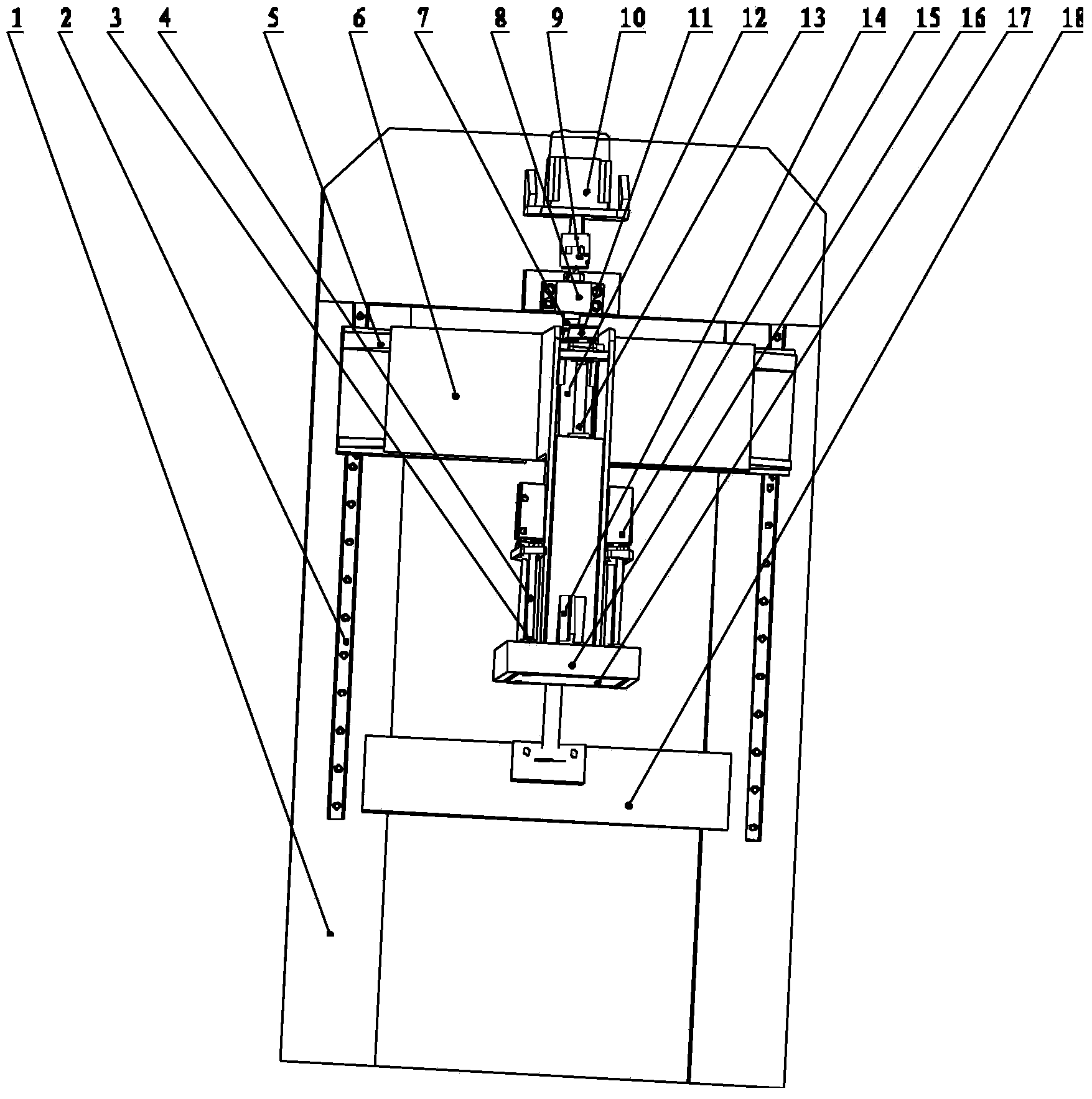

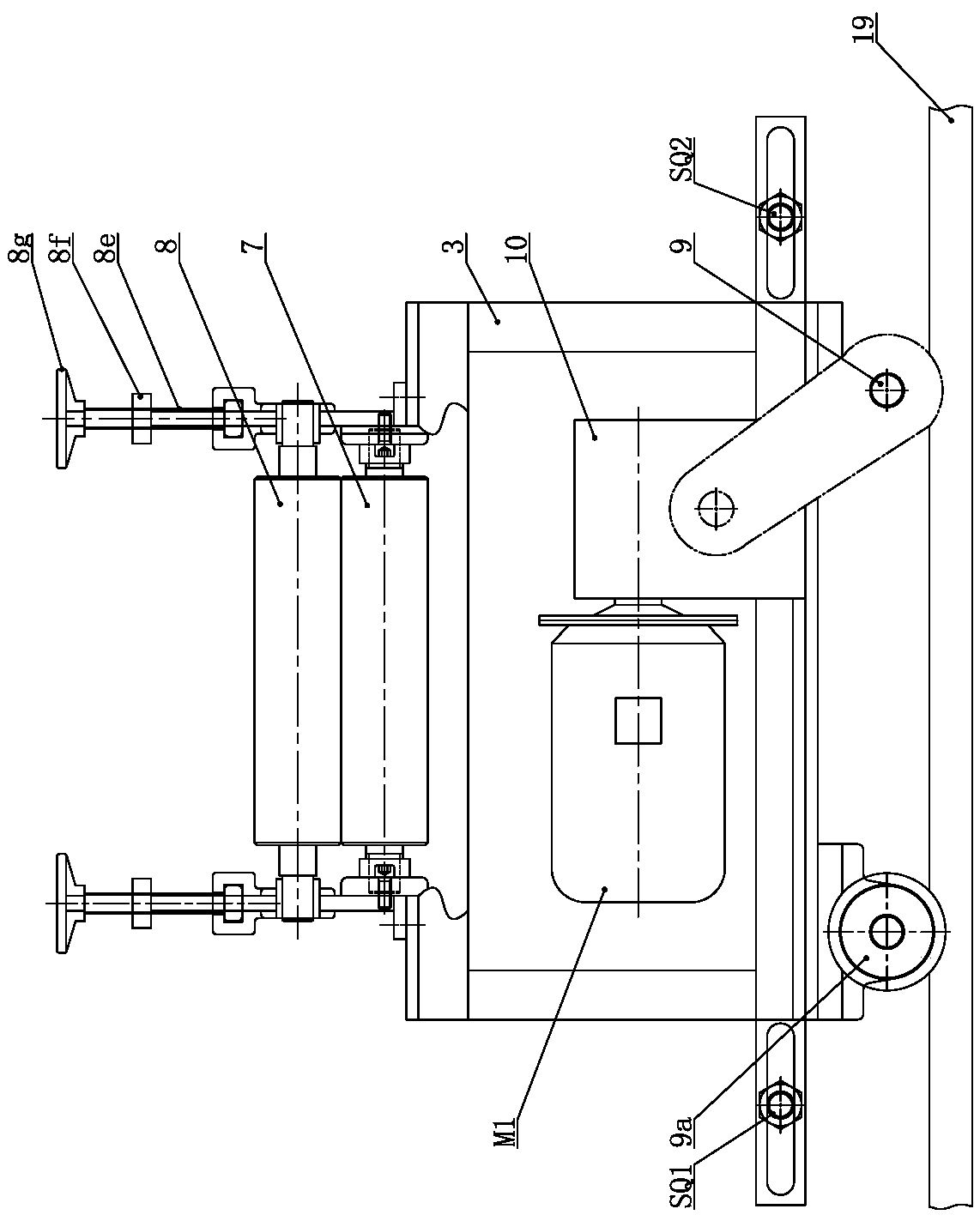

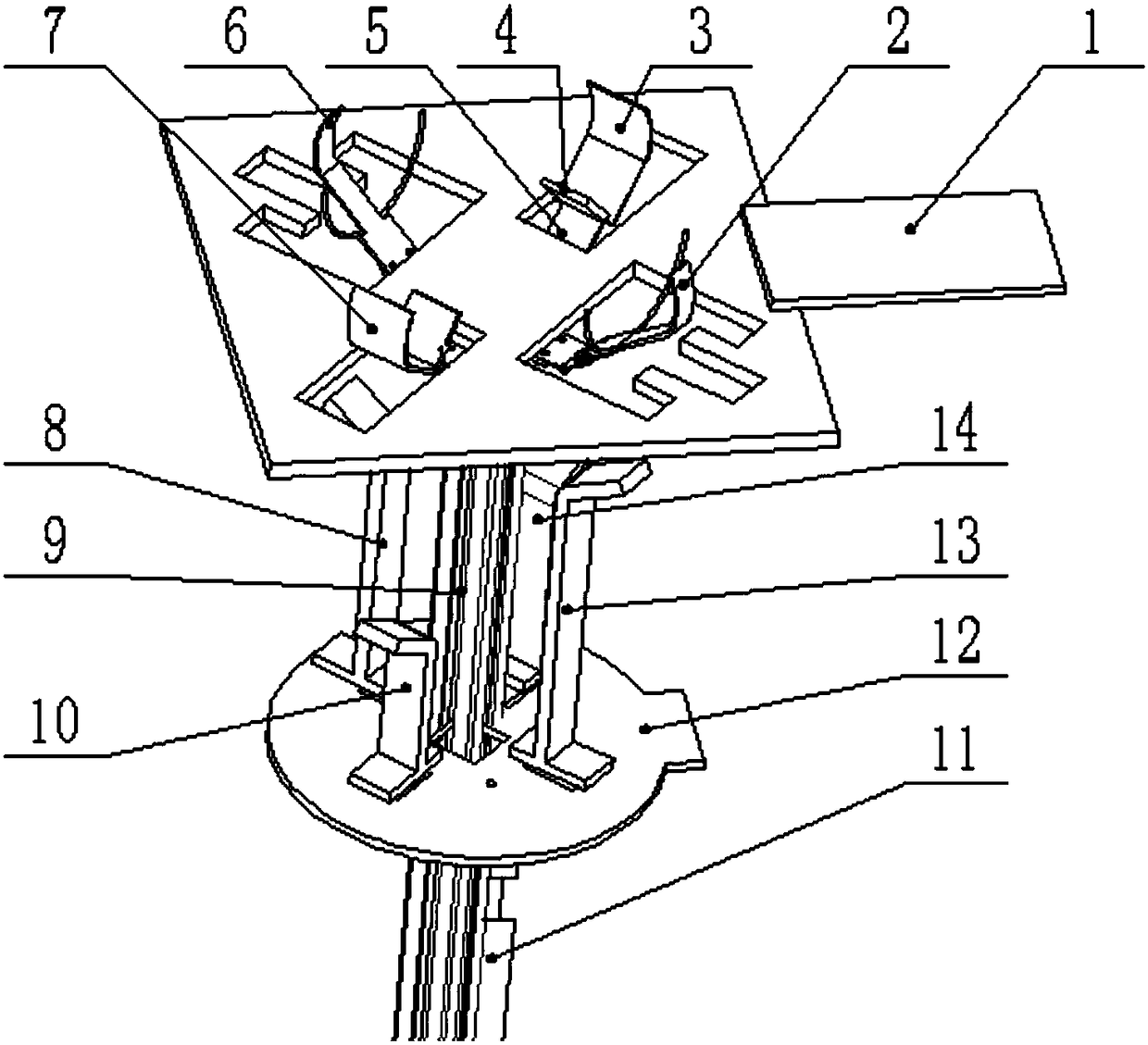

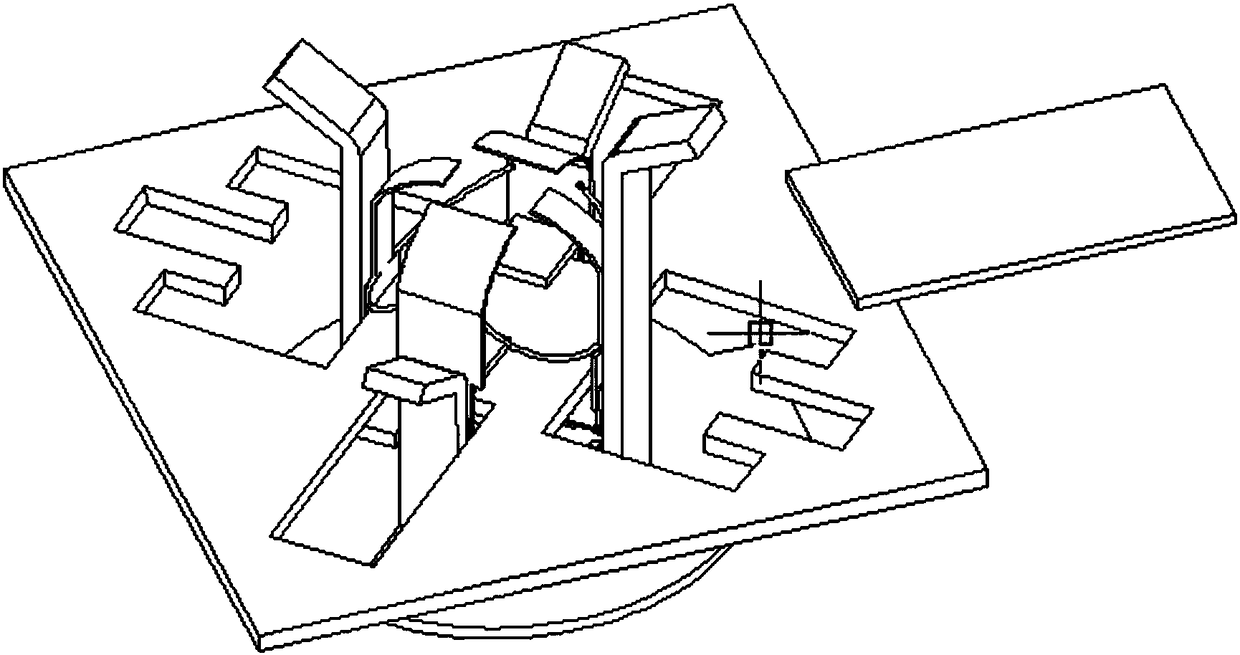

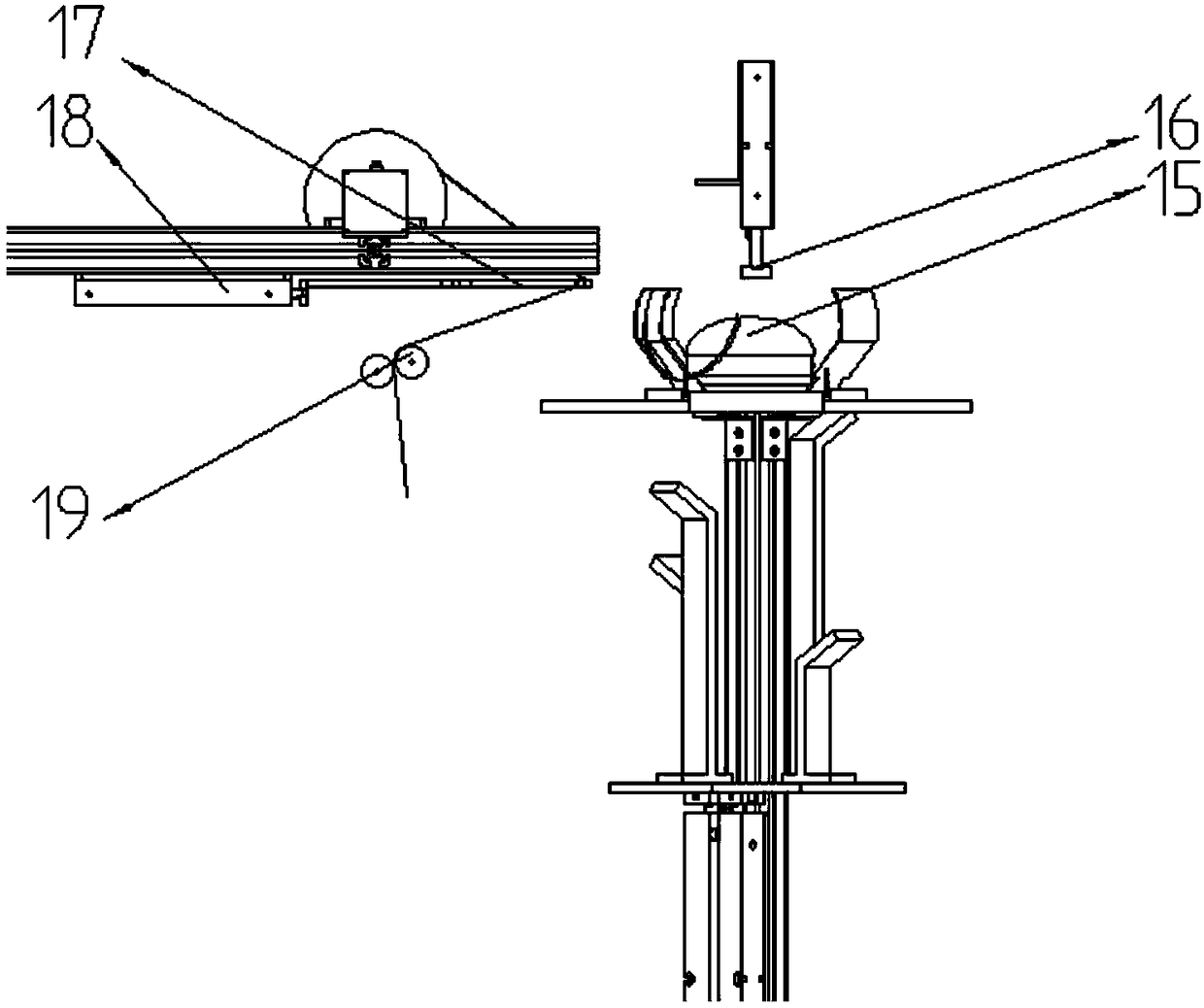

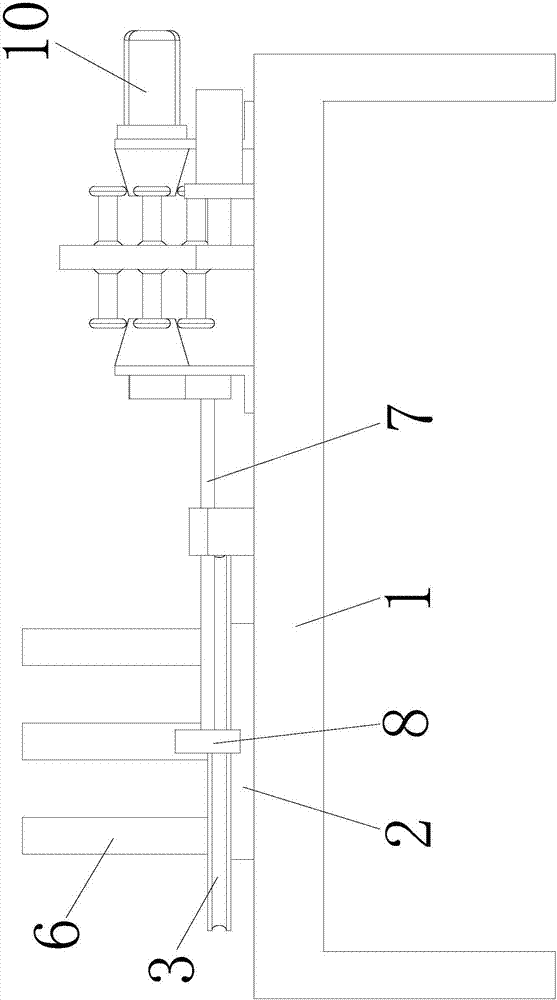

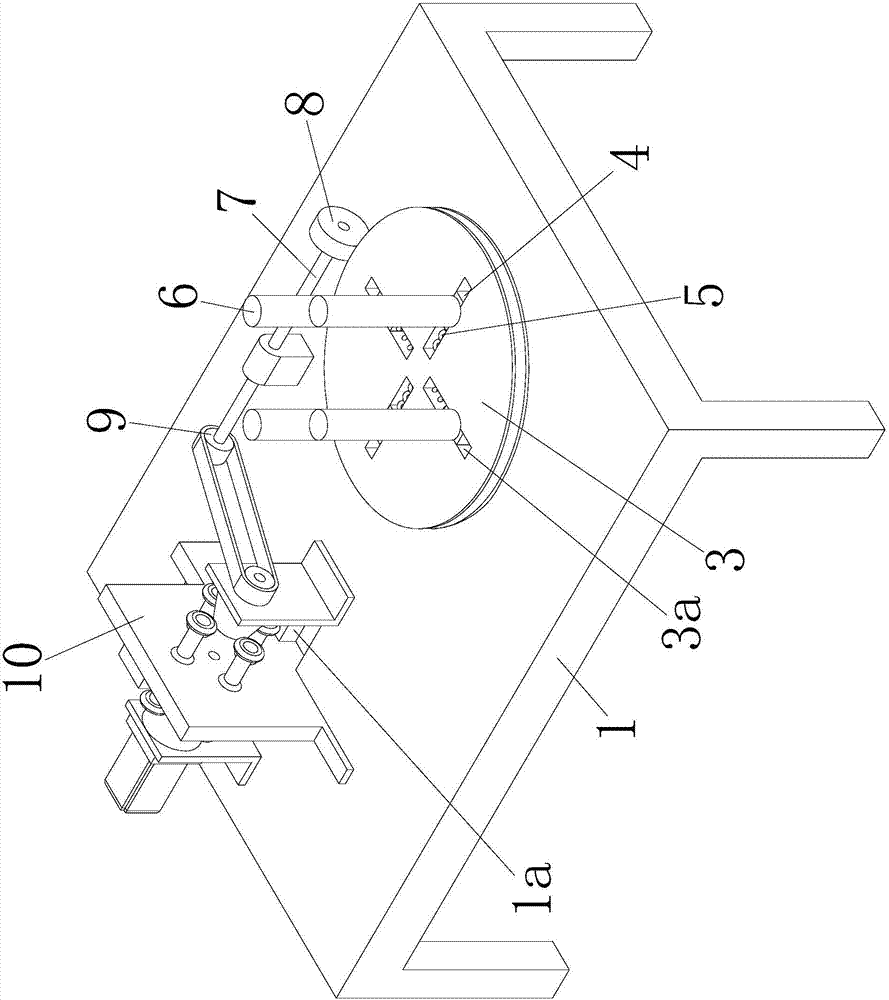

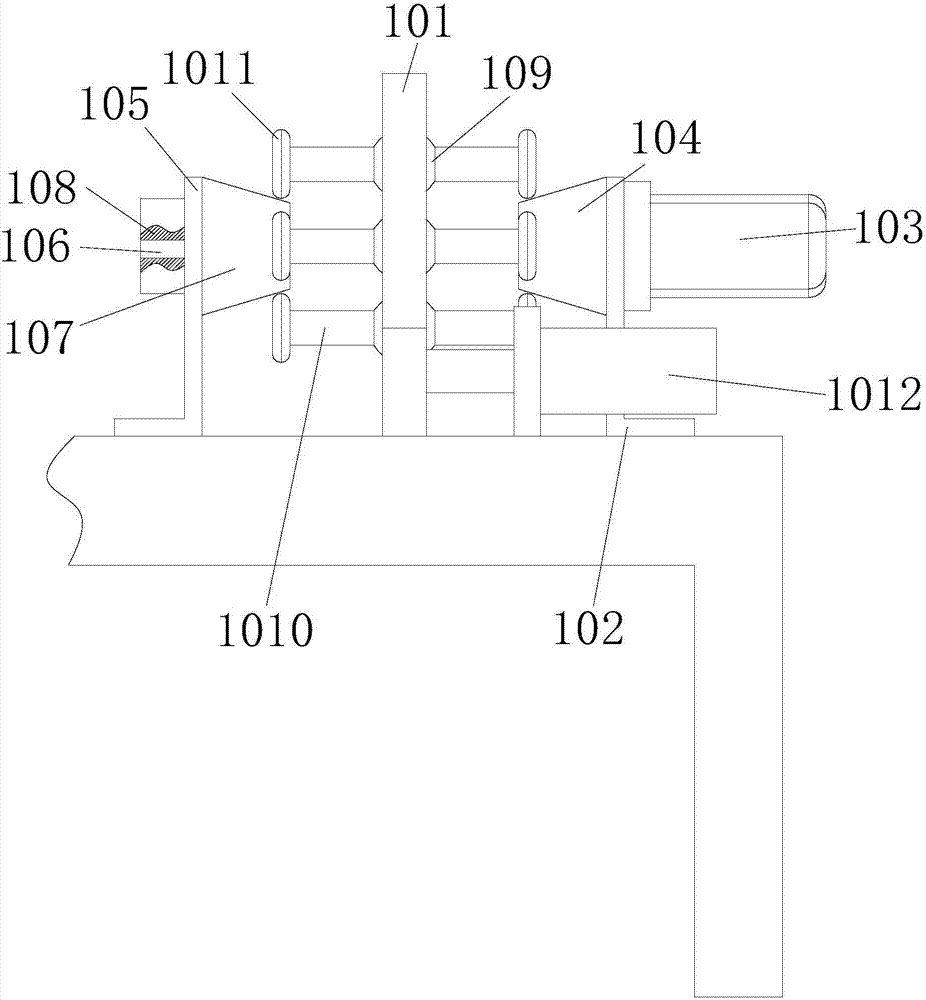

Motor stator coil cloth wrapping machine

ActiveCN106882409ANovel structureIngenious designElectric machinesWrappingConductor CoilMechanical engineering

A motor stator coil cloth wrapping machine comprises a machine frame. A feeding device is arranged on the top face of the machine frame. A gripping device is arranged on the left side of the feeding device. A cloth strip winding drum is arranged on the bottom face of the machine frame. A cloth strip tensioning device where a cloth strips penetrates through is arranged on the top face of the machine frame. A cloth strip passing device is arranged on the rear side of the cloth strip tensioning device. A cloth cutting device is arranged on the rear side of the cloth strip passing device. A telescopic cloth strip pressing device is arranged on the left side of the cloth strip passing device. A workbench is arranged on the rear side of the cloth cutting device. A cloth winding device is arranged in the rear middle part of the workbench. A cloth supporting device is arranged on the front side of the workbench. A coil clamping device is arranged above the workbench. A rotary device used for driving the coil clamping device to rotate around the cloth winding device is arranged above the coil clamping device. Telescopic coil jacking devices which are arranged in a staggered mode are arranged on the left side and the right side of the workbench. Adhesive dispensing guns are obliquely arranged on the right side of the coil clamping device. A material receiving is arranged on the front side of the machine frame.

Owner:泉州市生辉电机设备有限公司

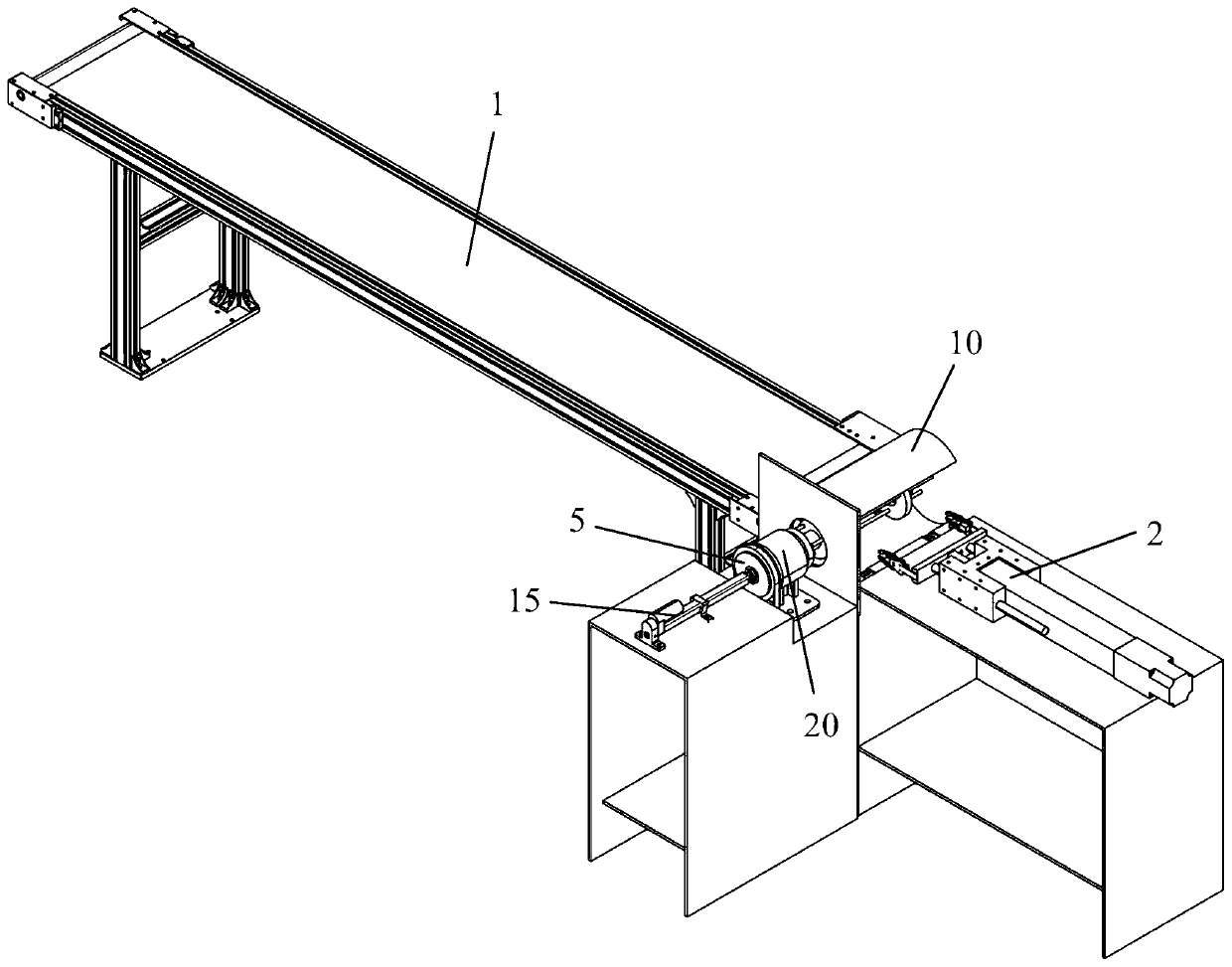

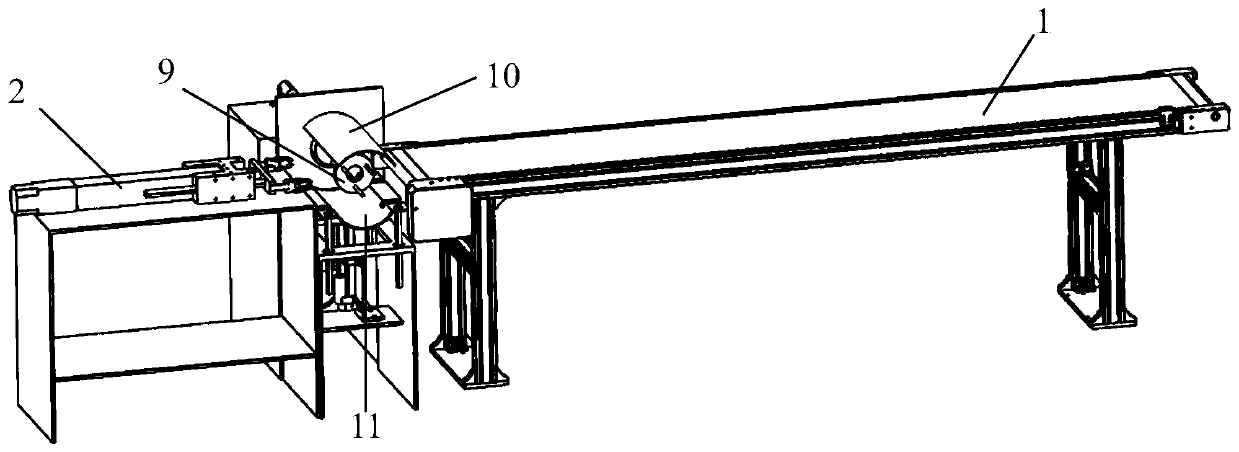

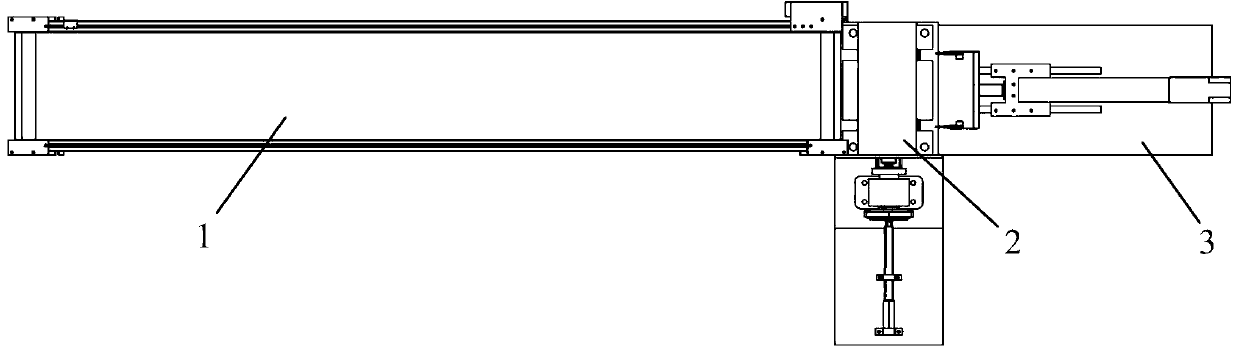

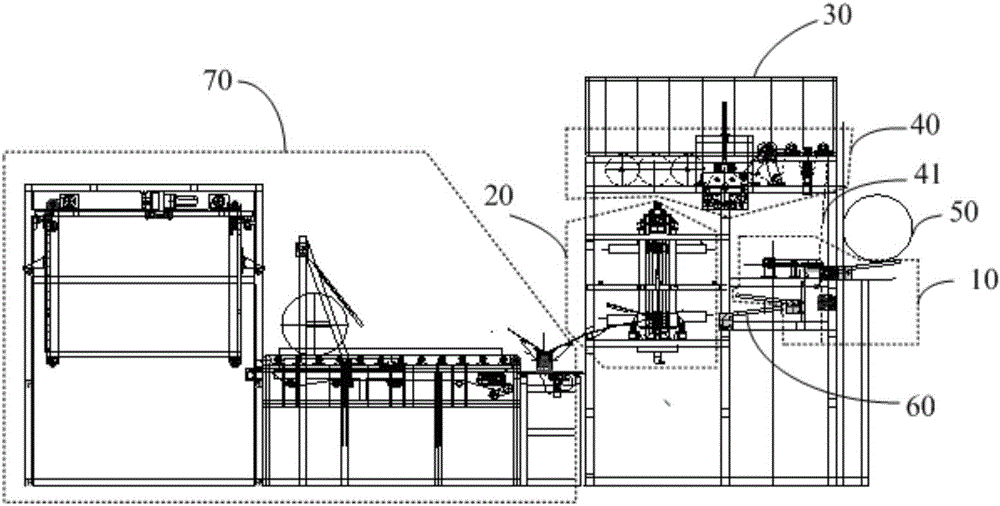

Automatic production equipment for heat-preservation rock wool pipeline

InactiveCN112283499ARealize automatic productionNo manualThermal insulationWrappingWoolProcess engineering

Owner:李文华

Automatic production process of heat-preservation rock wool pipeline

InactiveCN112268165ARealize automatic productionNo manualThermal insulationWrappingProcess engineeringHeat conservation

The invention discloses an automatic production process of a heat preservation rock wool pipeline, and belongs to the technical field of heat preservation rock wool processing. The automatic production process comprises the following steps of: step 1. automatically feeding a roller; step 2. inserting a fixed shaft into the roller; step 3. automatically rolling wool on the roller; step 3. automatically rolling wool on the roller; step 4. automatically compacting the rock wool on the roller; step 5. automatically wrapping the heat-preservation rock wool pipeline with paper; step 6. cutting off the remaining paper after paper wrapping is completed; and step 7. performing automatic discharging and stacking. The process is ingenious in design and smooth in procedure connection; automatic rollerfeeding, wool rolling, compacting, paper wrapping, paper cutting and automatic discharging and stacking are achieved through mutual operation of all the procedures; automatic production of the heat-preservation rock wool pipeline is achieved; manpower is not needed; the whole production efficiency is improved; and the remarkable economic value is achieved.

Owner:李文华

Combined movable head for surface-paper covering

ActiveCN103753862ARealize wrapping workRealize automatic wrappingContainer making machineryCouplingCarton

The invention provides a combined movable head for surface-paper covering. The combined movable head comprises a longitudinal supporting plate, guide rails, linear bearings, guide pillars, a slider, a head connecting frame, a first lead screw, a lead-screw supporting seat, a coupling, a first servo motor, a synchronous belt, a second servo motor, a second lead screw, an air cylinder, an inner mold outer frame, an inner mold and a fixed connecting plate. The combined movable head serving as a nut forms a first screw-nut pair with the first lead screw and is fixedly connected with the head connecting frame; the head connecting frame is fixedly connected with the slider; the inner mold serving as a nut forms a second screw-nut pair with the second lead screw; the second screw-nut pair is connected with the second servo motor through the synchronous belt. The internal-forming head that is of the combined moving structure is used to realize internal forming and automatic surface-paper covering of cartons, so that production efficiency is improved greatly and input cost for production is reduced.

Owner:星光印刷(苏州)有限公司

A carbon-coated ultra-thin femose 4 Preparation method of nano potato chip-like potassium ion anode material

ActiveCN109244426BGood lookingSimple methodNegative electrodesSecondary cellsMolybdic acidOleylamine

Owner:UNIV OF SCI & TECH BEIJING

Outdoor tent automatic round baler

The invention discloses an outdoor tent automatic round baler comprising a tent feeding mechanism, a rolling mechanism and a tent pulling mechanism. The tent feeding mechanism, the rolling mechanism and the tent pulling mechanism are arranged sequentially from the head end to the tail end. The rolling mechanism comprises a rolling motor, a synchronous pulley, a spindle and a tent rolling guide rod. The rolling motor is in transmission connection with the synchronous pulley through a synchronous belt. One end of the spindle penetrates in the synchronous pulley. The tent rolling guide rod is installed at the other end of the spindle. The outdoor tent automatic round baler is simple and convenient to operate, an outdoor tent can be rolled automatically, and the problems that the outdoor tentis rolled manually for a long time, time and labor are wasted, and efficiency is low are solved.

Owner:ZHEJIANG NORMAL UNIVERSITY

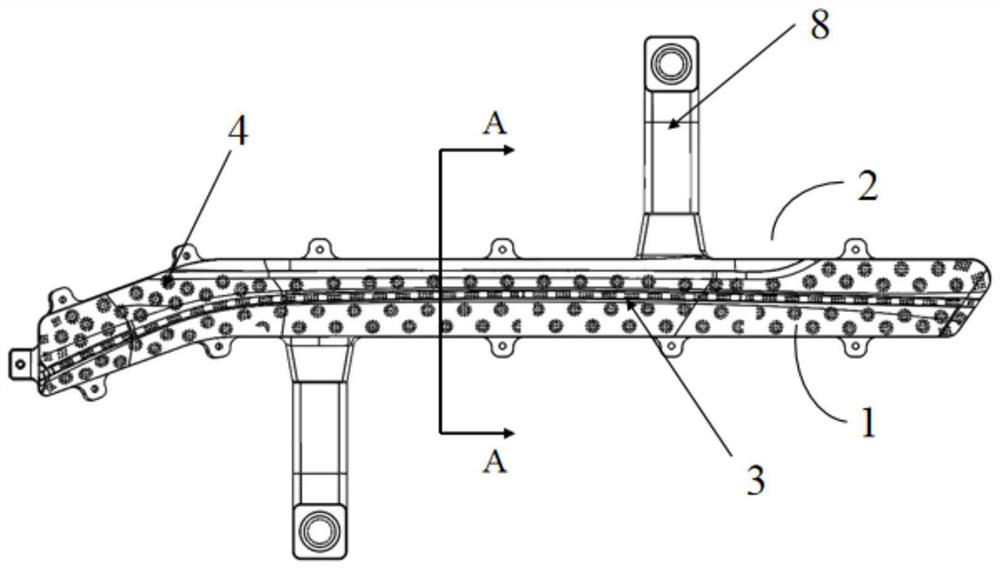

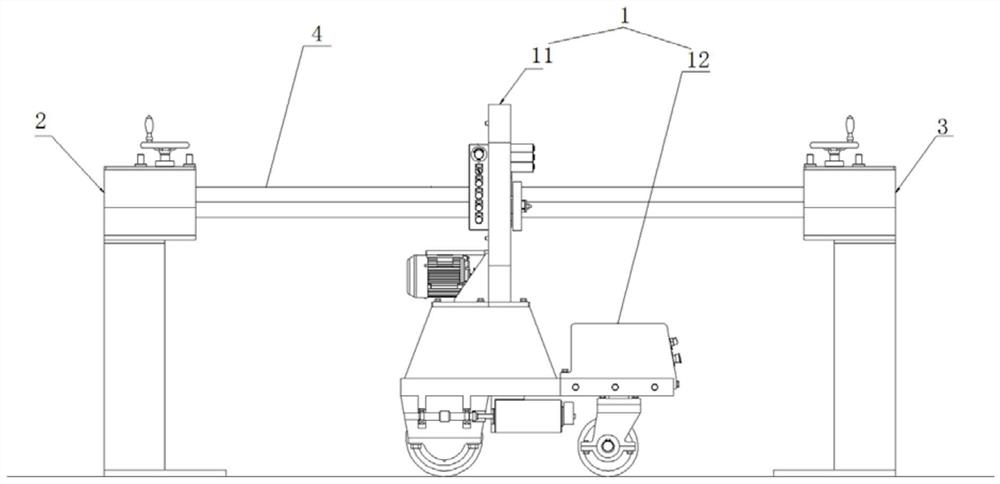

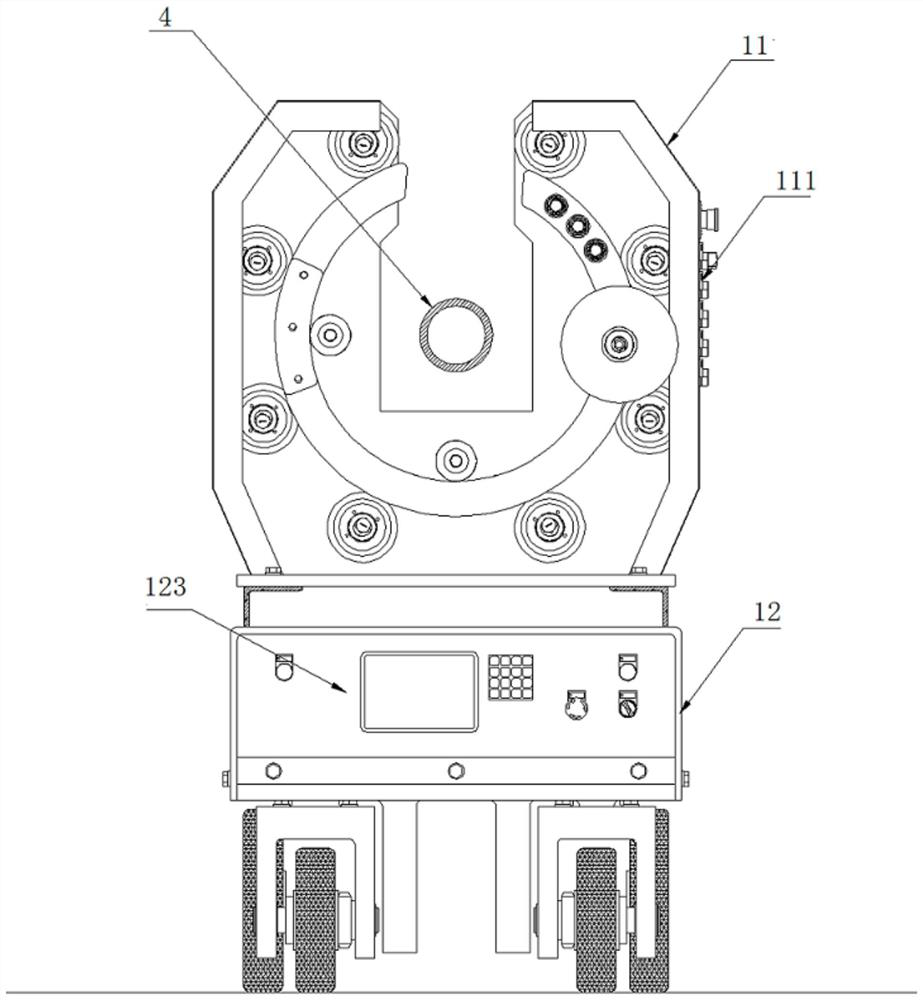

A pipe bus wrapping equipment

ActiveCN111180140BSolve the problem of not being able to wrap curved tubular busbarsRealize automatic wrappingInsulating conductors/cablesBusbarStructural engineering

The invention discloses a pipe busbar wrapping device, which comprises a wrapping assembly, a first busbar fixing frame and a second busbar fixing frame, one end of the pipe busbar to be wrapped is fixed on the first busbar fixing frame, and the The other end of the pipe busbar is fixed on the second busbar fixing frame, and the wrapping assembly includes a wrapping head, an AGV trolley and a patrol line, and the track of the patrol line is consistent with that of the pipe busbar to be wrapped. The shape is the same, the busbar of the pipe to be wrapped passes through the wrapping head, and the wrapping head is used to wrap the busbar of the pipe to be wrapped, and the wrapping head is fixed on the AGV On the trolley, the AGV trolley can drive the wrapping head to run along the trajectory of the patrol line. The invention uses the AGV car to patrol the track, so that the wrapping machine head can wrap along the line of the busbar, which can not only realize automatic wrapping, but also solve the problem that the current old-fashioned mechanical wrapping equipment cannot wrap the curved tubular busbar, and improve the Production efficiency and quality.

Owner:WUHAN BASHI BO TECH CO LTD

Material coil coating device

InactiveCN106742207AAvoid damageRealize automatic wrappingPaper article packagingEngineeringMechanical engineering

The invention provides a material coil coating device which comprises a rack, a film feeding unit, a first coating unit and a second coating unit, wherein the film feeding unit is arranged at the top of the rack, and used for feeding a packaging film to the first coating unit; the first coating unit is arranged on the first side of the rack; the second coating unit is arranged on the second side of the rack; the first coating unit is used for coating the side surface of a material coil in a hot pressing manner; the second coating unit is used for coating the two end surfaces of the material coil in a hot pressing manner; and a rotatable conveying unit is arranged between the first coating unit and the second coating unit, and used for conveying the material coil coated in a hot pressing manner at the first coating unit to the second coating unit. By adoption of the material coil coating device provided by the invention, the purpose of automatically coating a material coil with a film is fulfilled, thereby solving the technical problem that in the prior art, both time and effort are wasted during manual film coating.

Owner:广州呈佳自动化科技有限公司

External corrosion prevention integrated equipment for oil-water well pipeline

ActiveCN111006097AUniform coatingUniform and stable coatingGrinding drivesLiquid/gas/vapor removal by squeezing rollersGlass fiberMechanical engineering

The invention relates to external corrosion prevention integrated equipment for an oil-water well pipeline. The equipment comprises X-direction guide rails which are parallel to the oil-water well pipeline and extend in a left-right direction; the two X-direction guide rails are parallel to each other and are fixed on the ground at the rear side of the pipeline; a fixed bottom plate capable of advancing along the guide rails is supported on the two X-direction guide rails; a movable bottom plate is hinged to the fixed bottom plate; an asphalt paint dipping tank is fixed above the middle part of the movable bottom plate; a cloth roller extending in an X direction is arranged behind the asphalt paint dipping tank; a glass fiber cloth roll is wound on the cloth roller; a cloth dipping rolleris arranged in the asphalt paint dipping tank; a pair of rollers is arranged in front of the asphalt paint dipping tank; glass fiber cloth led out of the glass fiber cloth roll penetrates through therollers upwards after being wound on the cloth dipping roller downwards, and then wraps the oil-water well pipeline forwards; a horizontal swing air cylinder is hinged to the rear portion of the movable bottom plate; and the outer end of the horizontal swing air cylinder is hinged to a supporting seat on the outer side of the fixed bottom plate. The external corrosion prevention integrated equipment for the oil-water well pipeline can safely and efficiently complete external corrosion prevention work of the pipeline with low strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

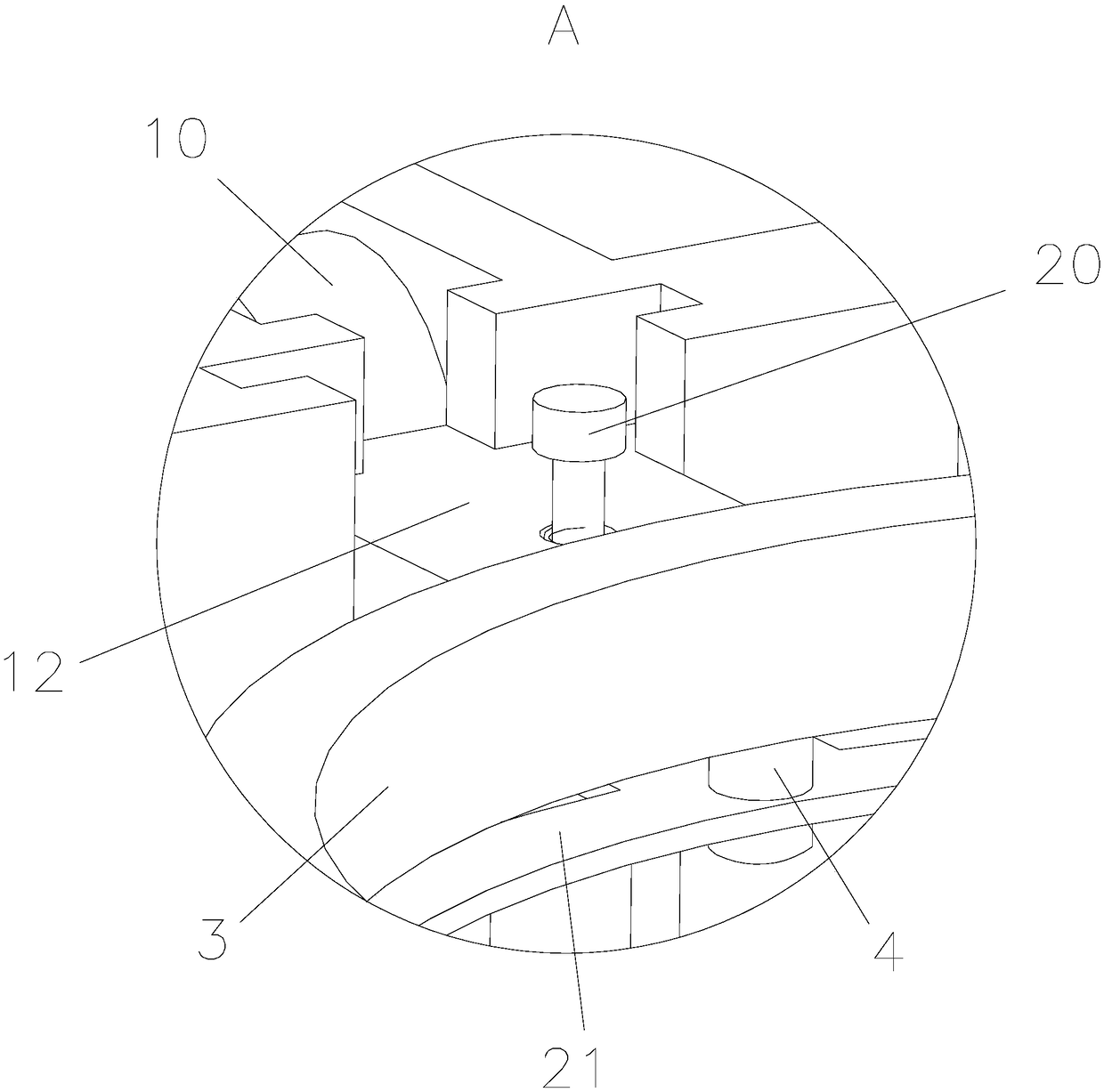

A seat frame barrier cotton automatic covering device

ActiveCN113562683BRealize automatic wrappingIncrease productivityUpholstery manufactureEngineeringStructural engineering

The invention relates to an automatic wrapping device for seat frame barrier cotton, comprising a floating mechanism, including a floating platform, a floating component connected with the floating platform to realize the vertical displacement of the floating platform; an up and down positioning mechanism, including a positioning mechanism suspended above the floating platform Disk, the telescopic assembly connected with the positioning disk to realize the vertical displacement of the positioning disk; the side positioning mechanism, including the positioning side plate located at the side wall of the floating table to press the inner periphery of the barrier cotton against the side wall of the seat frame; wrapping The mechanism includes a wrapping piece, a push-pull assembly connected with the wrapping piece to move the wrapping piece toward the bottom peripheral edge of the seat frame; Wrapped on base. Compared with the prior art, the present invention replaces the artificial covering process of the seat frame barrier cotton, realizes the automatic covering of the seat frame barrier cotton, has high production efficiency and guarantees the wrapping quality.

Owner:UE FURNITURE CO LTD

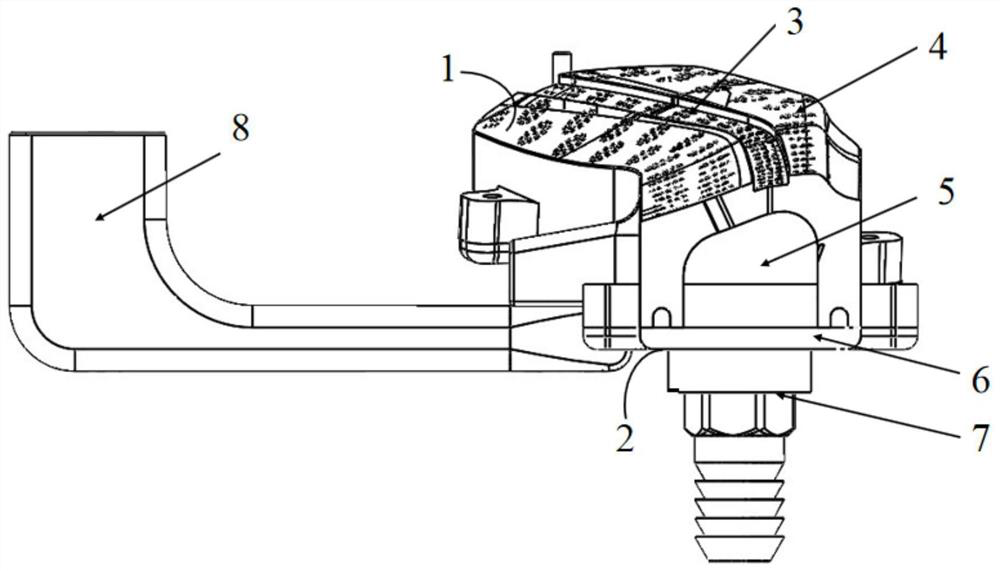

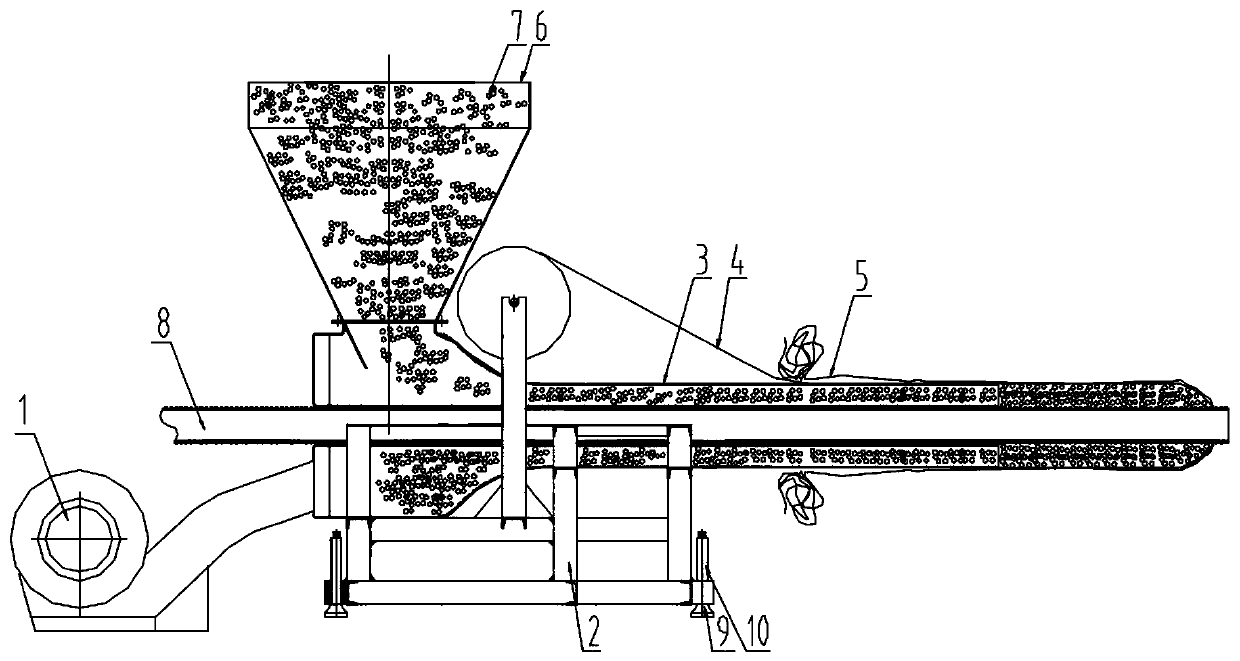

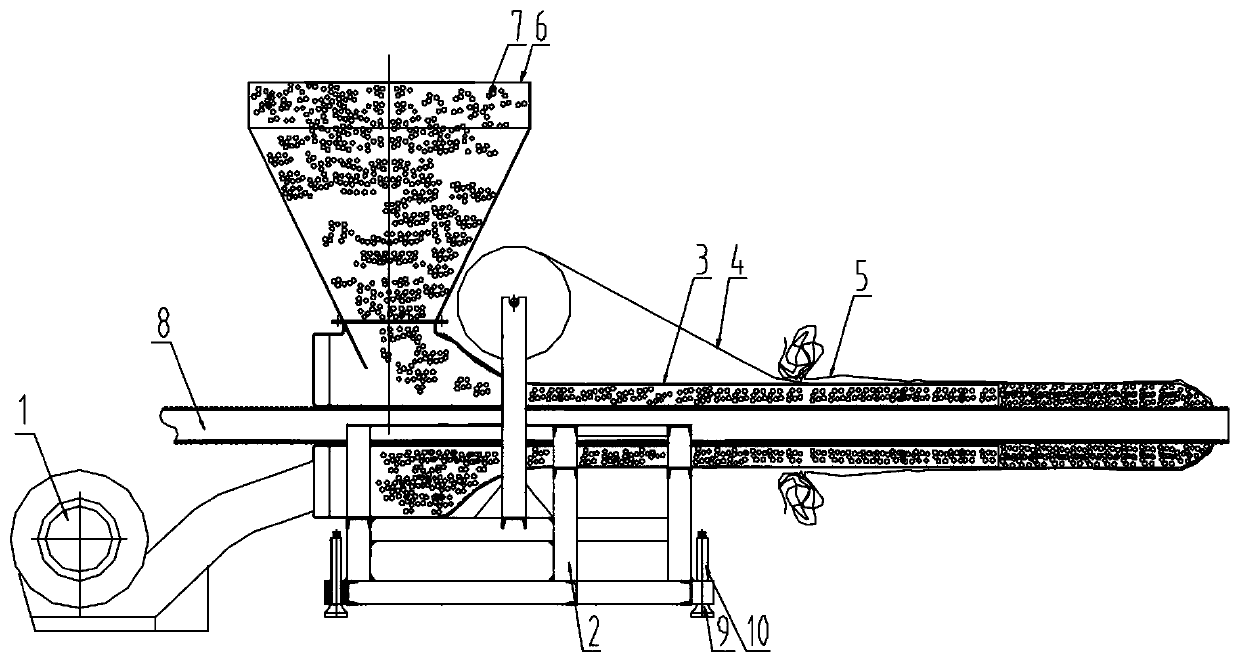

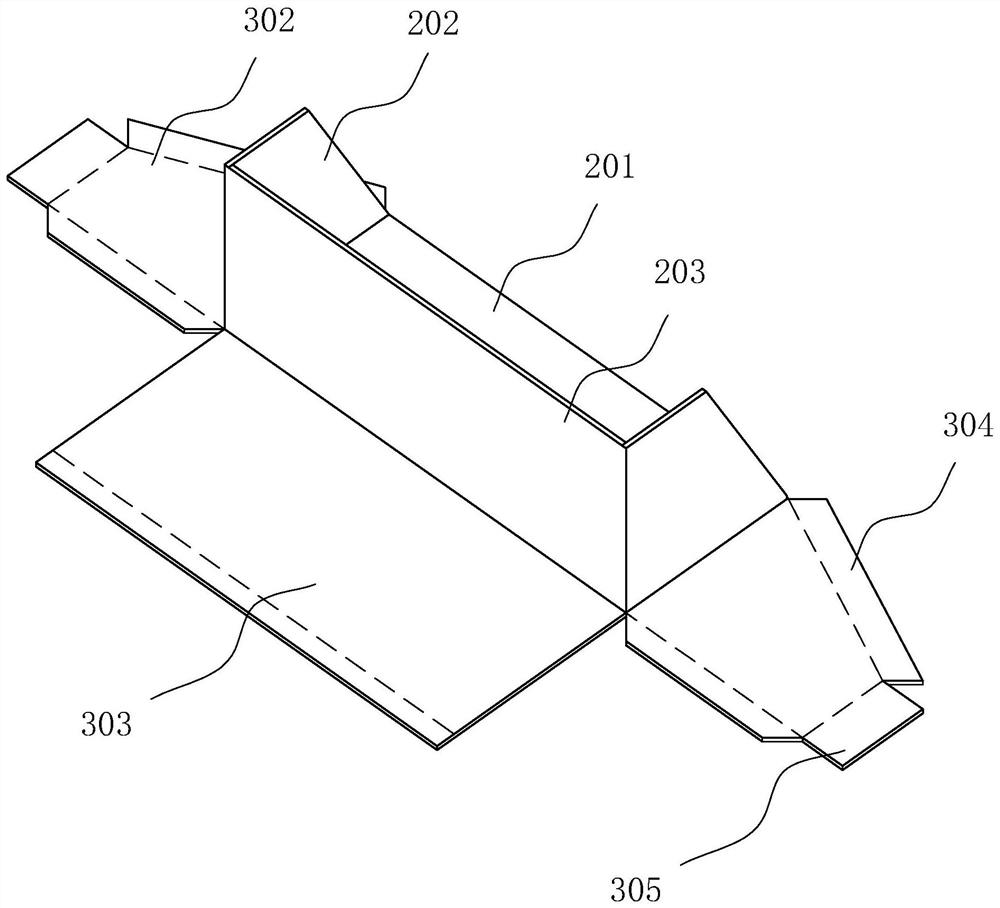

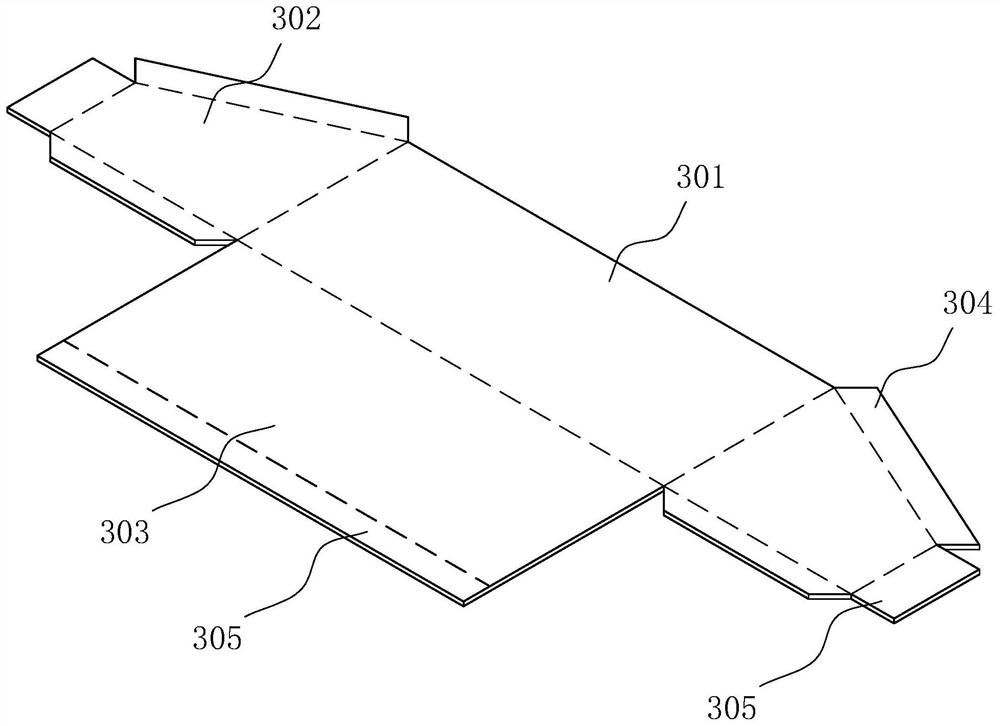

A percolation tube coating device

ActiveCN106362490BRealize online wrappingRealize automatic wrappingMembrane filtersFiltration separationStructural engineeringAir blower

The invention discloses a percolation pipe wrapping device. The device comprises an air blower, a frame, a jacket pipe, geotechnical cloth, a net cover and a hopper used for containing plastic foam. The jacket pipe is fixed to the frame and comprises an inner channel and an outer channel, wherein the inner channel is used for allowing a percolation pipe body to pass through, the outer channel is used for allowing the plastic foam to pass through, an air outlet of the air blower is fixedly connected to the lower portion of the feeding end of the outer channel, the hopper is fixedly connected to the upper portion of the feeding end of the outer channel, and the geotechnical cloth and the net cover sequentially wrap the discharging end of the outer channel. The device has the advantages that on-line wrapping of a percolation pipe can be realized, the production process is simplified, automatic wrapping is realized, and manual labor intensity is lowered; the working procedure during construction of the percolation pipe can be simplified, therefore, construction efficiency is improved, and construction cost is lowered.

Owner:SICHUAN SENPU PIPE

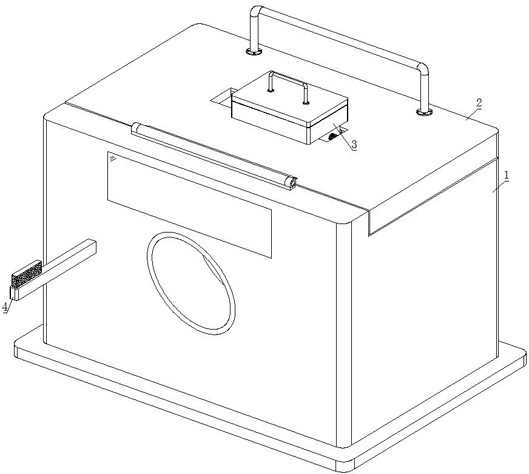

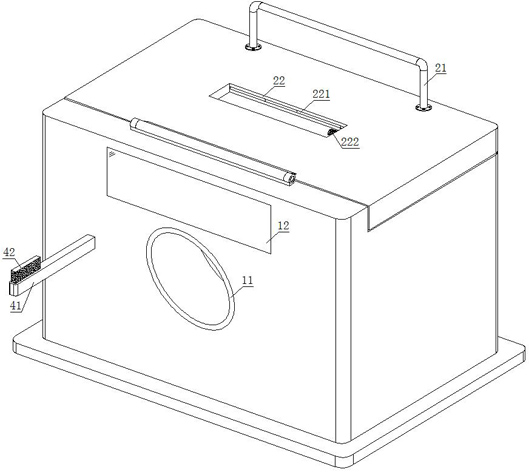

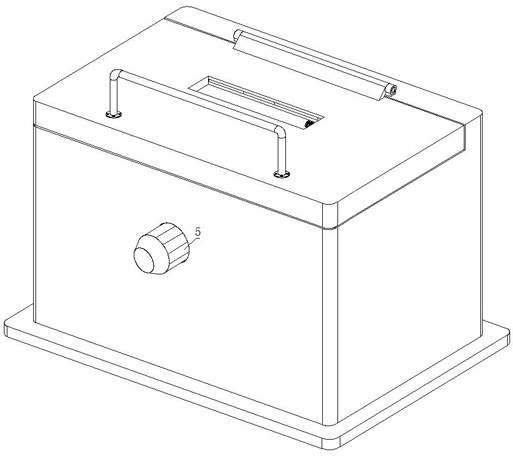

A smart packaging wrapping mechanism for carton production equipment in an intelligent workshop

ActiveCN112918002BHigh degree of automationIncrease productivityBox making operationsPaper-makingCartonEngineering

This application relates to the field of carton surface processing mechanisms, in particular to a fine packaging and covering mechanism for carton production equipment in an intelligent workshop, which includes a machine base and a mounting seat arranged on the machine base, and an installation cavity is opened on the mounting base , there is a mounting plate in the installation cavity, and a lifting element in the installation cavity; a fixed rod is provided at the bottom of the mounting plate, a pressure block is provided at the bottom of the fixed rod, a forming block is provided at the bottom of the mounting plate, and the fixed rod runs through Forming block, the pressing block is set on the bottom surface of the forming block, the bottom surface of the forming block is provided with accommodating groove, the adjusting assembly is provided on the mounting plate, the housing cavity is opened on the machine base, a tray is arranged in the accommodating cavity, and the bottom surface of the tray A support rod is provided, and the bottom end of the support rod is provided with a driving part; a first forming device is arranged in the accommodation cavity, and the first forming device is arranged in the accommodation cavity, and a second forming device is arranged below the first forming device, and the second forming device The device is arranged in the containing cavity. This application has the effect of improving the production efficiency of a carton.

Owner:昆山科望快速印务有限公司

External anti-corrosion method for oil and water well pipelines

ActiveCN110919517BEven and stable lap widthUniform coatingGrinding machinesMining engineeringMechanical engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

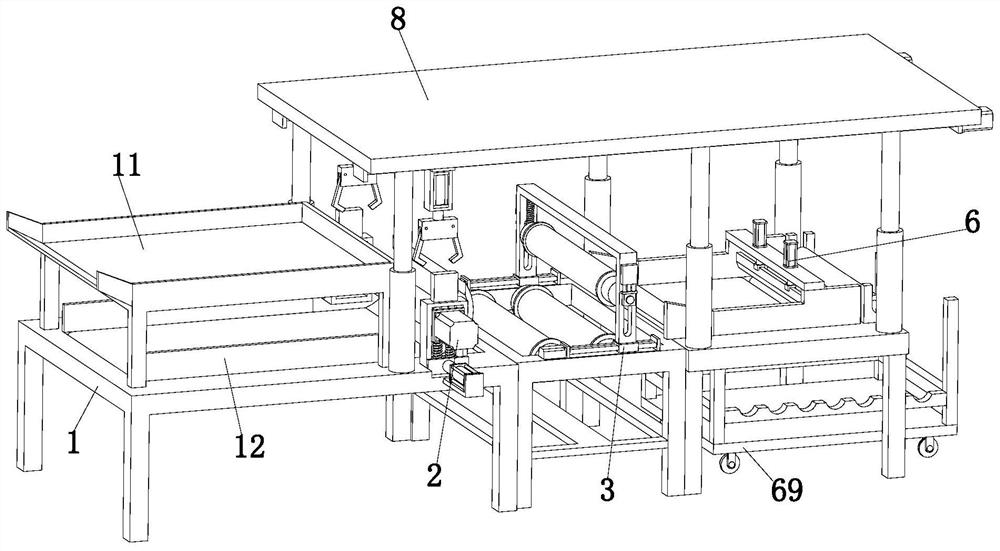

Wrapping and sticking device of automatic hamburger packaging machine

ActiveCN105857702BRealize automatic paper wrappingThe process is complete and smoothWrapper folding/bending apparatusWrapper supporting apparatusPulp and paper industryPackaging machine

The invention discloses a paper wrapping and pasting device of a full-automatic hamburger packaging machine. The paper wrapping and pasting device comprises a rack, wherein a working platform is arranged on the rack; four mechanical claw arms are respectively arranged on the working platform; the four mechanical claw arms comprise two groups of front claw arms and rear claw arms arranged oppositely; sponge strips are arranged in the middle of the rear claw arms; the sponge strips face to a paper wrapping station; compression springs are arranged at the connecting parts of the four mechanical claw arms and the working platform; push rods are mounted on a push platform; the push platform is connected with a lifting driving component; through holes through which the mechanical claw arms are turned downwards and the push rods penetrate are formed in outer sides of the four mechanical claw arms on the working platform; a paper pressing cylinder and a pressing block are arranged above the paper wrapping station; a paper pasting mechanism is arranged on a side above the paper wrapping station; the moving end of the paper pressing cylinder is connected with a paper belt plate; an upper paper coiling wheel is mounted on the rack; a paper pasting piece is mounted on a roller of the upper paper coiling wheel in a sleeving manner; and the paper pasting piece penetrates through the end part of the paper belt plate and penetrates through a lower paper coiling wheel. The paper wrapping and pasting device is automatic in operation, saved in time and labor and relatively high in working efficiency, and automatic paper wrapping of hamburgers can be achieved.

Owner:ZHEJIANG UNIV OF TECH

Quick and automatic chalk film-pasting robot assembly line

InactiveCN109204931ARealize automatic feedingImprove feeding efficiencyWrapping material feeding apparatusRod-shaped articlesAssembly lineEngineering

The invention discloses a quick and automatic chalk film-pasting robot assembly line. The quick and automatic chalk film-pasting robot assembly line comprises a rack, a chalk feeding mechanism, a chalk distributing mechanism, a sticker conveying mechanism and a compressing mechanism; and the sticker conveying mechanism is located between the chalk distributing mechanism and the compressing mechanism, and the compressing mechanism is close to the sticker conveying mechanism. Compared with the prior art, the quick and automatic chalk film-pasting robot assembly line is provided with a tooth-shaped cutting roller, thus tearing mark grooves which are formed at intervals are formed in a sticker, chalk is coated with the sticker with the formed tearing mark grooves, in this way, when a user usesthe chalk, the user can tears off the sticker circle by circle along the tearing mark grooves according to the using demands, the sticker is torn according to the needs, the hands are not polluted, the situation that the hands are stained with chalk dust for a long time is effectively eradicated, and the defect of poor health of the user is avoided; through the chalk coated with the sticker, thesituation that when the chalk is not used, the chalk dust falls off to affect the surrounding environment can be effectively prevented; and according to the quick and automatic chalk film-pasting robot assembly line, the automatic feeding and automatic film-coating processes are achieved, and the efficiency is higher.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Exquisite packaging wrapping mechanism of intelligent workshop carton production equipment

ActiveCN112918002AHigh degree of automationIncrease productivityPaper-makingBox making operationsEngineeringSurface processing

The invention relates to the field of carton surface processing mechanisms, in particular to an exquisite packaging wrapping mechanism of intelligent workshop carton production equipment. The exquisite packaging wrapping mechanism comprises a machine base and a mounting base arranged on the machine base, a mounting cavity is formed in the mounting base, a mounting plate is arranged in the mounting cavity, a lifting element is arranged in the mounting cavity, a fixing rod is arranged at the bottom end of the mounting plate, a pressing block is arranged at the bottom end of the fixing rod, a forming block is arranged at the bottom end of the mounting plate, the fixing rod penetrates through the forming block, the pressing block is arranged on the bottom surface of the forming block, a containing groove is formed in the bottom surface of the forming block, an adjusting assembly is arranged on the mounting plate, a containing cavity is formed in the machine base, a tray is arranged in the containing cavity, a supporting rod is arranged on the bottom surface of the tray, a driving part is arranged at the bottom end of the supporting rod, the containing cavity is internally provided with a first forming device, the first forming device is arranged in the containing cavity, and a second forming device is arranged below the first forming device and is arranged in the containing cavity. The exquisite packaging wrapping mechanism has the beneficial effect of being capable of improving the carton production efficiency.

Owner:昆山科望快速印务有限公司

Postoperative wound dressing device and method convenient for applying medicine

InactiveCN114587860AEasy to take medicineEasy to operateMedical devicesMedical applicatorsOperative woundWound dressing

The invention discloses a postoperative wound bandaging device and method convenient for applying medicine, belongs to the technical field of orthopedics, and aims to solve the problems that wound bandaging can be completed only by assisting bandaging by other people, the whole bandaging can be completed only by pressing gauze, wrapping, cutting and other steps, the operation is very troublesome, and the cost is high. The device comprises a binding box and a box cover movably installed at the upper end of the binding box, a medicine feeding box slidably penetrates through the middle of the box cover, a rubberizing assembly is fixedly installed on the outer wall of one end of one side of the binding box, a driving motor is fixedly embedded in the outer wall of the middle of one side of the binding box, and a driving rotary disc is arranged in an inner cavity of one side of the binding box; a wrapping assembly is slidably arranged on the outer wall of one side of the driving rotary disc, and a cutting assembly is arranged on the inner wall of the inner cavity of the other side of the binding box, the device can be driven by one driving motor to achieve automatic wrapping and automatic cutting operation after wrapping for a certain number of turns, and a patient can conduct wound binding operation by himself / herself.

Owner:郑州市骨科医院

Lead wrapping machine

The invention discloses a lead sheet wrapping machine, and belongs to the field of machinery. The lead sheet wrapping machine aims to solve the problems that lead sheet strips are usually packaged bymanual winding at present, production efficiency is low and labor intensity of workers is high. The lead sheet wrapping machine includes reels, a support frame, a lead sheet conveying unit for conveying lead sheets, a reel conveying unit for conveying reels, a wrapping unit, a visual positioning unit and a control system. The lead sheet conveying unit and the wrapping unit are correspondingly disposed on the support frame, and the reel conveying unit is disposed above the wrapping unit. The reels each include a central shaft and two end plates, the central shafts are provided with positioninggrooves, and the end plates are arranged at both ends of the central shafts. The lead sheet wrapping machine can realize automatic wrapping of the lead sheets on a lead weight, greatly improves the production efficiency, and effectively reduces the production cost. The lead sheet wrapping machine is ingenious in concept and reasonable in design, can greatly improve the efficiency of lead sheet wrapping, and has higher application value and wider application prospects.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A wrapping device for fishing nets

ActiveCN105923435BRealize automatic wrappingImprove wrapping efficiencyWebs handlingRotary stageMaterial resources

The invention discloses a fishing net winding device. The fishing net winding device comprises a support table; a rotating table is mounted at the left part of the support table; a worm wheel is fixed at the upper end of the rotating table; a chute 1 is formed in the right part of the support table; chutes 2 are uniformly formed in the upper end of the worm wheel; slide blocks are respectively mounted in the chutes 2; springs are respectively mounted on the slide blocks; positioning columns are respectively mounted at the upper ends of the slide blocks; a connecting shaft is mounted at the front part of the support table; a worm rod sleeve is mounted at the left end of the connecting shaft; a belt wheel 1 is mounted at the right end of the connecting shaft; and an adjustable driving device is mounted at the right part of the support table. The fishing net winding device has such advantages as reasonable structure design and convenience for use, realizes automatic fishing net winding, replaces manual winding, improves the fishing net winding efficiency, saves the manpower and material resources, uses the adjustable driving device for realizing adjustment of the fishing net winding speed, and guarantees the finishing net winding quality.

Owner:安徽省安国渔具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com