Material coil coating device

A technology of wrapping device and material roll, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problem of time-consuming and laborious, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

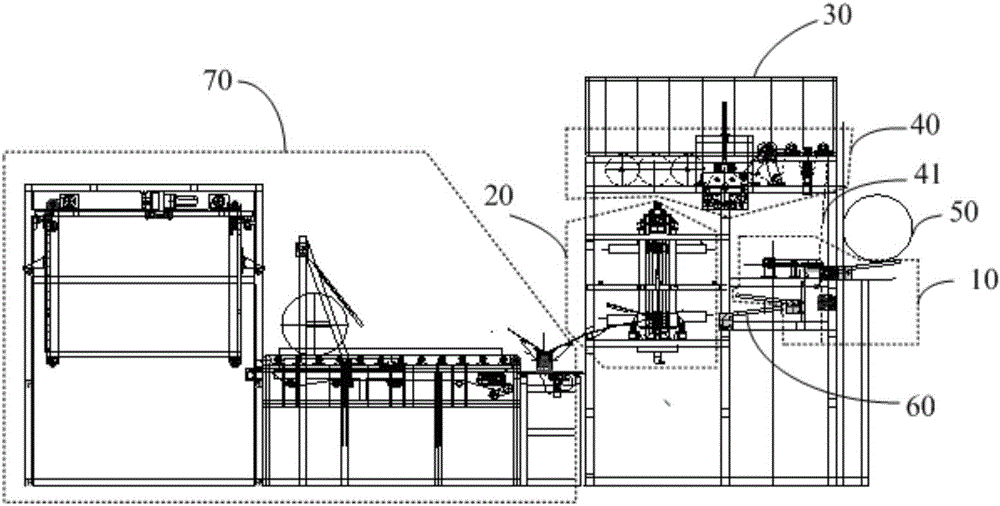

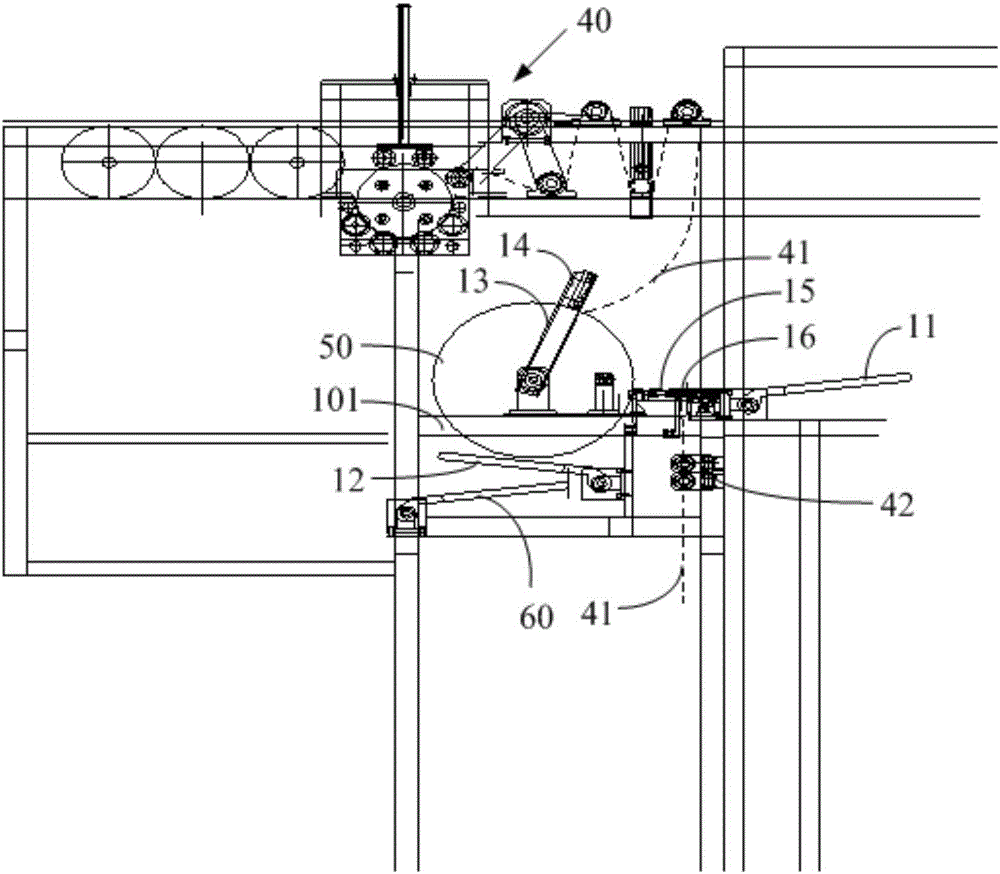

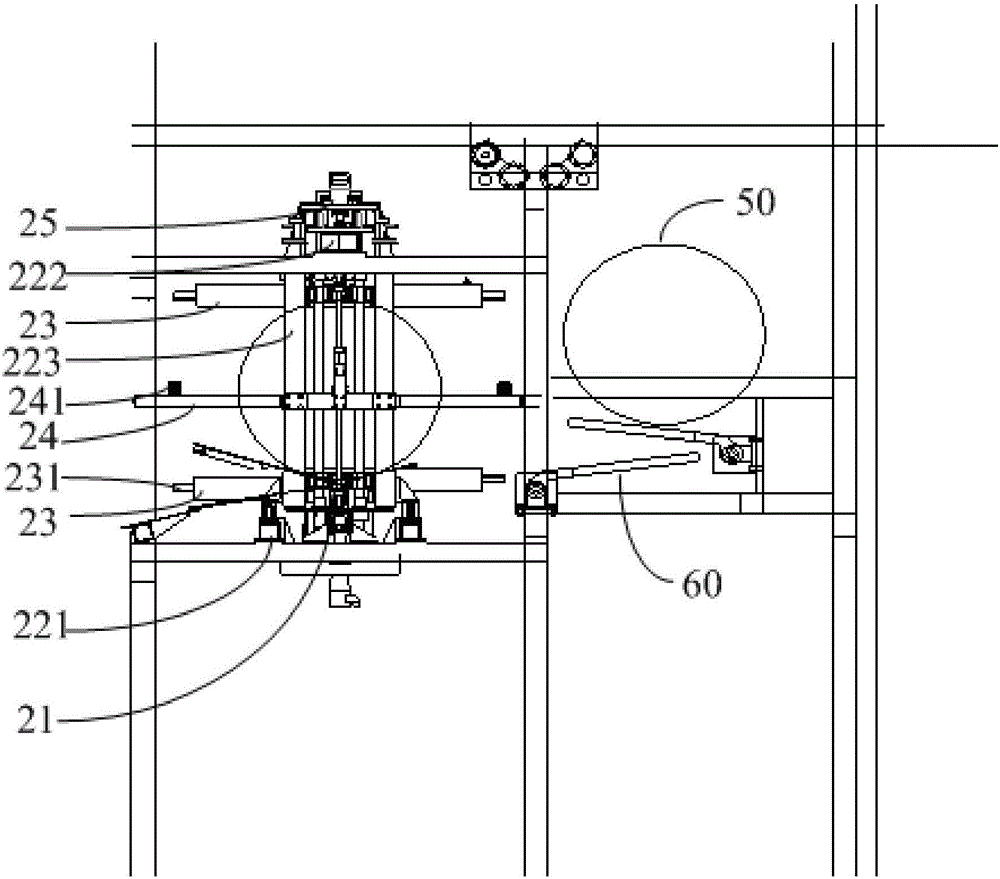

[0067] Figure 4 It is a structural schematic diagram of the framing unit in the roll 50 coating device of the present invention. On the basis of the above-mentioned embodiments, in this embodiment, as figure 1 and Figure 4 As shown, since the material roll 50 covered with the packaging film 41 needs to be framed after the wrapping of the material roll 50 is completed, in the prior art, the operator manually performs the frame mounting, but manual frame mounting is time-consuming. It is laborious again, so in the present embodiment, the coil 50 wrapping device also includes:

[0068] The framing unit 70 is arranged on the side of the V-shaped lifting platform 21 away from the conveying unit 60 , and the framing unit 70 is used for framing the wrapped coil 50 on the V-shaped lifting platform 21 .

[0069] Specifically, such as Figure 4 As shown, the framing unit 70 includes: a V-shaped manipulator 71, a transmission mechanism 72 and an iron frame lifting mechanism 73, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com