Wrapping and sticking device of automatic hamburger packaging machine

A hamburger, fully automatic technology, applied in the direction of packaging paper support device, packaging paper bending device, packaging bakery, etc., can solve the problems of low work efficiency, manual operation, time-consuming and labor-intensive, etc., to achieve a complete and smooth process, complete process, The effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

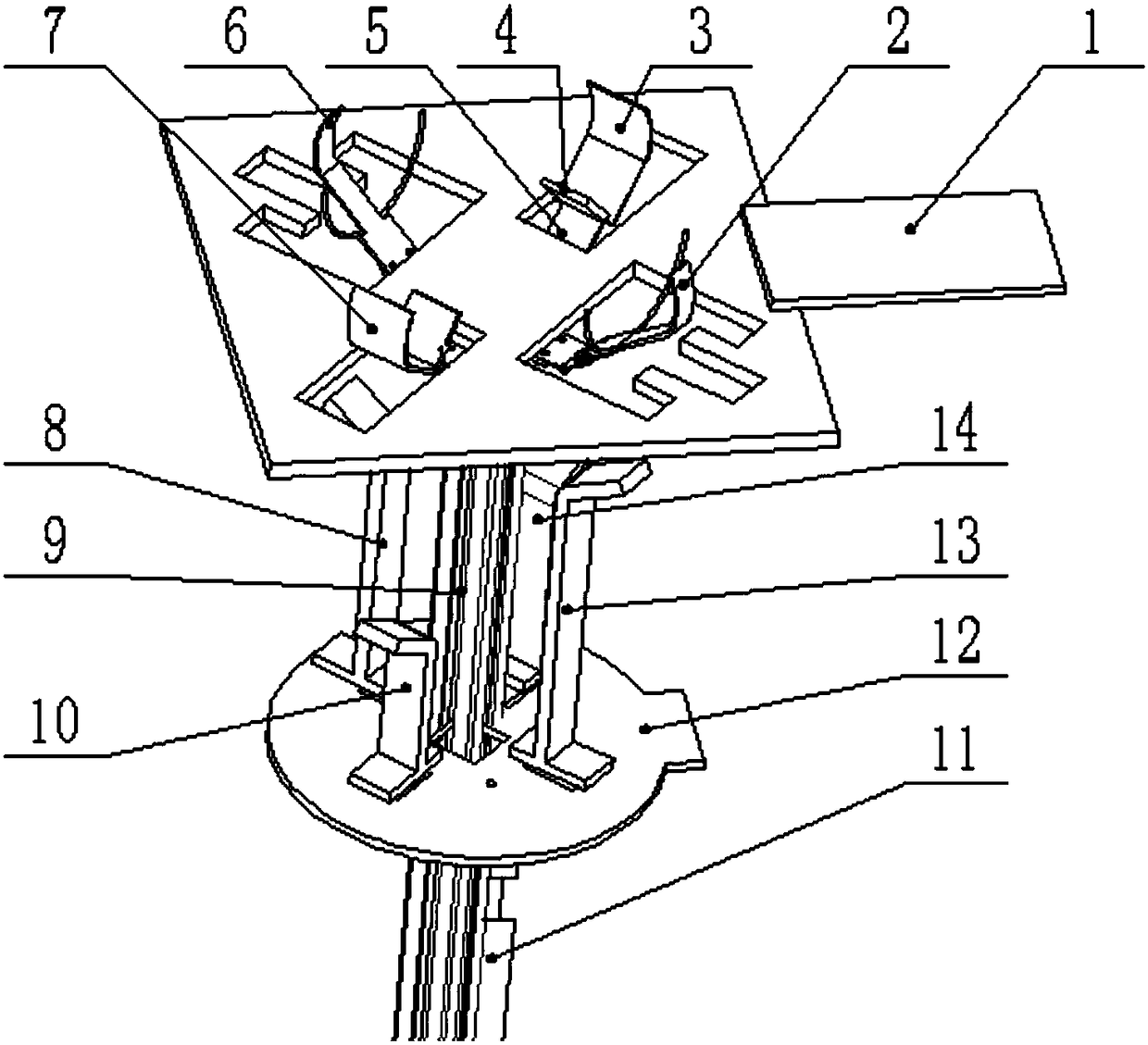

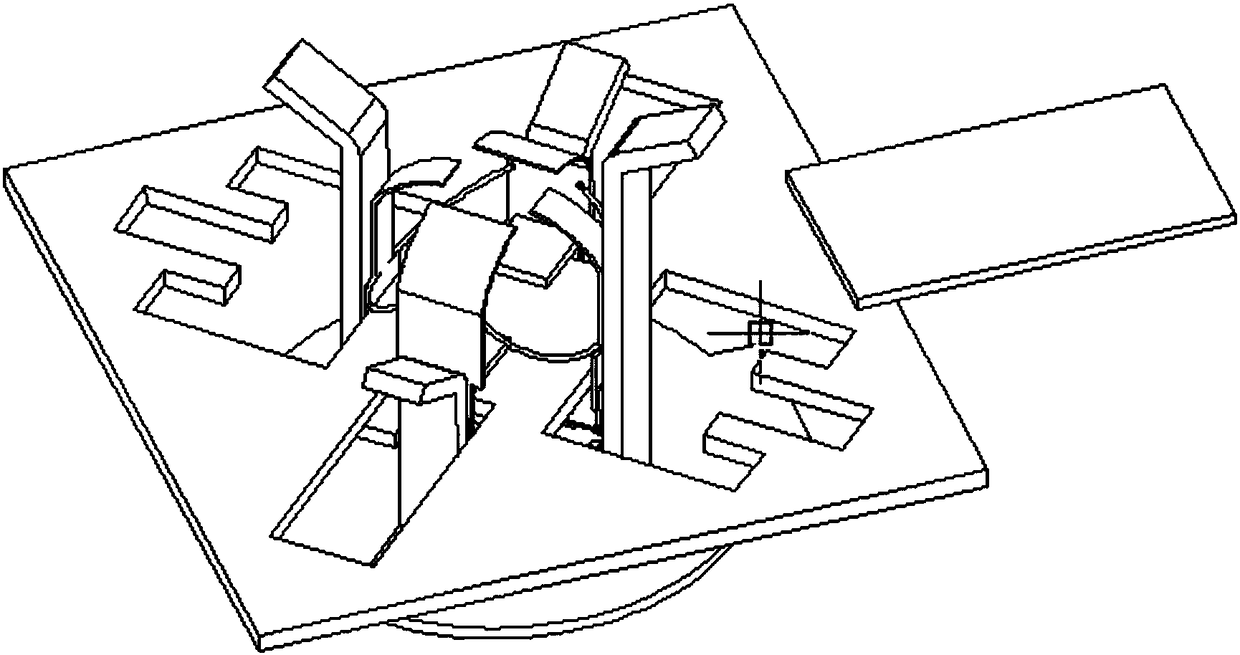

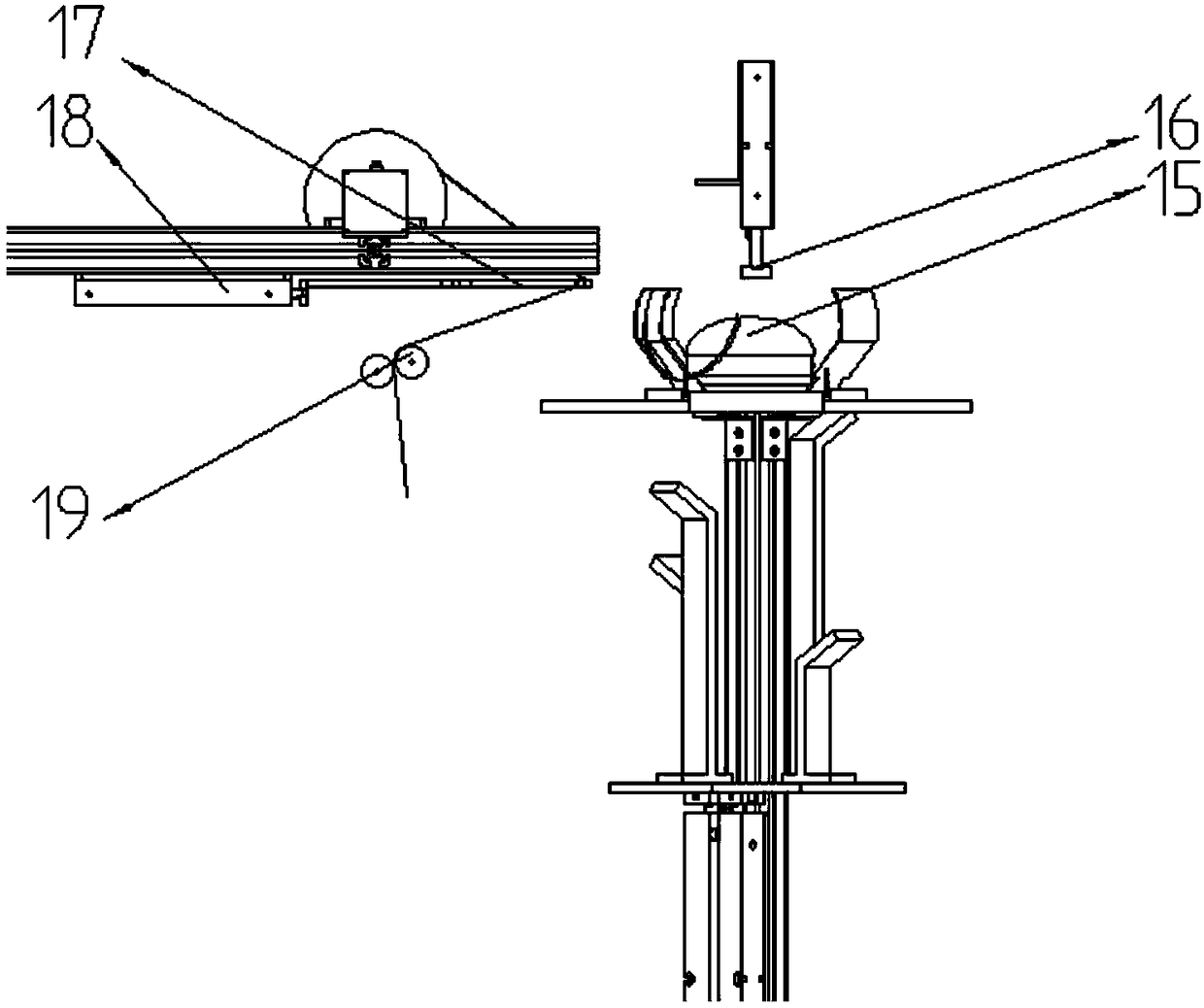

[0019] refer to Figure 1 to Figure 5 , a paper wrapping and sticking device of a fully automatic hamburger packaging machine, comprising a frame, a working platform 1 is arranged on the frame 9, and four mechanical claw arms are respectively arranged on the working platform 1, and the four mechanical claw arms include Two groups of front claw arms 2, 6 and rear claw arms 3, 7 are arranged oppositely. The space surrounded by the inside of the four mechanical claw arms is a wrapping station for placing hamburgers to be wrapped. The middle part is provided with a sponge strip 4, the sponge strip 4 faces the paper wrapping station, and the connection between the four mechanical claw arms and the working platform is provided for driving the mechanical claw arms to expand outwards and is located under the working platform. The compression spring 5 is used to push the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com