Equipment production line for rubber plasticizing processing and production technique thereof

A technology of production line and rubber material, which is applied in the equipment production line of rubber material plasticization processing and its production technology field, can solve the problems of low automation, unstable quality, high product cost, etc., achieve high automation, reduce manpower and material resources, and produce high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

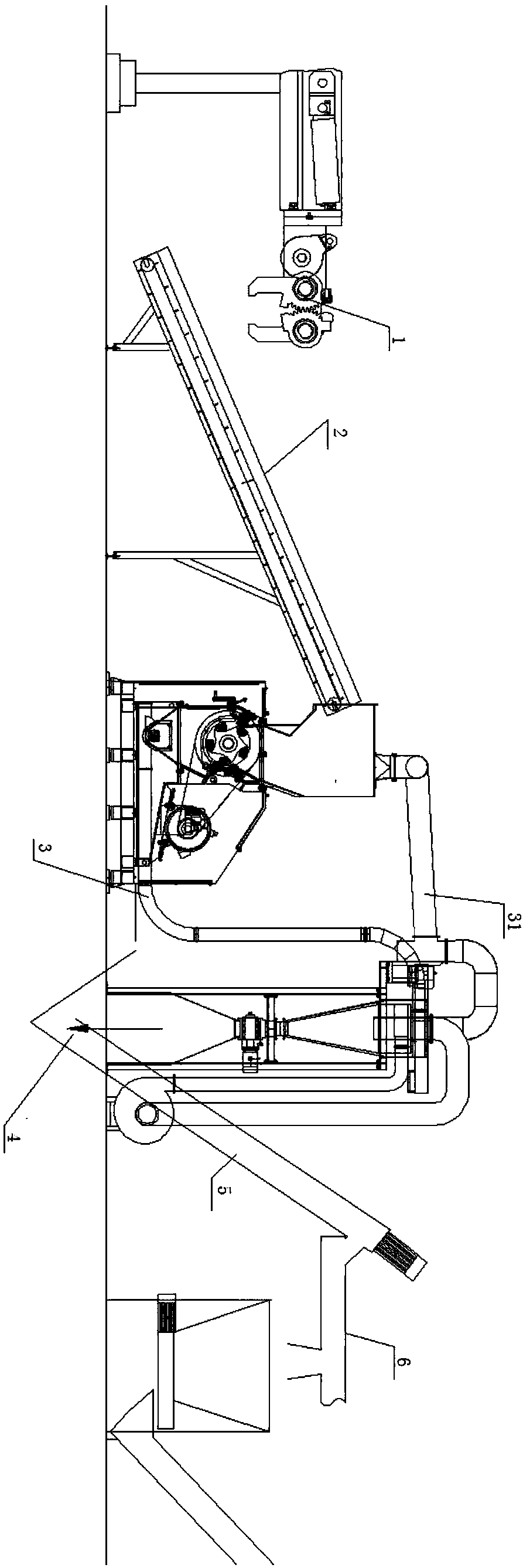

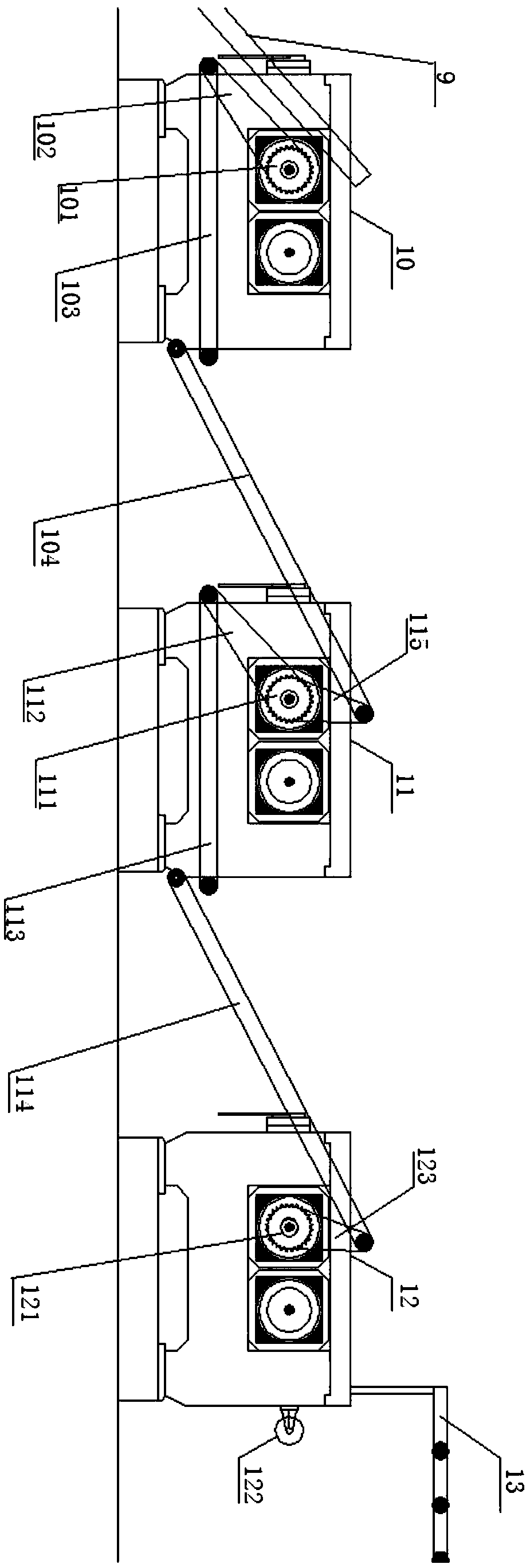

[0034] An equipment production line for rubber plasticizing processing, including a feeding stage, a plasticizing stage, a rubber mixing stage, a refining stage, and a post-processing stage.

[0035] The feed stage as described figure 1 As shown, it includes a manipulator 1, a conveyor belt 2, a raw material processing device 3, an underground feeding hopper 4, an inclined auger conveyor 5 and a horizontal auger feeder 6. The manipulator 1 places the rubber material on the conveyor belt 2, passes the rubber material to be processed into the raw material processing device 3 for processing through the conveyor belt 2, and sends the processed rubber material to the underground feeding hopper 4 , and then transported to the plasticizing stage through the inclined auger conveyor 5 and the horizontal auger feeder 6 in turn.

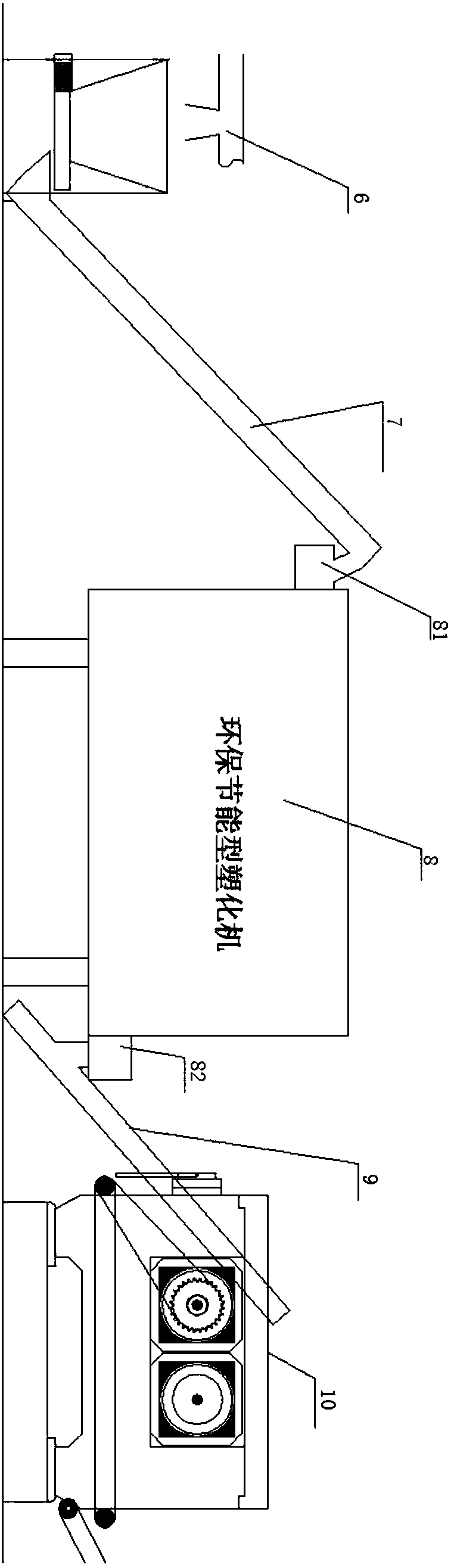

[0036] The plasticizing stage as described figure 2 As shown, it includes an environment-friendly and energy-saving plasticizing machine 8, and the rubber m...

Embodiment 2

[0040] Embodiment 2 is the same as Embodiment 1, and on the basis of Embodiment 1, the following technical means are added: the upper end of the raw material processing device 3 is provided with an exhaust pipe 31, and the treated waste gas is sucked away through the exhaust pipe 31.

Embodiment 3

[0041] Embodiment 3 is the same as Embodiment 1, and on the basis of Embodiment 1, the following technical means are added: There are four horizontal auger feeding machines 6, which are connected side by side to convey rubber materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com