A percolation tube coating device

A technology of covering devices and percolation pipes, applied in the field of pipelines, can solve the problems of high labor intensity, complicated construction procedures, and low construction efficiency, and achieve the effects of simplifying construction procedures, reducing labor intensity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

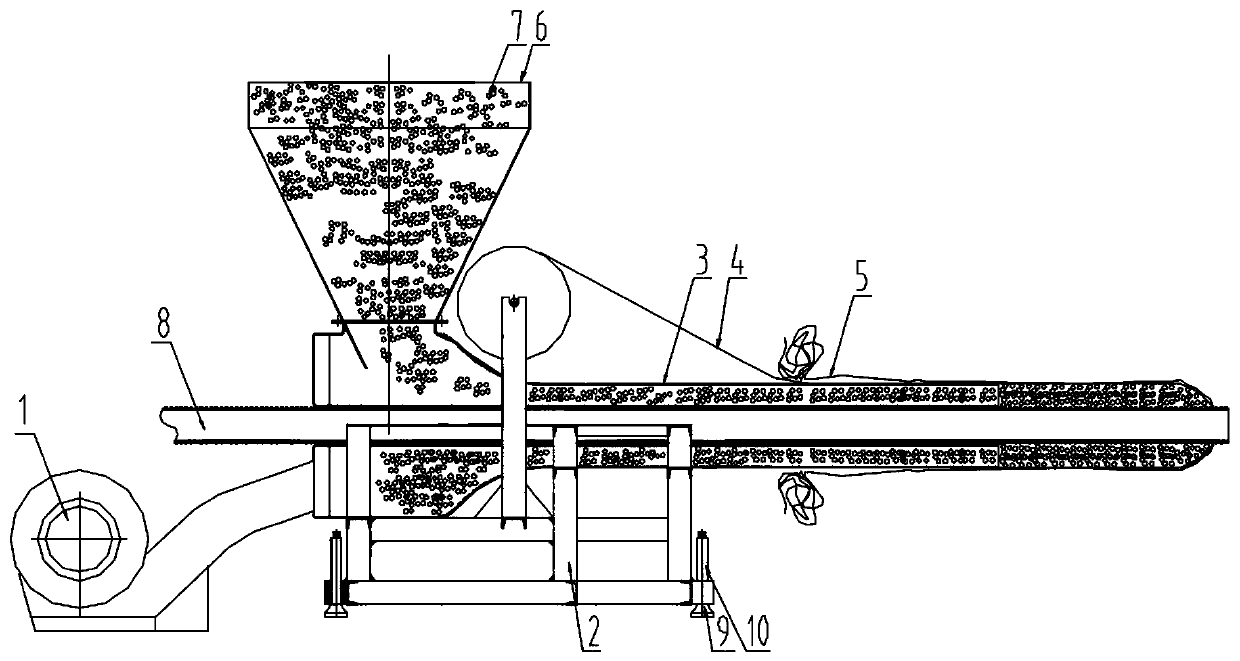

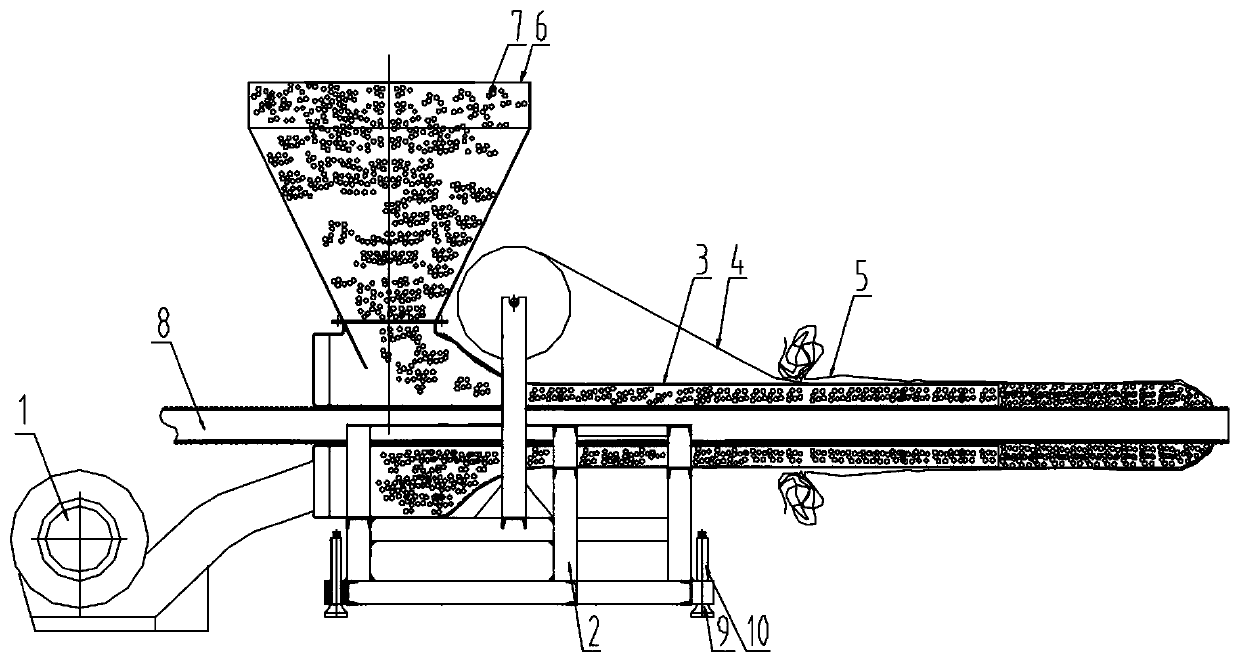

[0016] A percolation tube coating device, comprising a blower 1, a frame 2, a jacketed material tube 3, a geotextile 4, a net cover 5, and a hopper 6 for holding plastic foam 7. The frame 2 is provided with The lifting adjusting member 9 is a threaded lifting member known in the prior art. The jacketed material tube 3 is fixed on the frame 2. The jacketed material tube 3 includes an inner tube and an outer tube fixedly sleeved on the inner tube. The inner diameter of the inner tube is equal to that of the percolation tube body 8. The outer diameter is adapted to form an inner channel through which the percolation tube body 8 passes, and an outer channel for plastic foam 7 to pass is formed between the inner tube and the outer tube; the air outlet of the blower 1 is fixedly connected to the outside The lower part of the feed end of the channel is used to blow the plastic foam 7 toward the discharge end, the hopper 6 is fixedly connected to the upper part of the feed end of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com