External anti-corrosion method for oil and water well pipelines

A technology for oil-water wells and pipelines, which is applied in the field of automatic anti-corrosion work. It can solve problems such as safety, hidden dangers in quality, decline in anti-corrosion quality, and unsteady speed of manual pipe transfer, so as to avoid the danger of mechanical damage, uniform and stable lap width, and efficient Conducive to the effect of labor protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

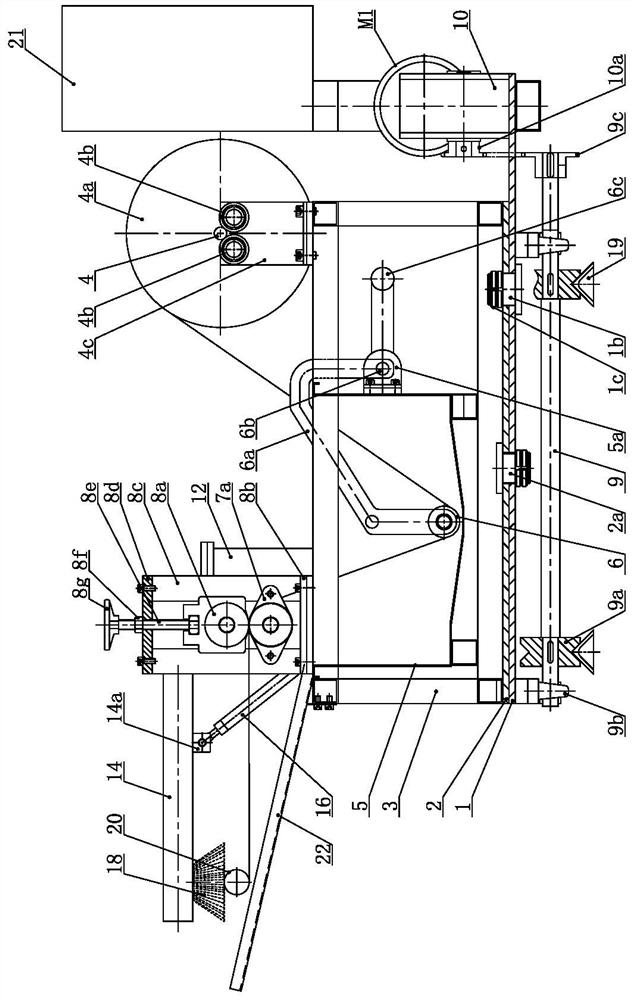

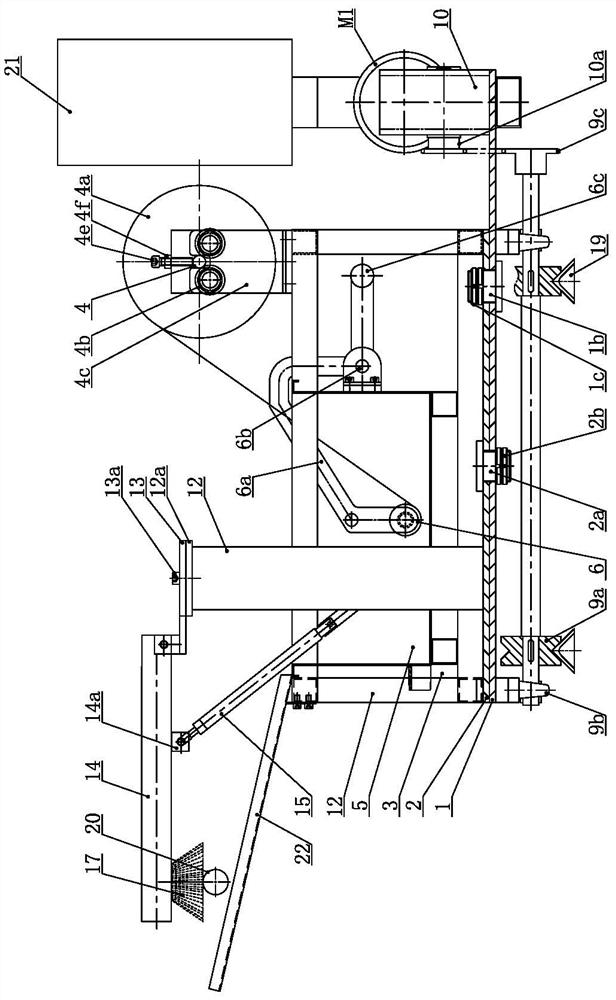

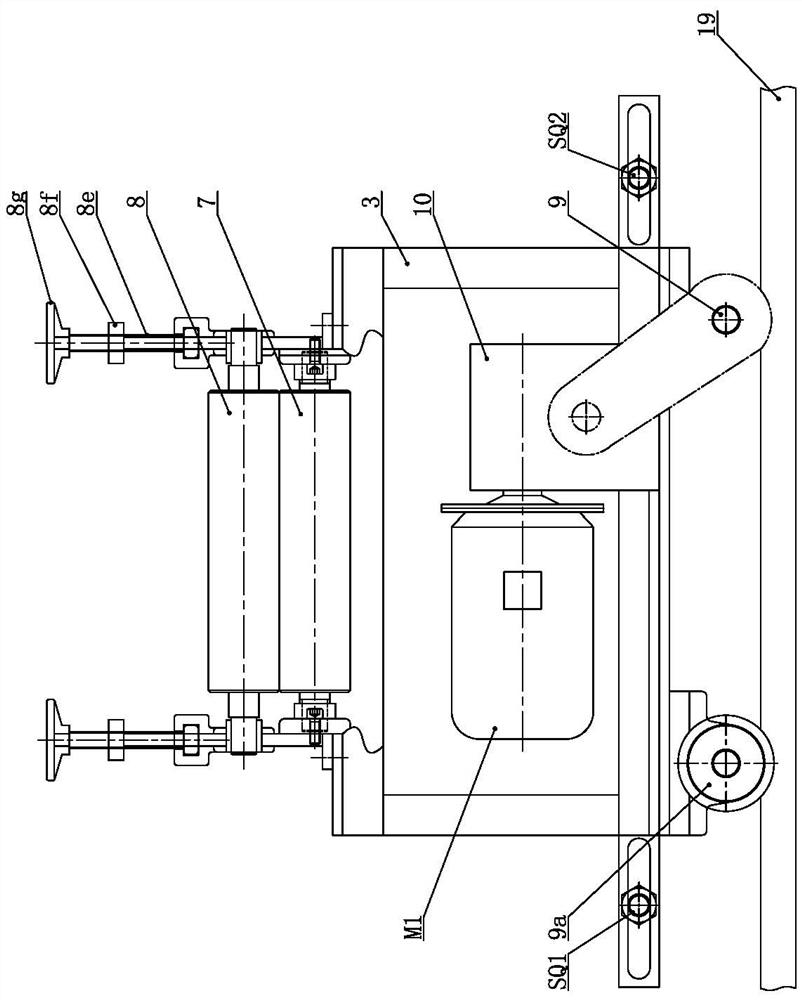

[0030]The external anti-corrosion method of the oil-water well pipeline of the present invention comprises the following steps in turn: (1) fixing two mutually parallel X-guiding rails 19 on the ground at the rear side of the pipeline driving support; (2) installing special anti-corrosion equipment on the X-guiding rails 19; (3) installing The two ends of the oil-water well pipeline rest on the pipeline driving bracket, and the axis of the oil-water well pipeline is parallel to the X guide rail 19; Translate to the other end along the X guide rail 19, and at the same time, the pipeline drives the bracket to drive the oil-water well pipeline to continuously rotate, and the rust-removing grinding head rotates at a high speed to derust the oil-water well pipeline until it reaches the other end of the oil-water well pipeline; (5) Rust-removing grinding head, dedicated Both the anti-corrosion equipment and the pipe driving support are stopped, and then the derusting grinding head is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com