Fishing net winding device

A wrapping and fishing net technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of not being able to meet the production scale, and achieve the effects of reasonable structural design, convenient use, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

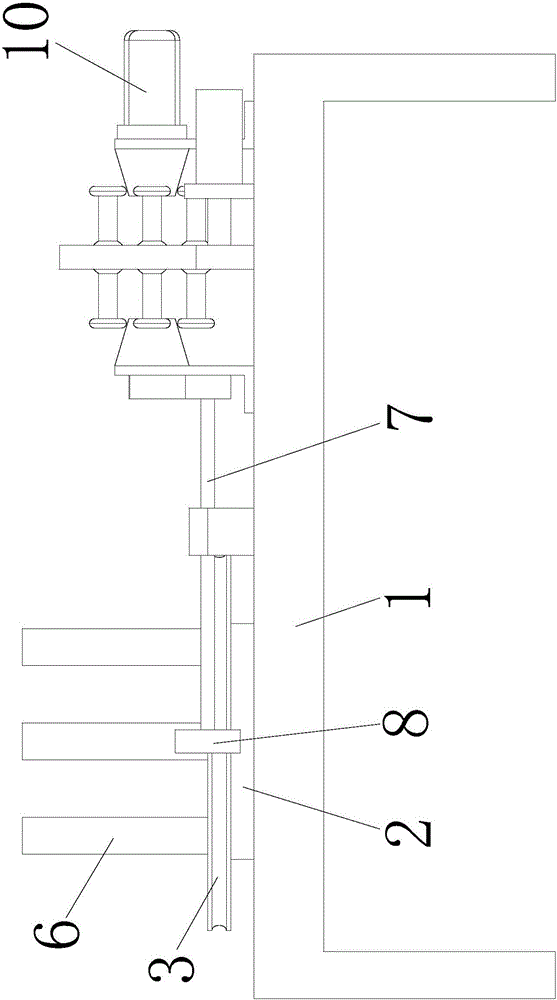

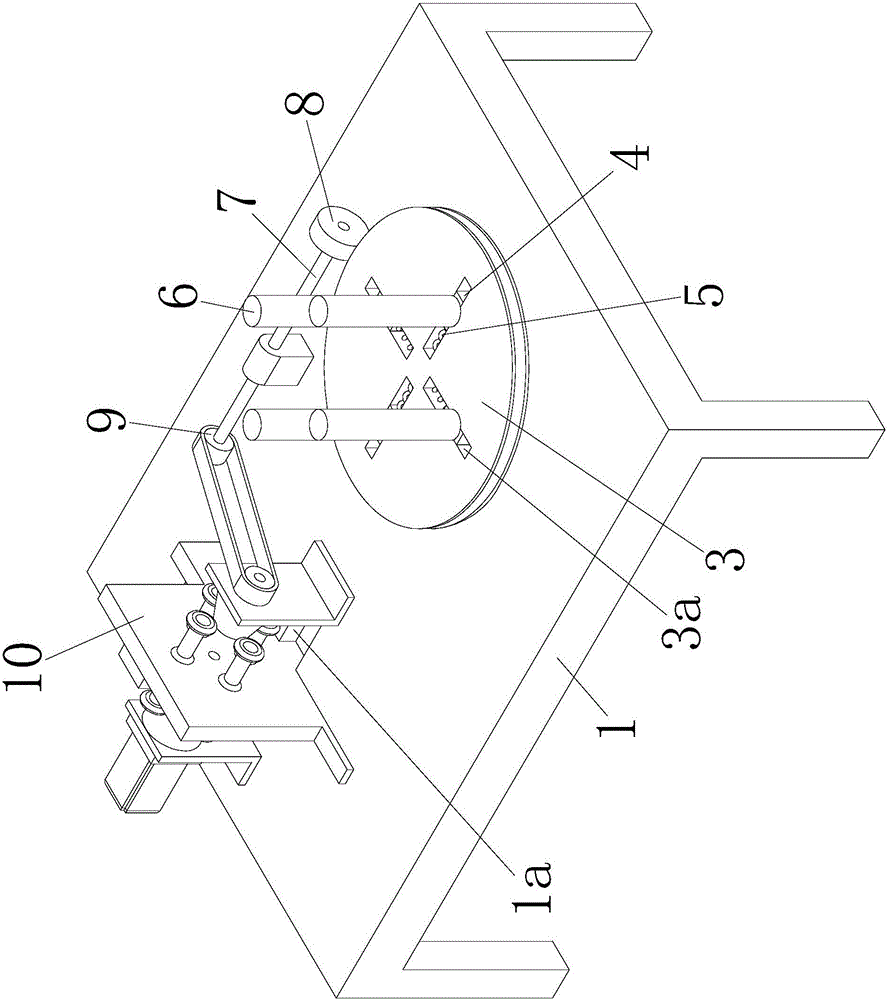

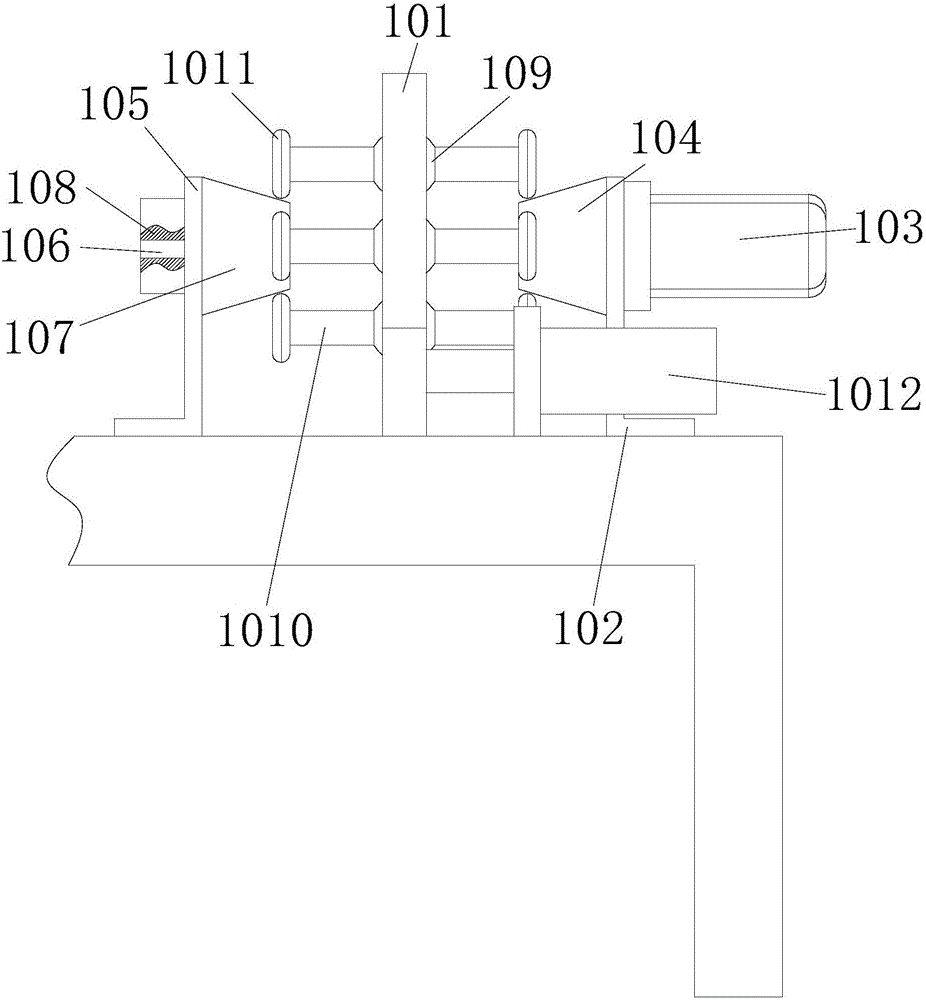

[0018] Such as Figure 1 to Figure 4 As shown, a wrapping device for fishing nets includes a supporting platform 1, a rotating platform 2 is installed on the left part of the supporting platform 1, a worm wheel 3 is fixed on the upper end of the rotating platform 2, and a right part of the supporting platform 1 No. 1 sliding groove 1a is provided, and No. 2 sliding groove 3a is evenly provided with the upper end of described worm wheel 3, and slider 4 is all installed in described No. 2 sliding groove 3a, and spring 5 is all installed on described slider 4, so The springs 5 are all installed in the No. 2 slide groove 3a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com