Full-automatic film winding mechanism and using method thereof

A wrapping film, fully automatic technology, used in packaging/bundling items, packaging, wrapping items, etc., can solve the problems of wasted labor, low work efficiency, increased costs, etc., to reduce production costs, reduce labor, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

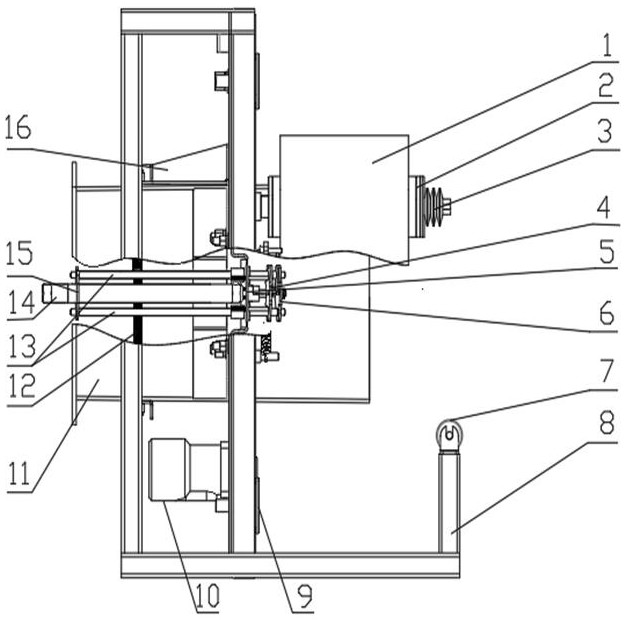

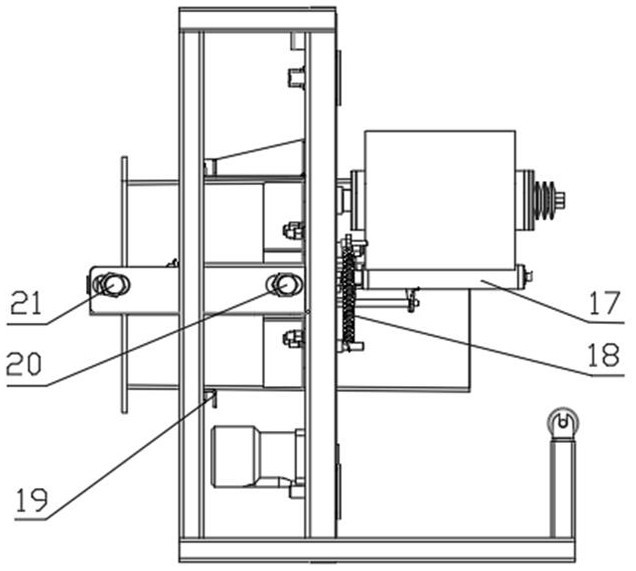

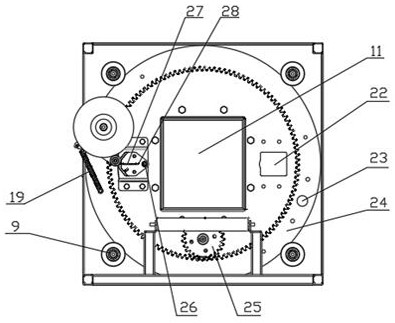

[0023] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0024] A fully automatic stretching film mechanism, comprising a frame 8, a film puller fixed bottom plate 5, a hydraulic motor 10, a discharge bell mouth 11, a fastening screw 12, an upper fixed rib plate 16, a lower fixed rib plate 19, and a gear ring 24 , spur gear 25, stretching film device and film puller, hydraulic motor 10 and ring gear 24 are set on the frame, and spur gear 25 is set on hydraulic motor 10, and described spur gear 25 is meshed with the inner side of ring gear 24; The mouth 11 passes through the ring gear, and is fixed on the frame 8 through the upper fixed rib plate 16, the lower fixed rib plate 19 and the fastening screw 12. The ring gear is concentric with the discharge bell mouth, and the compacted straw Push out from the discharge bell mouth; the gear ring 24 is provided with a stretch film device mounting hole 23, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com