A seat frame barrier cotton automatic covering device

A technology of covering device and barrier cotton, which is applied in the field of furniture, can solve the problems of unsuitable mass production, unguaranteed quality, and low output, and achieve the effects of automatic wrapping, guaranteed wrapping quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] It should be noted that, in the reference orientation involved in this embodiment, "up and down" refers to the longitudinal direction; "bottom" of the "periphery of the bottom of the seat frame" refers to the lower surface of the seat frame when the user rides the seat, not the seating surface.

Embodiment

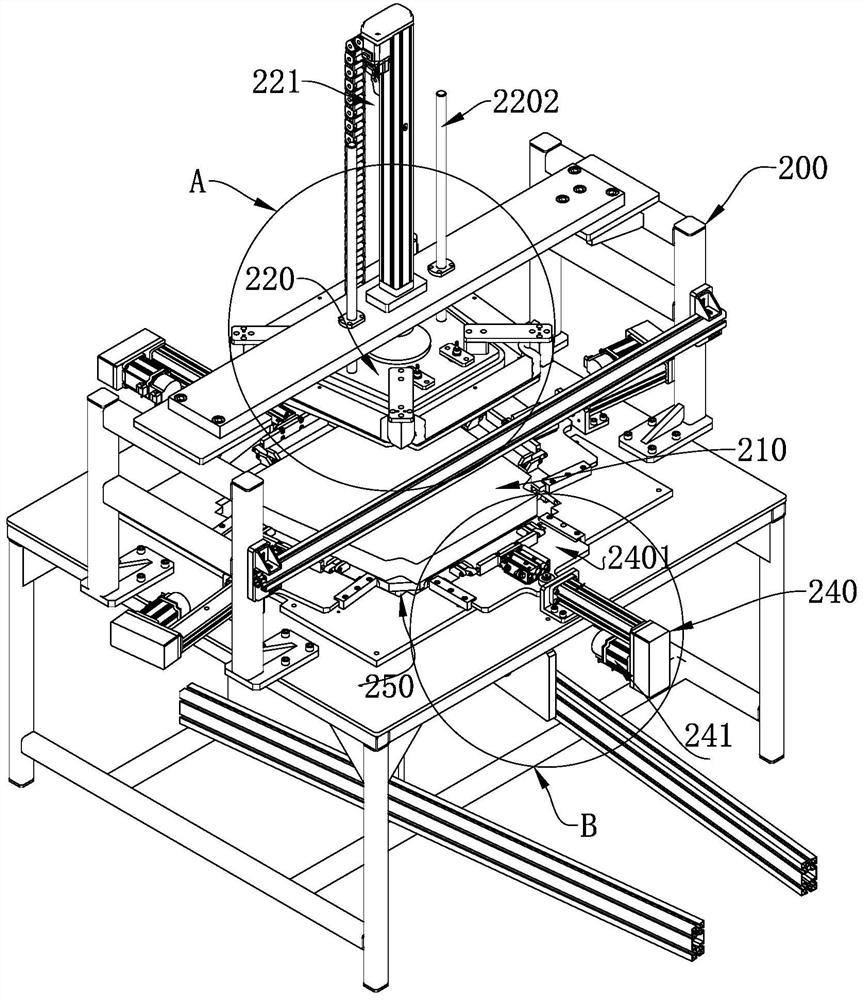

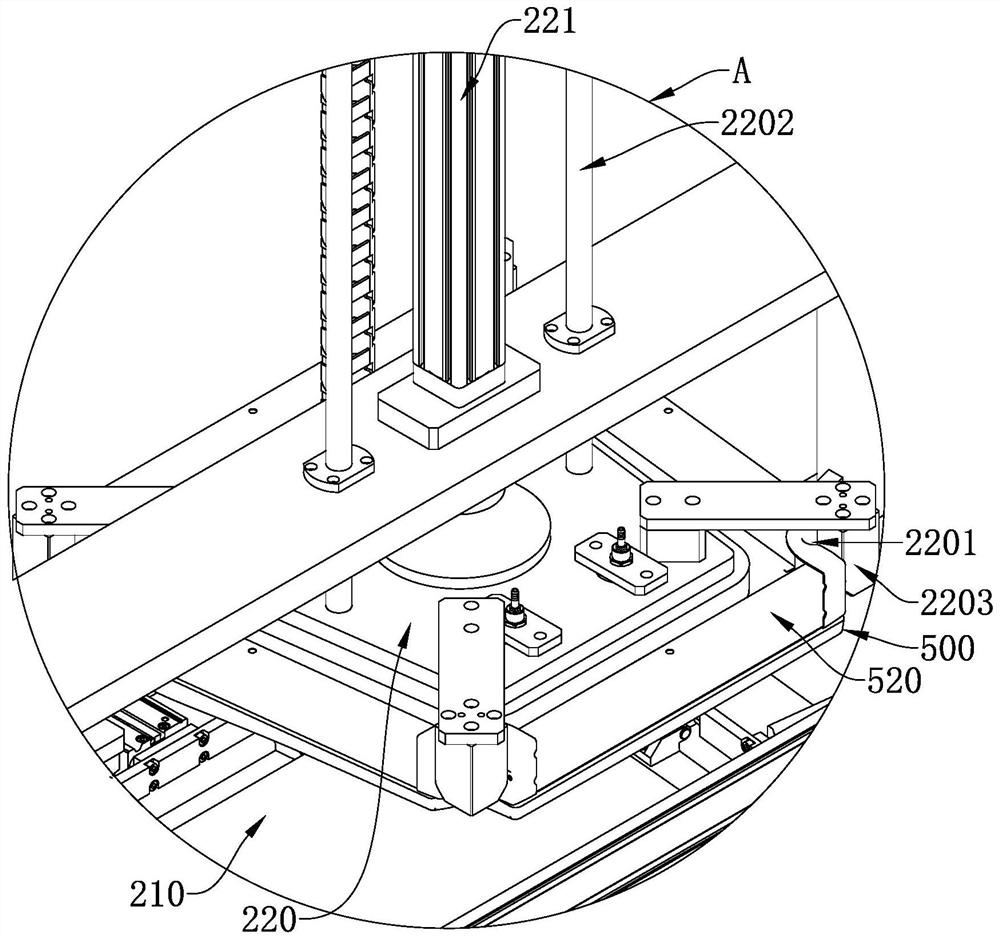

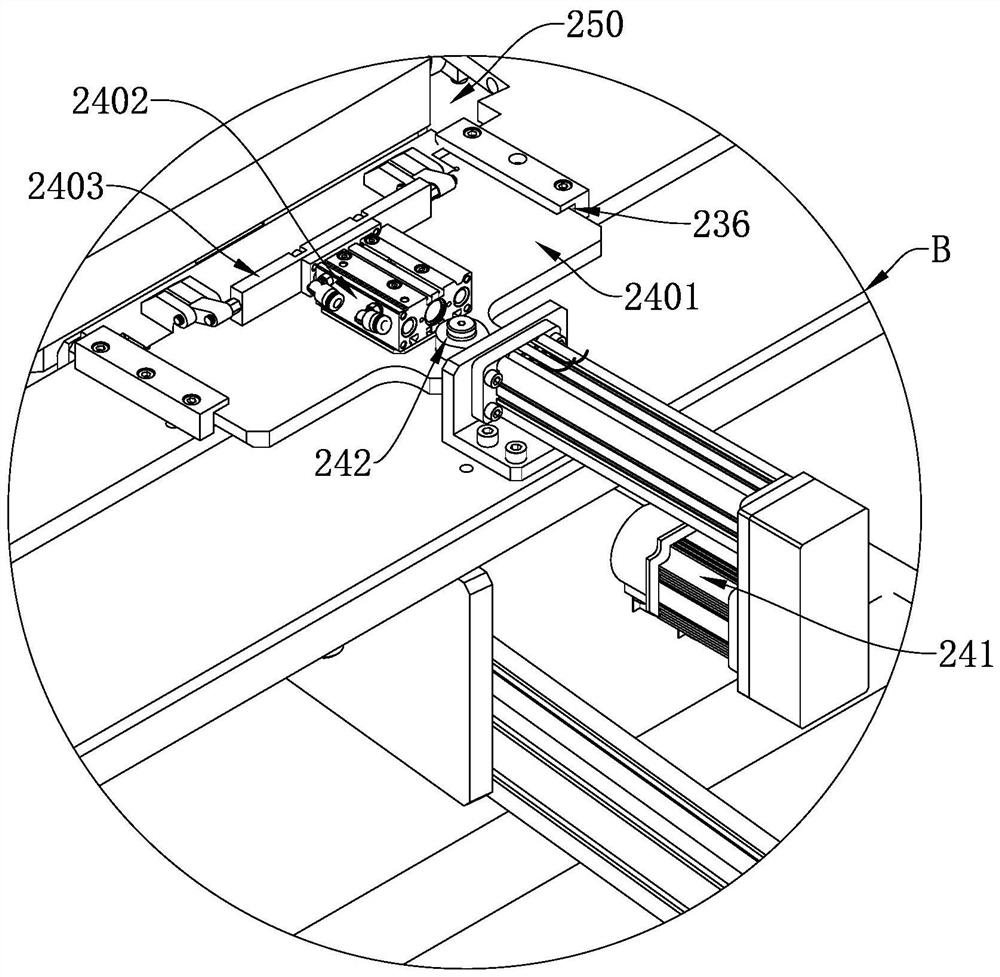

[0061] A seat frame barrier cotton automatic wrapping device, such as Figure 1-9 As shown, it includes a wrapping base 200. The wrapping base 200 includes an upper base 201 and a lower base 202 that are connected up and down, and an escape opening 250 is opened on the lower base 202; The base 202 is connected with a floating mechanism, a side positioning mechanism and a wrapping mechanism.

[0062] Specifically, the floating mechanism includes a floating table 210 around which a blocking cotton gripper (not shown) for positioning the blocking cotton 400 is provided, and a floating assembly connected with the floating table 210 for realizing the up and down displacement of the floating table 210; Specifically, the upper surface of the floating table 210 is matched with the top surface of the seat frame, and the upper surface of the floating table 210 is in a certain arc-shaped concave shape, so that the floating table 210 has the function of positioning the seat frame 500, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com