Surface wrapping machine for puffed foods

A puffed food and wrapping technology, which is applied in the field of food processing, can solve the problems of low wrapping efficiency, uneven wrapping on the food surface, affecting the taste of puffed food, etc., and achieve the effect of improving wrapping efficiency and wrapping evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The food wrapping machine of the present invention can be applied to the surface wrapping of puffed food, candy, stick rolls and other foods, and adopts an automatic multi-level wrapping method, so that the wrapping on the surface of the food is more uniform, and there is no missing wrapping area. In the embodiment, the method of wrapping stick food is described, but the present invention is not limited to stick food, and can also be adapted to geometric shapes such as spherical or irregular shapes.

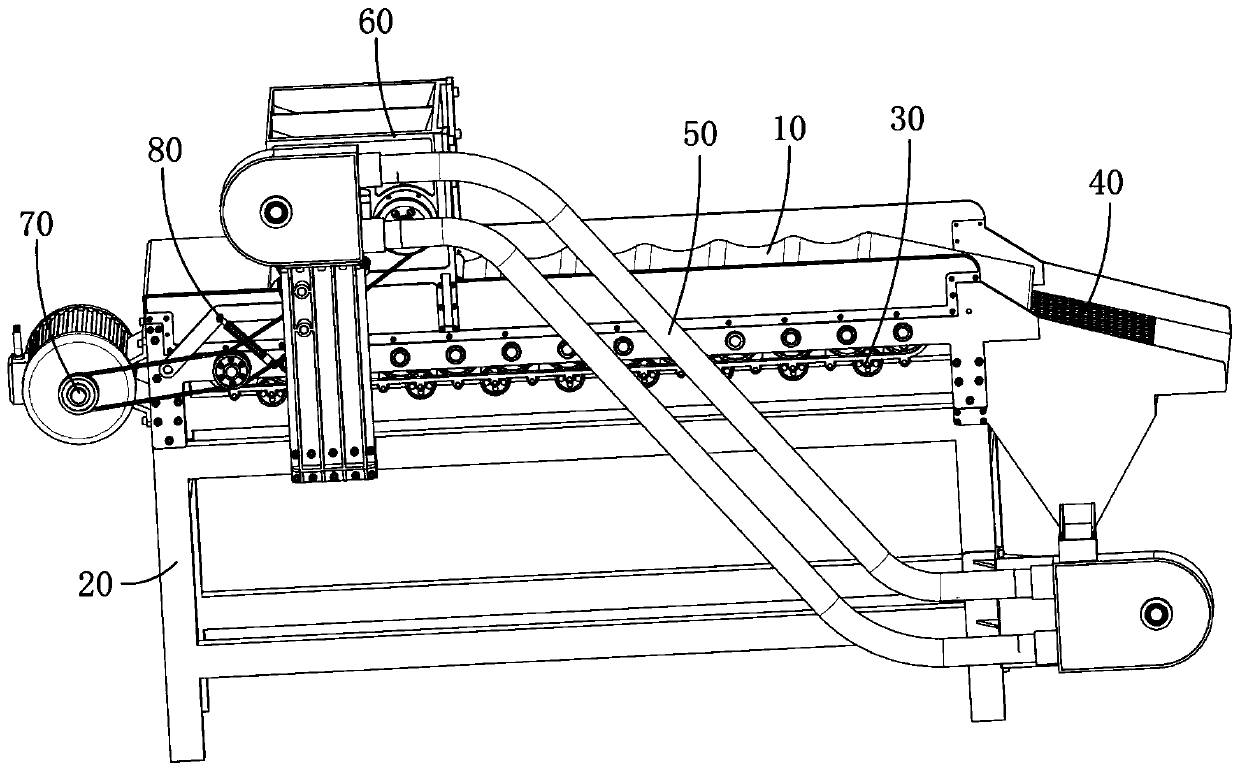

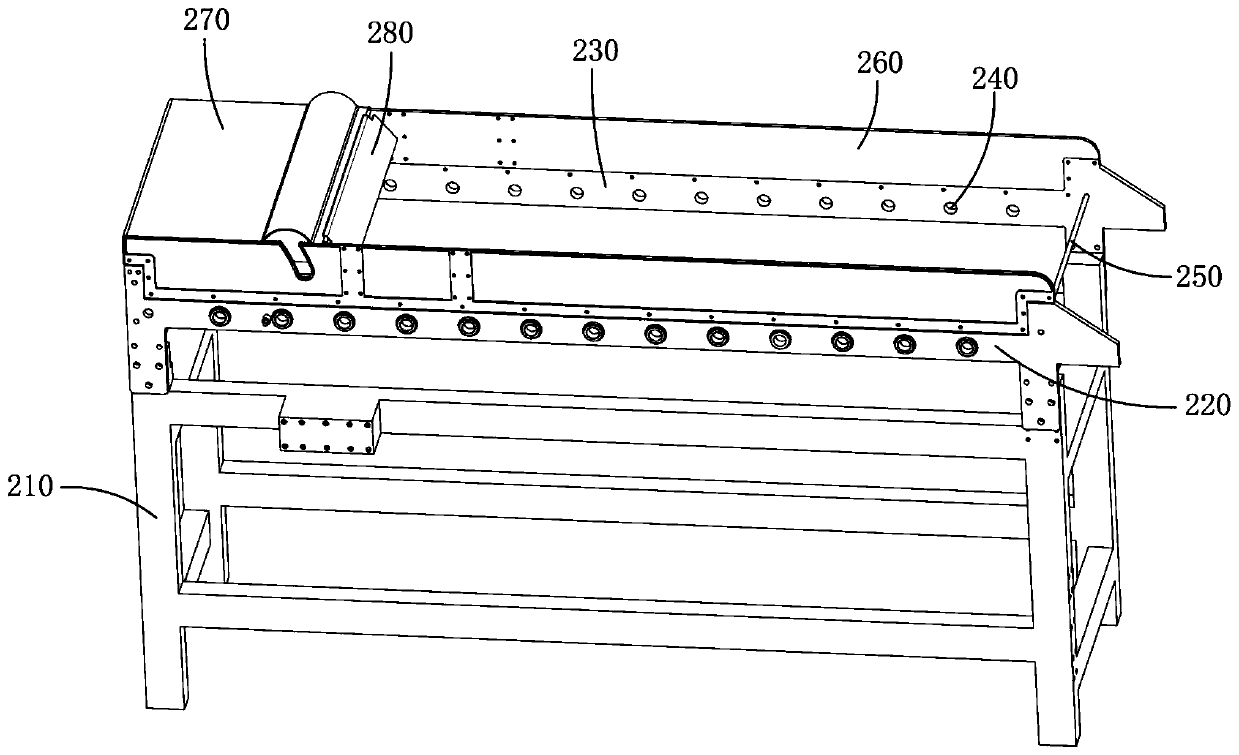

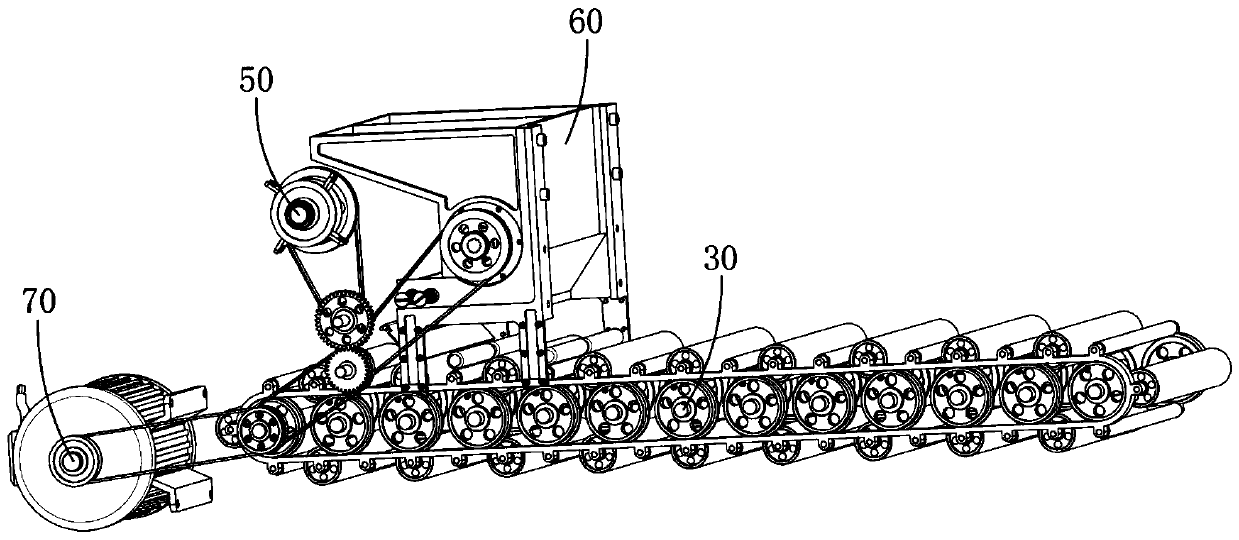

[0055] Such as Figure 1-25 As shown, the surface wrapping machine for puffed food includes a mounting frame 20, a conveyor belt 10, a transmission conveyor mechanism 30 for transmitting power to the conveyor belt 10, and a power supply mechanism 70 for providing power to the transmission conveyor mechanism 30. , the conveyor belt 10, the transmission conveyor mechanism 30, and the power supply mechanism 70 are installed on the mounting frame 20, the conveyor belt 10 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com