Automatic yarn package device and automatic yarn package process for mucilage glue yarn cake with long yarns

A silk cake and automatic technology, which is applied in the field of silk cake wrapping, can solve the problems of great influence on the quality and work efficiency of silk wrapping workers, low degree of automation and high labor cost, so as to reduce the labor intensity of workers and reduce The effect of labor cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

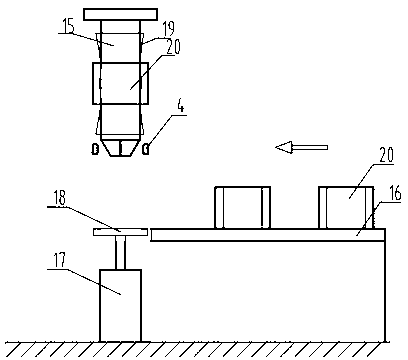

[0049] An automatic wrapping device suitable for viscose filament cakes, comprising a silk cake transfer device 16 and a silk cake lifting device 17, the silk cake lifting device includes a push plate 18 that moves up and down, and also includes a bagging device and Packaging device 19, the silk cake lifting device 17 is arranged at one end of the silk cake conveying device 16, the packaging device is arranged above the push plate 18, and the bagging device is arranged between the push plate 18 and the packaging device 19 .

[0050] In the present invention, a silk cake 20 and a packaging bag 15 are also included, the silk cake 20 is transported to the silk cake lifting device 17 through the silk cake conveying device 16, and the packaging bag 15 is set on the packaging device 19 through a bagging device; The silk cake 20 is pushed onto the packaging device 19 with the packaging bag through the push plate 18 .

[0051] In the present invention, the packaging device 19 include...

Embodiment 2

[0061] An automatic wrapping device suitable for viscose filament cakes, comprising a silk cake transfer device 16 and a silk cake lifting device 17, the silk cake lifting device includes a push plate 18 that moves up and down, and also includes a bagging device and Packaging device 19, the silk cake lifting device 17 is arranged at one end of the silk cake conveying device 16, the packaging device is arranged above the push plate 18, and the bagging device is arranged between the push plate 18 and the packaging device 19 .

[0062] In the present invention, a silk cake 20 and a packaging bag 15 are also included, the silk cake 20 is transported to the silk cake lifting device 17 through the silk cake conveying device 16, and the packaging bag 15 is set on the packaging device 19 through a bagging device; The silk cake 20 is pushed onto the packaging device 19 with the packaging bag through the push plate 18 .

[0063] In the present invention, the packaging device 19 include...

Embodiment 3

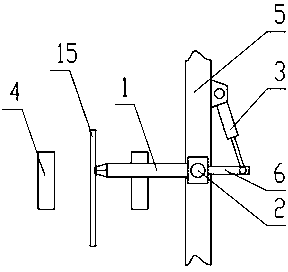

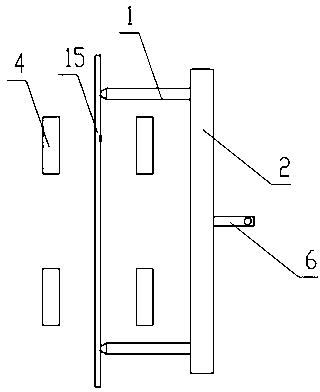

[0073] The difference from Embodiments 1 and 2 is that in the present invention, the swing rod driving mechanism 3 is arranged on one side of the swing rod 2 .

[0074] When in use, the swing rod drive mechanism 3 drives the vacuum suction cup 1 to swing laterally from left to right through the swing rod 2, so that the packaging bag box can be placed on one side of the frame, and the expansion part is set on the other side. Absorb and turn over to achieve the purpose of taking the bag and sending the bag; then through the expansion and conveying of the expansion piece, the purpose of pulling open and wrapping the packaging bag on the packaging device is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com